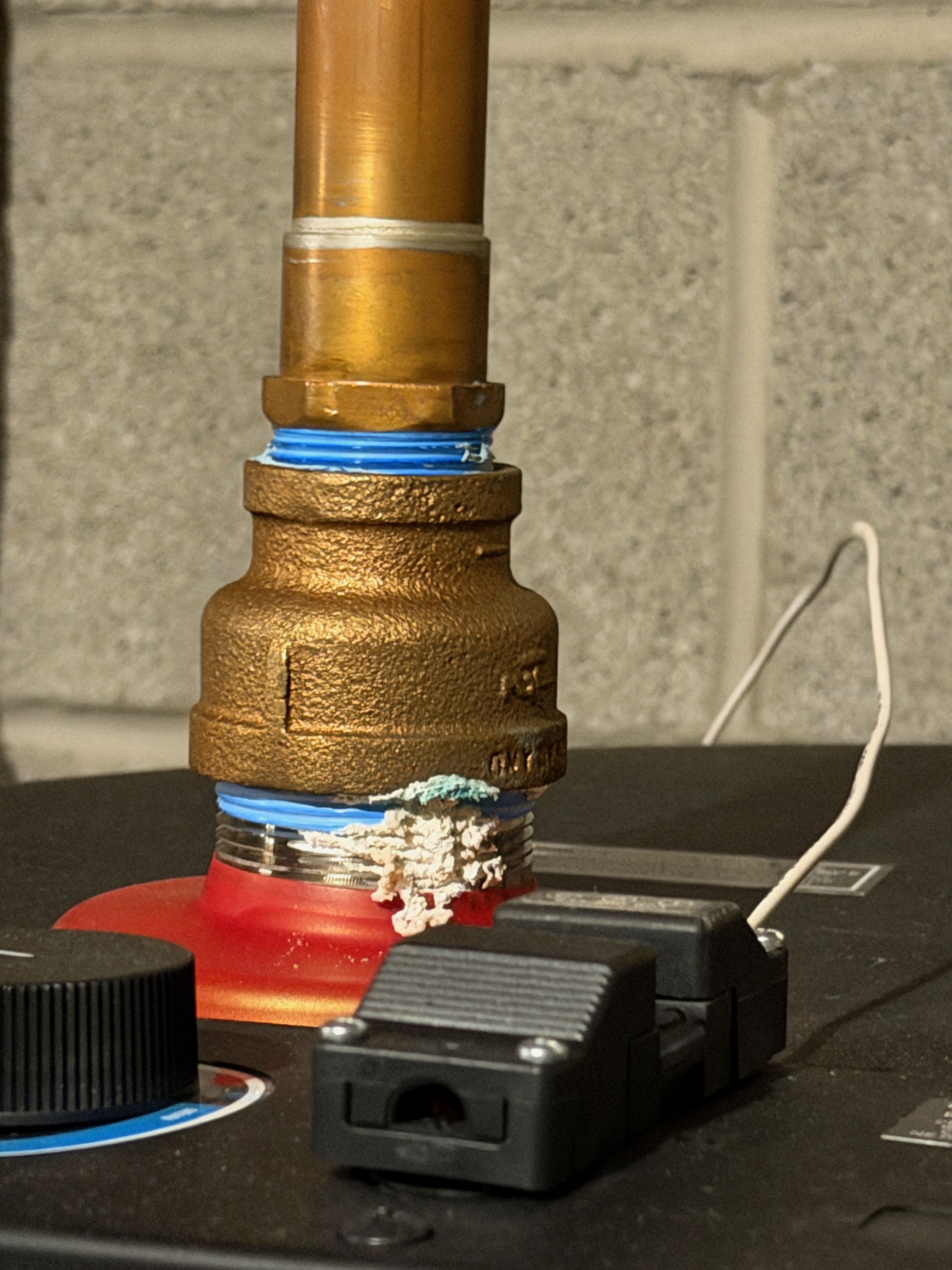

Corroded connectors on new boiler.

Hello, I had a new boiler installed in March 2025 and I just noticed the inlet and outlet connectors are corroded and leaking. Brass reduction fittings were used on them. Will the boiler need to be replaced?

Comments

-

Could you supply some more information? Pictures and model of the boiler. If the boiler was just installed 8 months ago it will not have to be replaced.

Did you contact the installer?

0 -

Pictures? That's awfully quick for ccorrosion..

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

0

-

It's a TriangleTube Smart 80.

0 -

-

-

Isn't that galvanic corrosion though?

0 -

-

-

I agree but dissimilar metal sometime are a little more difficult to join together thus are more likely to leak

0 -

Those are stainless steel nipples that are welded to the inner tank. Use more teflon tape or teflon rope.

I just installed a Viessmann indirect that had the same stainless nipples and the cold nipple at the bottom of the tank leaked. I redid the threads multiple times with different applications of tape and dope; none of those worked. What finally stopped the leak was Loctite teflon cord wound into the threads.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab2 -

-

or poorly machined brass…

0 -

Chances are something is made in China.

0 -

or everything. even if the tank was assembled in the us the weld nipples are probably from china

0 -

@Alan (California Radiant) Forbes

I had that happen on Viessman indirects as well. PP adapter onto the ss nipples was bone dry when installed a year later no water but a little corrosion.

Maybe the SS & brass expand at different rates.

0 -

Your installing contractor has to take them apart clean them and actually make them tight this time

Fixed it for both of you 😅Chances are something is made in China.

Because american fittings can't be incorrectly taped and tightened, Ed? Come now 🙂

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

-

The problem is the dissimilar metals. Brass and stainless steel. I have had a problem with Lochinvar indirect tanks that leaked for that very reason. I unsoldered the heat exchanger copper piping 3 times one particular time, using different thread sealants. I had leaks every time. The solution that stopped the leaking was the use of Locktite Anaerobic thread sealant. That's all I use for these connections, now.

Looks like you have hard water in your boiler sys. Too much mineralization. I would replace your water with good water.

0 -

You know the quality of China stuff is all over the place. Some is ok and some is not.

I bought a box of Chinese nipples at a supply house late in the day and never looked in the box and when I opened it the next morning more than half the nipples had torn up threads. It didn't help that I was 2 hours away from that supply house in the morning and nowhere around to buy more. I am not talking about a couple of nicks I mean totally unusable and I needed them. So yeah. If that makes me prejudiced than I guess I am. And as far as brass goes have you ever (in recent times) bought any brass that was not made overseas?

I have bought Ward (when they were in business) and Anvil stuff and seldom had a bad fitting. My problem is the damage to those nipples could be easily see. Someone looked at them threw them in the nipple pack and didn't care.

We also did a gas job once with black foreign pipe. It wouldn't pass a pressure test. High pressure gas line 10psi. This was 100s of feet of pipe all with welded fittings. We spent days wasting time looking for leaks. Pipe was 15' in the air. Had to cut it all out new pipe reweld re pressurize etc. Lot of money wasted.

Turned out it was the seam in the pipe itself that leaked

1 -

I don’t deny some garbage has come out of China. But remember, it was specified, ordered, accepted, paid for, and/or stocked by American companies.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

neither the people making it or selling it knew what they were looking at.

I had that problem with a knockoff of a supco piercing tap. It had this spiral up the side of the needle that wasn't machined off so all the refrigerant leaked out in a few weeks. Why someone would knock it off in the first place i have no idea, like I don't see that as being a big market to go through the trouble.

home depot brass nipples are the first time i had problems with npt joints leaking

0 -

-

Leaks at transition fittings is part of the reason I use unions when connecting appliances. Typically, Propress x male or female. Expensive, but they save time if there's a leak and the next guy that has to service the equipment will thank you, even though you may no longer be in this world.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab4 -

OP the good news is that this is fixable. The bad news is that the company that made this indirect water heater went out of business on the 3rd. (it's not a boiler in your photo, and its a leak on the domestic side, so no boiler water involved with the leak)

It doesn't matter what language the people that made the pipe nipples speak, you can get a leak free connection there. These are generally regarded as good tanks, despite the company going under

1 -

And I'd say you can forget about the lifetime warranty.

Make sure the cap on the auto air vent is tight. Most SMART failures I've see have been because the air vent leaks and rusts through the outer tank.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab2 -

Thanks everyone!

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements