Ever use an off brand press tool?

Just curious for a future video

It seems like Milwaukee, Ridgid, Viega, and Dewalt are the known brands for press tools and jaws. Have you ever used an off brand and what were your results? I see so many choices now and they all seem to have rave reviews, brands like Zupper, Vevor, & Hhewlee.

Does anyone ever solder or braze anymore?

Thanks in advance

Boiler Lessons

Comments

-

-

i havent used one but the vevor has a great price point id also like to know if some has any experance with it.

0 -

they now have press fitting for ac pipes dont know if i would trust them with the higher pressures they use now

0 -

I sweat just about everything but personally own a Ridgid press tool that only goes up to 1-1/4". I had a job last year that was 2" and I wanted to press it due to time constraints, so I borrowed a Vevor tool from a friend and was quite impressed with it actually. He's had it for a few years and has no complaints that I'm aware of. I used to be in commercial and had a Ridgid 320 in my truck plus the shop had a few DeWalt tools as well, and I can say with absolute certainty that the Vevor one was better than the DeWalt on all accounts

1 -

I’m using the vevor right now for a faster service scenario. That said I’m new to propress fittings and don’t love not having as much control over making my piping look plumb and square when the tool crimps- maybe a learning curve. My tool is about 15 crimps in and so far so good. The megapress has been a lifesaver on a job recently. Vevor had a pretty good deal to add mega press jaws also.

1 -

-

I've been using the manual press too that Supplyhouse.com sells. I am only using it for DIY in my own house, and it is a pain in the arse to use. But it seems to give good results and the price is right for pressing a few fittings.

https://www.supplyhouse.com/Bluefin-CPTLKIT-Copper-Press-Tool-w-1-2-3-4-1-Jaws

0 -

Crooked pipe with press tools is common. Some say to press alternate sides of the pipe to try and avoid this.

Personally I like to solder. But a 4" copper pipe with a leaking valve you can PP a new valve on very easily so it sure has its place.

Is there anything VEVOR does not make? They must be a huge company.

I would bet getting any repair parts or fixing their products is a big hassle.

I predicted 25years ago that HD, LOwes etc would be selling knock off press tools. It took them longer than I thought but here we are.

0 -

Thank you all and especially @Alan (California Radiant) Forbes for the slushy machine LOL

@EBEBRATT-Ed I see DIY ductless systems and that scares me

Ray Wohlfarth

Boiler Lessons2 -

The very first press tools to hit the US shores were REMS and Rothenberger, both German brands.

I've had my REMS for 30 years, built like a tank!

Newer brands and models are much lighter, maybe value engineered?

I have had bad experiences with Vevor tools, three attempts. When their tag line is 1/2 the price of other brands, be suspicious

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

what were youre bad experiences with them. i have a hole pile of milwakkee tools that the triggers are gone bad on.

0 -

I read that as "sushi machine" and thought that was some sort of fish chunk or paste for a second

0 -

you could also do what i did with pex expansion tools, i bought the off brand manual tool but bought the name brand heads thinking that most of the precision is in the head

0 -

i asked REMS about using other brand tongs in mine, or mixing expansion heads in other tools

Officially no, unless they were tested and listed together to be compatible. ASTM F-1960

Perhaps all the expansion pex failures are related to mismatched tools and heads?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

We've been selling uponor in northern michigan basically since they had a rep here. I've seen 2 "failures" the first installer didn't mind the min pipe distance to fittings and stuck the expander in the 90 that was already installed, 2 weeks later several thousand gallons dumps into a ladies apartment at a senior living facility (she was super nice, even baked us cookies since she knew we were coming to look at it) the second one was a mystery when we looked in the field. we sent the pipe back to uponor and they cut it open and kind of laid it out flat, you could see the grooves from the expander head were only in one cross pattern, we investigated the customers tool and sure enough the thing did not rotate itself! it was plain as day to see when they cut open the pex

4 -

-

Since Viega will not Warrant any joints unless it has the "V Watermark" on it we use the approved tools with great results and no breakdowns !

Another press tool that comes to mind is Klauke.

0 -

we're back to the brand name dies and off brand tool :)

0 -

-

you'd get the logo that viega wants to see

0 -

I think some of the newer electronic tools tell you when they need to be sent back for re-calibration.

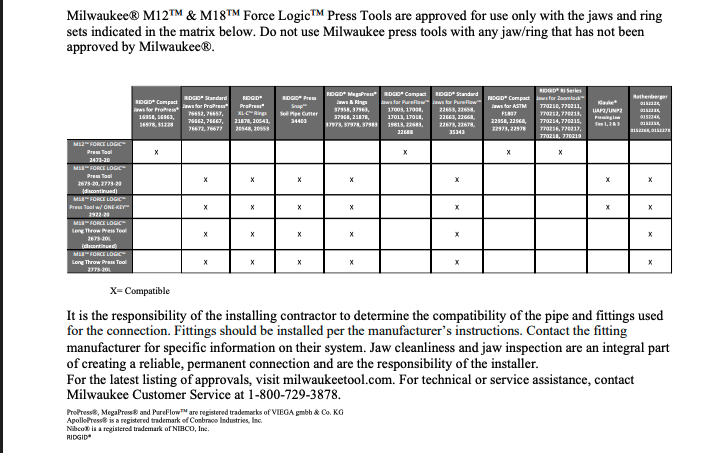

Here is Milwaukee's compatibility chart and disclaimer about mixing brands.

As @Derheatmeister mentioned the fitting manufacture could void warrant if an approved "calibrated" tool is not used. I suspect failed press joints are often related to improper tool maintenance and compatibility, as well as operator error?

I wanted to get some Milwaukee compact jaws for my REMS. The manufacturer recommended against it.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

The MFGs don't want any liability so of course they (in most cases) will tell you you have to use their tool and their heads.

0 -

I bought an ibosad hydraulic manual tool from Amazon for around 100 dollars for that price i figured what the hell. Surprisingly it works good but I had to add pipe extenders to the handle because it was just too hard to use repeatedly. So far it's about a year old and still works great

0 -

-

Its like an electrical panel.

You buy an Eaton panel your supposed to use Eaton circuit breaker even though other breakers may fit. Its the old liability thing. Your building goes up in flame because you didn't use the right breakers and neither Eaton or the other breaker mfg just point fingers at each other.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements