A New One On Me

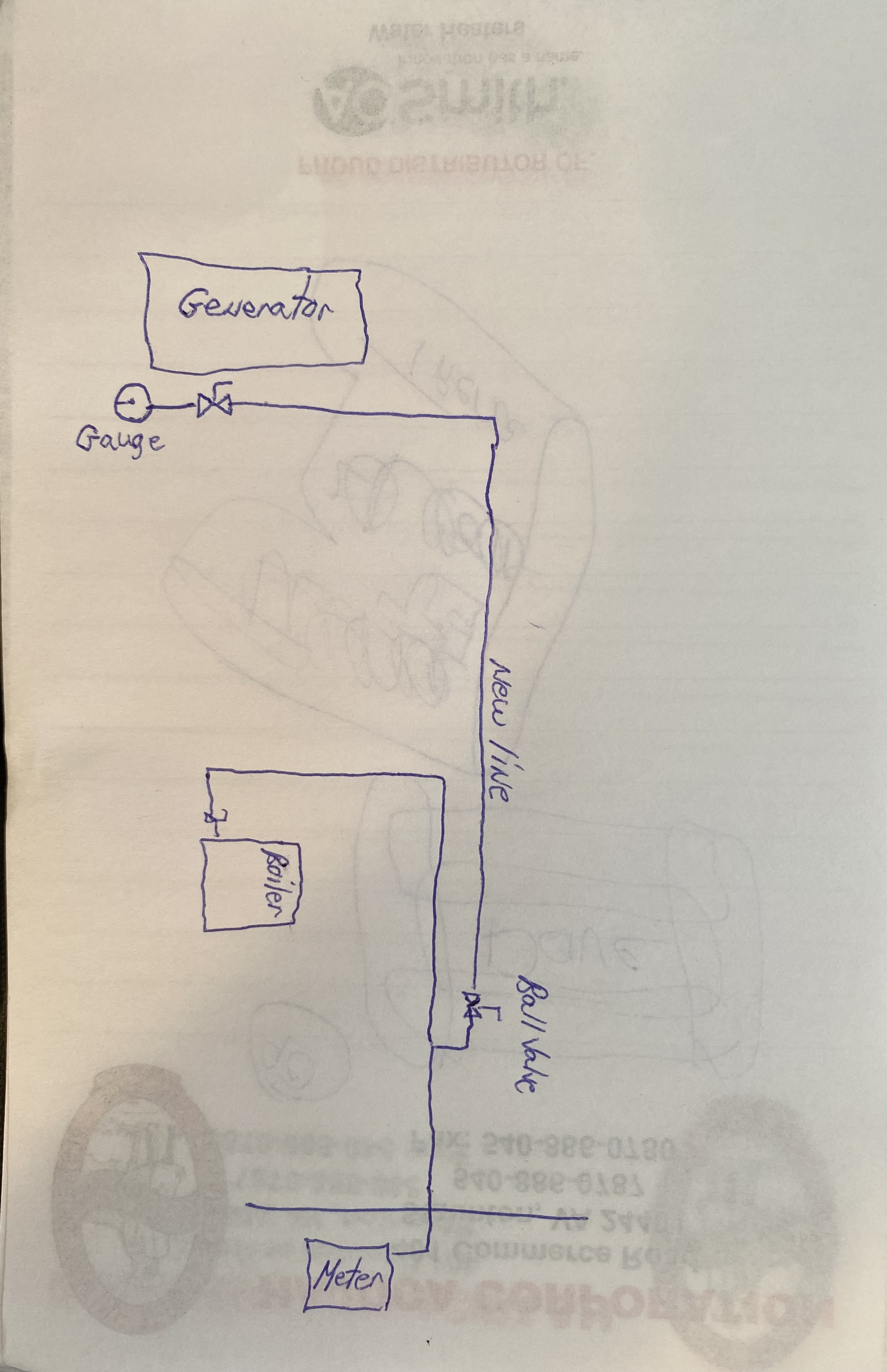

We installed a new run of 1-1/2” black gas line to supply a generator on a house. We connected it to the existing gas line where it enters the house and put a shut off valve there.

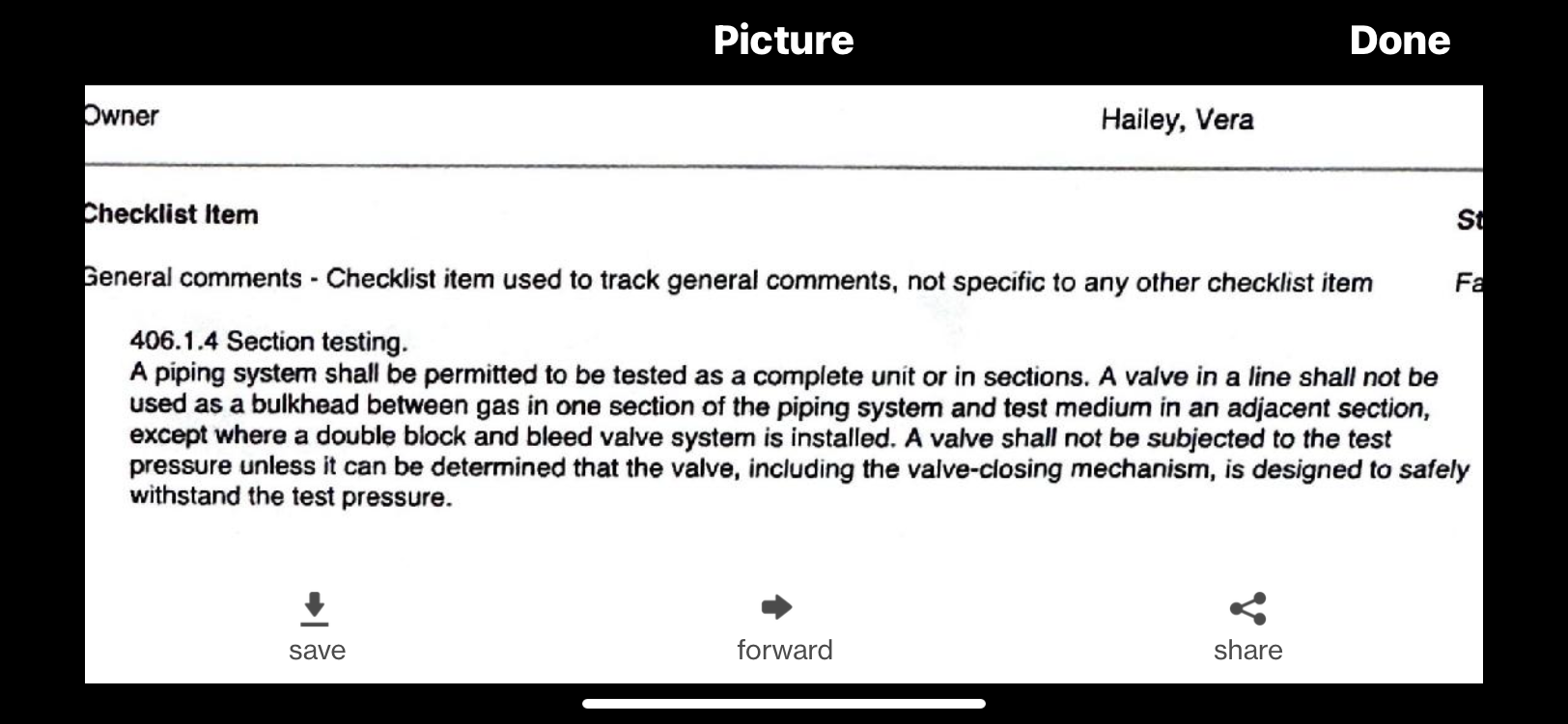

We put a pressure test on it (which held) and called for an inspection. The inspector failed it and cited this as the reason:

Has anyone here ever heard of this being applied to a gas line before? We do generators all around our area in several different jurisdictions and have never come across this before.

He also said not to paint the line until it passed the pressure test. Apparently, he thinks paint could stop a leak?

You can choose to do what you want, but you cannot choose the consequences.

Comments

-

Apparently, he thinks paint could stop a leak?

Curious, what is your test pressure?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

15 psi.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Just proves what I've always said, @Ironman : if you take any code, and a fussy inspector, he or she can always find something… which may or may not make any sense at all.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

Yes...It's part of the ICC Fuel Gas Codes. Painting is ONLY after the pressure test. If you Paint in before, you'll have to pressure test it at much higher level. 90 P.S.I. minimize (without looking it up). I'd like to see some pictures of what you did and all the tie is before, I give you a 100% answer that you can hang your hat on. Mad Dog

2 -

-

Yes.

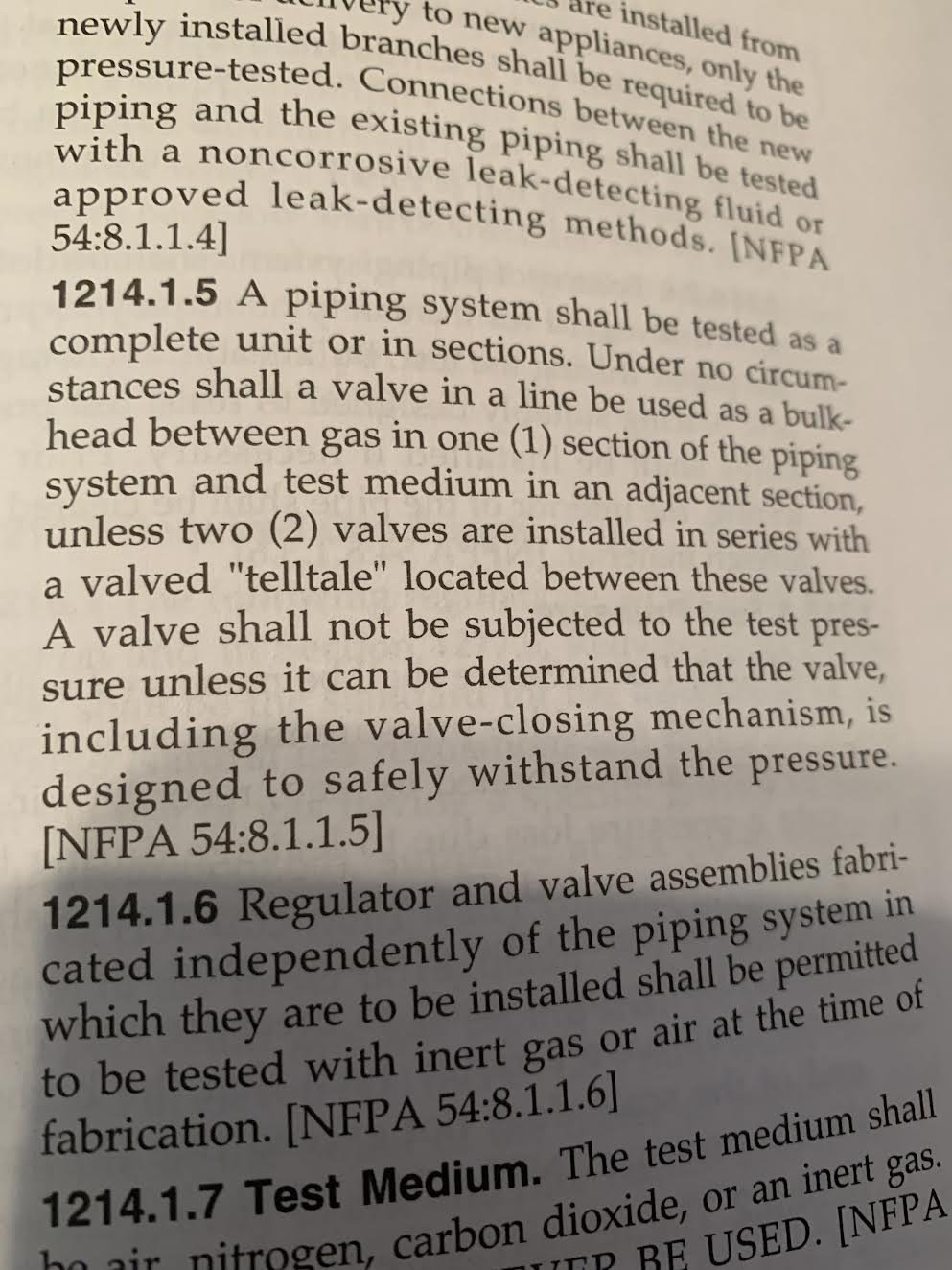

Technically the gas pipe is supposed to be isolated from everything for the test and a gas valve is not supposed to be a bulkhead.

This is a holdover from the old "gas cock" days when the plug cocks could leak air test pressure into the live gas line.

Common sense is that ball type valves don't leak and most inspectors in my area allow it or look the other way.

I guess some inspectors don't care that this causes you to add another union that is a leak possibility

As far as paint goes that a battle you can't win. MA requires all outdoor gas pipe to be painted.

I have had inspectors tell me "Why did you paint the pipe you can't paint it until after the pressure test" and I have also heard " Why didn't you paint the pipe I don't want to come back"

So as stupid as it is you have to ask before hand.

2 -

It's included in our UPC and it looks as though they get it from the NFPA; they are the biggies.

We've done it like you for years - as left and right couplings and nipples are a PITA - an have never been called on it. It's probably a remnant from when wedge-style valves leaked.

Regarding the last sentence of the code: Find out the working pressure spec.'s of the valve. If it's like 100 psi and you're only testing at 15, maybe you could convince the inspector that it's OK.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab1 -

This is good to know and something I haven't come across. We often do gas line additions and modifications to existing facilities and pressure test the new lines. Often the tie in to the existing is not completed during the test, but there have been plenty of times when it was just a ball valve. I will keep this in mind for the future. On another note, I was given a failure earlier this week on a new package HVAC unit b/c the factory installed convenience outlet was not labeled as weather resistant, even though it did have the rated cover.

0 -

if you use mega press sometimes they dont want it painted so they can see the label that it was rated for gas. i also have had inspectors complian that it wasnt painted then another town complained it was.

0 -

Around here, they've always required us to test gas piping before any connection is made to the meter or existing piping. Depending on the jurisdiction, test pressure can be 15 to 60 PSI.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

@Ironman, I believe if you had a valve behind your valve, and a tee with a gauge in between, that will meet the requirements.

1 -

@Ironman Does the valve have the "WOG" letters on the side? If it does, and I bet it does, you can point it out to the inspector so that they can put a pass sticker on the job. The valve with "WOG" on it stands for water, oil, and gas. It's rated for the purpose of gas. I had an inspector question this once, then pass the job after some hemming and hawing and head scratching. I asked, Why wouldn't you want the valve tested? That's why it's there.😉 As long as the test is isolated from any other connections, it shouldn't be an issue.

As to the painting of the gas pipe. I've had some battle ship gray on the truck for after the inspection. I guess paint can hide a leak??

0 -

-

-

-

This is pretty common. I've even had a few that demanded 100 psi all the way to the gas valve, but when I brought up the impossibility of testing through the regulator or pushing 100 psi into the gas valve, just rolled their eyes like I was the fool. One in particular made me remove the regulator (on a 2M BTU rooftop unit) and piece in straight pipe as well as remove the nipple from the gas valve and cap it. When he showed up to reinspect that the next day, failed it again because the regulator and gas valve were not part of the test. I do not miss working in Minneapolis one bit.

1 -

Most quality ball valves will have the listings needed to be used for NG or LP. Regardless of the WOG label.

Jomar has been my go to valve for years when I bought valves by the case. They have ASME, C SA, UL and FM.

When I did fire protection work the specs always called for FM listing, inspectors looked for that.

So buying valves with the multiple listings covers all the hydronic and fire protection.

Here is an older basic Jomar, pre lead free days, and Watts, for example

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Here’s a diagram of the piping:

Thanks for all the input.

I think that I’m just gonna disconnect the new section until it’s pressure tested and approved. That’s simpler than adding more valves and with the current warm weather here, the boiler won’t be needed now.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements