Protecting wires while pulling in conduit

I am pulling some #1 thhn through 1.5" emt and conduit bodies. I am finding when it makes the turn in the conduit bodies it gets stuck on the edge of the hole for the conduit connections inside of the body(one of the bodies is a tee and the #1 turns out the side of the tee. In hindsight I would have used a 2" conduit body and bushed it down. It is outdoors so I don't really want to use a pull box.). I found that I could put a piece of cardboard inside the conduit to let the wire slide over the edge of the opening sort of like a shoehorn. Is there a legitimate tool or method for this? The wire is too stiff to make it bend like that without some sort of tool. I see that greenlee makes essentially a plastic strip for larger conduit sizes.

Comments

-

You don't pull through conduit bodies, except maybe a C body. (Even then, you're r generally adding the C body because you're over on bends—so you shouldn't be pulling through it.) Pull a loop & then pull the loop out (one conductor at a time) once you're done.

Protip: if it's stamped with volume & you're under fill, you can make joints in a conduit body.

At least, that was Code the last time I read a code book. It may have changed since then, been a while.

1 -

I'm not pulling through them, it is hard to get the loop of wire to bend and slide in to the 2 conduits entering the body when it is #1 wire when i get most of it pulled out of the conduit body. It catches on the edge of the opening as you try to flatten the loop out. Putting a piece of cardboard over that edge helps it slide instead of digging in to the nylon. I'm not splicing 2 #1 wires in a 1.5" conduit body.

0 -

Ok, yeah, that's a problem. Cardboard is what we did back in the Noughties; that and beat it in with the butt of a hammer. THHN is surprisingly resilient.

0 -

-

Lube wasn't helping because the edge of the opening was digging in to the insulation.\

although I was trying this stuff for the first time, I don't think it was the problem:

0 -

-

Cardboard or sacrificial tape on the edge , one pulling, one feeding. Backpull on the long way to finish.

Trying to squeeze the best out of a Weil-McLain JB-5 running a 1912 1 pipe system.0 -

Pulling cable, in my not very humble opinion, through anything other than long sweep bends is not a very good idea… if there is unseen damage to the insulation you really have a problem. if you must go through turn in a box, though, two people are a must — one doing the pulling and one guiding the cable at all times.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

Never tried cardboard. I have run into this problem many times.

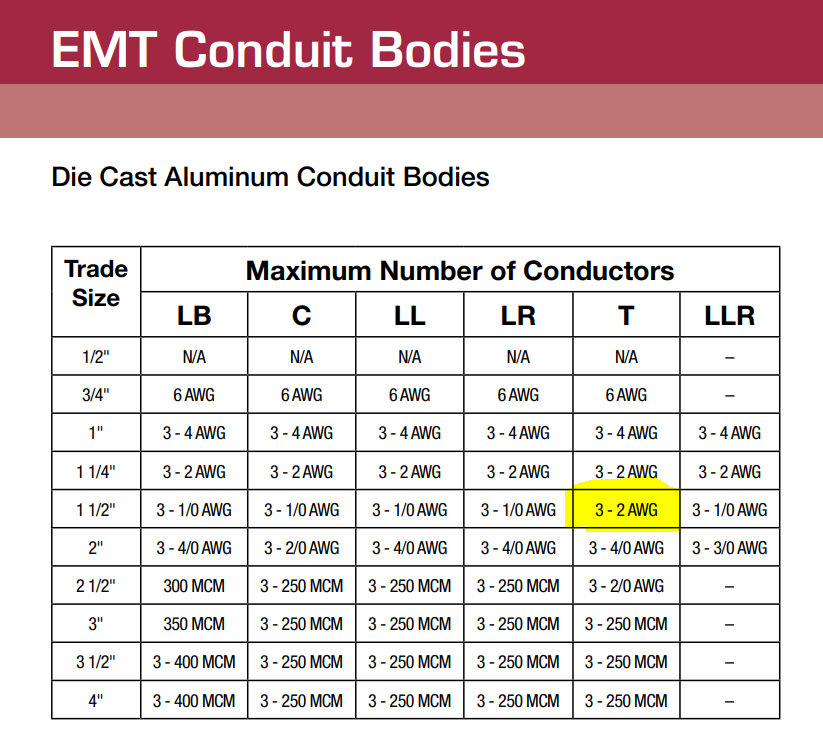

One issue is conduit fill. You calculate the size of the conduit needed for the conductors installed and that is fine.

But if your near the maximum conduit fill you will find that the LBs and other conduit bodies are not rated for the maximum conduit fill.

For conduit bodies you have to follow what is stamped inside the LB for the maximum wires installed.

This is frequently less than what the conduit itself is rated for.

Some tricks:

Wire lube

Use a piece of plastic cut from an old milk container

Use a larger LB. I have frequently put bushings in a 2" LB to use it on 1 1/2" conduit

They also make "Mogul" LBs and conduit bodies which are very large and cost $$$$ and probably need to be ordered.

Use a pull box weather proof is available

Use a weatherproof section of wireway or gutter

When all else fails a bigger hammer or rubber mallett!!!!! not my recommendation but many do this.

Tees have to be avoided at all costs, same with the short pulling elbows if your anywhere conduit capacity.

2 -

i'm at about 30% fill right now. technically the branch could be 60% because it is under 2' chasing boxes together but I don't think that's what you meant :-)

I was going to look for something plastic but it was getting cold and dark and i had the box the wire came in right there. I think the piece of corrugated box has more structure than a piece of disposable thickness plastic container anyhow.

0 -

-

I made it work. Pieces of plastic taco bell drink cup work well to protect the wire. If it were going 20 ft i would have had to use a 2" LT but since the branch was just chased in to a box it was possible to do it safely using plastic strips to protect the cable.

0 -

-

Yeah, if i reworked it i would have just used a straight nipple and not worried about making it flush. if i did that i would have had to tweak the 3/4 emt too.

0 -

Was the square d torque spec for their ground and neutral bus bars an afterthought? If you're careful you can do it with a straight blade but there is no way you can do it reliably with a robertson. You really need that special combo straight/robertson bit from Milwaukee. It seems like they were engineered for a lower torque then they tested them decades later and found they needed the higher torque to reliably stay tight. Maybe it only really needs the full spec with aluminum wire.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements