Problem with short-cycling, low water, and leaks

Comments

-

That's the order I would do things, except with 1 and 2 being switched and those being way, way higher than all the other items.

Yeah the velocity might not be great, but the boiler manufacturer isn't going to recommend near boiler pipe sizing that is going to fail you.NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

IF the leak is below ground then middle of sight glass should be more than sufficient.0

-

Thanks @KC_Jones, I was always under the impression that the vents needed to reach a certain temp - like 170-180F to close? Maybe the can close at lower temps?KC_Jones said:

Your assessment is missing one thing. If the steam isn't closing the vent it's because it physically isn't there, so it doesn't matter that it's open, there is no steam to leak out. And again, that amount of steam leaking in your house you would know, easily as you'd have liquid water condensing on nearby cold surfaces, like the walls, or windows.DiegoB said:

@KC_Jones - it's an odd theory, I know. I just haven't been able to identify a leak otherwise. Steam is getting to the radiators. I mean the house is getting steam heat now and we're in subzero temps, so steam is getting to the radiators. It's just that this boiler it hitting the low-water cutoff all the time.KC_Jones said:Knowing what I know today, I would take every effort to get that boiler tuned into your system. I recently changed my system so it is firing at a similar rate to the radiation as yours about -3% pick up factor, and the system is the best it's ever been.

I completely disagree with those saying change it, waste of money and time from where I'm sitting. The issues you are having have nothing to do with sizing, nothing at all. Losing water is a leak. To give perspective 99 gallons should be 10-15 years of water usage, and you say you have underground returns? That is the place to start with water usage. If they need replaced, I would not put them underground again unless there are zero other options, for me it's always been a dumb idea.

For reference to lose that much water through venting only, a Gorton #2 main vent would have to be venting steam continuously for ~340 hours to release 99 gallons of water. You wouldn't have to look around to find that, the walls dripping would tell the story. Also, since you say the steam isn't reaching the radiator vents, they can't be losing steam by definition.

After you make sure it's not surging and you aren't losing water, then you can tackle venting and balance. Start with main venting, then move to radiator venting, if necessary.

I agree with above about looking at upgrading that header and possibly separating the mains, it looks like they are tee'd together and while it's controversial around here, I believe it's better to have them fed off the header individually for balance reasons.

If we take your Gorton #2 analogy and apply it to all the radiator vents. It would go something like this -- the entire house has the equivalent of about 5 Gorton #2 vents (assumption). 340 hours / 5 = 68 hours of venting. 68 hours of venting / 120 days = 0.56 hours per day. So, if there isn't enough steam being created to close the vents it's conceivable that over time steam is getting out that way. The easier thing to imagine is a leak in the return somewhere -- admittedly that is a possibility b/c we have not inspected that returns.0 -

Unless the hartford loop goes up to that level. By raising the water level you make sure to avoid that problem and you give the water more "head" to push it out the leak faster so you can see if it is, in fact, leaking.dabrakeman said:IF the leak is below ground then middle of sight glass should be more than sufficient.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

No, that sounds about right for closing.DiegoB said:

Thanks @KC_Jones, I was always under the impression that the vents needed to reach a certain temp - like 170-180F to close? Maybe the can close at lower temps?KC_Jones said:

Your assessment is missing one thing. If the steam isn't closing the vent it's because it physically isn't there, so it doesn't matter that it's open, there is no steam to leak out. And again, that amount of steam leaking in your house you would know, easily as you'd have liquid water condensing on nearby cold surfaces, like the walls, or windows.DiegoB said:

@KC_Jones - it's an odd theory, I know. I just haven't been able to identify a leak otherwise. Steam is getting to the radiators. I mean the house is getting steam heat now and we're in subzero temps, so steam is getting to the radiators. It's just that this boiler it hitting the low-water cutoff all the time.KC_Jones said:Knowing what I know today, I would take every effort to get that boiler tuned into your system. I recently changed my system so it is firing at a similar rate to the radiation as yours about -3% pick up factor, and the system is the best it's ever been.

I completely disagree with those saying change it, waste of money and time from where I'm sitting. The issues you are having have nothing to do with sizing, nothing at all. Losing water is a leak. To give perspective 99 gallons should be 10-15 years of water usage, and you say you have underground returns? That is the place to start with water usage. If they need replaced, I would not put them underground again unless there are zero other options, for me it's always been a dumb idea.

For reference to lose that much water through venting only, a Gorton #2 main vent would have to be venting steam continuously for ~340 hours to release 99 gallons of water. You wouldn't have to look around to find that, the walls dripping would tell the story. Also, since you say the steam isn't reaching the radiator vents, they can't be losing steam by definition.

After you make sure it's not surging and you aren't losing water, then you can tackle venting and balance. Start with main venting, then move to radiator venting, if necessary.

I agree with above about looking at upgrading that header and possibly separating the mains, it looks like they are tee'd together and while it's controversial around here, I believe it's better to have them fed off the header individually for balance reasons.

If we take your Gorton #2 analogy and apply it to all the radiator vents. It would go something like this -- the entire house has the equivalent of about 5 Gorton #2 vents (assumption). 340 hours / 5 = 68 hours of venting. 68 hours of venting / 120 days = 0.56 hours per day. So, if there isn't enough steam being created to close the vents it's conceivable that over time steam is getting out that way. The easier thing to imagine is a leak in the return somewhere -- admittedly that is a possibility b/c we have not inspected that returns.

What I'm saying is steam can't leak unless it's physically there. So the steam isn't at the vent, steam can't leak, the closing of the vent stops the steam when it arrives at the vent. If the vent is functioning properly, once the steam arrives, vent closes and keeps steam in system. If it's staying open and is cool/cold the steam isn't there, so it doesn't matter with respect to leaking.

For reference, my radiator vents almost never ever close, and I have zero water usage issues. 60 gallons in 11 seasons, which isn't perfect, but isn't a problematic amount either.1 -

A couple of things here. First, I think @LRCCBJ may have misread the boiler capacity. The net steam output is listed at 180,000 BTUh, and it is very likely that that is exactly what they mean. That does not allow a "pickup" factor. The installed radiation requires about 190,000 BTUh at capacity, also with no "pickup: factor. The net steam output, which does account for losses, is 135,000 BTUh.

It really doesn't matter a whole lot what set of numbers one used -- at the most optimistic the boiler is undersized by 10,000 BTUh, and with real world conditions, by 55,000 BTUh.

For the keyboard warriors out there, yes, I know, with very careful balancing it may be possible, with time, to get the heating up to a usable condition without changing the boiler. Most people don't have the time -- or inclination -- to spend the next two heating systems changing vent sizes. Most people seem to just want to heat their house.

It reminds me a little of a car I owned ack in 1955. It was a fun little car. On a level road, no wind, 65 degree day, it would get up to 75 (it's advertised top speed) and cruise there all day. It took about 5 miles to get there, and the slightest disturbance would slow it dramatically, but it would do it. Was the engine undersized? Depends on how you look at it, doesn't it?

I think that an honest error was made in sizing the boiler, and that it was sized more accurately to building heat loss -- which is fine for hot water, but not for steam. I think that the plumber's suggestion that he put in a hot water system for the first floor is his or her way of acknowledging the error, though it's not how I would recommend doing it -- and we would be considerably more expensive than just simply resizing the boiler to what it needs to be.

Now to the water loss. It is possible, since with the undersized boiler the vents are never ever going to close, that most of it may be attributable to the vents. That is not something which can be fixed with the present boiler; it will limit the life of the boiler to a few years does to corrosion, but that can't be helped without fixing the underlying problem of size. However, since it is said that there are buried returns that they may be actually leaking. At the end of the heating season, fill the boiler to the top of the sight glass and observe the water level. It shouldn't drop. If it does, you have a leak -- and since this is a new boiler, it is most likely to be in those wet returns.

On the water level. The new boiler was set on the floor. Most of them are. It is very likely that one or more pipes or pipe connections which were intended to be below the water line, and thus prevent the passage from one pipe to another, are now above the water line. You will need to find all of those and repipe them so they are below the water line.

I might add that until you do that there is no point in even trying to balance the venting on the system. Don't even think about it.

I always applaud fiddling with skimming and such activities. In this instance, however, while entertaining I doubt that it will do any good.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

The plumber threaded almost every pipe by hand.Not easy to cut threads on 2 inch pipe by hand. Another indication your guy doesn't do much steam, and might not have the knowledge to identify and fix other issues.

I love old tools. My 1916 home has 2 1/2 threaded pipe. I like to look at it and think of the deadmen who threaded it by hand 108 years ago.

1" to 2" are threaded at 11 1/2 threads per inch. 2 1/2 and up are threaded at 8 threads per inch. That is why 2 1/2 and up utilize a different pipe threader. Steam boilers in new construction homes stopped about 1940. Today, large diameter threaded pipe is mostly obsolete. Other joining methods have replaced threading. Very few plumbers have the tools to thread large diameter pipe.

In your case 3" header is better, because today's boilers have an undersized steam chest (area inside boiler).

1 -

@KC_Jones - this is super helpful. I think I need to start having a closer look at the return lines for leaks.KC_Jones said:

No, that sounds about right for closing.DiegoB said:

Thanks @KC_Jones, I was always under the impression that the vents needed to reach a certain temp - like 170-180F to close? Maybe the can close at lower temps?KC_Jones said:

Your assessment is missing one thing. If the steam isn't closing the vent it's because it physically isn't there, so it doesn't matter that it's open, there is no steam to leak out. And again, that amount of steam leaking in your house you would know, easily as you'd have liquid water condensing on nearby cold surfaces, like the walls, or windows.DiegoB said:

@KC_Jones - it's an odd theory, I know. I just haven't been able to identify a leak otherwise. Steam is getting to the radiators. I mean the house is getting steam heat now and we're in subzero temps, so steam is getting to the radiators. It's just that this boiler it hitting the low-water cutoff all the time.KC_Jones said:Knowing what I know today, I would take every effort to get that boiler tuned into your system. I recently changed my system so it is firing at a similar rate to the radiation as yours about -3% pick up factor, and the system is the best it's ever been.

I completely disagree with those saying change it, waste of money and time from where I'm sitting. The issues you are having have nothing to do with sizing, nothing at all. Losing water is a leak. To give perspective 99 gallons should be 10-15 years of water usage, and you say you have underground returns? That is the place to start with water usage. If they need replaced, I would not put them underground again unless there are zero other options, for me it's always been a dumb idea.

For reference to lose that much water through venting only, a Gorton #2 main vent would have to be venting steam continuously for ~340 hours to release 99 gallons of water. You wouldn't have to look around to find that, the walls dripping would tell the story. Also, since you say the steam isn't reaching the radiator vents, they can't be losing steam by definition.

After you make sure it's not surging and you aren't losing water, then you can tackle venting and balance. Start with main venting, then move to radiator venting, if necessary.

I agree with above about looking at upgrading that header and possibly separating the mains, it looks like they are tee'd together and while it's controversial around here, I believe it's better to have them fed off the header individually for balance reasons.

If we take your Gorton #2 analogy and apply it to all the radiator vents. It would go something like this -- the entire house has the equivalent of about 5 Gorton #2 vents (assumption). 340 hours / 5 = 68 hours of venting. 68 hours of venting / 120 days = 0.56 hours per day. So, if there isn't enough steam being created to close the vents it's conceivable that over time steam is getting out that way. The easier thing to imagine is a leak in the return somewhere -- admittedly that is a possibility b/c we have not inspected that returns.

What I'm saying is steam can't leak unless it's physically there. So the steam isn't at the vent, steam can't leak, the closing of the vent stops the steam when it arrives at the vent. If the vent is functioning properly, once the steam arrives, vent closes and keeps steam in system. If it's staying open and is cool/cold the steam isn't there, so it doesn't matter with respect to leaking.

For reference, my radiator vents almost never ever close, and I have zero water usage issues. 60 gallons in 11 seasons, which isn't perfect, but isn't a problematic amount either.0 -

As far as the underground returns go, looking at how high the Hartford loop is, I'd go with what @ethicalpaul recommends in overfilling, the water will only drain down to the level of the Hartford loop when the boiler is off, so make sure it's filled above that level for the test. That Hartford loop does seem high, but it could be the angle of the picture. May need to take some measurements to confirm.3

-

Based on the size of your post, @Jamie Hall I'd say you might be the fiercest keyboard warrior here

We already had this discussion on some other threads, but until the radiators are full of steam, the boiler doesn't even "see" that it has too much radiation. The radiators fill with steam slowly on a call for heat. The fear of balancing issues here is overstated I believe.NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Sorry to call you out again @Jamie Hall but I think you might be mis-thinking about water loss in a one-pipe system:Now to the water loss. It is possible, since with the undersized boiler the vents are never ever going to close, that most of it may be attributable to the vents.

If the radiator vents never close, they, by definition, are never ever going to see any steam, so they will not have any leakage of steam/water.NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el2 -

My radiator vents almost never close.ethicalpaul said:Sorry to call you out again @Jamie Hall but I think you might be mis-thinking about water loss in a one-pipe system:

Now to the water loss. It is possible, since with the undersized boiler the vents are never ever going to close, that most of it may be attributable to the vents.

If the radiator vents never close, they, by definition, are never ever going to see any steam, so they will not have any leakage of steam/water.

I loose very little water, which I think most of it is just from humidity.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

4 -

@Jamie Hall

The problem I have is your car analogy is wrong.

The car was annoying to drive and grossly underpowered.

An appropriately sized steam boiler isn't annoying or an inconvenience.

It silently heats a house evenly without blowing dirt and debris into vents. Without making noise and hissing. It's easier for a thermostat to control and easier to make transparent to the people who live in the house.

It's much nicer than an oversized one.

And honestly, I'm a bit surprised by the keyboard warrior comment. I didn't see anyone making abusive or aggressive comments in this thread nor was anyone hiding their identity. Just because you don't agree with someone doesn't make them a keyboard warrior. Honestly that's a really disrespectful insult.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

2 -

Thanks @Jamie Hall - some really good points here. I would say that this boiler is behaving very differently from my previous Weil-McLein - SGO-6. The SGO-6 got the radiators so nice and hot, and in no time at all. That boiler had a nice big header, and made really nice dry steam. Maybe that's what we need to get back too. There is also the difference in the water content, going from a 6-section to a 4-section as well. As for the leak, it looks like the consensus is that its not coming from the vents. While I'm not ruling it out, it seems like it would be worth having a look at the returns very closely.Jamie Hall said:A couple of things here. First, I think @LRCCBJ may have misread the boiler capacity. The net steam output is listed at 180,000 BTUh, and it is very likely that that is exactly what they mean. That does not allow a "pickup" factor. The installed radiation requires about 190,000 BTUh at capacity, also with no "pickup: factor. The net steam output, which does account for losses, is 135,000 BTUh.

It really doesn't matter a whole lot what set of numbers one used -- at the most optimistic the boiler is undersized by 10,000 BTUh, and with real world conditions, by 55,000 BTUh.

For the keyboard warriors out there, yes, I know, with very careful balancing it may be possible, with time, to get the heating up to a usable condition without changing the boiler. Most people don't have the time -- or inclination -- to spend the next two heating systems changing vent sizes. Most people seem to just want to heat their house.

It reminds me a little of a car I owned ack in 1955. It was a fun little car. On a level road, no wind, 65 degree day, it would get up to 75 (it's advertised top speed) and cruise there all day. It took about 5 miles to get there, and the slightest disturbance would slow it dramatically, but it would do it. Was the engine undersized? Depends on how you look at it, doesn't it?

I think that an honest error was made in sizing the boiler, and that it was sized more accurately to building heat loss -- which is fine for hot water, but not for steam. I think that the plumber's suggestion that he put in a hot water system for the first floor is his or her way of acknowledging the error, though it's not how I would recommend doing it -- and we would be considerably more expensive than just simply resizing the boiler to what it needs to be.

Now to the water loss. It is possible, since with the undersized boiler the vents are never ever going to close, that most of it may be attributable to the vents. That is not something which can be fixed with the present boiler; it will limit the life of the boiler to a few years does to corrosion, but that can't be helped without fixing the underlying problem of size. However, since it is said that there are buried returns that they may be actually leaking. At the end of the heating season, fill the boiler to the top of the sight glass and observe the water level. It shouldn't drop. If it does, you have a leak -- and since this is a new boiler, it is most likely to be in those wet returns.

On the water level. The new boiler was set on the floor. Most of them are. It is very likely that one or more pipes or pipe connections which were intended to be below the water line, and thus prevent the passage from one pipe to another, are now above the water line. You will need to find all of those and repipe them so they are below the water line.

I might add that until you do that there is no point in even trying to balance the venting on the system. Don't even think about it.

I always applaud fiddling with skimming and such activities. In this instance, however, while entertaining I doubt that it will do any good.

0 -

I give up. There are two problems here. One is that water is leaving the system somewhere. I'll leave it to the experts to figure out where. The other is that the boiler isn't heating up the radiators. I'll leave that to the experts, too.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

I sense some animus in your reply. I hope you didn't feel attacked. We are all trying to narrow down the problem to what could actually be causing it.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el2 -

Of course, a smaller boiler would produce less steam and, therefore, less water. However, you are in the negative category right out of the box and reducing the boiler size is likely to be counterproductive to your best interests.DiegoB said:

Yes, absolutely agree - the steam coming into the main is going to be very very wet. It almost seems like one thing we could try is to reduce the nozzle size to get less aggressive heating? Would that work?LRCCBJ said:

Yes, unfortunately, in the race to the bottom, ECR has recommended piping sizes that are simply too small to result in dry steam. This boiler would ideally be piped with TWO risers and they don't even offer that option!DiegoB said:

I know the piping is small. Everything you say makes sense, but here is the recommended piping in the install manual:

The goal is to have a steam velocity of 15 ft/sec in the header with 15" between the top of the riser and the first takeoff for the main. This provides the best possible situation for dry steam. You have 45 ft/sec in the header with the main takeoff within 6" of the top of the riser.........nearly worthless to allow the water to drop from suspension.

If you get the near boiler piping to return 98% of the water to the boiler via the equalizer, your "leak" will magically disappear. I don't believe you have ANY leaks (unless you have underground returns..............that's a different story.) Run the test that Paul suggested to rule that in or out.0 -

A slight modification to this test:DiegoB said:

I will definitely try this. In the summer, the water level stayed in the middle of the site glass but that is prob too low to test for leaks.

The water level in the sight glass CANNOT fall below the level of the connection from the Hartford Loop (with the boiler not operating). So, fill the boiler to the top of the sight glass and then, overnight, see if it falls to the level of the hartford loop elbow. You probably have 4" or so. If it does fall those 4" overnight, now you have confirmed your leak in the underground returns.

1 -

Leave the header alone for now. Follow what @KC_Jones & @ethicalpaul have said. Get the two returns connected below the boiler water line. If you don't do that the venting will not work right.

Skim the boiler and get the water make up under control your loosing water some where. Fix underground returns if you have them and search the system for leaks.

You need to fix the surging to stop the short cycling. You need to find out why the boiler is short cycling its most likely steam pressure or the most common culprit if your surging is the low water cut off.

Once you get the venting surging and MU water under control you can address the header but you may not need to do that1 -

@EBEBRATT-Ed - I set aside some time tomorrow morning to do some skimming, and will do the return leak test during the day while it's warmer (above freezing) and no one is in the house. I can give it a go 10-12 hours before I have another look in the evening. Yes, will have another look at were the returns tie in as well.EBEBRATT-Ed said:Leave the header alone for now. Follow what @KC_Jones & @ethicalpaul have said. Get the two returns connected below the boiler water line. If you don't do that the venting will not work right.

Skim the boiler and get the water make up under control your loosing water some where. Fix underground returns if you have them and search the system for leaks.

You need to fix the surging to stop the short cycling. You need to find out why the boiler is short cycling its most likely steam pressure or the most common culprit if your surging is the low water cut off.

Once you get the venting surging and MU water under control you can address the header but you may not need to do that0 -

Yeah, will have to look more closely at where the returns tie in and so water can get back to the equalizer without delay. Also, seems like expanding the header to reduce velocity and get drier steam could be something to look at as well ... but will try the other recommendations first.LRCCBJ said:

Of course, a smaller boiler would produce less steam and, therefore, less water. However, you are in the negative category right out of the box and reducing the boiler size is likely to be counterproductive to your best interests.DiegoB said:

Yes, absolutely agree - the steam coming into the main is going to be very very wet. It almost seems like one thing we could try is to reduce the nozzle size to get less aggressive heating? Would that work?LRCCBJ said:

Yes, unfortunately, in the race to the bottom, ECR has recommended piping sizes that are simply too small to result in dry steam. This boiler would ideally be piped with TWO risers and they don't even offer that option!DiegoB said:

I know the piping is small. Everything you say makes sense, but here is the recommended piping in the install manual:

The goal is to have a steam velocity of 15 ft/sec in the header with 15" between the top of the riser and the first takeoff for the main. This provides the best possible situation for dry steam. You have 45 ft/sec in the header with the main takeoff within 6" of the top of the riser.........nearly worthless to allow the water to drop from suspension.

If you get the near boiler piping to return 98% of the water to the boiler via the equalizer, your "leak" will magically disappear. I don't believe you have ANY leaks (unless you have underground returns..............that's a different story.) Run the test that Paul suggested to rule that in or out.0 -

On the leak or not... perhaps I misread or misunderstood, but I was under the impression that water was being consistently added at some rate and that while some of it came back, the boiler was not overfilling. That to me says that the water added has to go somewhere... perhaps I'm misinterpreting.

On boiler size vs. radiation. I'd like to try a thought experiment here. Let us suppose we have only one nice big radiator with an EDR of 100 square feet. At a steam temperature of 215 Fahrenheit, that radiator will be capable of radiating 24,000 BTUh. However, as we know from working with hot water heat the radiating capacity varies with temperature -- and the critical temperature is the temperature of the radiator which is often assumed to be the same as the working fluid, but in fact isn't; it's a balance between the temperature of the working fluid and the space temperature. It can get a little messy mathematically, but for the sake of a reasonable approximation for the temperature ranges we are dealing with the radiating capacity is a linear function of the temperature of the metal, according to the formula BTUh = 1.7 * (Tmetal - Tspace). This can be rearranged, of course, to predict the temperature of the metal, given the BTUh at equilibrium and the space temperature.

What does this have to do with the present instance? Well, the power output of the radiator cannot exceed the power input to the radiator. So what happens if we power the radiator with a boiler producing 24,000 BTUh? Our formula will give us a radiator temperature of about 215, which is what we would expect. But what happens if we power the radiator with a smaller boiler -- producing, just for the sake of this discussion, 12,000 BTUh? The formula above will give us the equilibrium metal temperature of the radiator as 145 Fahrenheit, more or less. And with that power input, the temperature will never increase further. That is the temperature at which power input equals power output. No magic can alter that.

More practically, if there were a vent on our hypothetical radiator, it would never close -- vents close on temperature, not the presence or absence of "steam".

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Yes, the vent wouldn't close (and also, as mentioned, there wouldn't be any water loss out of it, even it was failed open).

But I think your thought experiment is kind of ignoring how steam fills a one pipe radiator. The sections heat up from one side to the other so I think you'd see 212 or so in the sections where the steam arrived, and cool or warm to the touch on the other sections.

Yes the average might be 145, but in reality you would have the equivalent of a smaller radiator fully hot.

This is why we don't see balance issues with an "undersized" boiler.NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el2 -

Jamie Hall said:On the leak or not... perhaps I misread or misunderstood, but I was under the impression that water was being consistently added at some rate and that while some of it came back, the boiler was not overfilling. That to me says that the water added has to go somewhere... perhaps I'm misinterpreting. On boiler size vs. radiation. I'd like to try a thought experiment here. Let us suppose we have only one nice big radiator with an EDR of 100 square feet. At a steam temperature of 215 Fahrenheit, that radiator will be capable of radiating 24,000 BTUh. However, as we know from working with hot water heat the radiating capacity varies with temperature -- and the critical temperature is the temperature of the radiator which is often assumed to be the same as the working fluid, but in fact isn't; it's a balance between the temperature of the working fluid and the space temperature. It can get a little messy mathematically, but for the sake of a reasonable approximation for the temperature ranges we are dealing with the radiating capacity is a linear function of the temperature of the metal, according to the formula BTUh = 1.7 * (Tmetal - Tspace). This can be rearranged, of course, to predict the temperature of the metal, given the BTUh at equilibrium and the space temperature. What does this have to do with the present instance? Well, the power output of the radiator cannot exceed the power input to the radiator. So what happens if we power the radiator with a boiler producing 24,000 BTUh? Our formula will give us a radiator temperature of about 215, which is what we would expect. But what happens if we power the radiator with a smaller boiler -- producing, just for the sake of this discussion, 12,000 BTUh? The formula above will give us the equilibrium metal temperature of the radiator as 145 Fahrenheit, more or less. And with that power input, the temperature will never increase further. That is the temperature at which power input equals power output. No magic can alter that. More practically, if there were a vent on our hypothetical radiator, it would never close -- vents close on temperature, not the presence or absence of "steam".

The steam will be at 212f and will close the vent if it gets to it. If it doesn't get to it there's no reason for it to close.

It's not going to drop to 145f and exist as a gas with a vent open.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

1 -

-

delcrossv said:

"It's not going to drop to 145f and exist as a gas with a vent open." Why not? Water vapor (not steam) can exist at any temperature. You can have a pretty good amount of water in the air as vapor at 145F.

Because humidity isn't water in gas form and if the steam isn't advancing there won't be air getting pushed out of the vent.

This is how all single pipe systems behave.

On mild days there shouldn't be steam getting to vents.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Because humidity isn't water in gas form and if the steam isn't advancing there won't be air getting pushed out of the vent.ChrisJ said:delcrossv said:"It's not going to drop to 145f and exist as a gas with a vent open."

Why not? Water vapor (not steam) can exist at any temperature. You can have a pretty good amount of water in the air as vapor at 145F.

This is how all single pipe systems behave.

On mild days there shouldn't be steam getting to vents.

It's not?Trying to squeeze the best out of a Weil-McLain JB-5 running a 1912 1 pipe system.0 -

Not to my knowledge no.delcrossv said:

It's not?

Because humidity isn't water in gas form and if the steam isn't advancing there won't be air getting pushed out of the vent.delcrossv said:"It's not going to drop to 145f and exist as a gas with a vent open." Why not? Water vapor (not steam) can exist at any temperature. You can have a pretty good amount of water in the air as vapor at 145F.

This is how all single pipe systems behave.

On mild days there shouldn't be steam getting to vents.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

The steam will be at 212f and will close the vent if it gets to it. If it doesn't get to it there's no reason for it to close.ChrisJ said:Jamie Hall said:On the leak or not... perhaps I misread or misunderstood, but I was under the impression that water was being consistently added at some rate and that while some of it came back, the boiler was not overfilling. That to me says that the water added has to go somewhere... perhaps I'm misinterpreting.

On boiler size vs. radiation. I'd like to try a thought experiment here. Let us suppose we have only one nice big radiator with an EDR of 100 square feet. At a steam temperature of 215 Fahrenheit, that radiator will be capable of radiating 24,000 BTUh. However, as we know from working with hot water heat the radiating capacity varies with temperature -- and the critical temperature is the temperature of the radiator which is often assumed to be the same as the working fluid, but in fact isn't; it's a balance between the temperature of the working fluid and the space temperature. It can get a little messy mathematically, but for the sake of a reasonable approximation for the temperature ranges we are dealing with the radiating capacity is a linear function of the temperature of the metal, according to the formula BTUh = 1.7 * (Tmetal - Tspace). This can be rearranged, of course, to predict the temperature of the metal, given the BTUh at equilibrium and the space temperature.

What does this have to do with the present instance? Well, the power output of the radiator cannot exceed the power input to the radiator. So what happens if we power the radiator with a boiler producing 24,000 BTUh? Our formula will give us a radiator temperature of about 215, which is what we would expect. But what happens if we power the radiator with a smaller boiler -- producing, just for the sake of this discussion, 12,000 BTUh? The formula above will give us the equilibrium metal temperature of the radiator as 145 Fahrenheit, more or less. And with that power input, the temperature will never increase further. That is the temperature at which power input equals power output. No magic can alter that.

More practically, if there were a vent on our hypothetical radiator, it would never close -- vents close on temperature, not the presence or absence of "steam".

It's not going to drop to 145f and exist as a gas with a vent open.

@Jamie Hall - this was my thought as well. All sections of the radiators heat up, its just that the density of steam inside the radiator is not as much as it should be (lower Input in Jamie's analogy). So, because there are fewer - call it steam particles - the metal of the radiator doesn't heat up to as high as you would expect. And I've measured this throughout all the radiators of the house. This also goes for the mechanism inside the vent, if the density of steam reaching the vent is to little, the vent will not close. At the same time, the steam still has a velocity and will want to diffuse to points of lesser temperature or lesser steam.0 -

-

That’s not how my radiators work. As a section heats, it goes up to 200F, while the other sections are stone cold.

Respectfully, @DiegoB your system is not typical until some of your issues get sorted.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el2 -

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

2 -

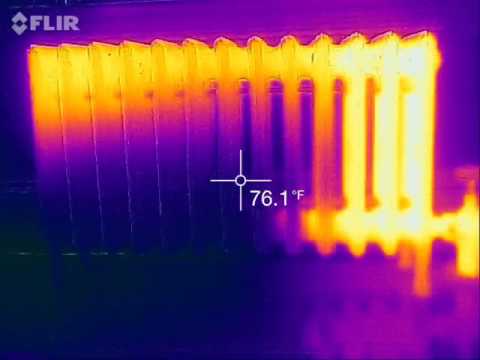

You can see that this radiator has a faster vent than I have! But still where the steam goes it gets hot. The steam gives up its heat as it goes.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

@DiegoB Let me go for the low hanging fruit on one issue ( IMO)..

If your boiler is undersized now turn off 3 ,4,5 etc radiators closest to the boiler to see if the rest of the radiation heats to temperature you are expecting.At least you should get higher temperatures at the other radiators , if so you'll know you're on the right track.

Think of it a

experiment , ( I know very little about 1 pipe so that's why it's so simple to me , I have no reason to think otherwise) IMHOOne way to get familiar something you know nothing about is to ask a really smart person a really stupid question0 -

Listen you have to determine if you have a system pipe leak. Remember that if you are adding cold water to the system to replace the water that has left then a lot of Btu's are going into that new water. That's going to cut down your output to the radiators as its going to lower the temperature of the boiler water. It's like boiling a pot of water on the stove and adding fresh water to the steaming water. it stops steaming.

Underground piping is susceptible to leaks. Especially if you have a high water table because the pipe will rot from the outside in if there is a lot of moisture and worse yet if it's sitting in water.

2 -

@reggi, i haven't tried this yet and it is worth having a look!reggi said:@DiegoB Let me go for the low hanging fruit on one issue ( IMO)..

If your boiler is undersized now turn off 3 ,4,5 etc radiators closest to the boiler to see if the rest of the radiation heats to temperature you are expecting.At least you should get higher temperatures at the other radiators , if so you'll know you're on the right track.

Think of it a

experiment , ( I know very little about 1 pipe so that's why it's so simple to me , I have no reason to think otherwise) IMHO0 -

@ChrisJ - this is an awesome video / love the cat at the end. I wish I had one of those devices to make a video of my radiators for you guys to see (and myself)! Agree that radiators should be getting to 200F. It's just that my boiler is short cycling due to low water cutoff, so i think it gets to a uniform temp across the radiator eventually, but it happens over a number of cycling attempts and never gets to past 130-140F.ChrisJ said:

Will be doing some more skimming tomorrow morning, and then will be testing the returns over the course of the day. If its the returns that are leaking, then that'll need to be fixed pronto and can prob address the location of return ties while we're at it.0 -

Are you sure that the boiler is shutting down on low water? It has a CycleGard lwco which will shut off the boiler every x minutes (usually something between 15 and 30 minutes) depending on model to test the level.

Are you having trouble heating the house or are you just losing water?(and i don't think we've adequately addressed if you are actually feeding water when the cycleguard calls for it or if it just keeps making calls but the vale isn't actually feeding). The Hydrolevel doesn't measure water, it just turns the valve on for some period of time and assumes a given amount of water was fed when it called for the valve to open for that period of time)0 -

@DiegoB

This looks like it was set by a plumber trying to force the steam to the radiators ( Again I'm not a 1 piper but it looks high to me) Someone will correct me if I'm wrong

One way to get familiar something you know nothing about is to ask a really smart person a really stupid question1 -

It is but in this case it is probably problem #8 after you deal with the wet steam and the water seal that is above the water line and probably main venting.reggi said:@DiegoB

This looks like it was set by a plumber trying to force the steam to the radiators ( Again I'm not a 1 piper but it looks high to me) Someone will correct me if I'm wrong

If the vents never get steam hot then it isn't building pressure which isn't a bad thing as long as it is heating evenly.1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements

https://youtu.be/TgcTvNlOa8A?si=Qc64YKLY53UYEFrm

https://youtu.be/TgcTvNlOa8A?si=Qc64YKLY53UYEFrm