The case of the high gas costs, this Friday's case

Boiler Lessons

Comments

-

-

Both primary valves were bleeding though, but the bleed valve was handling it so gas went to the roof. That was inadvertently changed to the opposite function (NO -> NC or NC -> NO) so the gas ended up leaving though the chimney so no one smelled it any longer.0

-

The missing clue is if the old bleed passed gas when boiler firing or off?0

-

agree with @JUGHNE first comment0

-

I also have to agree with @JUGHNE, that the wrong vent valve was used or that they used the correct valve but screwed up the wiring somehow. (wow 2 wires to screw up). Maybe you can explain to me just what and why anyone would add a vent valve between 2 gas valves. I always thought that some idiots thought they were saving the world when they wrote this into the code. If it were me, I would have wanted a pressure sensor instead of a vent valve. What a waste of money.1

-

@retiredguy

The normally open vent valve was and IRI (Industrial Risk Insurer's) (now called FIA) requirement.

It was required in locations (usually factories) where their insurance was in place)

The vent valve was sized at 1/2 the gas train size. So, a 2" gas train would get a 1" vent, 2 1/2" would get a 1 1/4" vent etc.

They were considered the strictest insurance code for boilers and burners. Stricter than FM --Factory Mutual0 -

Like others mentioned above, I suspect the old vent valve was normally open and was replaced with a new normally closed valve.0

-

@EBEBRATT-Ed I knew why it was there, I just thought that it was a stupid requirement since it served no purpose except to sometimes dump raw gas out the vent piping. That is why I always believed that some sort proving sensor in addition to the N?O vent valve would have been a wise addition.1

-

Someone explained what they were for a little while ago. Apparently, some of the really old valves wouldn't reliably close off if they had pressure downstream, so they had to relieve the pressure. Now, I'm not sure that's a good reason to vent a bunch of gas if the first of your (allegedly) redundant valves fails, but whatevs. Maybe the vent line used to have a whistle on it?0

-

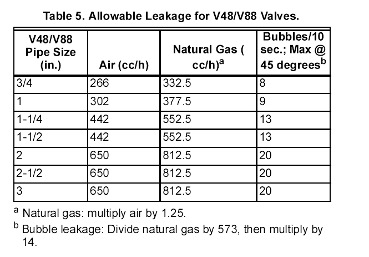

Good morning the customer indeed replaced the normally open vent valve with a normally closed one. They look so similar. The vent valve was used to vent any gas leaking through the first gas valve. It amazes me that there is a certain amount of gas leakage permitted with a gas valve. I have enclosed the allowable leakage chart for a Honeywell V48 valve

Here is the link to this weeks case, The Case of the High Gas Costs https://youtube.com/watch?v=3GfQKxglZso

I also posted another video. It was an article I wrote for Mechanical Business Magazine Its called Troubleshooting Hydronics https://youtube.com/watch?v=YIMBJ78cWyI

Ray Wohlfarth

Boiler Lessons2 -

-

@ratio The idea behind the vent valve is that IRI or FIA wanted two gas valves in series on boilers they insured.

However if one valve fails you will never know it could be that way for years.

Adding the vent valve in the hope that someone notices the high gas usage or smells leaking gas makes sure one of the valves gets fixed.

Last time I looked FIA still requires this.0 -

Just for general info concerning the safety of the block--vent--block system;

Our hospital has 2 Kewanee 80 HP steam boilers, installed in the mid 1970's.

They alternate operation every Monday, run 24/7/365 since the 70's.

The off line boiler gets it's king valve closed, but it was continuing to build up steam pressure. Originally the king valve was suspect but the pressure rose higher than the system PSI.

Looking in the burner sight glass you could see a fair sized flame that had been burning since shut down.

These had only one 2" GV per boiler, HW V4055 fluid drive supposed to close within one second.

This one was obviously not sealing and passing gas, thankfully it was still burning and drafting up the flue.

Changing the valve of course solved the problem.

The operators were informed that it is good policy to shut off the manual gas stop/valve of both the 2" gas train and also the pilot line stop when taking the boiler out of service.

Also the pilot light solenoid valve had failed to completely seat on a previous occasion and had a standing pilot until it was noticed.0 -

wouldn't the main gas valve on something in the 70's have been required to be redundant?0

-

@mattmia2, To the best of my memory, that would depend on the "code" that was in place at the time of the unit's installation and what safety devices were grandfathered in after that date. The codes that had to be followed were dependent upon a lot of different parameters including the size of the boiler, the operating pressure, it's BTU input, and the jurisdiction that covered that installation. I never knew what code was enforced but that was stated in the boiler's specification sheet and/or engineering drawings. You could always tell what code was enforced just by looking at the "trim" that was being furnished and installed. It wasn't my place to determine what code was being followed, that was the job of the State/insurance inspector. I have seen quite a few installations that fired 10,000 to 20,000 cu ft of natural gas/hr with a single gas valve. Was it safe, heck no, but the state or insurance inspector had the final say in that matter.1

-

How many gas valves a burner has, and weather more than one valve is required is determined by local code which may be superseded by the insurance company for the boiler.

mass code for instance requires two valves on any burner in a building used for 'public assembly."

Some require a "proof of closure switch" in one valve which won't allow the burner to start if the valve is not seated.

And this is not limited to gas. Oil burners subject to FIA requirements must be equipped with two oil solenoid valves.

As @retiredguy mentioned there are a lot of old jobs with burners of any size that still may only have a single valve when they were installed as that was all that was required at that time.0 -

We had a school that had a single gas valve on an old boiler and it had a manual switch which would open the gas valve manually ( I know scary right) It was only replaced a few years ago

Ray Wohlfarth

Boiler Lessons1 -

I would expect that to be used by someone troubleshooting and I'd expect them to have enough knowledge to use it in a safe manner.RayWohlfarth said:We had a school that had a single gas valve on an old boiler and it had a manual switch which would open the gas valve manually ( I know scary right) It was only replaced a few years ago

There was a time when such assumptions could be made.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Those usually got used in a power failure to provide some gravity heat, or in the case of steam, heat.

The ones I have seen also had a bunch of warnings near them. This seems like it has no warning. I suppose at least it has a standing pilot.0 -

@mattmia2 and a safety valve lol0

-

I have seen a number from the 50's or so with just a manual opening knob of some sort to fire the furnace in a power outage.EBEBRATT-Ed said:@mattmia2 and a safety valve lol

0 -

In the 50's there were, and maybe still are, furnace gas valves that would operate off of 12VDC or the 24VAC.

I am imaging you would take off the lower blower door, hook up a car battery, leave the basement door open and then insure that you had enough fresh air in your already leaky basement and let it fire.

The high limit and wall tstat would have control of the flame.0 -

I've kept a school warm with a Honda generator some extension cords and 55gal drums of oil during power outages from big storms which we knew were going to last 48 hours or more. 3 phase oil pumps and heavy oil heaters weren't going to run with a small generator. That was a steam system. No univent blowers, but we kept the buildings from freezing!Serving Northern Maine HVAC & Controls. I burn wood, it smells good!0

-

These valve systems were called double block and bleed. Back in the day when gas companies did 99% of the service and the service men were well trained these never presented a problem. We also back then allowed valves to bleed of at the pilot before opening. There are still a lot of those around they are tricky because when the small bleed coming of the valve gets plugged the valve will not open. You will have power to the valve so the tendency is to replace the valve. All you really have to do is clean the tubing and the valve will work fine. Today all of our valves on residential are redundant valves so they are much safer than the old valves.1

-

Two years ago we watched someone from our gas company wrapping PTFE tape the wrong way around a pipe on 4+ joints, and then the tape unwrapped when he screwed the joints together and even that didn't effect him.Tim McElwain said:These valve systems were called double block and bleed. Back in the day when gas companies did 99% of the service and the service men were well trained these never presented a problem. We also back then allowed valves to bleed of at the pilot before opening. There are still a lot of those around they are tricky because when the small bleed coming of the valve gets plugged the valve will not open. You will have power to the valve so the tendency is to replace the valve. All you really have to do is clean the tubing and the valve will work fine. Today all of our valves on residential are redundant valves so they are much safer than the old valves.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

I wonder if these valves were used when they had full time boiler tenders on site. Even then, I would be nervous someone would turn it on and walk away.Ray Wohlfarth

Boiler Lessons0 -

The customers who had these old systems knew exactly how they worked. In fact when I was just a "newbie" I often learned about systems from the customers. Sure not that way today for sure. There are still parts of Providence RI that still have these old gas actuated systems. When they finally went years ago we converted the to self-generating (Powerpile).2

-

Tape on gas pipe threads? Is that even legal there?ChrisJ said:........ Two years ago we watched someone from our gas company wrapping PTFE tape the wrong way around a pipe on 4+ joints, and then the tape unwrapped when he screwed the joints together and even that didn't effect him.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

I think so, I've never done it so I never looked into it. But even if it is, wrapping it backwards?Steamhead said:........ Two years ago we watched someone from our gas company wrapping PTFE tape the wrong way around a pipe on 4+ joints, and then the tape unwrapped when he screwed the joints together and even that didn't effect him.

Tape on gas pipe threads? Is that even legal there?

I guess incompetence can be found almost everywhere.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0

Categories

- All Categories

- 87.2K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 60 Biomass

- 427 Carbon Monoxide Awareness

- 118 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 113 Geothermal

- 164 Indoor-Air Quality

- 3.7K Oil Heating

- 73 Pipe Deterioration

- 1K Plumbing

- 6.4K Radiant Heating

- 393 Solar

- 15.5K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 49 Job Opportunities

- 18 Recall Announcements