Two-pipe to one-pipe conversion

Comments

-

An oil suppliers 1st priority is selling oil. Having techs on the payroll is a definite + but are they paying them competitive wages and benefits?

here on the Isl of long all the independent dealers are being swallowed up by big business.I don’t like Review sites for service contractors there pay to get good reviews.I lean toward the small 1-2 man shops that still care about the customer.1 -

-

In addition to Ray's explanation there's also the danger that somebody messes up a properly adjusted damper. So some gas utilities insist on passive fresh air supply even when two way damper is present where ever.0

-

I have first hand experience with a 2 pipe fuel line installed, years before I acquired the customer, that has a shut off valve on both the supply and the return. I did a tune up on that customer several years in a row and was pleased that there were existing valves to keep the fuel from siphoning from the tank when servicing the fuel pump strainer. One year in my haste to get the service call completed quickly, I neglected to open the service valve on the return line... I was puzzled as to why the pump was not priming so I opened the bleeder to help the priming process. Once the fuel flowed out the bleeder port I naturally closed the port and since the return was closed off, the only pressure relief for the returning fuel was the pump seal. There was oil all over the place. inside the burner, on the floor and in the combustion chamber. It only took a few seconds for the mess to happen, then I shut off the electric to the burner.

My service call just got to be 2 hours longer. I needed to replace the fuel pump, clean all the spilled oil from the floor, remove the burner fan and clean the inside of the burner with degreaser and towels. I needed to remove the burner fan and take it over to the garden hose to remove all the oil from the blades. Otherwise that fan would collect all kinds for dust and lint over the next heating season. I had to do all this extra work at no extra charge to the customer. So much for saving time.

Then that experience made me think "What if there was a Fir-o-matic valve on a return line during a fire?" The possibility of that valve closing during a burner operating cycle could lead to a real problem. All the fuel leaking from the pump seal for just 2 or 3 minutes until the other Fir-o-matic on the supply would close might be the difference between a firefighter saving the home or the firefighter getting caught in a fire fueled by an additional accelerant.

That was early in my service career, and that is when I looked up the fuel gas code to find that part about no valves on the return pipe. I removed every return line valve from that day forward at no additional charge to my customer. I would gain a valve and lose a union… It was a fair trade for me.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

@EdTheHeaterMan, thanks for that story, that really makes it clear.

Out of curiosity, what did you do on that system (after you removed the valve) and on other systems with no valve on the return line when servicing the strainer or whatever? How did you stop the siphoning oil?

(BTW, I’m thinking of switching to one-pipe with a tiger loop.)0 -

Place a deep dish cookie sheet or other container under the fuel pump. have all the parts ready for a fast replacement. then remove the pump strainer cover and scrape the gasket as quickly as possible, replace the dirty strainer with a clean strainer and new gasket, align the cover bolts quickly and get one cinched up as fast as possible. I would lose about one or 2 cups of fuel in the process.

If I was going to do a long repair, Like replace the fuel pump, there were 2 options.

Option 1 is to have a flare plug available to plug off the fuel line after disconnecting the fitting from the fuel pump.

Option 2 is to use a push-pull pump to fill the fuel line with air all the way back to the tank, in order to break the syphon.Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Thanks @EdTheHeaterMan, so now I know how it’s done. “Flare plug.” I want one. Pump too. And if a person has neither I guess he could try @CTOilHeat’s technique of blowing back the oil using the fuel pump.I will not be trying any of these techniques at home myself anytime soon, but I’m really glad to know them … well maybe after I take HVAC 1 at our county trade school…0

-

Correct the return should end above the oil level of the tank and no service valve is needed . Running both oil lines to the near bottom of the tank is common practice but not by the rules . I grew up in the oil industry , return lines are a hazard , ask me how I know that? And are not needed on your system since we now have Tigerloops . Day tanks yes need a gravity return .Day tanks are used if your tank is lower than 12' from the burners .

Fire-O-Matic valves theoretically close if fire melts the solder in the handle to cut off fuel as to not feeding the fire .They should be installed before filters and pumps . I seen them shut by kicking them and the handles fail . If the return line plugs either the pump seal will spill combustibles or it will pump the extra oil to burn into the appliance . I would use a ball valve on the top of your tank .

That safety contained cover of yours gives you second containment but does not allow you access to the bottom feed to drain off the water , so expect sludge build up . The sludge will eventually eat away the bottom of the tank sorry to say . Some areas make it mandatory to install top feeds but expects someone to drain off the water ... Has to do with freezing , water will freeze . The cure to all would be a pitched tank , bottom feed and the oil line pitched into the warm house . The suits that make the rules would never ask the mechanics working out in the field .

There was an error rendering this rich post.

2 -

Thanks @Big Ed_4, that was very helpful. Here’s a question for @Big Ed_4 and @EdTheHeaterMan who mentioned the push-pull pump, (and of course anyone else).

I want very much to have a shutoff valve installed in the supply line at the tank, and I think I will go to one-pipe eventually since no valves should go on the return. However I am going away for a while very soon and will shut off the system, and may not be able to get somebody to install a shutoff before I go.

Although we have now had 20 years without any kind of leak (although someone mentioned when they saw the above photos that I might have a tiny leak, because there is a slight coating of oil on the line), I now have siphoning and leaks on the brain (and I read that the New York State DEC gets about 16,000 spill reports a year).

For peace of mind while I’m gone, if I can’t get a shutoff, is this a viable option for me to do myself?: I buy a push-pull pump like @EdTheHeaterMan mentioned (maybe like the one pictured below) and push the air out of each line, then I don’t have to worry about siphoning. The pump’s not cheap, but could be useful for future repairs.

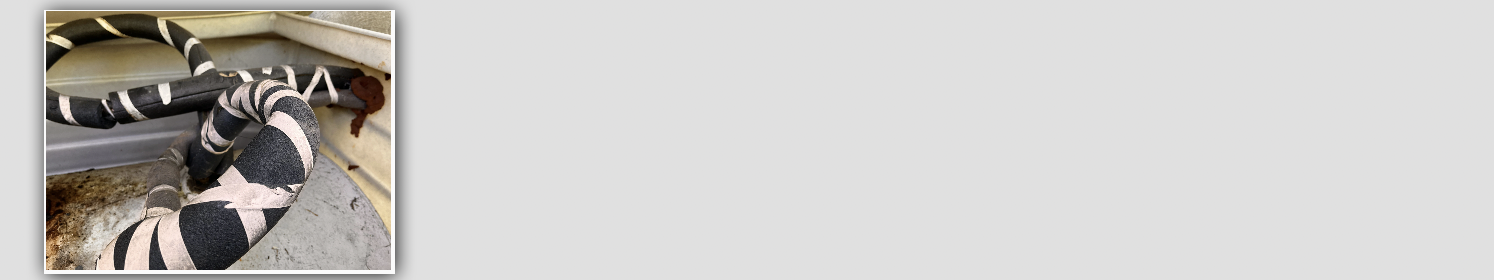

If this is viable, how do these pumps connect? To flare fittings only? On the return line (see photo below) there is a flare after the (illegitimate) Firomatic, so I could close the Firomatic and disconnect the flare without oil flow, then connect the flare to the push-pull pump, then open the Firomatic and pump. But on the supply the only flare is into the Firomatic that comes before the filter (after that it’s weird clusters of unions and stuff all the way to the fuel pump).To get to the flare, I’d have remove the Firomatic, and oil will be flowing while I try to attach the pump, but I guess it would be possible to do that? Or I could try to attach the pump to one of the fittings or the filter housing (can you empty a line by pushing through the filter?), but maybe I’d need an adapter? (I’ll try to find a manual for the pump.) This stuff would be a good skill for me to have anyway. Thanks for reading through all this.

0

0 -

If you want to purchase the push pull pump, that is just fine, you would add this fitting to the 3/8" female pipe thread on the discharge (out) side of the pump.

You could also add one of those fittings to any air hose that can be connected to a compressor or bicycle pump. All you are doing is introducing very little air into that fuel line in order to force the fuel into the tank in order to break any syphon that may occur You can use a bicycle pump to this adaptor and connect the flare adaptor together with a coupling.

The place to connect to the fuel line is on the opposite side of the shut off valve. Close the valve then connect the air pressure source, pump up some pressure, then open the valve. Continue to pump air into the fuel line until you hear the bubbles in the tank.

This set up may be less expensive and may be able to use something you already have

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

@EdTheHeaterMan, I am speechless.I just bought most of the components (still need to get a bicycle pump).

If I try the method out with just the return line, after it’s empty of oil can I just restart the boiler?

And if and when I clear the supply line, to restart do I have to somehow suck the oil back, or can I just let the fuel pump do that (maybe with the bleeder screw open until I get just oil, no air)?

This is on the level of wizardry.0 -

… The pictures were hugely helpful.0

-

@seized123 You should be able to empty both fuel lines. When you recommission, then just start the pump to recharge the lines when you are ready. The suction of the pump gear set is usually enough to lift the oil from the tank to the fuel pump. The reason it does not work on single pipe system is... Thye gear set is recirculating the air in the strainer chamber thru the internal bypass hole (the hole that gets the bypass plug). There is no exit for the air in the fuel pump, since you can not compress the air enough to open the nozzle port on the fuel pump. Once the gear set has fluid in it (Oil will not compress) the pressure will build enough to open the nozzle port and let oil out thru the nozzle port to the nozzle assembly.

Since the bypass opening is plugged on a 2 pipe system, the air and not bypass to the strainer chamber.

It has an exit back to the tank in the return line. That is why 2 pipe systems are self priming. If that makes sense... Great. If you still have questions about it I can show you the diagrams that will help you visualize the process.Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

-

0 -

Haven’t we discussed this already?0

-

Yes, definitely, that’s where I’m getting the possible sequence of tasks, from the help I got from you guys. But before it was not so much in the context of me tackling it myself, so I thought I’d lay out the exact steps I think I would follow and see what people think about it as DIY, which I thought should maybe be a new thread. It was a lot of text, I know!0

-

You should ask Erin to merge this post with your other post.

There was an error rendering this rich post.

0 -

Okay, I will do that. Is this the way?:

@Erin Holohan Haskell, it’s been suggested this be merged with the thread https://forum.heatinghelp.com/discussion/192521/is-this-barometric-damper-installed-okay/p1

Sorry if I’ve contributed to thread proliferation!0 -

-

Warning: This is the world's longest post. I will reimburse for coffee anyone who gets through it. It originally appeared as a new thread but it was suggested that we merge it with this long one which was related, which happened but the following post went to the beginning of this thread (which started out on barometric dampers, but now is renamed with the new thread name), so I figure many of you who have been helping me would not see it. Thus I copy it here at the end (sorry about all that, I'm new at forums and thread-merging and so on):

Based on what I've learned from you guys here and some prior research, I would like to switch from one-pipe to two pipe. My question is, can I do this myself?

I already know the answer from many of you, and I will take it very seriously if someone says to just hire a pro. One thing I do have in my favor is that I am retired and can take all the time I need, plus it's summer and the system can be down for as long as it takes. I also figure that if I make a mistake, like with flaring, I'll hopefully see it right away once the system starts (or will I?) and can either re-do or call for DIY rescue. Comments welcome.

Below is what I'm envisioning. Almost all of the details as to what to use inside the house are thanks to @STEVEusaPA, but also to other folks. Apologies to @STEVEusaPA if I get some of this wrong, any miscues are probably mine. Anyway, going from the tank to the burner:

First I clear both lines of oil using the handy bicycle pump setup suggested by @EdTheHeaterMan.

Next, there is a duplex bushing at the top of the tank for the supply and return lines. I figure I could leave the duplex in, remove the return tubing from it and plug that hole. Then I could just leave the first few inches of existing ½ inch supply line that comes out of it and attach the first valve (see below re: valves). Alternatively I could remove all the supply line too and send new 1/2 inch soft copper back down into the tank (I think the idea is you push until it hits bottom and then back off 4 inches or so?), using a new compression fitting at the bushing. Another alternative is to buy a single-line bushing if available, but I figure why go through the hassle of removing the old one and putting in the new (?)

Next, at the tank, cut the line and put in both an anti-siphon valve, if I can find one suitable for the top of the tank, which is about 7 feet above the burner, and also a manual shutoff, whether ball valve or Firomatic (Beckett says it's okay to use them outside as shutoffs). The way I read it, for my system, an anti-siphon valve is required outside by the New York State Mechanical Code, see below, and I would also to have a manual shutoff. Both valves would be protected by the tub. As for the anti-siphon, putting together a couple of sections of the code it says 1) a shutoff valve must be installed outside the building (for outside tanks, obviously) and 2) if it's top feed above the level of the burner (no mention of inside or outside) an anti-siphon valve must be installed "in lieu of" the shutoff valve; thus, since the shutoff it would be in lieu of had to be outside, they seem to be saying the anti-siphon valve must be outside for an outside above-ground tank. It's possible that they didn't mean this, that they meant you can either install a shutoff outside, or, with top-feed above level of burner, an anti-siphon in lieu of it which maybe can be inside or out.Either way, I like the idea of one at the tank because it would cover a leak anywhere from the tank to the burner, but the one's I've found are like $400, unlike the Suntec PRV-38, for example, which is cheaper but can't be more than 3' above the burner. My impression is, correct me if I'm wrong, putting an anti-siphon outside at the tank is overwhelmingly not done in the real world - do you guys ever put in anti-siphon or OSV valves at the tank, for residential? BTW by OSV I do not mean Firomatics, which I see some people call OSV's too.

Everything would be flare, which if I have ever done it it was decades ago, but before attempting any of this I would buy the tool and practice on ½ inch soft tubing for as long as it takes until I felt confident, days, weeks ... If I never feel confident practicing then I abandon the project. Since I now have a good idea what components to install, flaring seems to me to be the possible weak point in all this.

So, moving on from the valve(s) in the tub, currently there is a lot of excess tubing curled around above the tank and I figure I do that with the new line, or make neat loops. (Should there be loops or excess line outside the tub too where it goes to the house?) Everything after will be ½ inch jacketed copper line. My number one primary concern is safety regarding possible oil spill/leakage, and I know there is also corrugated tubing you can put outside a line, I would be willing to do this in addition to the jacketed line if that would increase the safety factor, or maybe you'll laugh if that's really overkill. Suggestions welcome.

Anyway, out the side of the tub and down to the hole in the wall at ground level. There is a rough hole there, and I believe the old lines are electrical taped in the hole to protect from contact with concrete, and some of that orange foam fills the hole. I would consider making the hole nicer and putting a small length of PVC in it to further protect the lines, unless that would be too much overkill. I guess I would spray more orange foam in to seal it. Next add insulation to the outside line, as I assume that even jacketed line needs that.

Now we're inside the basement. The line will go down 3 or 4 feet (to just above the floor, I guess, hopefully there are brackets I can get to hold the filters over the floor nicely) then into a Firomatic and my old General filter housing and then into a Garber spin-on filter - unless I get a Tigerloop Ultra, which has the spin-on attached, and which I assume has to go right before the pump.

If I can't put an anti-siphon outside, where's the best place for an OSV inside? Before or after the filters?

@STEVEusaPA then suggested two options (I hope I understand them right):

1) Another Firomatic just before the pump, no Tigerloop, remove the bypass plug and plug the now-unused return port.

or

2) Install Firomatic followed by Tigerloop, copper lines preferable to flexible lines from Tigerloop to pump, do not remove bypass plug, done.

Steve, maybe I misunderstood,but it seemed like you preferred option 1. If so, why? I thought Tigerloops were good things in general.

The big alternative of course is to have someone else do everything. I have a ballpark estimate from a local largish home services outfit with nice shiny vans, (no luck so far finding that old time 1-2 man operation like my recently retired plumber) and I think the whole thing would come to $1000-2000 (ignore that if I'm not supposed to post even ballpark pricing). Money is not the issue, that does not seem to me to be outrageous for this kind of work, but part of me really would like to tackle it myself, and I would love to hear all opinions.

Thanks in advance. If you read through all of this you get a free ride on my private jet, if I ever get one (at this rate not likely, though).0 -

WOW. You are really overthinking this.

Since you have a tank above the burner, you will always have the problem of Syphon if you use the top feed, or just pouring out the bottom of the thank if you use the bottom feed. You are not the first one to have this set up. You also have the tank located outside. This may be a problem in severe cold weather if there is a small amount of condensation (water) stuck in the fuel line. That water will freeze and you will end up with no heat when you need it the most.

There has been much discussion about this issue on this forum over the years. If I were the professional that was tasked with installing a fool proof fuel line at your location I might start from scratch. the first problem I would tell you about is the water in the fuel line freezing.

As a result of the high and low spots in this rollercoaster path there are several places where water can lie until the freezing temperature will block all fuel flow. Since the one pipe design will ultimately have a much slower GPH flow in the tubing, any water will definately freeze. look at this comment for a better explanation https://forum.heatinghelp.com/discussion/comment/1737746#Comment_1737746.

The second thing you might want to address is to try not to have any fittings at the top of the syphon part of the fuel line. If you end up with a leak resulting from a badly made Flare on the tubing, you will always be loosing the prime on the fuel line. The leak will act as a vent on the syphon loop, breaking the seal and causing enough air to enter the line to loose the pump prime.

Next thing is to have one piece of 3/8" copper start at the bottom of the tank (within 2" to 4" from bottom) then exit the top thru the compression fitting and drop to below the tank in one piece with no fittings. This will make any leaks in the fuel line a positive pressure leak that will show up as a fuel drip or seepage. It's easier to find those leaks to repair them.

Continue the fuel line in a downward slope until it enters the conditioned space, (Basement or crawlspace) away from a possible freezing condition once the fuel line is inside the basement, you can install a fuel filter and OSV with a proper support attached to the wall (not supported by the fuel lines alone). From that point on to the oil burner can then go up and down until you get to the tiger loop. Install a valve at the tiger loop and then connect it to the fuel pump.

All the small photos should have a matching file below to look at and enlarge for detail.

Does this make sense?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

@EdTheHeaterMan, overthinking is one thing, and then there's overthinking wrongly as I was apparently doing. Thanks for the very clear info.

Am I correct in taking away that there should be no fittings on the supply until the line is in the house? (Perhaps more accurately, no fittings until below the tank?) If so, the most timely issue is: My oil company is coming on Wednesday to install a shutoff valve at my request at the top of the tank because I've gotten the idea that I should be able to shut down the oil supply right at the tank whenever I want, the same way I can shut down the water, and the closer to the tank the better, and I wanted to have this in before I go on vacation later this week. Should I cancel that for now? (To placate the Anti-Siphon Virus that I've apparently caught, if I cancel the shutoff installation I can just pump out the supply and return before I leave with the pump setup you suggested and deal with these other details when I get back. We've never had a spill or leak, but the system's getting old plus there is apparently weeping inside along the lines, and now that I have the Virus I don't want to leave the house for an extended period without knowing it's somehow safely shut down either via valves or pumping the lines clear.)

The low point stuff is very interesting, and I now realize that roller coaster of oil line is not to be imitated.0 -

My oil company is coming on Wednesday to install a shutoff valve at my request at the top of the tank because I've gotten the idea that I should be able to shut down the oil supply right at the tank whenever I want.

If you are having a professional do the job, then putting the valve at the top is probably fine. Can you be sure that the professional will do the flare correctly and stand behind the work they do? I was able to solve a nuisance lockout problem by removing a problem flare fitting and re-flaring the tubing after properly preparing the end of the tubing. One of my friendly competitors did the faulty flare and called for my assistance. After about 1/2 hour of testing and searching, I asked the oil company owner if he had changed anything on the oil line. He installed the valve at the top of the bend... I took it apart and found the tubing was not prepared before applying the flaring tool. I re-flared the end and solved the problem.

As far as installing a one piece fuel line from the bottom of the inside of the tank to a point below the bottom of the tank outside the tank when you have a TankTub enclosure is concerned, that is easier said than done. I have done it successfully several times, but I have also had tech that worked for me fail miserably at the same task. There is a trick to getting that right. And there is a trick to getting the fuel line to end inside the conditioned space without having any trap or unintended dips in the line. The goal is to have only one high point. From that high point, there should be only 2 ways for any condensation to settle in the fuel line. On one end (the bottom of the tank) it should be all downhill to the bottom of the fuel line. That way, water can leave the line at the bottom. In the other direction, it should be all downhill until the fuel line is in a conditioned space away from the possibility of freezing weather.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Have you asked the techs or service manager at carpenter and smith to convert your 2 pipe oil line system to a single pipe ? It s not the most difficult thing to do for any one w experience . Request a spin on Westwood or bengar filter and a tiger loop be added , a firematic valve to the oil supply remove the by pass plug and re plug check pump pressure and do a combustion test and you should be good aside from a opening the boiler removing the top brushing the sections and clean out the chamber,checking target wall condition and reassembling clean the nozzle assembly and blast tube check turbulator or f head electrode gap also chk and clean the blower housing and blower wheel chk burner coupling . As for the barometric damper as others have stated wrong location easy fix .all the stuff I have mentioned is suppose to be performed each year during your yearly cleaning ,if not you got the wrong oil co . One would think that a company who has been around as long as them would do better than that mess . I know there’s not much better in your area when it comes to oil they all talk a great game and c and p where brought up by a very large company on the stock market so there very corporate and have really changed there commitment to maximizing there profits while under performing for there customers in my opinion ,and really sticking it to the service guys ,I know I had some inside info on the whole dealo. Totally corporate but they delivery and will come out at night if you have a service contract and most burner stuff is cover at least that’s the way it used to be but times they are a cha cha Ching changing .on a side note most of the plumbing companies up your way are the worse at oil burners and will want a small fortune just to open it up and clean most just want to replace and then they do a crap job ,I know I live right on the border and see it all to often but there prices are cheaper on a replacement then service mainly cause there clueless lol

Peace and good luck clammyR.A. Calmbacher L.L.C. HVAC

NJ Master HVAC Lic.

Mahwah, NJ

Specializing in steam and hydronic heating0 -

@EdTheHeaterMan, prior to this I never thought about the effects of dips in the line, thanks. Also, please comment on a bigger question: I have gotten involved in all this because I found out our homeowner's insurance won't cover oil spills, as most don't, and so I looked at my old system and I read about a few nightmare stories where people's savings were wiped out by some small leak, and now I have leaks on the brain. I plan to update/improve the lines eventually using advice from this thread, maybe going to one pipe, but as you can tell have gotten so paranoid about leaving the system while I go on a long vacation that I have looked into the shutoff valve outside (might as well do it, they're coming Friday, I'll watch the flaring though I don't know exactly what to look for), and even pumping the lines clear using the bicycle pump as you suggested. But am I being ridiculous by going through all that? You mentioned overthinking - am I seriously overthinking the possibility of a leak while I'm gone? I've never had a leak, and if I don't do anything like pump before I go I'll still turn the boiler off, so nothing will be running and so there will be no pressure in the lines other than the weight of the oil in them; there might have been some weeping going on because there is a sheen of oil on the lines inside the house (that the 3 different pros who've come in the past few months for different reasons says doesn't mean anything, though I imagine it probably does), but no visible drips; no one will be in the house to jostle anything; yes, a tree could fall on the lines outside or a lion could rend them asunder with its teeth but that won't happen and even if it did, if the damage to the line was above the bottom of the tank siphoning would not occur (true?). So the odds of a leak while I'm gone seem pretty close to zero even if I don't pump out the lines. Please comment. Think of me as a particularly nervous and annoying customer you are advising on the phone. Good thing for me you can't charge me, though (this website is amazing).0

-

Hi @Clammy, yeah I read about C&S being bought up. They were never our service people before; I had an old time plumber who was very responsive and never ripped us off and showed up no problem if there was an emergency, though he did stuff like put in a Firomatic on the return which is verboten (but maybe that wasn’t code when he put it in) and he never used a combustion analyzer, etc. Still, I really wish he didn’t retire, it’s a jungle out there, hard to find the old time small operators, and I’m trying out C&S for service to see how they do.

One thing I’d get with a service contract with them is the option of oil spill cleanup “insurance” through their parent company’s “CARE” program which would cover up to $100K in cleanup. The company (“Star Gas” or “Star” something) insists it’s not technically insurance - so if it’s not, what is it?Except for the fact that I could get that, I might otherwise resist getting the service contract for now; I bought an old Mastercraft vacuum and think I might be able to clean the boiler insides and do the checks you mentioned myself, I think I can change the nozzle and clean the the gun stuff and space the electrodes with Beckett’s little orange gauge, plus I bought a used wet kit which seems to work okay, although it cannot measure CO directly. If I find I can’t do all that, then: service contract.

And yes, when they come tomorrow to put in the shutoff valve that I want because I’m paranoid about not being able to turn off supply in case of a leak, I’m going to ask about them about converting it to one pipe in the future. I thought of maybe doing without the Tigerloop because it seems to me the increased two pipe-like flow between the TL and the burner would be a lot of volume in case of a leak there, compared to the one pipe’s relatively sluggish gph with no TL . (Told you I’m paranoid.) But I know there are benefits in case of air in line, etc.0 -

I ve be been using Tigerloop s for 20 years ,I would never think of doing a 2 pipe on oil . Why pump and filter the pump capacity and burn only say a gallon with a tiger loop your only pulling from the tank what you burner the pump sees less vacuum your filter only filter what your burning plus it de aerates the oil and help reduce any pump cavitation and works great w new pre and post oil relays w a oil delay valve . It’s really a better approach on the whole picture and most flame retention burners do not like pulling vacuum especially since there usually running a smaller nozzle size and higher pump pressure for better fuel atomization and better eff # ,hence the higher reliability of less fuel related issues due to the above mentioned issues.

Kinda sad about corporate buying up c and s , But in reality the fuel oil business ain’t what it used to be ,I think the buy up changed the way they operate and made is more formal and corporate like which doesn’t t always work for every business but if you corner the market then nobody has much of a choice except to go along w the program . In the old days the contracts at least cover most burner parts which nowadays are not that cheap and usually they have a replacement parts for most oil burners they service but who knows if there allowed to change a part unless a manager gives approval . I’ve heard about this happening w another company that got brought out years ago by yet another gone w the wind buy out deal .

Peace and good luck clammyR.A. Calmbacher L.L.C. HVAC

NJ Master HVAC Lic.

Mahwah, NJ

Specializing in steam and hydronic heating0 -

-

Here is a good site to look at for proper flaring techniques https://www.copper.org/applications/plumbing/cth/cth_8flrdjts.html

If the tubing is not properly prepared the bur of the tube may bend over the edge. this will result in a small leak. In the case of the leak at a fitting above the tank, Air will leak in, below the oil line oil will seep out. Here are flared ends that needed to be cut off because they leaked

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

That whole site looks very useful.0

-

@EdTheHeaterMan, it worked! See photos below. I pumped until the oil in the outside tank bubbled, and checked that no oil came out when pump was removed. Then closed both Firomatics for good measure and left a big note to myself on the service switch not to turn on until Firomatics are open. When I get back I’ll just open them and fire it up.

You just saved me I figure about $100-200 on a push-pull pump.

1

1 -

I was schooled by two great Oil guys at R.S.English on Long Island 🏝 to treat fuel oil 🛢 like its Plutonium...Dont spill a DROP...Have plenty of good rags, speedy dry and small Baked Ziti pans or deep baking trays under your work. Conversions....you Better protect floors heavily and not drop any oil or splooge off the runners. Little Nicky aka Mr.Joey..Pastore an old school oil guy PRIDED himself on his own home having ZERO trace of #2 Smell in the basement. He was surgically hygienic on his burner, tank and all flare joints. mad Dog 🐕1

-

NYC rat 🐀 problem is worse than ever. Very simple solution. $10 bucks for every rat you turn in. Set up Feral.Cat colonies in problem areas, outdoors. Jack Russell Terriers and Dachsunds indoors....Nah...that would make too much sense....Right? Mad Dog 🐕

0 -

Hi @MikeAmann, and all, I’m in the Alps! Trip of a lifetime. Back in a few days and will update. Before leaving I had a very good experience with a tech from my oil company, he was very receptive about the whole one pipe conversion and thoughtful and knowledgeable, I am encouraged re having a service relationship with this oil company, especially if I can request this guy.0

-

-

@Mad Dog_2, Switzerland (and France) say hi back. We did the Tour du Mont Blanc which is hiking all around the Mont Blanc “massif” - and it is massive - through three countries. (This was NOT climbing Mont Blanc itself, nor any other real peak, as in mountain climbing, but it was pretty spectacular hiking.)0

-

… oh yes, here are some photos.

0

0 -

0 -

These heating looking things are all over.

0

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements