New drop header, disappearing water

I purchased my current home 20 years ago and it was my first experience with both oil and steam heat. At some point I stumbled on Dan's "We Got Steam Heat" and I started to gain a minor understanding of what I was dealing with. The heat in the house worked and I learned enough to keep it going.

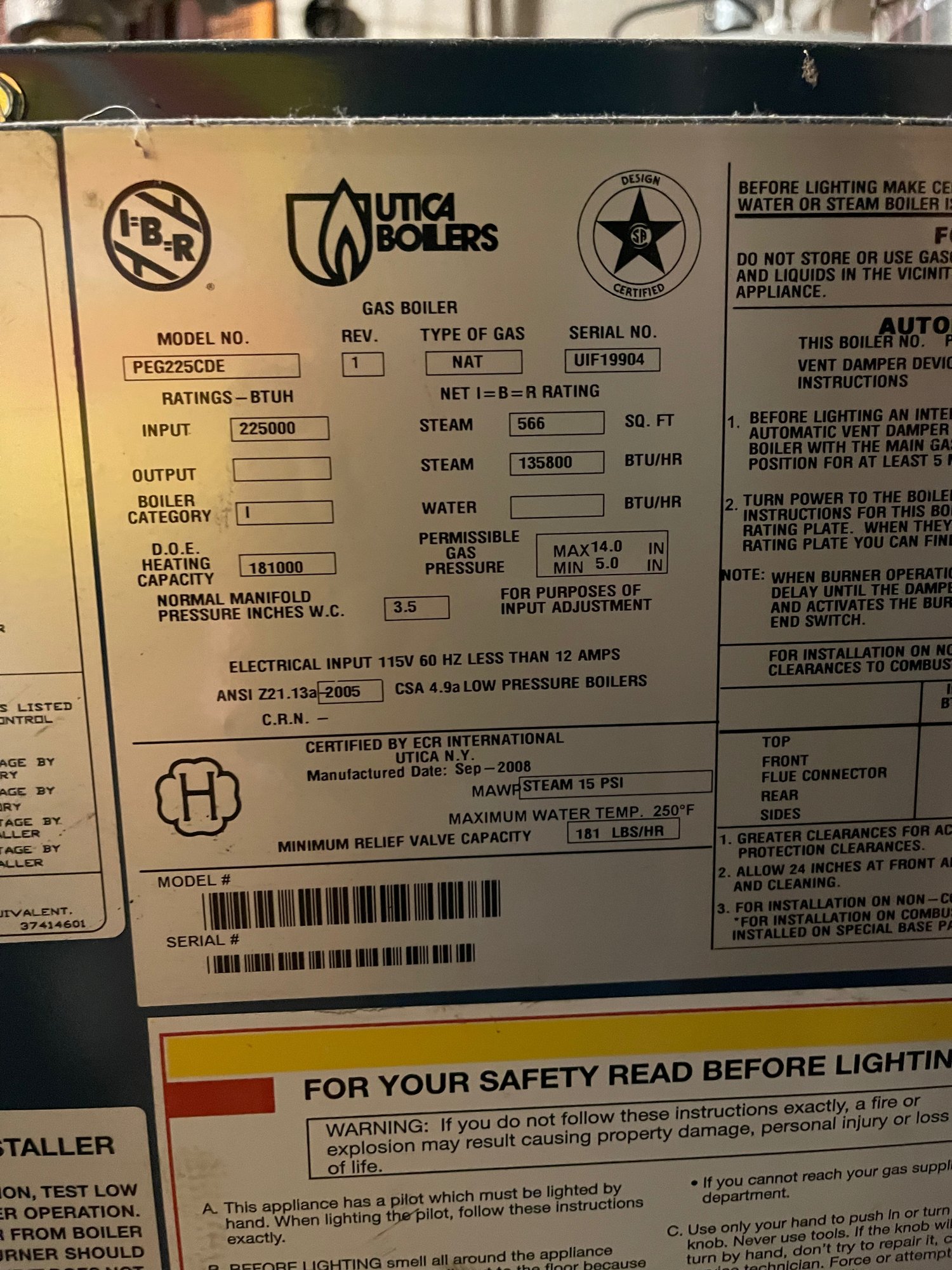

In 2008 I decided to pull the 1000 gallon oil tank out of the ground because several homes in the neighborhood had experienced leaks, which resulted in very costly soil remediation. Luckily mine had not leaked, but as I priced new above-ground storage tanks and I compared heating oil prices to natural gas, I opted to spend the money on a new NG boiler. My steam knowledge at the time was just enough to make me think I knew what was what, and I hired a family run company that had been doing it for decades and was in their 3rd generation, so I believed they knew what they were doing.

My new boiler worked similarly to the old boiler but MUCH quieter, and I was pleased. As time passed and I grew tired of banging pipes and gurgling, I grew curious and started looking for answers, which brought me to Heating Help and The Wall. Here I learned about radiator and pipe pitches and vents, and I made little tweaks and changes that had varying minor effects.

Then I saw Dan's video on the importance of near boiler piping, and I learned that my boiler header wasn't "arranged" properly. Then, after reading a post here that said I should look at my installation manual, I realized that the header was smaller than the boiler manufacturer called for (2" vs 2-1/2"). Now I knew I needed to rebuild the header so back to The Wall where I tried to learn to "think like steam" and gain some understanding of what is occurring in that near-boiler piping. Of course that brought me to the subject of drop headers.

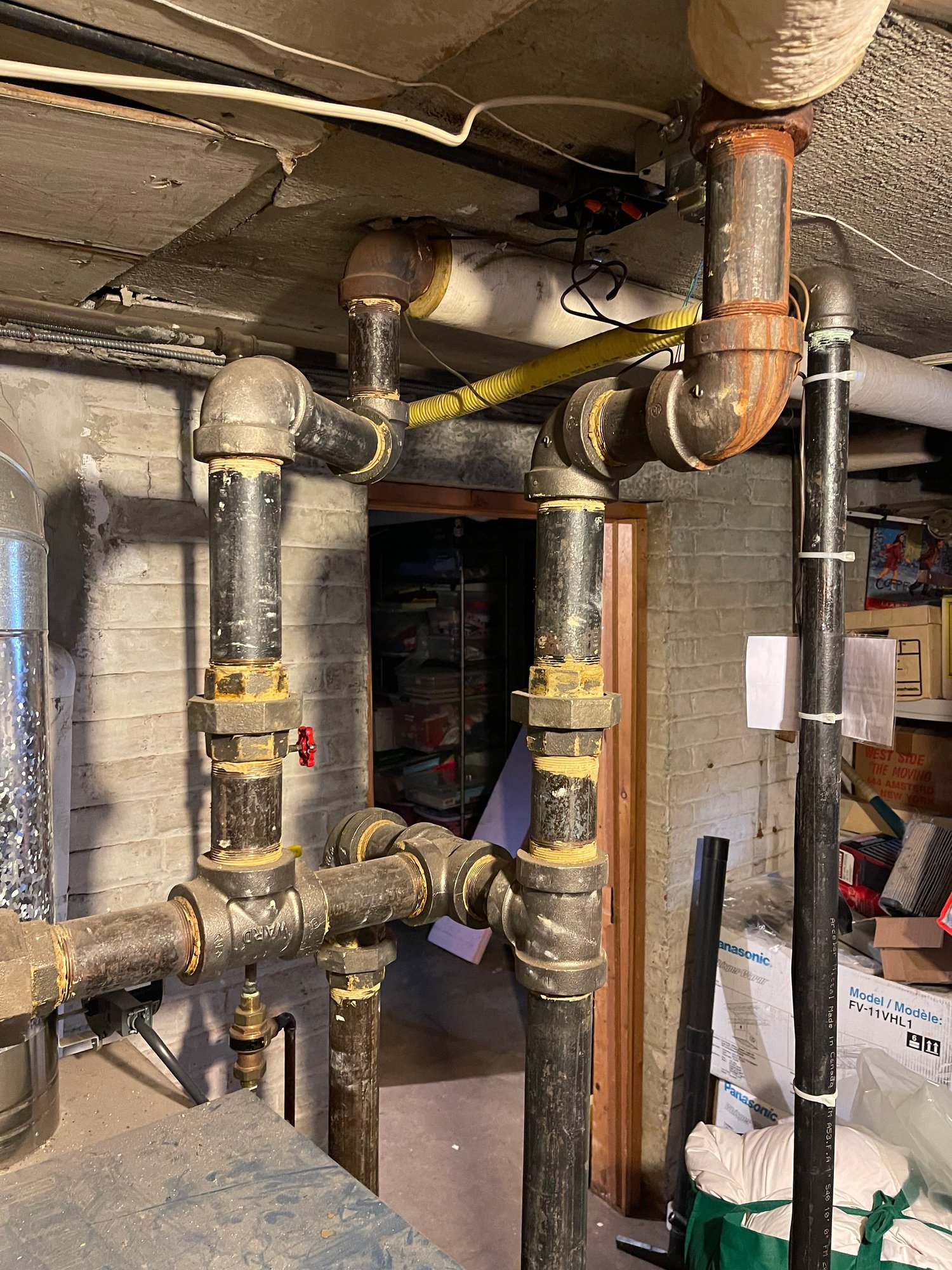

Last heating season one of my mains started to leak at the basement ceiling above the boiler so I decided the time to act was before the next heating season began. Last week I installed my new drop header using all the info I could gather here. I know it's a bit messy, that blue goo is hard to keep neat (for me at least). Hopefully I did it correctly. I know you all will point out where I may have gone wrong or could have done better.

Since finishing I am actually quite amazed by the difference in the system. It is nearly silent except for an occasional creak from metal expansion, and the heat seems much more even. I do have a curious issue however that I can't explain. Now the water is disappearing from the boiler much too fast. Previously I would add water about once a week, now it's once a day and it's not that cold so the boiler isn't even coming on very often.

My first thought was that maybe I had a leak inside the boiler above the water line that was sending steam up the chimney, But I flooded the boiler up into the header and no water dripped down into the burner chamber (or anywhere else thankfully). My wet returns are above the floor and there is no water on the floor anywhere. I can't see any leaks on any pipes or radiators. Can anyone offer a clue as to what might be going on.

My pressure gauge barely moves, or maybe it doesn't move at all.

Only one of my mains is vented. It looks to me like the vent was added at some point after the original install. It is a single Gorton #1 tapped into the elbow that drops the main down into the return, after the last radiator take-off.

Attached photos include original header, previously leaking main, and new header.

Comments

-

Is the water completely disappearing, or does it come back after a while?

It sounds like it's leaving by your description, just want to confirm as new piping and all will likely cause surging which would put a bunch of water into the mains, which would eventually return after shut down. The solution for that is skimming.

If it's leaving, then it's going somewhere as you seem to know. A bad vent, or vents could do it, but they would have to be really bad, and in quantity to lose a significant amount like you seem to be.1 -

Nice piping job!

Check for bad vents as @KC_Jones says, also check the packing nuts on the radiator shutoff valves. You're probably building a few ounces more pressure now that the steam is better quality, which would exacerbate leaks.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting2 -

-

@KC_Jones The water is definitely disappearing and not coming back. Tomorrow I plan to spend several hours skimming.

@Steamhead Thanks for the compliment. Tomorrow I will closely inspect the vent's and valves.

@realliveplumber Yes there is indeed a lot of dope visible. I purchased 1" wide teflon tape and then put dope on top of that. I was worried about leaks despite making each connection as tight as I could plus 1 more, and there was usually a bit of tape and dope still visible in addition to what got squeezed out as I tightened. Whenever I could reach I would clean out any that made its way inside the pipes and fittings. Although I had read in other posts about washing the new pipes and fittings to reduce oil, that part slipped my mind once I'd gathered all the bits and was ready for action. I know I have a lot of skimming ahead of me, do you recommend I add anything to the boiler water to make that process more effective?Paul0 -

Isn't that water under the boiler blocks in the second to last pic?0

-

I have used TSP with great results. You have to flood the boiler. You have gate valves on the system risers so you can shut them down after you flood the boiler. This will prevent the TSP from getting out into the system. heat up the water to less than steaming and let it sit for a couple of hours. just keep boiler water around 180. THEN FLUSH WATER OUT OF BOILER

Might want to check with manufacturer. This procedure is recommended by weil mclain. L have used it on large commercial boilers with great success. You have to keep from reaching rest of system. Will clean everything.3 -

Are you sure the returns got filled when you filled the boiler?

Is the water line stable when it is steaming, not bouncing more than a little bit?0 -

I would skim the boiler with tsp 1 lb./50 gallons of boiler water.

But you need to find out where the water is going. If it's not coming back it's going somewhere.0 -

-

@pedmec Yes, that is water under the boiler blocks, but that was the result of me over-filling the drain pan and then clumsily spilling it as I poured it into a bucket. I think I have some TSP so I'll give that a shot. The Utica manual says to skim and blow down (monthly!) the boiler and if still dirty try a cleaning product.

@MikeAmann I will look for that, too. Thanks.

@mattmia2 That's an interesting question about the returns. I assumed they would fill as I filled the boiler. The water line is relatively stable, it does not bounce excessively. Thanks for the paint thinner tip, I'll give it a try.

Yesterday I spent a good deal of time skimming. Afterward I drained water into a pan and boiled it on the stove and there was no foaming. I did pull the cap off the return tee and discovered some sludge, so now I plan to build a wand to clean that out. I have no floor drain so I need to devise a system to deal with all that water.

It's been so warm here that the thermostat hasn't been calling for heat so the water level is not dropping. Today it's cooler, I'll open some windows and doors and crank it up to see if I can locate a leak. @mattmia2 Thanks for the mirror tip, that's a good one!

Is it possible that there is a leak inside the boiler above the waterline that only opens up while the boiler is firing and pressure has built? My pressure gauge really doesn't budge from zero so that's either broken or the system pressure is too low to move it. I did clean out the pigtail to it so I know that's not plugged. Is there a way to test that gauge or should I just replace it? Should I add a lower pressure gauge?Paul0 -

I will say one thing about sneaky steam leaks....they add up quick!!!! I had what I thought was a minor steam leak between two radiator sections. Only was loud enough to hear up close when the boiler cycled on pressure. No water drips or anything....so I assumed it was very minor.

I had been adding up to 5 gallons of water make up per week during the coldest times of the winter and was beginning to assume there was steam going up the chimney!!!! I flooded the boiler and no water was found anywhere so I started chasing leaks.

I fixed that leaky radiator and found a little bit of a leak on a radiator valve. Just those two changes had me go from 5 gallons per week to a gallon or two per month!!! It adds up really quick!2 -

@AdmiralYoda Thanks for that, it's very reassuring! I bought this house from the daughter of the original owner, she was 92 and had lived here since she was 1 year old, moving her parents to the 3rd floor after she married and had kids. House and systems maintenance was minimal or nonexistent and any work done went to the lowest bidder no questions asked! I will be very surprised if I don't discover some leaks.Paul0

-

-

How much water are you adding daily? Make sure all of your radiators and pipe runs have the correct pitch. Water may be sitting in radiators that don't have proper pitch or in return pipe(s) that aren't properly pitched. If this is a one pipe system, make sure all of your radiator valves are either fully open or fully closed. You can't adjust steam flow by adjusting radiator valves. That has to be done by sizing the radiator vents properly.0

-

The 0-30 psi gage is required by code, since the system should not get any where close to that, it is kind of useless but legally required. If that was my system, I would remove the tee from the pigtail, add a union to a cross and add a 0-3 psi gage.0

-

Just an update. It has been so mild here in NJ that the boiler wasn’t coming on. At the start of this week the temp has dropped and ever since it started firing regularly I have had a series of issues. One interesting but unsurprising development is that the radiators off the main with no vent don’t get as hot as the radiators on the main that is vented. Unfortunately the thermostat is on the vented main side so only half the house gets warm. I definitely need to add a vent/s to the cold side.The other thing is with the water level. I haven’t located a leak yet, but what happens is when the level drops and I add water to the fill line, after the boiler fires again, runs a cycle and shuts off the level will be higher than the fill line and it stays there. If I remove water to bring it down to the full line, the next time it runs the water line winds up significantly lower. What could be the cause of that happening? Could air be getting trapped somewhere?Paul0

-

What are the condition of your returns? Ninety-two years of mung?0

-

What happens if you don't adjust the water level back down but leave it somewhat high? Depending on the boiler, that shouldn't cause a problem with steaming (unless the water level is less than an inch or so from the top of the glass). Mostly curious -- but water may be getting hung up somewhere out in the wilderness with the higher boiler water line?Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

There *should* be a drain cock somewhere on a wet return. Open it and see what happens. If the water trickles out, well you have returns clogged with mung. You should have a healthy flow of water. Also, if the wet returns were drained, it will take a bit of condensate to refill them...0

-

I assume you have tested your LWCO to make sure it works. Assuming you have, just fill the boiler a little more than halfway up the glass and try leaving it alone. At the end of the cycle you have mentioned the water looks low and you manually add water. Don't this time and see if the site glass fills back up before the next cycle? If it doesn't your tested LWCO will shut the boiler down safely and you either have a leak or a very slow return. If it does then you may still have a slow return but maybe something you can live with for a bit.0

-

@Long Beach Ed Indeed I do have drain cocks on the wet returns. When I open them the water flows freely. I drained the returns completely to see if I saw any sludge but they seem pretty clean except for a bit of rust colored water.

@dabrakeman Yes the LWCO definitely is working, after I drained/rinsed the returns the boiler shut off on low water and I needed to add water to it. It shut off on LW about every 12 hours and I had to add, but after 2 days the level stopped dropping so quickly. Perhaps @mattmia2 is right and the returns aren't getting filled when I fill the boiler.

In any event, I still must add water every day or 2, so I'm definitely losing it somewhere that it's not obvious. I've replaced all vents but one in the last 2 years, tomorrow I'll change that one.Paul0 -

It's all been discussed here. Any water removed from the returns below the nipple in your Hardford Loop has to be replenished. And steam leaks do, indeed use up LOTS of water. I had a system with a new four section Independence boiler I wrote about here in 2011 that was losing a gallon a day.

The only way I found the leaks was by pressurizing the system with air. There were a half dozen leaky radiator valve stems and a leaky union. That's where the steam was going. You couldn't see them at all, but after they were tightened, all the leaks went away.0 -

@Long Beach Ed Does pressurizing the system with air require removing vents and plugging? What pressure is safe?Paul0

-

I remove the vents and plug the radiators with threaded plugs. Remove the pressurtrol and thread an adapter from a small air compressor. If you go above 15 lbs the safety will trip in the boiler. But you only need a couple of pounds to hear the air whistling out of every leak there is... At five or ten pounds you should hear things happen.

Listen to the gauge glass, every union and every radiator valve and tighten or fix them one by one. A few hours work, but you'll find every leak.

3 -

Well, good news and bad. Good news is I think I've found the leak. Bad news is it's the boiler itself. Yesterday I added some Rectorseal Scale Flush then ran the boiler for about an hour. I let it cool down, drained it and flushed it out then refilled. Before bed I went down to make sure there was enough water in the boiler, since it takes several cycles to re-fill the returns, and I noticed water on the floor under the boiler. Upon closer inspection I saw water dripping from the boiler jacket. This morning I went down and the water is dried up and the dripping has stopped, but I think it's safe to say the main leak is coming from the boiler itself. I pulled off the top of the jacket and there is no obvious sign of leaking on the outside so it must be inside the combustion area. I guess it's time to replace.

I pulled out Dan's E.D.R. book and figured out all my radiators, came up with 464. Do I need factor in the mains? I have two 2" mains with 1" fiberglass insulation, one is 51' the other is 21'.Paul0 -

The rating of the steam output of boilers has a 30% pickup factor added in for the piping. This is usually far more than the actual loss to the piping. If you do some rough measurement and calculation of the piping you can add that to your EDR, convert that to BTU output of the boiler and use that to select a boiler that better matches your system.

Or you can just use your measured EDR and compare it to the steam output on the rating plate and end up a little oversized.0 -

i am new to the world of steam and the drop header (have project currently) but a general question about the union on the side that is bolted - why that style over the other types of unions? (I ask because in my design i didnt include that style). Thank you, sorry if its not on the exact topic of your problem.0

-

Please don't add anything to your EDR, the Net Sq Ft of steam amount is plenty inflated

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Unless they want to convert it to btu and look at the btu output of the boiler which isn't inflated.ethicalpaul said:Please don't add anything to your EDR, the Net Sq Ft of steam amount is plenty inflated

0 -

@Subdural I had both union options available, one fit and the other was too big!

@ethicalpaul @mattmia2

Radiator EDR = 464

rough pipe EDR from boiler to radiators (2": 72'*.622=44.78) (1.5": 33'*.497=16.4) (1.25": 64'*.435=27.84) (1": 39'*.344=13.42) =102.44

Total EDR = 566*230=130,180 btu

So, a boiler with a minimum output of 130,180? Or could I get away with 129,000 (Peerless) or 125,000 (Weil-Mclain) or am I better off going up a notch to 147,000 or 149,000?

Paul0 -

BTUs are so prone to confusion with the input, the output, the math.

Regarding the net sq ft I think the same guy who came up with the 30% was the great great grandfather of the guy behind the counter who says "you can get by with this smaller one, but get the next size up just to make sure"

I would say multiply the boiler net sq ft by .80 and find a match that wayNJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Do not add in the pipe.panick007 said:@Subdural I had both union options available, one fit and the other was too big! @ethicalpaul @mattmia2 Radiator EDR = 464 rough pipe EDR from boiler to radiators (2": 72'*.622=44.78) (1.5": 33'*.497=16.4) (1.25": 64'*.435=27.84) (1": 39'*.344=13.42) =102.44 Total EDR = 566*230=130,180 btu So, a boiler with a minimum output of 130,180? Or could I get away with 129,000 (Peerless) or 125,000 (Weil-Mclain) or am I better off going up a notch to 147,000 or 149,000?

Radiators only!1 -

@ethicalpaul

I see what you mean, using the Peerless 63-05L as an example, specs show an input of 206,500 btu, DOE output is 171,000 btu and IBR output (which doesn't pertain to my situation) is 129,000 btu.ethicalpaul said:BTUs are so prone to confusion with the input, the output, the math.

Is this what you mean? (again using Peerless as an example):ethicalpaul said:I would say multiply the boiler net sq ft by .80 and find a match that way

The 63-05L (DOE output 171,000 btu) produces 533 sq ft steam multiplied by .80=426

The 63-05 (DOE output 196,000 btu) is 613 sq ft multiplied by .80=490

Taking the advice of @KC_Jones and factoring in radiators only with a 464 EDR, I'm somewhere in the middle between the above 2 boilers.

Then if I use the btu method suggested by @mattmia2, again accounting for radiators only (464 multiplied by 230) returns only 106,720 btu's, the Peerless 63-04 (DOE output 147,000 btu) produces 458 sq ft of steam.

I'm either confused or confusing it. Maybe both.

I'm unsure what to do.Paul0 -

Ok, so you have 464 sq ft of radiation. The classic method is to take that number and install the boiler with the closest rating to that number, but not smaller than that number, so you'd install the 63-05L rated for 533, because the 63-04 is rated at 458 which is below the 464 of your system.

Now all that said, for me, the 63-04 is so close, it will run just fine on your system, and I will show the numbers as to why.

63-04 has a gross input of 177,000 btu, it's efficiency is 82.4%, so that leave you with a gross output of 145,800 btu

You have 464 sq ft of radiation. We multiply that by 240 btu/sq ft and get 111,360 btu needed to heat the radiators fully.

If we compare that to the gross output of the boiler we see there is 34,440 btu extra which is considered the pickup factor. That gives you 30.9% pickup factor and the classic amount of the pickup is 33%. You are so close, that it will be fine in my opinion, actually more than fine.

There are some of us that would even make the argument for going to the 63-04L, (~9% pickup for you) but there are probably only a couple contractors in the country that would even contemplate doing that.

Within the Peerless 63 series I'd put in the 63-04 and no way would I allow anyone to put in anything bigger.

3 -

At some slight risk of muddying the waters... The manufacturer's square foot rating does take into account an additional30% output (sometimes, erroneously called "pickup factor"). Now one might ask why? Two reasons. Well, three. First, they want to account for less than perfect 1 inch insulation on all the steam mains. Second, they want a margin for a slightly lower firing rate -- lower BTU content fuel, off-spec. combustion adjustments, some sooting of the heat exchanger or somewhat less than ideal near boiler piping. Third, they want to be sure that the installed power is sufficient and slightly over so the customer gets the heat they want.

Now that is not to say that the result will be ideal -- and if the customer, on his or her dime, wants to specify a smaller output, that is fine. Just don't complain to the manufacturer if it is discovered that you don't get the output you need.

On the other hand, don't go oversize. In your specific instance, I'd agree with @KC_Jones and pick the -04. Why? Because the EDR calculations (no offense please) are likely to have at least a 5% error in them, and it is much more likely that they are high rather than low -- so your 464 figure realistically is somewhere between 420 and 480, and the likely figure is more like the lower.

I do realise that there are those who feel that this approach is too conservative, and would reduce the oversize factor further. Well and good. I was an engineer in another life, and I appreciate engineering where the numbers are cut as fine as they can be. I'm not a bit keen on when the numbers are very close -- and the error is on the low side, and, folks, you need a lot more accuracy in all your numbers than we have in this business to justify that risk.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

KC's post is the one I would follow, he made it much clearer than I did!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

@KC_Jones @Jamie Hall @ethicalpaul Thank you all so much for your input.

@ethicalpaul I've been following your exploits here for a long time. If you had it to do over would you still go with the Peerless?Paul1 -

Yes, without a moment's hesitation I would buy a Peerless again. The only other brand I would consider would be a WM or its lower-tier stable-mate Williamson. Maybe *maybe* if I had to have oil I might pick a megasteam but frankly Burnham scares the heck out me.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements