Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

efficiency of hydronic vs forced air?

Options

Comments

-

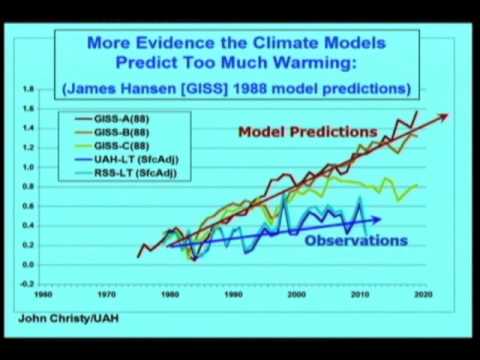

Please provide sources and references. I suspect you are substantially over exaggerating both the number and quality of scientists who disagree with current accepted climate models and scientific consensus.JakeCK said:Voyager said:And a good many very sound scientists disagree with those who are climate alarmists and for good reason.

Somewhat dated now, but well worth watching. Dr. Spencer is hardly a fake scientist. https://youtu.be/2GHlnjrZLUo 0

https://youtu.be/2GHlnjrZLUo 0 -

An opinion piece by a non scientist, classic. But this doesn't count.

And Spencer and his buddy Christy's claims have been proven wrong multiple times. Like back in the 90's when they claimed the data showed the atmosphere was cooling. They were wrong. When it was peer reviewed errors were found and in fact the atmosphere was warming. Not cooling. And this pattern has been repeated many times with those two. They have a bad habit of cherry picking data and then getting called on it.1 -

Warming isn't really the problem, though it makes very good press and a very good living for some people. The problem has much more to do with exactly when the equilibrium of the remaining continental scale ice sheets shifts from net gain to net loss, and this shift is not reversible without a very significant temperature drop -- 5 decgrees C at a minimum for Greenland. The consensus among glaciologists is that we are very close to that condition and it is most likely that Greenland has crossed over. Antartica is considerably more difficult to model, but honestly it doesn't look good...

The problem, as I see it, with the whole climate change global warming climate denier screaming match is that people are paying a lot of attention to temperature -- and almost none to climate dynamics. There are many reasons for this, but, regrettably, I think the major one is that climate dynamics is genuinely hard, while a nifty graph of temperature is easily understood (and misunderstood) and can be put out in 140 characters or less.

I have no desire at all to get enmeshed in the entirely political problem and fight regarding adaptation to a different climate regime vs. asserting that mankind can avoid having it happen if only we ban this or shift to that. I happen to think that mankind has the capability to adapt, should he choose to use it and that he does NOT have the capability to avoid having to adapt (keep the shifts from happening). The sea level rise from Greenland is modest -- it will be about 2 meters over the next 50 years or so. The effect of shifting the Gulf Stream south, which the loss of the Greenland Ice Sheet will cause, is somewhat more dramatic.

Particularly if you like French wine...

I'm glad there are at least a few other people who are still around programming in Fortran. It's not that user interface is difficult, as such, provided one plays by the rules -- but other languages are better suited, in my opinion at least.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Of course mankind can adapt in time, but I doubt our society will. We are going to suffer a mass die off just like every other species has when an unfavorable change in the environment occured. We just happened to be the architect of those changes.

A good example of how precarious our way of life is, is the 30% of the worlds wheat production that has been removed from market in just the past month by a single event. Not climate related though0 -

-

This has turned into one of the most interesting threads! Derailed or not.

The good and the bad about internet forums...we never really know who is behind the keyboard. Here on HH there certainly appears to be some of the most intelligent people who have more passions than just HVAC.

Several other forums I'm on it isn't so....many useless posts and random gobbledygook which any real pro can se straight through.

This place makes me think and read.Serving Northern Maine HVAC & Controls. I burn wood, it smells good!0 -

This discussion has been closed.

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements