Missing main vent & high heating bills

There's a hydronic loop feeding baseray style cast iron baseboard radiators for the basement.

For context, the house isn't terribly big - 40x21 footprint. Open floor plan on the bottom, 3BR on the top. The upper floor takes SIGNIFICANTLY longer to heat than the lower. There's about a 3-4 hour diff for upper to match lower temp. Of course by that time the lower floor is absolutely swealtering hot

All radiators have maid-o-mist vents installed about half way down. I've tried to size the little vent screw caps based on approximate distance from the boiler, but since all piping is in the walls, it's hard to tell the true puping length.

Here's my issues:

1 - My heating bills are insanely high, even with my Nest smart tstat.

2 - It takes about 45min to 1 hour from the time the tstat turns the boiler on 'till the radiators get decently hot.

3 - They do eventually get pretty hot up top and the heat/steam even makes its way to the 'far side' eventually. The problem is on almost all the radiators, the bottom half is lukewarm or cool to the touch, even when the top is hot enough to blister skin.

4 - on a 30 degree NYC day (F), it takes about 2+ hours to raise the home temp 10 degrees. I've lived in steam heated homes before and that ain't normal (in my opinion).

The home is fairly well insulated as it was recently gut renovated and we took care in that department. All rads are either at least level or slightly pitched toward the steam boiler valve (most are pitched).

I don't think the boiler is short cycling as I've timed it and it runs about 7-10 min per cycle. Pressuretrol is set to .5 cut-in(lowest setting) with 1psi delta (1.5 cut out?)

Questions:

1 - Any ideas why the bottom half of my rads aren't getting hot? Is this a red herring/normal? In my mind that means I'm missing out on half of my potential heat output but maybe it's nothing.

2 - what could cause the long heating time? I noticed that i don't see a main vent near the boiler/header piping. Also my header piping isn't insulated. Would this really make much of a difference? Keep in mind everything's in the walls so it would be difficult to insulate the pipes or see if there's a main vent further down (i honestly doubt there's one).

3 - Would the 3 bullet style vents in the bathroom risers count as main vents?

4 - If not, where should i install one? See attached photos of the boiler room. What you see is pretty much the extent of the exposed piping

5 - should i try downsizing the air vents on the radiators that take forever to heat? Some are much quicker than others.

6 - the gas valve died last year and i replaced it with the same model (see pics). I did no adjustment as i was told it should be good to go with default settings out the box. Could this be part of the cause for my ridiculous bills? Maybe i should've turned the gas going into the boiler down a bit?

I've been trying to get to the bottom of this for 2 years with no luck. Hopefully the steam pros on here can point me in the right direction...

Comments

-

A couple of suggestions:

1. Get rid of the Nest. It doesn’t belong on a steam system and it’s not saving anything. Probably using more since the system was never designed for setback.

2. You need to have properly sized, functional main and radiator vents. Maybe riser venting also. What sizes would be difficult to know without all the factors.

3. The only way that gas pressure should be set is with a manometer according to the boiler manufacturer’s specs. There is no “default” setting.

4. Replace the CycleGaurd LWCO with a SafeGard. The CycleGaurd is what’s short cycling the boiler.

Your system was originally designed to be coal fired where there was a constant fire and the home owner would adjust the intensity (modulation) of it depending upon the weather. When an automatic burner was installed, it went from being a constant, modulating fire to being on- off. The original venting wasn’t designed for this. You’ve added a setback thermostat and the CycleGaurd on the boiler both of which only exacerbate the short cycling and make the situation worse.

You really could use a good STEAM PRO (not a plumber or HVAC tech) on site to evaluate everything.

Try the contractor locator above or post your local for a recommendation.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

@Justin20

You need main vents and you need your boiler piping fixed....it's a mess. You burning a ton of fuel and all your doing is making wet steam and then even that can't vent.

First all of @Ironman comments are on point.

Check "find a contractor " on this site. PM @JohnNY if you in the city you need some serious help. you can't change a gas valve without c=doing a combustion test and checking gas pressure. That's like working blind0 -

I disagree about replacing the CycleGard. It's not the source of your problem. Save your money to get the near boiler piping re-done. You need two supply risers and an oversize header to get dry steam from a Dunkirk. Get the venting issues taken care of now, and while they're at it they can give you an estimate on the re-piping.Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-241 -

Thanks for all the comments. I honestly didn't expect so much so quickly.@EBEBRATT-Ed could you elaborate on the piping being a mess? I'm by absolutely no means an expert but based on what I've read/seen about near boiler steam piping, it's not terrible. There is no drop header setup but it *seems* to be an ok setup based on the main being placed above the header with 2 risers connecting them. I measured at least 24 inches from the piping coming off the boiler to the header Also, the equalizer appears to be where it should?Now - i am BY NO MEANS challenging you experts but based on all my novice reading, i can't find anything immediately/obviously wrong with the near boiler piping other than crappy boiler placement and lack of insulation. Please educate me on this point.Btw i can provide photos/video of any angle/part of the system requested.@NHOwner The boiler room shown in the photos is the only exposed piping other than the two 2" riser pipes heating 3 bathrooms (both risers have vents at the end at the top floor). Can you point to where a vent should be installed if in the boiler room? I want to make sure anyone i bring in doesn't try to bamboozle me like the plumber apparently did1- @ironman Is there any recommended tstat if the Nest isn't best for steam?2 - i count about 7-10 min of "on time" between it cutting out. I was told that was *not* short cycling and normal. Is this not the case?3 - completely agree that i was way out of my depth replacing the gas valve but it wasnt cutting on the boiler and making this incredibly loud buzzing sound in the dead of winter so i was desperate. I ran to the local plumbing supply just to prevent us from freezing. I just did a swapout without adjusting anything. In the future i would call an expert now that i know how precise this must be adjusted.I will reach out to a steam expert. I had a plumber install the piping and let's just say I'm beginning to doubt his knowledge of steam systems 👍.0

-

You don't need two connections to the main if there's only one main. If you have two mains, they should each be connected separately to the header. I don't know what the person who piped your header was thinking. It's just crazy.

But the real problem is that there's only one supply riser from the boiler. On a Dunkirk, you need both, and you need a bigger header. 3" minimum. The equalizer should also be bigger, and it should drop straight from the header to the water line. It can elbow below the water line if it has to, but since you can position the header almost above the return, you shouldn't need to.Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-240 -

I never said that the CycleGaurd was the source of the problem, but cutting the boiler off every 10 minutes is what’s causing the short cycling and contributing to the problem.Hap_Hazzard said:I disagree about replacing the CycleGard. It's not the source of your problem. Save your money to get the near boiler piping re-done. You need two supply risers and an oversize header to get dry steam from a Dunkirk. Get the venting issues taken care of now, and while they're at it they can give you an estimate on the re-piping.

Yes, the near boiler piping is wrong, but what the OP stated has to do mainly with the venting, the Nest and the CycleGaurd, not the near boiler piping. Changing the CycleGaurd would cost less than 1/10th of redoing the near boiler piping. I think that would be more economical.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Any standard thermostat that can be set to 1 CPH.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

I still think replacing the LWCO would be a waste of money. I have a CycleGard, and while I'm not crazy about the intermittent level test, that's not what I'd call short cycling. I can make it short cycle by setting the heat anticipator to .3 though, and it doesn't even run long enough for the ILT to kick in, so you're probably right about the thermostat. If you set the thermostat for short cycles, short cycles are what you get.Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-241 -

I've taken some photos showing the near boiler pipe diameter. My eyes could be wrong, but it doesn't look like the outlet hole could even fit a 3" pipe diameter. It looks like most everything is ~2"+ diameter. The small section of pipe coming directly from the boiler seems to be slightly larger (maybe 2.5"?). I took a pic of the main header coming out of the other end of the wall. It's the same diameter of the other near boiler piping. That was just to show that I'm pretty sure it's that same 2"+ diameter into the ceiling.I've also taken an up close photo of the boiler label that shows the specs of the boiler.So the piping is undersized. Would this cause slow heating and high bills? I'm also going to ask the steam specialist about the Cycleguard vs Safeguard.@NHOwner the risers in the bathrooms have vents as they serve as radiators. This is common in NYC bathrooms (having a riser going up through that actually acts as a radiator and heats the bathroom). The 1st floor bathroom just has the riser going straight through it. It actually heats it fairly well. The 2nd fl bathroom directly above it is where the riser ends. It has a bullet vent at the tip/end of the pipe. There's also another riser tee'd off from the first riser in between the floors. This heats another 2nd fl bathroom next to the first 2nd fl bathroom. I'm going to post photos of this tomorrow.Any idea where vents should/can be added in the boiler room?

0 -

@Justin20

Though the near boiler piping is not correct, it’s not the main issue. You’re being misdirected by homeowner opinions when you’ve been given the correct advice from pro’s with over 100 years combined experience.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.2 -

Just to clarify, all radiators have maid-o-mist vents. Now whether or not the little orifice caps on them are sized right... that's a different story, lol.(One of) my question centers around main venting... which I'm not sure i have. UNLESS the riser pipes heating the 3 bathrooms with bullets at their ends on the 2nd floor count as main venting? 🤷♂️0

-

"4 top & bottom connected 'traditional' radiators and 1 baseray baseboard style). The top floor has 4 of the same style 'traditional' steam radiators (connected on top & bottom)."

We need to see a picture of a typical radiator in the OP's house. If that description is correct this is a 2 pipe non air vent system and all the talk about radiator vents is invalid because they shouldn't be there.1 -

I might be just a dumb homeowner, but I know how to read. This is from page 11 of the Dunkirk IOM.

I also know that Dunkirk boilers are very sensitive to bad piping, and the diagram shown is the minimum required piping for this model. A larger header will help considerably.

I'm not saying this is a priority job during heating season, but I am saying you won't get dry steam until you get it piped correctly. The venting needs to be addressed right now, but wet steam will damage your new vents if you don't get the piping fixed soon.Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-241 -

On the picture diagram of the one pipe steam system

Kindly observe that the pipe labelled "dry return" in that diagram is not the same as a "dry return" in a two pipe steam system. The two serve entirely different functions and need to treated very differently in a number of ways.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Just an update:I spoke with the installing plumber and he kindly informed me that while he repiped all of the risers to rearrange the radiator locations based on the new floor plan, he did not touch the near boiler piping. He then proceeded to give me a hefty several-thousand dollar quote if I wanted him to perform a NBP redo.With that quote fresh in mind, I started looking at any lower cost alternatives to achieve the desired result before digging that deep into the coffers.To recap, i have uneven heating across my radiators with all of them taking at least 45 min to start heating up and others taking ~2+ hrs.Once the heat gets going... hours after the therm calls for heat... Lol, all radiators eventually get blistering hot (a good thing) and heat the home sufficiently. Although i have noticed that the bottom half of almost all rads never really get hot. Am i crazy in thinking that an losing out on 40-50% radiated heating surface area because of this??- my heating bills are hundreds of dollars a month... it's insane.- There are no main vents. This is the plumbers fault.- as you guys have pointed out above, there are 2 mains that are inexplicably connected (see photos). Could this cause one main to get more steam than others?- longest main runs along the support beam of the house (run is about 35'). Other main is maybe 15'? Maybe shorterI took a look at my Dunkirk PSB-6D boiler manual and noticed they recommend the main vent on the last foot or so of the dry return before it dips back into the wet boiler return*** I've added a Big mouth vent at the recommended location with no noticable difference. I admittedly need to run more timed/feel tests though. I just installed it last night. The next step i guess is another at the end of the main... that will require cutting into the ceiling at the front of the house and drilling and tapping a 2" <> 1-1/4" reducing elbow as there's no unions in sight.I've taken some photos of the radiators, near boiler piping, and before/after vent installation:There's a single riser that heats 2 bathrooms directly above/below one another. A 3rd bathroom is fed by another riser tee'd off of the first one in between the floors. All 3 bathrooms get hot (eventually). It works pretty well when it finally gets going

Here's a photo of the dry return:BEFORE:

Here's a photo of the dry return:BEFORE:

AFTER:

AFTER:

NBP:

NBP:

MANUAL:

MANUAL:

0 -

First off, while the boiler piping is... um... creative, I don't think that that's the entire problem, and probably not even the major part of the problem.

Second, on timing. It is quite likely that the lack of main vents is a good part of the problem. You don't have any, or at least you haven't posted any pictures of any. Each steam main -- you seem to have two? -- needs to have a main vent on it somewhere past the last radiator takeoff. It really doesn't make any difference how far past. I doubt very much that that one Big Mouth you picture is doing much for you -- and I'm not sure what pipe it's on anyway. That's not a steam main, although it may be a condensate return line of some kind (the elevation makes it difficult to tell whether it's normally wet or normally dry -- looks very close to the boiler water line?). Strictly speaking, there are no dry returns on a one pipe steam system. There are extensions of the steam main, and there are wet returns -- but no dry returns.

So think about some main vents.

On the heat only part way down a radiator -- that's pretty normal for one pipe steam. Generally one finds that the inlet side of the radiator (if the steam vent is opposite the inlet) is warm most of the way down, while the vent side often is not hot much below the elevation of the vent.

You mention it taking time to recover from a 10 degree setback. I'm not a bit surprised. That's much more than is usually recommended for steam, or any relatively high mass system. Just as a reference for you, it takes a bit over an hour on one of the buildings I care for to recover from a 2 degree setback -- and that is with a system which is sized and working flawlessly.

You also mention a Nest. I'm sorry to hear that. Unless you have disabled all -- and I mean all -- the smart features of the Nest, it is costing you fuel and money. They work well, in common with most occupancy sensing thermostats, on systems they are meant to be installed on: forced air. They work poorly on anything else. Sometimes extremely poorly. Either disable it -- or swap it for a thermostat designed for steam or hot water.

You mention dismay at the heating bill. That same building -- a large residence -- which I mentioned above -- can quite happily run through a couple of hundred gallons of fuel per week in the colder weather. the amount of fuel you use is very much determined by the heat loss of the structure and much less by the heating system (except, as noted, large setbacks are going to cost you much money).

I notice that none of your steam piping appears to be insulated. Not saying it's going to help a lot to do it -- but it will help some.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

The vent i added yesterday is at the end of what i believe to be the dry return (per the boiler manual). Am i to understand a one-pipe has no dry return? See photos and manual below:

I realize that I'll likely have to add another at the end of the main run but it's not going to be easy(From earlier post)The next step i guess would be to install one at the end of the longest main... although that would require cutting onto the ceiling at the front of the house and drilling/tapping into a 2" <> 1-1/4" reducing elbow as there's no unions in sight.

I realize that I'll likely have to add another at the end of the main run but it's not going to be easy(From earlier post)The next step i guess would be to install one at the end of the longest main... although that would require cutting onto the ceiling at the front of the house and drilling/tapping into a 2" <> 1-1/4" reducing elbow as there's no unions in sight.

0 -

KC_Jones said:

"4 top & bottom connected 'traditional' radiators and 1 baseray baseboard style). The top floor has 4 of the same style 'traditional' steam radiators (connected on top & bottom)."

We need to see a picture of a typical radiator in the OP's house. If that description is correct this is a 2 pipe non air vent system and all the talk about radiator vents is invalid because they shouldn't be there.

Yes, I had this question then but was away.

Has this ever been answered???

And how many homeowners are we dealing with for this posting??0 -

JUGHNE said:

"4 top & bottom connected 'traditional' radiators and 1 baseray baseboard style). The top floor has 4 of the same style 'traditional' steam radiators (connected on top & bottom)." We need to see a picture of a typical radiator in the OP's house. If that description is correct this is a 2 pipe non air vent system and all the talk about radiator vents is invalid because they shouldn't be there.

Yes, I had this question then but was away. Has this ever been answered??? And how many homeowners are we dealing with for this posting??

Single homeowner. 2 family, 2 story home with basement. Please see my post earlier tonight for radiator photos 👍

0 -

Nomenclature. i do wish that the ongoing -- seemingly perpetual -- confusion over what to call pipes in a steam system would go away.

There are some pipes which connect directly to the boiler steam header if you trace them back far enough. Not much question that these are referred to as steam mains -- or risers or runouts. The problem arises in that in many one pipe steam systems, these pipes are carried along -- at a continuing slight downward pitch -- back to near the boiler, where they connect to a vertical pipe which goes back to a wet return (I'll get there). These are often referred to as "dry returns". Unfortunately for clarity, there are pipes in two pipe steam systems which really are dry returns. The problem is that the two need to be treated quite differently.

In a two pipe system, the dry returns never should see steam (if they do, something else is very wrong) and always are at or near atmospheric pressure (except vacuum systems, which are different yet again). In a one pipe system, the pipes sometimes referred to as "dry returns" do carry steam, and are at boiler pressure.

In a one pipe system, if there is more than one "dry return", they must NOT be connected back together at the boiler or anywhere else, but must end in an individual drop to a wet return. Since they are merely extensions of the steam mains, they do need to be vented; these will be steam main vents, and those vents can be placed anywhere along the "dry return" after the last radiator takeoff. In contrast, in a two pipe system, the dry returns can, and often are, connected together near the boiler and then there is a single drop to the wet return. They are almost always very near (usually slightly below and to one side) the steam main with which they are paired. Main vents are placed where they come together at or near the boiler, and are absolutely essential. In some but by no means all two pipe systems the steam mains will have vents at their distant ends; in others, there will be steam traps at the distant ends which connect to the paired dry return and no steam main vents are needed (or wanted).

You have, @Justin20 , a one pipe steam system. Therefore, you can place your main vents anywhere along your steam mains or the "dry returns". It also appears that you have two steam mains; I would not be surprised if, on tracing the pipes, you found that both of them come back to near the boiler. If that is the case, note that they must NOT join before they drop to the wet return. They must drop separately, and each will need its own main vents.

I note that I mentioned wet returns above. They are not always present, beyond a mere short loop leading to the Hartford Loop. If present, they are and must be below the boiler water line. A not uncommon failing where boilers have been replaced is that some pipes which were supposed to be wet returns are now above the water line. An interesting variety of poorly functioning and impossible to balance systems can be caused by this; it's worth checking on.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England7 -

I'm going to add another vent to the end of the main (after the last radiator) and will need to cut into the basement ceiling to access it.Before i do so i want to have a game plan. Here are photos of the end of the main. Apologies for the photos - it's only viewable from within a utility closet.Where should i drill/tap and what's the recommended tap size? I have 1/8 and 1/4 NPT taps.

0

0 -

-

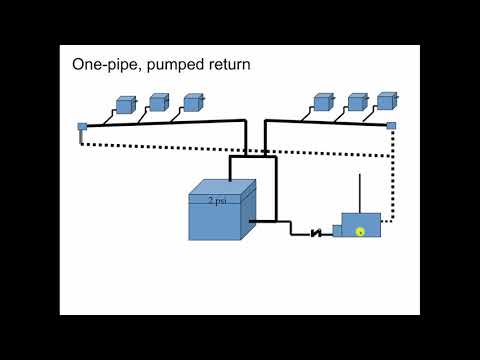

Here's a crude drawing of my system. My 'return' (i know there's not really a return as it's one pipe) drop is actually about 2 feet out of view from the above pictures. The red arrow in the drawing illustrates where i'm trying to install a vent.NHOwner said: https://www.youtube.com/watch?v=tpA1epqFMCw

https://www.youtube.com/watch?v=tpA1epqFMCw

Here's a link. Which one pipe system do you have?

The last 2 radiators at the end actually get hot first.. its the guys in the middle that take forever... go figure...

Regarding an adding a proper antler with a tee, as you can see - there are no unions anywhere in that location to disconnect the pipe to add one, and the main is in like 20'+ sections. I can't really see where i can easily get a tee in there. I'm open to suggestions from you experts.

0 -

If that drawing you made of your system is more or less accurate -- and looking at the pictures it may be -- that return on which you placed the vent may be partly flooded as soon as the boiler produces an pressure at all, since there doesn't appear to be an equalizer. So it's no wonder it doesn't help much.

However. Do I see a union just out of the picture to the left where it says "to boiler"? What is on the boiler side of that union, if it is a union? If it is a length of pipe, which I would probably try is to take that length of pipe, shorten it about a foot or so, put in a T and a nipple joining back to the union, and mount my main vents on that T. That won't be a bad place for the main vents in that system, and it involves a minimum of difficult work.

If that's a union...Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

NHOwner said:Let me guess 2nd floor middle radiators take forever the heat up?

YES!!! How'd you know?Bear in mind the radiators in the middle of the house DO get hot eventually... just 2 or so hours after the guys at the front (very end of the main). It's all quite strange. I suppose the fact that they get hot proves the vents work?It is very possible that he sized the pipes wrong. I'll try to measure the inlet size of some of the 'worse offenders' and report back.@Jamie Hall you may be right about that union: see photo, but now I'm wondering if there's a point to adding a main vent here since my return apparently is not in the right place.I will see if there's room to add a vent where you recommended rather than at the end.Btw there is an equalizer. See photos. This is before i added the Big Mouth on the dry return.

0

0 -

It's too low to be a dry return and too high to be a wet one. A dry return, or any horizontal pipe above the water line, must be considered a steam pipe. Even if it never sees live steam, it's still subject to steam pressure, and it must be at least 28 inches above the water line to allow the condensate to return to the boiler.Justin20 said:Here's a crude drawing of my system. My 'return' (i know there's not really a return as it's one pipe) drop is actually about 2 feet out of view from the above pictures.

Also, you don't show the header in this diagram, but I'm pretty sure you have one.Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-241 -

Hap_Hazzard said:It's too low to be a dry return and too high to be a wet one. A dry return, or any horizontal pipe above the water line, must be considered a steam pipe. Even if it never sees live steam, it's still subject to steam pressure, and it must be at least 28 inches above the water line to allow the condensate to return to the boiler. Also, you don't show the header in this diagram, but I'm pretty sure you have one.

@Hap_Hazzard Good eye. You can't tell from my photos but unfortunately my "A dimension" is more like 17 inches instead of the recommended 28 (i measured it). There's nothing I can do about that without basically tearing open every wall of my basement along that side of the house.@Jamie Hall I'm STRONGLY considering moving the vertical drop of the dry return to the end of the line in addition to adding another main vent. (See drawing)

I've modified my earlier diagram to be a bit more accurate since i didn't include the equalizer, hartford loop, header, etc.

- my Hartford loop drawing may be a bit off but you get the idea.. it's there, and in proper position best i can tell

- as some of you have pointed out ( @EBEBRATT-Ed ) my 2 mains are connected. I have no idea what that's about or why it was done this way.

0

0 -

I don't think moving that drop at the end is going to make much difference. However, lowering that whole lower line -- or raising it, which ever is easier (if you raise it, it has to pitch back to the boiler!) might just make a significant difference. Where it is there is an awful chance that it floods, even with the equalizer 9thank you for adding that).Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Aside from all the advise you have received your boiler near boiler piping is your biggest issues aside from lack of main venting , insulation on your steam mains and from the return piping no real way to really bottom clean you boiler of mud and rust . The near boiler piping will not produce dry steam which will effect steam distribution especially radiators at the ends of the mains . Your boiler also looks like it’s up there in age it would be wise to figure your edr of your radiators to ensure the boiler is properly sized for starters . I have a saying steam is very forgiving and I’m sometimes surprised that some steam boilers even work being piped like crap but they do but there’s always issues that will never be resolved w a bad near boiler piping ,over time a wet steam producing boiler w no insulation on mains will get leaks due to pipe grooving from excessive condensation flow add in no main vents and time and you will have repairs . Aside from the above a improperly piped steam boiler will never deliver the comfort it should and will always cost more to operate then a properly piped steam boiler and always have issues related to even distribution . The excuse that that’s the way steam is is a bunch of bull any contractor who states this is not a competent steam guys plain and simple and should be shown the door . Usually the only thing that stands between properly installed steam boiler and a improperly installed ,piped and cleaned one is the contractor and money the later usually being the case . The sweeten of a cheapened price is soon forgotten after the bitterness of poor quality .

Peace and good luck

ClammyR.A. Calmbacher L.L.C. HVAC

NJ Master HVAC Lic.

Mahwah, NJ

Specializing in steam and hydronic heating0 -

To separate the two supplies at the upper cross connect, other than access and ripping out the fittings, the union and pipe nipples could be removed, destructively if needed. Then pipe plugs could be inserted in the openings of the two tees. It doesn't eliminate the bullheaded tees, but could go a long way to eliminating any problem by having the two supplies connected.0

-

I don't see that upper cross as an issue,

what harm does it cause?known to beat dead horses0 -

@Hap_Hazzard made a comment, "You don't need two connections to the main if there's only one main. If you have two mains, they should each be connected separately to the header. I don't know what the person who piped your header was thinking. It's just crazy."

It may be no harm, but when I saw it and Hap_Hazard's comment, knowing how the typical diagrams are done, there is no reason to have two parallel connections between the two mains. It looks pretty unusual. If the two mains are receiving the exactly same amount of steam, there would be essentially no flow through the cross connect. If one main wants more steam, it is possible it could be getting it from the other main connection through the cross connect, potentially reducing what the lesser main gets.

I know this sounds far fetched because the lengths are so small considering the diameter of the pipe, so I need to explain more about my "Why".

In my 1 pipe system with 2 mains (one significantly longer than the other), I had a problem at the return end where the returns were connected a few inches apart from the return vents then to the wet return. After a lot of troubleshooting, I discovered this and thought the shorter main was using the longer main's vent, reducing how quickly it would take for the longer main to completely vent. I repiped the shorter main return to connect below the water line and it solved my problem. I realize the situation is at the opposite end of the system, but thought, what the heck, maybe there's something here.

0 -

@Jamie Hall I've gone through the entire run based on photos during the home renovation and have determined that the return line is not sloped at all towards the boiler, but is instead completely straight with no slope at all. This could be an issue. Ive always had hammer on initial boiler startup when it starts making steam but only for a minute or so and not incredibly bad (I've heard worse) so I've ignored it. I'm guessing this is the cause.Honestly i can live with this, but if the lack of slope is driving up bills then i will RAISE the return line - fixing two issues at once... 1) adding the 1"/20' slope and increasing my 17" A-dimension to 28".To be clear, if this needs to be done then i will do it, no problem. But my main issue remains the delayed heating of the long main rads, and most importantly DECREASING my monthly heating costs.I purchased some varivents that arrived last night and replaced my Maid-o-mists on the problem rads with those. The radiators went from taking 2 hours to 1 hour to get hot. Yes.. i had tried the various M-o-M vent cap sizes with no luck (i went as high as "D")I also found that one of my bathroom "radiator" (really just a riser pipe) vents had failed and won't close. It's hissing and letting steam out even after it's hot (see photo):

----------At the boiler I very carefully watched/felt the 'dry return' pipe and noticed it doesn't even get hot until maybe an hour after turning the boiler on.. around the same time the slow rads begun to heat. The header/main got hot maybe 20-25 min after a cold start... maybe another Big Mouth will help?@clammy @neilc @SteamingatMohawk i am also not 100% convinced the connected mains, while certainly not ideal, are the primary cause of my issues. Repiping is definitely in my future, but i think once i am ready to go that route, I'm going to just replace the whole damn thing as well. The $6k+ quotes I'm getting in my area for the job (excluding the cost to repair/replace the walls/ceilings that would need to be torn up) has me looking for stop-gap solutions to at least keep me warm and not paying crazy bills for maybe another 2 winters?I could definitely fix that A dimension and return pitch issue myself though. I could also separate the 2 mains with pipe plugs as @SteamingatMohawk suggested.Updated drawing

----------At the boiler I very carefully watched/felt the 'dry return' pipe and noticed it doesn't even get hot until maybe an hour after turning the boiler on.. around the same time the slow rads begun to heat. The header/main got hot maybe 20-25 min after a cold start... maybe another Big Mouth will help?@clammy @neilc @SteamingatMohawk i am also not 100% convinced the connected mains, while certainly not ideal, are the primary cause of my issues. Repiping is definitely in my future, but i think once i am ready to go that route, I'm going to just replace the whole damn thing as well. The $6k+ quotes I'm getting in my area for the job (excluding the cost to repair/replace the walls/ceilings that would need to be torn up) has me looking for stop-gap solutions to at least keep me warm and not paying crazy bills for maybe another 2 winters?I could definitely fix that A dimension and return pitch issue myself though. I could also separate the 2 mains with pipe plugs as @SteamingatMohawk suggested.Updated drawing 0

0 -

I think you need to abandon that main vent location due to the A dimension, that line is likely flooding and shutting off any vent action, although I'm surprised that vent isn't spitting at the same time, water oughta be backing right up there,

get your main vent up on the high main as you show in this last drawing,

or raise that whole dry return and vent up high at the boiler, respecting return pitch to the boiler the whole wayknown to beat dead horses1 -

I'm not sure any cross-currents could happen there that can't already happen in the header, and since the order in which the mains connect to the header is essentially arbitrary, I don't think the redundant connections could cause balancing issues. They're just redundant, and a sign that the person doing the piping didn't really understand what he was doing. He was probably doing something he was told to do once because it made sense in a different context, but he didn't understand the Why.SteamingatMohawk said:In my 1 pipe system with 2 mains (one significantly longer than the other), I had a problem at the return end where the returns were connected a few inches apart from the return vents then to the wet return. After a lot of troubleshooting, I discovered this and thought the shorter main was using the longer main's vent, reducing how quickly it would take for the longer main to completely vent. I repiped the shorter main return to connect below the water line and it solved my problem. I realize the situation is at the opposite end of the system, but thought, what the heck, maybe there's something here.

It's kind of like the situation with my own near boiler piping as I found it.

The guy probably thought he was making a header and swing-arms, but he didn't really understand what they do or how they work, so he stuffed it up. I still haven't figured out what he thought he was doing making the mains connect to the opposite risers though.Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-240 -

Like I said, with my experience at the other end, I thought it was worth mentioning. I tend to agree with you.

Somewhere recently I read about uneven water levels inside the boiler I think with multiple steam tappings each supplying a single main ( two tappings, two mains, nothing in common). It might have been on HH or in Dan's book.

0 -

SteamingatMohawk said:Like I said, with my experience at the other end, I thought it was worth mentioning. I tend to agree with you. Somewhere recently I read about uneven water levels inside the boiler I think with multiple steam tappings each supplying a single main ( two tappings, two mains, nothing in common). It might have been on HH or in Dan's book.But in my case there's only a single tapping. Also, i don't believe the shorter main is connected in any way to the return. I could be wrong here since it's in the ceiling but based on my digging around, i think that second main has no return and is some sort of weird counter flow without a drip, lol. I think the condensate just falls back into the header?? The whole setup is screwy.So here's my plan:per my earlier post, i was able to cut the slow heating radiators heat time in half by dumping the maid-o-mists (with the many different little vent cap sizes) for varivents. I realize some ppl here don't care for them, bit they seemed to have helped tremendously (wide open).The next step is to add a vent to the main. I ordered another Big Mouth, will remove the one i added right before the wet return drop and take BOTH and install them at the end of my main per my upgraded crappy diagram.

I figure this will speed up the rads even more.I also cleaned my pigtail (was completely clogged) and added a 0-3psi pressure gauge to it.Cut the hole in preparation for tomorrow's main install

I figure this will speed up the rads even more.I also cleaned my pigtail (was completely clogged) and added a 0-3psi pressure gauge to it.Cut the hole in preparation for tomorrow's main install

@Hap_Hazzard i agree that the connected mains likely aren't the primary cause for my uneven heating times (recall that all rads eventually get hot, it was just hours apart) so I've decided to shift my focus away from NBP issues, especially since adding the varivents made such a difference already

@Hap_Hazzard i agree that the connected mains likely aren't the primary cause for my uneven heating times (recall that all rads eventually get hot, it was just hours apart) so I've decided to shift my focus away from NBP issues, especially since adding the varivents made such a difference already

0 -

@SteamingatMohawkSteamingatMohawk said:Somewhere recently I read about uneven water levels inside the boiler I think with multiple steam tappings each supplying a single main ( two tappings, two mains, nothing in common). It might have been on HH or in Dan's book.

If you run across the reference I would be interested. That near boiler piping is very common our neighborhood. Each boiler tapping supplies a different main, each has its own header and own equalizer. The equalizers are tied together below the waterline. Whoever did it is probably a Deadman but new heating guys often preserve the the arrangement.0 -

Can do.

Have you ever come across my monologue on venting?0 -

No, I am pretty new here0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements