Is a second pressure gauge allowed?

Hi everyone,

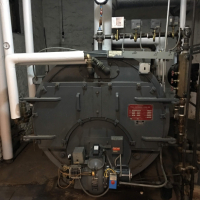

Hi everyone,I'm including a photo of our boiler with the position indicated where we would add a gauge.

Thanks,

Eric

Comments

-

-

Put your second gauge on a tee with the gauge you have. No need to put it where you're indicatingYou can have it good, fast or cheap. Pick two0

-

Did the "professional" quote the specific code? If not, I'd be questioning them to do so, if they can't then there is likely no code. My next question would be why they are against installing one. I'm not in NY, but I've never heard of any code restricting such an add on.

I would also suggest something lower than 0-5 PSI, 0-3 PSI would be more in line in my opinion. All depends how much piping loss you have in the building as to what pressure is needed, it's typically a lot lower than people think.1 -

@JUGHNE It's possible they thought we were planning to replace the other. I'll confirm.

@Canucker Thanks for the tip on using a T. That definitely seems like a better choice.

@KC_Jones I'll ask about the specific code. And we're running below 2lbs of pressure. Switching to low fire around 0.5lbs. I already got the 5lb gauge (oops) but I'll get a 3lb if it's better.Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)1 -

There is no code that I know of prohibiting a second gauge. You could put a gauge on every one of those pigtails for each pressure control by adding a Tee fitting. That way you can see if a pigtail is blocked and how accurate the pressure control is performing. To prevent a steam leak from a ruptured gauge you can place a valve between the gauge and the system pressure and only open the valve to take a reading.

Tell him to put that in his pipe and smoke it!

LOLEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

If you bought already, see how it works for you.eappleton said:@JUGHNE It's possible they thought we were planning to replace the other. I'll confirm.

@Canucker Thanks for the tip on using a T. That definitely seems like a better choice.

@KC_Jones I'll ask about the specific code. And we're running below 2lbs of pressure. Switching to low fire around 0.5lbs. I already got the 5lb gauge (oops) but I'll get a 3lb if it's better.0 -

speaking of belts and suspenders, code or no, 3 pressuretrols and a vaportrol . . . asking for a friend? I can see a vaportrol for control and a pressuretrol for safety cutout, maybe a manual reset depending on btus or maybe even a safety cutout and a manual reset cutout set above that but i'm starting to run out of fingers to count what to do with those.

the electric bus is a nice touch but can't see what's holding it up (if anything) on the left hand end.0 -

After seeing where you do run, you could add even a 0-32 ounce third gauge with the isolation valve under it for protection if you over pressurize for some reason.

But no valves under any control devices.0 -

@eappleton

I would put a low pressure gauge on with an isolation valve underneath it. Keep it closed.

I don't believe that would be against any code with a valve on it.

Without a valve it could be against code. The boiler has a 15psi safety valve and all connections to the boiler must be rated 15psi.

I would put the new gauge and valve over on the right hand side above your gauge glass it would be easier to reach.

Just keep the valve off and open it when you want to check the pressure.

JMHO0 -

@EBEBRATT-Ed is there any harm in leaving the isolation valves open? I thought these gauge could handle a vacuum, no?0

-

@AdmiralYoda

In most residential steam systems you could put a low pressure gauge on and that's it....you would never have an issue.

But pigtails on pressure controls can plug (ask me how I know) so it is possible (but unlikely) that a low pressure gauge could be subjected to pressure higher than it's rating.

And ASME code requires that anything on the boiler has to be rated 15 psi because that is what the safety valve is rated for.

The gauge only needs to be on when you go in there to check the pressure, so you turn the valve on check the pressure and then shut it off.

So JMHO if it's a code issue I say it needs a valve on it

In reality it probably doesn't0 -

OOPS the valves I mentioned were to isolate the gauges only. not the pressure controls. I should have made that clear.

Regarding the wire connections to the pressure controls. here is a short story made long...

Installed a steamer in a church with 3 controls all wired in series with duplex connectors to accommodate 3 BX wires on the single opening knockout. every other year I would remove the gauges and controls to clean out the large on-site fabricated trap in place of the individual pigtails.

it was a PITA to remove all the wires from the controls so I could unscrew all the controls to access the piping to remove the sludge that would build-up over the 2 seasons.

One year after the maintenance the first cold day happened and I got a call that the boiler was banging and they turned it off. Turns out that after rewiring the operating control (it was the mercury switch type) I looped the wire around the mercury tube in a way that would keep the switch from turning and the boiler continues to build pressure to the second operator that was installed as an auto-reset high limit. (The third was the manual reset limit)

The problem was resolved after I saw my error in locating the wire that I affixed every other year without incident. Then I got to thinking how long it takes to remove wires and re-wire every time I do maintenance.

So I rewired the controls the next summer with quick connect plugs to facilitate removing the controls. I purchased standard 110V. plugs and receptacle-ends like the type you might use to repair an extension cord. But you can purchase dedicated Moles connectors that clip together so the connection does not vibrate apart.

I have an illustration below:

@archibald turtle ...if you take a closer look you can see the little man holding up the left end of the electric bus box.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

where is thumbs up emoji @Erin Holohan HaskellEdTheHeaterMan said:

So I rewired the controls the next summer with quick connect plugs to facilitate removing the controls.

oh, i thought that was plug for easy servicing . . . :-)EdTheHeaterMan said:

@archibald turtle ...if you take a closer look you can see the little man holding up the left end of the electric bus box.

so i guess this system has a control vapor stat, a control presuretrol and then an automatic reset safety pressuretrol and a manual reset safety pressuretrol.

although honestly i'm never sure with pressuretrols in that range that you could get them to trip in the order you had in mind.

BTW- best indicator i ever had for low pressure steam system was my UEI EM152. I'd make a commando riser with valve and barbed fitting for the hose. This systems ran really well at like 14 inches. I guess maybe you could see that on a 3 pound gauge but many i loved watching what was going on down to hundreths of an inch of water. I don't know what happens to that technology if you put into permanent service, and it didn't do side by side with a EM201 on a trapped and non-trapped riser to see if there was much response difference but now i've got something to try next time i'm over at that job.0 -

@eappleton

Hi, Eric. I recognize that boiler. Whoever told you it was against code to add a pressure gauge measuring in the lower range was just plain wrong. As long as the 30# gauge remains, you can add more to your heart's content.Contact John "JohnNY" Cataneo, NYC Master Plumber, Lic 1784

Consulting & Troubleshooting

Heating in NYC or NJ.

Classes4 -

Thank you all. I think I will put the low pressure gauge on a T with the 30lb gauge. Seems like the simplest thing to do since there is already a valve below it.

@JUGHNE I like the suggestion of a 0-32 oz gauge. I'll wait to see what I learn from the 5lb gauge. I understand that all gauges should have isolation valves below them. And I assume they also need to be on pigtails.

@EdTheHeaterMan and @archibald tuttle I wish I fully understood all the controls, but I don't quite get them, even after years of trying to make sense. Layman's terms, left to right, the first pressuretrol is a safety cutoff at 10lbs or pressure. The next starts the burner in high fire and shuts it off at 2lbs currently. The third switches the burner to low fire, currently at 0.5lbs. The last connects to the Heat Timer and I don't know what it does. I've been asked to make a wiring diagram so that folks here can help me understand the system. One of these days I'll get around to that...

I've been asked to make a wiring diagram so that folks here can help me understand the system. One of these days I'll get around to that...

Hey @JohnNY Thank you for the NYC wisdom!

I really appreciate the responses. You all are incredible.

Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

FWIW

Thats not the proper mounting for that gauge. It should be mounted on a wall and piped to the boiler. The 1/4" threads are not designed to hold the weight.

Consider changing it at the same time0 -

@eappleton : I like the suggestion of a 0-32 oz gauge. I'll wait to see what I learn from the 5lb gauge.

of course the gauges will help you follow what is happening but now that I understand you have extra pressuretrols for high and low fire, and my initial quick view of the photo mistook the clear overed pressuretrol for a vaportrol (the difference being the scale, they both measure vapor pressure). my guess is you would be well served by a more accurate high fire cutout. there was some extensive discussion here of alternatives as honeywells mercury based controls got phased out that Dwyers are accurate but don't have range to provide cut in and cut out for high fire stage so a more complicated schematic with 2 dwyer was arrived at.

This was lost when some number of heating help threads went awol in a server migration or some such about 4 years ago although I did salvage some of the thread from the wayback machine and @MarkS reposted and reworked much of the material in very thorough format in a replacement thread (and even saw fit to repost alternative wiring suggestions from yours truly). I have never had mine in operation because I haven't installed the two stage valve yet on the boiler I have in mind. Funny how time goes by, but it's a brilliant idea and if you already have low and high fire steam I think it would improve operation and save you money.

https://forum.heatinghelp.com/discussion/156690/a-diy-vaporstat-alternative

That whole thread started because dwyer also makes powered monitors(i.e. electric gauges) and switches that aren't cheap but aren't that expensive by the standards of serious boiler work and energy expenditures that could perform both functions. e.g.:

https://www.dwyer-inst.com/Product/Pressure/DifferentialPressure/Gage-Switches-Digital/SeriesDH3/ModelChart

although as i mentioned to @EdTheHeaterMan UEI (and others i'm sure) make very accurate affordable manometers or differential manometers of which I have the old version (EM151) that only goes to 20 inch of water but the new ones go to 60 inch (just over 2 PSI) so not bad to establish your operating range and characteristics with a very sensitve ditigal output montoring.

https://www.ueitest.com/ECommerce/product/em152/em152

where you put the tee and isolation valve (not sure re the weight of those gauges and 1/4" pipe. my instinct would have been they are fine. Caution used to be needed to orient the pigtale across the mercury vial on earlier vaportrols to prevent expansion changing the level of the control but I don't recall the need to wall mount modest size gauges although I noted @pecmsg concern . . . anyone else?) you just install a male pipe by barbed fitting adapter temporarily into the isolation valve and you can use the EM152 or similar to measure pressure change very accurately to understand the range of permanent gauge and the accuracy thereof that might be useful and then use the shutoff valve until you obtain the permanent gauge. (the EM152 is no permanent gauge given battery consumption and the auto off function that requires it to be rebooted at room pressure so you have to pull the tubing for the reset, but i'm thinking a clever guy with electronics might be able to figure out how to power it with a DC output transformer if there is a way to pester it with input change such that it didn't auto off, or course the first explorers of such ideas will need to let us know how they fare under constant use where pipes may get hot)

Anyway, without discussing competing prices or particular sellers, the EM 152 tester is going to stand you a Franklin or so and really gives you an incredibly good idea of the steam pressure changes over a cycle. A good gauge is not cheap so it might actually be worth it to establish what would be a good gauge esp. if you could employ it for other uses (great draft measurer and differential across combustion fans and or circulation fans in scorched air. . . CAUTION: the maximum pressure you should expose the 152 to is 2.5 PSI so if you follow a cycle and it actually maxes the 60 inch WC reading then you want to turn off the isolation valve. the boiler I used this as a tester on for possible conversion to two stage never actually even went over the 20 inch WC range on my EM 151. Depending how tight your system is, I bet the 60 would be a decent indicator and although caution is merited you'd be unlikely to run much over its capacity. Have you ever observed the boiler to drop to low fire trip with the current control setup? (you could test that with a multimeter or you might recognize the difference in sound) and have you ever actually observed it to cutout altogether on pressure.

The importance of reading in those low ranges is that 2 lbs might well be high (although if you don't ever hit that cutout that one is not so relevant) but it's possible that .5 lbs high fire cutout (i.e. 14 inches WC) could be lower and or that the control you have now is not sensitive enough to reliably cut out at .5

The Dwyerstat linked above, although it uses two measuring devices is actually meant to replace your single high fire throttling control currently set for .5 PSI with a more accurate approach.

0 -

@archibald tuttle I’m afraid the DIY vaporstat details are over my head as an amateur. I’m currently focused on adding the low pressure gauge first before changing the controls, but I’ll revisit this after.Have you ever observed the boiler to drop to low fire trip with the current control setup? (you could test that with a multimeter or you might recognize the difference in sound) and have you ever actually observed it to cutout altogether on pressure.

If I understand you correctly, yes, i have observed the boiler to drop into low fire. It happens at approximately 0.5lbs but it’s hard to read on the 30lb gauge. The sound changes and a panel (vent?) closes on the burner. I have also seen it shut off on pressure at 2lbs. It is currently not shutting off on pressure generally, but if it drops into low fire too late (say, at 1lb), the pressure will keep climbing and hit 2lbs and shut off if the timing cycle is long enough. With low fire beginning at 0.5lbs, it seems to stay at generally steady pressure for the full cycle. I’d like the low pressure gauge to see this more clearly.

I’m going to plumbing store today and will post a photo of my intended low pressure gauge setup. Thinking to place it above the gauge glass (thanks, @EBEBRATT-Ed) so that it’s separate from the 30lb gauge. Thanks, @pecmsg for the heads up. I’m not going to change that gauge yet, but I don’t want to add weight there in case it’s an issue.

Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

They make a 3 way valve that is perfect for that application.

1 way to show the 0-30 the other to show the 0-3

https://www.amazon.com/L-Port-Forged-Valve-Handle-Female/dp/B07413FXRR/ref=sr_1_1_sspa?dchild=1&keywords=3+Way+Valve&qid=1609425706&sr=8-1-spons&psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUEyUjJQWThDNUFWUktLJmVuY3J5cHRlZElkPUEwNjg0OTg2MVM4VFZIRFhRMlpWViZlbmNyeXB0ZWRBZElkPUEwNDY2ODcxMjNKRlpDQUlPS0VBSyZ3aWRnZXROYW1lPXNwX2F0ZiZhY3Rpb249Y2xpY2tSZWRpcmVjdCZkb05vdExvZ0NsaWNrPXRydWU=0 -

@pecmsg i guess you could run with both on if the handle was half way, is there a both off position for that valve?0

-

Yes 45°. Also the capability of easily isolating the LP gauge.archibald tuttle said:@pecmsg i guess you could run with both on if the handle was half way, is there a both off position for that valve?

In plants we want the same gauge for measuring delta P, (More Accurate) that's where these valves come into play.0 -

I was an amateur until i spent 30 years on here.eappleton said:I’m afraid the DIY vaporstat details are over my head as an amateur. I’m currently focused on adding the low pressure gauge first before changing the controls, but I’ll revisit this after.

Anyway, I'm glad to hear that your current operations seem at least to correspond approximately (although without careful gauging) to nominal setpoints. At least it sounds like there is repeatability in your current setup suggesting that the combination of fire and controls is reasonable although my suspicion is that you could operate at even lower pressure. not even so much changing the cutout from 2 lbs. although possibly but reducing the low fire a little. If the low fire can actually make the cutoff with a little momentum you could probably go down a little. And the low fire is a good deal of your consumption and governs stack losses to the extent that you are in low fire for a good deal of the cycle (if not see how long it takes to make steam and maybe you could slightly increase high fire while slightly decreasing low). it is that kind of tuning which gets to the fine art and appreciation of this mode of heating.

And actually the DIY is pretty simple and made of easily obtainable components. It's a nice thing to wrap your mind around when you got an extra hour and the beauty and simplicity starts to jump out. Like nobody understands 3 way or 4 way light switching if you just stick a diagram under their nose for the first time, but it doesn't take long to drop in to the zen.

The reason that 'Dwyerstate' looks complicated is it replaces the 'deadband' or 'differential' built into controls that are less capable in the lower vapor ranges with a second control that provides the cutout by holding the high fire in until the .5 is reached allowing for more careful control of the cut in which would be notably lower, e.g. 50% of scale kind of thing.

Even as an amateur, I can't recommend enough doing something like putting a precise digital manometer on a steam system and watching the cycle. My equivalent for gauging the suitability of gravity vs. pumped returns but it has my digital manometer set up and demonstrates the relationship of the height of water in the returns to the water column inches we are discussing. https://www.youtube.com/watch?v=GCv7iKi0xgg

https://www.youtube.com/watch?v=GCv7iKi0xgg

If you watch the whole thing you will see I'm fully steamed and collecting return at about 7.25 inches WC as displayed on the digital manometer i describe which is hooked up to my dwyerstat control manifold with flexible tube to a barbed hosefitting w shutoff (just one main loop out of 3 in that house that I piped clear for the test, thanks to McMaster Car for the polycarbonate tubing which I found that its a 1" shark with its OD, not an ideal long term fitting for steam but just fine for this test) . Then you'll notice the weir of my Gifford Loop is about 40.5 inches and the height of my water column in the return is like 45.5 ( I think the floor was level within an inch IIRC) and the difference represents the loss of pressure around the system and with condensation in the return but pretty close close enough to a one for one correspondance to confirm the theory in emperical reality for me.

1 -

@archibald tuttle I have learned a ton here in my on-and-off 10? years, and hope to learn more...my suspicion is that you could operate at even lower pressure. not even so much changing the cutout from 2 lbs. although possibly but reducing the low fire a little. If the low fire can actually make the cutoff with a little momentum you could probably go down a little. And the low fire is a good deal of your consumption and governs stack losses to the extent that you are in low fire for a good deal of the cycle (if not see how long it takes to make steam and maybe you could slightly increase high fire while slightly decreasing low).Absolutely. That's my hope as well. I was thinking with the low pressure gauge, I can see more exactly when low fire happens and shut off, and keep lowering low fire initiation as low as I can.

I hadn't thought about increasing high fire. I think you mean using a larger nozzle so the high fire gets the steam happening quicker, then dropping into low fire at as low a pressure as possible. Am I reading that correctly? Increasing high fire is with a nozzle and decreasing low fire is adjusting the pressuretrol?

Here is the new gauge setup:

I may need a step ladder to read it correctly... Look alright to you all?

Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

I like it. You can reduce the height with a different bushing reducer in place of the one you have. Also, why do you need/want an isolation valve? I don't mind it, but I'm wondering about the reasoning.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Good point on the bushing. I could bring it down a few inches.

The valve is required by code. Read @EBEBRATT-Ed above.Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)1 -

Ok cool. You should also be able to ditch that coupling under the valve. The pigtail should be able to go straight into the valve

edit: ok I see it. My low pressure gauges are rated to 15psi, maybe yours is too

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

increasing high fire would be to get you more quickly to low fire setting if you experience a long wait to drop back. from a cold start and with something that size 5 even 10 minutes before downstaging wouldn't be excessive, and less if the boiler is already warm as would be the case between successive cycles during relatively cold outdoor temps.eappleton said:I hadn't thought about increasing high fire. I think you mean using a larger nozzle so the high fire gets the steam happening quicker, then dropping into low fire at as low a pressure as possible. Am I reading that correctly? Increasing high fire is with a nozzle and decreasing low fire is adjusting the pressuretrol?

It sounds like you have a 'heat timer' or "heat timer" that is designed to measure cycle length and regulate it compared to outdoor temp so you don't overrun in shoulder season. While this doesn't affect your high and lower fire directly, the length of cycles and downtime with the background load factor does affect your time in low fire.

So you are engaged in the right kind of inquiry which is to get typical cycle pattern, time at high fire, time at low fire and you could record outdoor temperature and/or indoor temperature depending if the response is to a single thermostat or . . .

As to the adjustment of high and low fire, there are different strategies. One problem with my theoretical proposition is if you up the nozzle size for high then you automatically up the firing rate for low because it is a relatively fixed percentage of the high fire rate. On the other hand there are systems that allow independent adjustment (on oil often obtained by lower pump pressure). I'm more familiar with gas applications where some of the dualstage valves have a fixed differential between low and high fire and some allow you to independently adjust the delivery pressure of the gas to vary the spacing between stages. Of course atmospheric gas is pretty good at handling a range of gas input and the venturi situation for entraining air responds reasonably well without adjustment. Oil (and gas) power burners require some kind of automated shutter on the air input to effect this and the range of adjustment will control the range of turndown you can obtain if really any.

What burner do you have? Thinking long term, do you have natural gas supply if you want to compare the possibility of finesse in control. There are some modulating or staged gas power burners that are pretty good and NG by the therm is about 2/3 the price of fuel oil in Rhode Island at the moment and I think probably that is reasonably similar to your market and while nobody has a crystal ball, if the anti-NG folks are not too empowered by the incoming administration this difference is likely to be maintained for some time (of course they are anti fuel oil too, but their current ire is focused on NG cause its cheaper and a comer for that reason, forgetting that similar to its cost advantage, it emits 2/3 the carbon as fuel oil and generally is easier to modulate; so don't ask me what their rationale is, or do and i'll tell you they aren't rational).0 -

Funny story. I asked a technician to install the new 5lb pressure gauge as a second gauge in addition to the 30lb gauge. He still seemed to think that it was against code, and didn't know why I would want it. I convinced him to do it and when upstairs. When I came back, he was finished and said that the gauge worked okay, but wasn't as accurate as the 30lb gauge, the low pressure gauge showed almost 4lbs of pressure and the 30lb gauge showed about 3lbs. Huh? 4lbs!?

I was scratching my head as he left. Was the pressuretrol so far off that I thought lowfire was happening at .5lbs but was really at 3lbs??? I turned on the boiler and watched the pressure climb on the low-pressure gauge to 2lbs and higher on high fire. ****? Then our super mentioned that the technician had made some adjustments, thought I knew... He had cranked up the pressure. Good lord.

It's back at about .5 switching to low-fire now, but more testing to come.Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

if some pressure is good more is better, except when its not. now you can map cycles a bit. i wonder what lead the tech to think the 30 lbs. gauge was more accurate. maybe he had set the control to what he considered to be 3 lbs., ergo if the gauge said 3 lbs it was more accurate than the gauge that said 4 lbs albeit that is under the assumption that the control is accurate . . .

It isn't inconceivable that a really high quality gauge with a broader range could give a low quality gauge with a smaller range a run for its money, although as between generally available gauges its generally a given that a gauge with a smaller range is going to be more accurate within that operating range.

those magnahelics like @ethicalpaul depicted are good in the low ranges.

anyway, you are well setup to clock your cycles now. how long to drop high fire (cold start and warm start) and what pressure do you get up to on continuous low fire. does the low stage eventually cut out? (is there a thermostat somewhere or are there thermostatic valves on the radiator and you keep pressure available based on outdoor temp?)

brian0 -

Never leave someone alone with your boiler!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements