A DIY Vaporstat Alternative

Many people here have expressed dissatisfaction with the modern Honeywell Vaporstat. This thread describes the "Dwyer-Stat", a do-it-yourself alternative to the Vaporstat for low pressure applications. It is fairly inexpensive, relatively easy to build and calibrate, and is accurate and repeatable throughout its entire pressure range.

The Dwyer-Stat uses two Dwyer Instruments differential low pressure switches, and a DPDT relay. The DP switches can be calibrated with a low pressure gauge, and repeatability of the switch is excellent. If you can find what you need on eBay, the whole thing can set you back less than $100.

The Dwyer model 1823-20 DP switch is commonly available on eBay for $30 or less, and has an operating range of 3 - 22 inches WC (1.7 to 12.7 ounces per square inch). Other ranges are available. Dwyer also makes a 1900-series switch which is somewhat smaller and has a lower list price, but those are less common on eBay than the 1823 series. Here are model lists and ranges for the 1820 and 1900 series switches from the Dwyer website:

Dwyer Series 1800 DP Switches

Dwyer Series 1900 DP switches

A word of caution: The Dwyer-Stat uses an electromechanical relay, and is suited for use only as an operating limit control. It should not replace any primary safety control on the boiler.

Midco LNB-250 Modulating Gas Burner | EcoSteam ES-50 modulating controls | 70 to 300 MBH |

3009 sf | 3 floors | 14 radiators | Utica SFE boiler | 4 mains, 135 ft | Gorton & B&J Big Mouth vents

Comments

-

How It Works

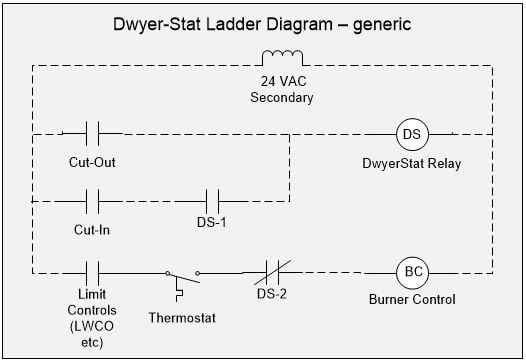

Referencing the wiring diagram posted below, here's how the Dwyer-Stat works:

The cut-out switch is calibrated to a higher pressure than the cut-in switch, with the difference being equivalent to the differential on a Vaporstat.

The thermostat activates the burner through relay terminals 1 and 4. When the cut-out switch trips on high pressure, the relay coil (7 to 2) energizes and the relay contacts move to 8-6 and 1-3. The latter will deactivate the burner. The former "seals-in" the relay, keeping the coil powered through 8-6 and the cut-in switch, which will already be tripped since it's setpoint is lower than the cut-out switch. When the pressure drops enough, the cut-in switch opens, which breaks the circuit through the relay coil. The relay de-energizes, closing the 1-4 relay contacts, and the burner re-fires.

The Dwyer-Stat is a passive control; it uses absolutely no power until the cut-out switch closes on high pressure.

With a bit of rewiring, this could be configured to operate a high-low fire burner.

1890 near-vapor one pipe steam system | Operating pressure: 0.25 oz | 607 sf EDR

Midco LNB-250 Modulating Gas Burner | EcoSteam ES-50 modulating controls | 70 to 300 MBH |

3009 sf | 3 floors | 14 radiators | Utica SFE boiler | 4 mains, 135 ft | Gorton & B&J Big Mouth vents1 -

Building the Basic Version

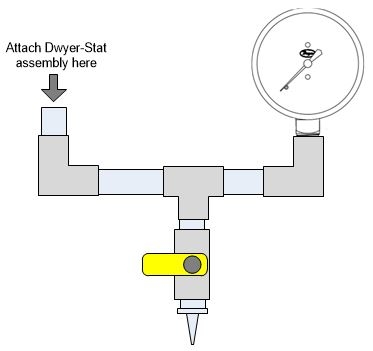

This is a suggested physical arrangement for the basic version of a Dwyer-Stat. This version will need to be calibrated on the bench before installing it on the boiler.

Connect the Dwyer switch to the manifold using the high pressure port. On the 1823 model switches, this is the port on the front side of the diaphragm as shown below.

Parts List

(2) Dwyer Instruments 8320-20 Low Differential Pressure Switches

(1) DPDT 24 VAC relay

(1) Relay socket

(1) electrical box to house the relay and socket

(2) 1/8" close nipples

(2) 1/8" female to 1/4" male adapters

(2) 1/4" 90 degree elbows

(2) 1/4" x 2" nipples

(1) 1/4" tee

(1) 1/4" close nipple

(1) 1/4" union

1890 near-vapor one pipe steam system | Operating pressure: 0.25 oz | 607 sf EDR

Midco LNB-250 Modulating Gas Burner | EcoSteam ES-50 modulating controls | 70 to 300 MBH |

3009 sf | 3 floors | 14 radiators | Utica SFE boiler | 4 mains, 135 ft | Gorton & B&J Big Mouth vents2 -

Building the Deluxe Version

The deluxe version has several advantages over the basic model. It features a low pressure gauge, valves, and a calibration port that allows the unit to be isolated from the boiler and calibrated in place.

Parts List

(2) Dwyer Instruments 8320-20 Low Differential Pressure Switches

(1) DPDT 24 VAC relay

(1) Relay socket

(1) electrical box to house the relay and socket

(1) 0 - 20 oz/sq.in. low pressure gauge (Wika 611.10 or equivalent)

(2) 1/8" close nipples

(2) 1/8" female to 1/4" male adapters

(1) 1/4" 90 degree elbows

(1) 1/4" tee

(2) 1/4" x 3" nipples

(1) 1/4" cross

(3) 1/4" close nipples

(2) 1/4" ball valves

(1) 1/4" union

(1) 1/4" NPT x 3/16" hose barb fitting

1890 near-vapor one pipe steam system | Operating pressure: 0.25 oz | 607 sf EDR

Midco LNB-250 Modulating Gas Burner | EcoSteam ES-50 modulating controls | 70 to 300 MBH |

3009 sf | 3 floors | 14 radiators | Utica SFE boiler | 4 mains, 135 ft | Gorton & B&J Big Mouth vents1 -

Wiring

Here is a wiring schematic and ladder diagram for most applications, with the exception of internally powered burner controls like the Genisys 7505 (see next post).

1890 near-vapor one pipe steam system | Operating pressure: 0.25 oz | 607 sf EDR

Midco LNB-250 Modulating Gas Burner | EcoSteam ES-50 modulating controls | 70 to 300 MBH |

3009 sf | 3 floors | 14 radiators | Utica SFE boiler | 4 mains, 135 ft | Gorton & B&J Big Mouth vents1 -

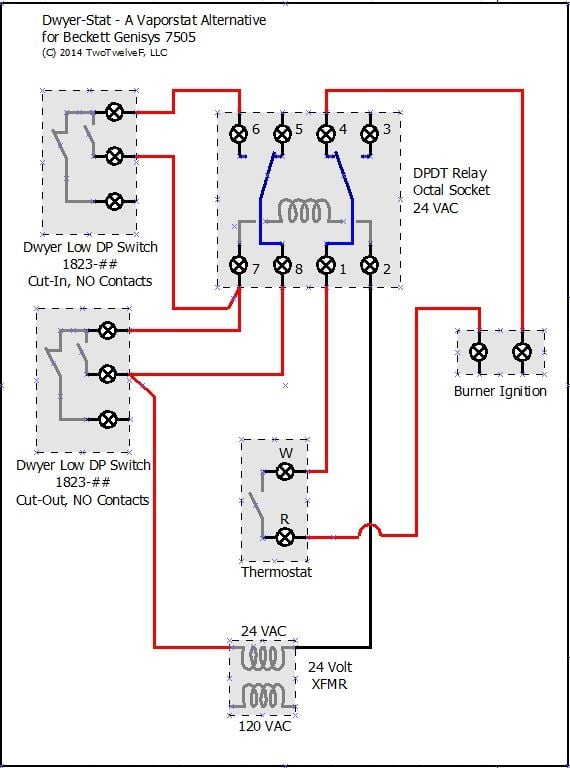

Wiring for Internally Powered Burner Controls

Some burner controls, like the Genisys 7505, only provide 24 VAC hot to the control circuit, and don’t have a user-accessible 24 VAC common wiring terminal.

Here's a wiring schematic and ladder diagram that should work with the 7505 and other internally powered ignition controls without an accessible 24V common. The thermostat and ignition controls are now isolated from the pressure controls, so an external 24 V transformer or other power source will be required to power the Dwyer-Stat relay.

1890 near-vapor one pipe steam system | Operating pressure: 0.25 oz | 607 sf EDR

Midco LNB-250 Modulating Gas Burner | EcoSteam ES-50 modulating controls | 70 to 300 MBH |

3009 sf | 3 floors | 14 radiators | Utica SFE boiler | 4 mains, 135 ft | Gorton & B&J Big Mouth vents1 -

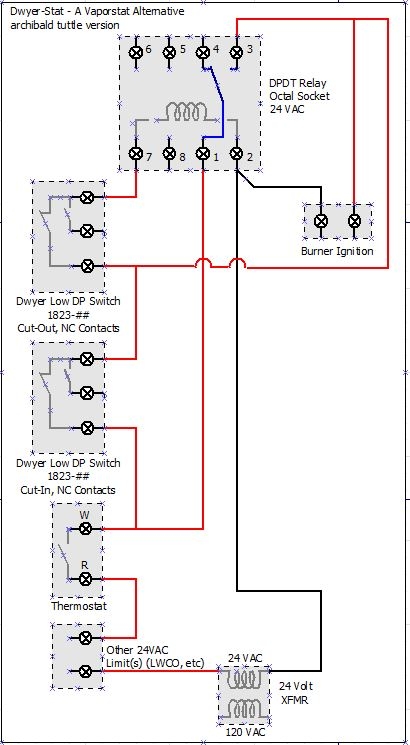

archibald tuttle's wiring version

@archibald tuttle proposed an alternative wiring scheme in last year's thread that uses a SPST relay in place of the DPDT. His scheme uses an active vs passive control philosophy, in that the relay is energized whenever the burner is running. The DP switches are wired to their normally closed contacts, so that the high pressure switch de-energizes the relay when it trips.

1890 near-vapor one pipe steam system | Operating pressure: 0.25 oz | 607 sf EDR

Midco LNB-250 Modulating Gas Burner | EcoSteam ES-50 modulating controls | 70 to 300 MBH |

3009 sf | 3 floors | 14 radiators | Utica SFE boiler | 4 mains, 135 ft | Gorton & B&J Big Mouth vents1 -

Calibration

The deluxe Dwyer-Stat can be calibrated in place on the boiler.

To calibrate the basic Dwyer-Stat, you will need to assemble a calibration jig made up of a pressure gauge, a ball valve, a hose barb fitting and assorted other nipples and fittings.

The calibration screw on the Dwyer 1823 DP switch is located under a rubber cap on the back of the switch.

Calibration steps:- If you are calibrating a basic Dwyer-Stat:

- Disconnect any control wires from the Dwyer switches

- Mount the Dwyer-Stat assembly to the calibration jig

- Disconnect any control wires from the Dwyer switches

- If you are calibrating a deluxe Dwyer-Stat:

- Remove power from the boiler

- Disconnect the control wires from the Dwyer switches

- Close the ball valve at the center of the Dwyer-Stat assembly to isolate the assembly from the boiler.

- Remove power from the boiler

- Open the ball valve next to the hose barb fitting.

- Attach a length of flexible hose to the hose barb fitting.

- Attach an ohmmeter to the common and NO contacts on one of the DP switches.

- Blow into the hose until the pressure gauge reads at or above the pressure at which you want the switch to trip.

- Close the ball valve.

- If necessary, gradually open the ball valve to bleed off pressure until the gauge reads the desired pressure.

- Remove the rubber cap from the calibration screw on the back of the switch you are going to calibrate.

- If the ohmmeter reads a closed circuit, turn the calibration screw counterclockwise until the circuit opens.

- Gradually turn the screw clockwise until the ohmmeter reads a closed circuit.

- Replace the rubber cap.

- Open the ball valve and repeat steps 5 thru 12 for the other switch.

- If you are calibrating a basic Dwyer-Stat:

- Open the ball valve

- Remove the Dwyer-Stat assembly from the calibration jig

- Mount the Dwyer-Stat assembly on the boiler and connect the control wires

- Open the ball valve

- If you are calibrating a deluxe Dwyer-Stat:

- Close the ball valve at the hose barb fitting

- Open the ball valve leading to the pigtail

- Reconnect the control wires to the Dwyer switches

- Restore power to the boiler

- Close the ball valve at the hose barb fitting

1890 near-vapor one pipe steam system | Operating pressure: 0.25 oz | 607 sf EDR

Midco LNB-250 Modulating Gas Burner | EcoSteam ES-50 modulating controls | 70 to 300 MBH |

3009 sf | 3 floors | 14 radiators | Utica SFE boiler | 4 mains, 135 ft | Gorton & B&J Big Mouth vents1 - If you are calibrating a basic Dwyer-Stat:

-

I think I mentioned this the last time this topic came up. How about controlling boiler temperature instead of pressure?0

-

Most EXCELLENT !! Thank you MarkS! i will definitely give that a try. I had three honeywell vaporstats come in today and two were bad right out of the box. Thank you for this.gwgillplumbingandheating.com

Serving Cleveland's eastern suburbs from Cleveland Heights down to Cuyahoga Falls.0 -

I'm still intrigued by the idea of using a Photohelic or Mini-Photohelic as a combination front-facing UI and sensor package. Add a DPDT relay and you're there...1

-

I own two of the Dwyer 1823 switches and so far love them.

No, they don't have a cool looking pressure scale that is wrong anyway like other devices, but they seem incredibly reliable. I'm using an 1823-2 on my system with the Ecosteam.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

@MarkS thanks for this. I've downloaded and saved this entire thread in case it goes missing again.0

-

Funny you should mention a Dwyer Photohelic. I have one set up as the operating control on a one-pipe steam system. I will try to get some photos, but it is a model A3040 which ranges from 0 to 40 inches of water.

I have the adjustable setpoints set at 14 inches cut-out; 4 inches cut-in. All the wiring is done on the back of the unit: there is no need for any other DPDT switches.

Input pressure is fed by a piece of 1/8" clear plastic tube after a typical pigtail. Works great.

Dennis

Dennis2 -

Nicely done, Dennis. The only limiting factor is price; those are half again as much as a Vaporstat. I bet that works great though.1890 near-vapor one pipe steam system | Operating pressure: 0.25 oz | 607 sf EDR

Midco LNB-250 Modulating Gas Burner | EcoSteam ES-50 modulating controls | 70 to 300 MBH |

3009 sf | 3 floors | 14 radiators | Utica SFE boiler | 4 mains, 135 ft | Gorton & B&J Big Mouth vents0 -

@dennis53

Awesome! The only chance I'd make is I'd go cammando and get rid of that pigtail siphon. Replace it with a straight length of pipe that drains well. I'm using an 18" 1/2" piece on my setup and as long as the switch/gauge at the end never leaks steam will never get to them.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Add up the price of a Vaporstat and a quality 4" low pressure gauge and the price of a new Photohelic starts to look workable. The new(ish) 3000MR series has integral relays and is only 2-1/2" deep. With all the dosh that goes into a proper drop header, the cost plus the cool factor seems like a no-brainer to me.

I picked some up at an auction a few months back and found boards built with early 1970's transistors. It took some prying but I managed to get some detailed specs out of Dwyer. I was hoping to find a way to directly connect the photodiodes to a DDC controller -- only one of mine came with the relay box, the others are just replacement heads.0 -

Thanks OP for putting this up , really nice alternative to what's on the market for this currently. I just feel that " Big H " has really turned it's back on the common man for many years now , like a grudge about the mercury or something.hvacfreak

Mechanical Enthusiast

Burnham MST 396 , 60 oz gauge , Tigerloop , Firomatic Check Valve , Mcdonnell Miller 67 lwco , Danfoss RA2k TRV'sEasyio FG20 Controller

0 -

Yes, the list prices on new Photohelics are high, but they come up on ebay fairly often as NOS. There are many models to choose from, too. 8 different models from 25 to 150 inches of water. 5 different models from 1 to 5 psi. 5 different models from 100 to 300 cm of water.

Of course, you still need a pressuretrol for safety's sake.

Dennis

Dennis0 -

-

@MarkS Care to take a crack at showing how to use this approach for a two stage valve? Hi to 3 oz. , then low at 3oz up to 8 oz, back to hi at 3 oz. all coupled with vaporstat to protect at about 9 oz.

or high to 5"wc, then low from 5" to 13", then high again if falling to 5". all at 24vac. I am having trouble figuring the switch-over. I am still envisioning 3 pressure switches.0 -

I like the concept and DIY nature of it, but do realize that steam is not a listed controlled medium as far as Dwyer is concerned.0

-

-

@furnacefigher15 Thanks for the input! I saw max temp for the Dwyer phoenolic was 125 deg f, maybe the Dwyer 1823 was 180deg f, but using a pigtail and priming it the current gauge and vaportrol never see steam or anything above room temp. Thanks for the input! I look at the T775U.0

-

@furnacefigher15 Looked like we might have a little trouble getting a sensor that could handle more than 10" wc pressure0

-

-

If I were to replace the boiler with one nearly half the EDR (400 rather than 750) would this be a less relevant concern? I have 399 sq ft EDR radiator surface. I am thinking of either a slant fin TR 30 or a TR 40 with a gas power burner. if the smaller size makes this a moot point I may just go with the normal setup. Any thoughts..I think the intrepid steam can use a Midco two stage radial burner, but if I am closer to the correct size boiler maybe this would be completely unnecessary???0

-

Very cool work. Very disappointed with new style vaporstats as well. Mad Dog0

-

Thanks Fred!0

-

Finally you admitted it.Fred said:@Koan , Right sizing the boiler will resolve pressure issues, no doubt and anything other than a pressuretrol on a right sized, one pipe system or a vaporstat on a two pipe vapor system just isn't necessary.

Let's hear it @Fred

"DOWN WITH 33%!!!!"

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

@ChrisJ , when I say "Right size", I am suggesting connected EDR plus up to 33% Piping and Pick-up. Anyone who feels they can and do get by with less piping and pick-up, I leave that "right sizing decision up to them and have no problem with how they choose to size their boiler. It is their money, after all. As I've told you before, I don't believe "One size fits all" and just because you can get by with less piping and pick-up doesn't mean the next house can too or on the flip side, that all houses need 33%, but that seems to work well as a current industry standard for steam boilers. Those of us who inherited over-sized boilers can make them work very nicely but I don't promote over-sizing just because my boiler works very, very well. Anyway, this has become an old, boring discussion that we just need to give it a rest until we have something new and meaningful to add.1

-

mark, didn't realize this had been recreated. thank you so much for your hard work. i have a question for any who are operating one or generally paying steam attention.

I set up my dwyerstat and tested but i never instituted it in permanent operation because the boiler full out is only making 19" anyway and what i really wanted it for was two stage control so i could drop back to low fire once i hit 8" or 10" and just stay there.

so my stat stack up to the tee is 1" black pipe to about 3' above the boiler. then i tee as depicted and have a valved port for a digital vapor reader to check against the dwyers.

i never put in any kind of trap and ran the tests for an hour or two and as long as i didn't accidentally open the access valve and let steam up the stack it basically seemed to stay at bay. the riser pipe eventually got warm by conduction but the ends of the dwyerstat tees didn't get hot. but now that i've got the condensate deal on this boiler straightened out, i'm ready to throw in the two stage valve next month and give it a try. what is the over under if i don't use traps. has anybody used the dwyers with traps. i would think in theory you get accuracy but then there is practice . . .

i could put a 90 trap (e.g. like in picture) on the horizontal tee legs to lead into the dwyers. just wondering what experience anyone has had running with or without steam trap.

thanks,

brian

0 -

-

@Koan just going back through one of the most productive steam control threads here and realized your question was never answered. sorry, this is probably late for the question by the seven year itch, but it is an interesting wrinkle.

the reason I started ruminating on these controls to begin with was to control two stage valve on an atmospheric. My suspicion is that the low stage is virtually a constant fire on call, so you just wire the dwyer stat to the high stage. and use the heating demand call to constant fire the low stage and if the low stage overruns desired pressure you can dial it back within limits (although not all two stage valves have adjustable delivery pressures, many do).

This could also be a case where you have zone valves and you are looking for lower operation with less demand. Generally you wouldn't need to tell the controls how many zones were calling because this would be signaled by pressure to an extent and your low stage still wants to be toward the low end of demand and if it lags call the high so it would operate more or less the same way as a single zone system that used high fire to make steam and fill system relatively quickly and then dropped back for operation. OBviously on a really complicated system with many zones and demand levels, a modulating power burner controlled by a dwyer digihelic would be the nuts.

One thing I've found is that the boilers are pretty much designed to run well at standard target input so i always see a drop off in efficiency at the lower stage, but for extended cycles still seems like a good plan because downfire 40% input and loose say 7% efficiency and you are still winning. In all but the tightest systems I like that vs. short cycling you could see if tightly controlling pressure in low range on single stage (all dependent on 'right sizing'.

0 -

Does anyone know enough about the applicable boiler code to know if DIY modifications are acceptable? While the ideas in this discussion might be DIY creative, the code is there for a reason.

That being said, I do know the 30psig gauge is impractical on a daily basis, but has a code basis. But that's fodder for a different discussion, like we have each heating season.

0 -

It shouldn't. There should be a manual-reset pressure control on every boiler so the worst that this can do is keep the boiler off when it's supposed to be on. That is predicated on it being correctly wired, but everything else is dependent on correct installation too, so I don't see that as a deal breaker.

The local AHJ has the final call, of course.

0 -

I do not believe code cares if there's additional (optional) lower pressure controls as long as the required ones are in place.SteamingatMohawk said:Does anyone know enough about the applicable boiler code to know if DIY modifications are acceptable? While the ideas in this discussion might be DIY creative, the code is there for a reason.

That being said, I do know the 30psig gauge is impractical on a daily basis, but has a code basis. But that's fodder for a different discussion, like we have each heating season.

For example, my boiler has the required pigtail, Pressuretrol and 30 PSIG gauge installed on it as per the manufacturers requirements. I even keep them clean and operational.

But in addition to that, I have my own controls that shut the boiler down for 10 minutes if it hits 4 ounces.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

2 -

Categories

- All Categories

- 87.4K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 121 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 168 Indoor-Air Quality

- 3.8K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.8K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements