Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Water bath for gas valve bleed?

Options

woobagooba

Member Posts: 186

in Gas Heating

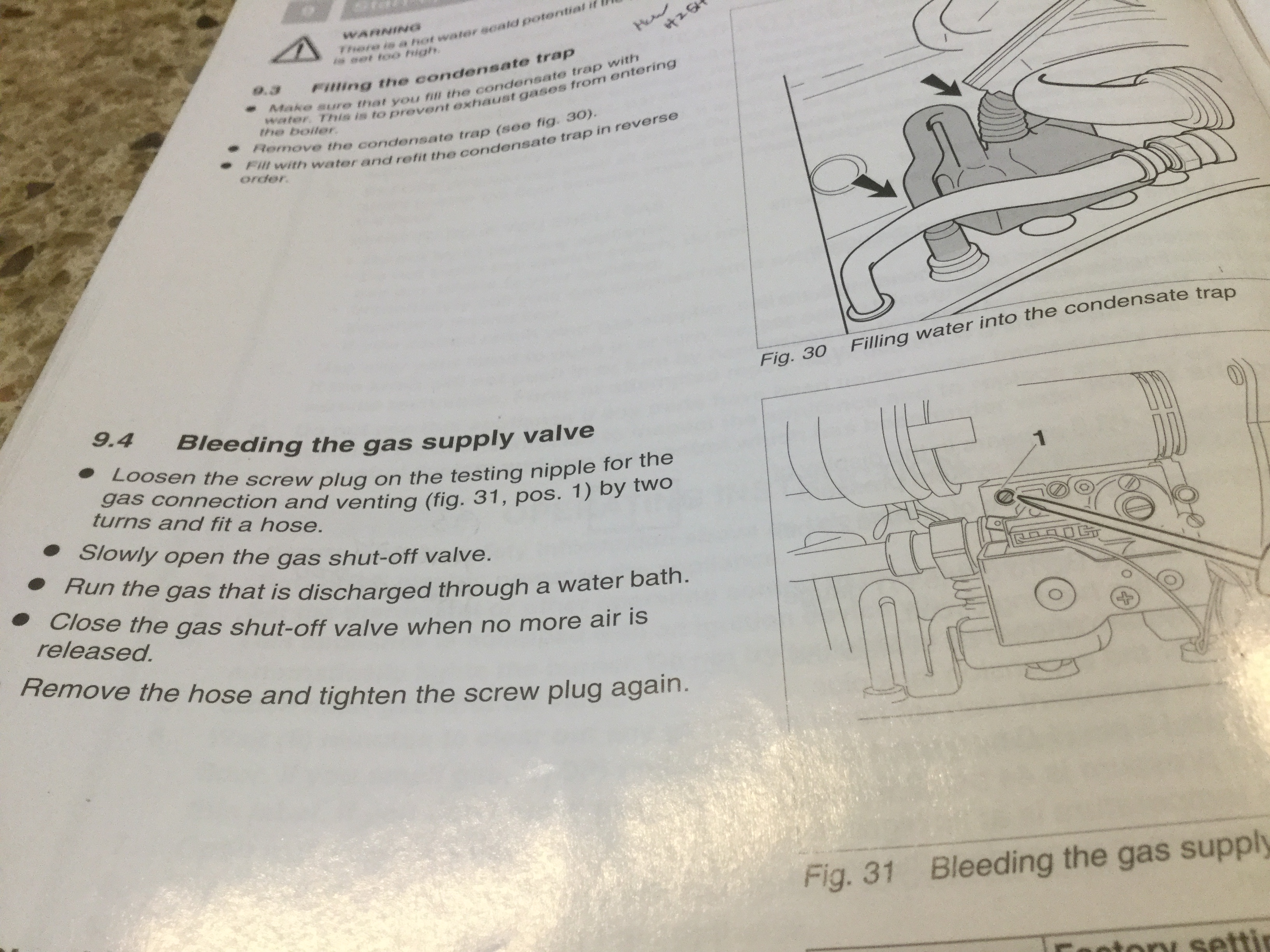

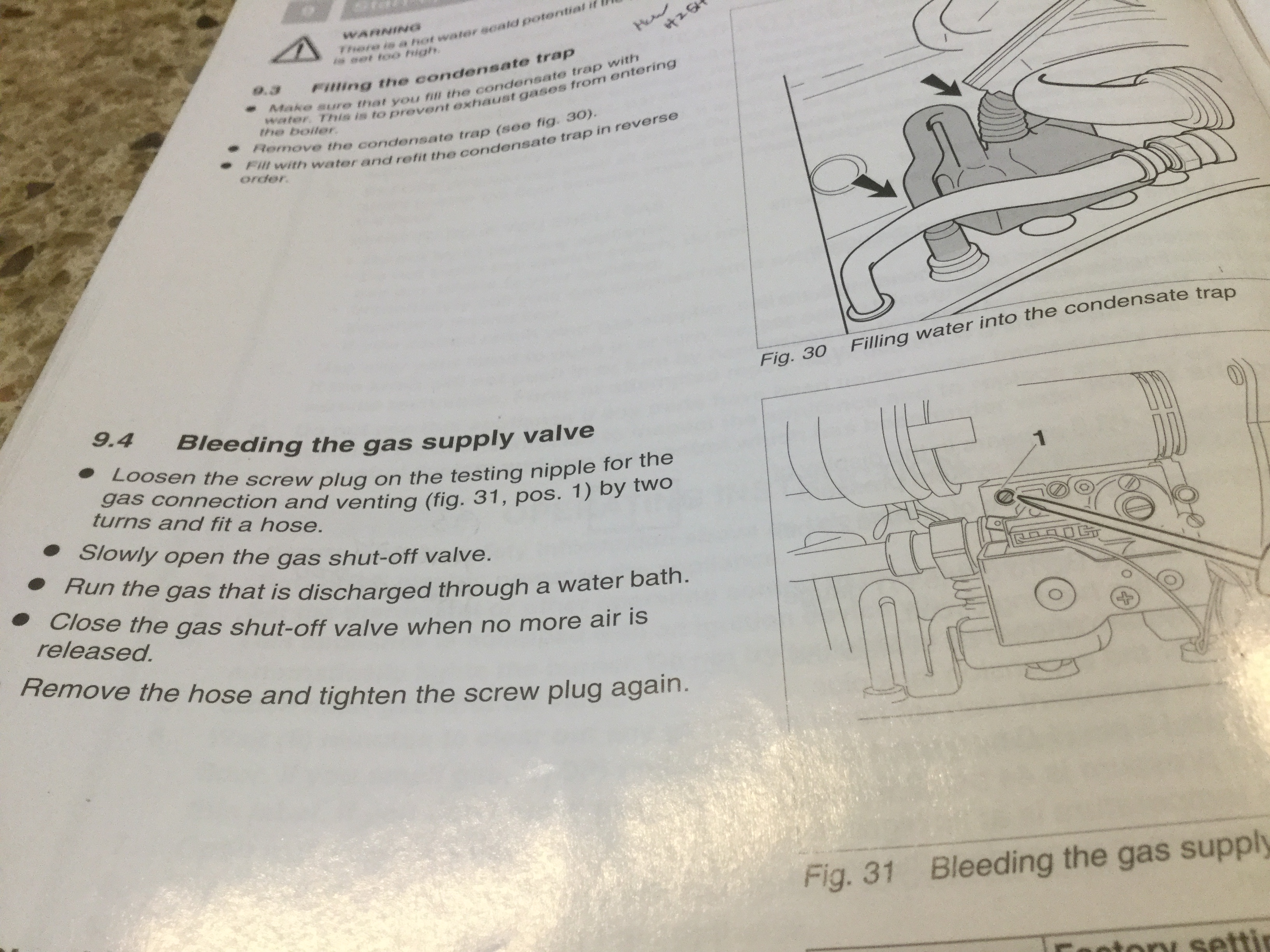

Getting ready to put my GB142 through its startup procedure. Steps to bleed gas valve are calling for a water bath. Can someone please explain? Excerpt attached. Thank you.

0

Comments

-

Yeah I'm not doing that...

That would be the safest way.There was an error rendering this rich post.

0 -

Weird.8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

-

But...doesn't the gas bubble right through the water? A hydrocarbon should pass right through water, shouldn't it? Maybe it would take the odor our of the gas? Is that desirable?0

-

I'm glad you said this because I didn't get it.STEVEusaPA said:Yeah I'm not doing that...

That would be the safest way.

All I could think about was this incident that happened down the road...

http://www.safetynewsalert.com/court-orders-conagra-to-pay-109m-settlement-in-fatal-slim-jim-plant-explosion/

...Maybe the scale is different but the problem looks the same.

What is a safe way to purge a gas line?0 -

I'm sure @Tim McElwain would have the expert answer. I thought the same thing @ratio posted.

But I never had to purge a large or industrial/commercial gas line.

Maybe it keeps it from filling the room and finding an ignition source by being located outside or being completely contained?

Who's bringing this rig to every job?

There was an error rendering this rich post.

0 -

-

How do you recommend I bleed this gas valve? Open the bleed, open the shutoff, smell for gas, then close the bleed?0

-

Hmmm, This might be a good application for that garden hose

Yours, Larry0 -

How much gas piping changed? Just the flex whip into the unit? If you didn't change a lot of piping, you'd probably be fine just turning it on & letting it try to start a few times.0

-

I understand everything in that sketch but the purge bucket and manometer port.0

-

the only safe way to purge inside is to use a quality combustion gas indicator that displays %LEL and you stop when you reach the flammable range of the gas your using.

maybe ( and now i'm guessing) a water bath works on the principal of different specific gravity between gas and air pushing through a beaker of water where one can see the depth or rate of rise through the water?? IDK0 -

None of the gas piping has changed. Just removed/replaced the internal gas connection to clean HX. I’ll try to start it a few times. BUT ... Unit is throwing a 3L error code, fan is getting power ... time for a new blower fan ... groan. That will put my parts total for this 11 year old boiler north of $500. Plan was to nurse this through a winter reno, might instead be replacing it now.ratio said:How much gas piping changed? Just the flex whip into the unit? If you didn't change a lot of piping, you'd probably be fine just turning it on & letting it try to start a few times.

0 -

I found the I&O manual for a power burner on a boiler I service.

Concerning bleeding air out of the gas line I quote:

"Make sure that all of the air is bled out of the gas line.

This can be done by disconnecting the pilot line immediately ahead of the pilot regulator and opening the manual pilot cock. Burn the escaping gas. When the flame indicates that a reasonably pure gas is present, shut off the pilot cock and reconnect the line. Open air shutter half way- if flap type etc. etc."

This burner was installed maybe in 1996, I got this I&O from the factory in maybe 2012.

This is for pros only. One must be aware of what you are doing.

You must check all connections for leaks with bubbles first, the air would show up just like the gas that is pushing on it.

You must keep the match/grill lighter flame on until the pilot tube gas starts to burn and stays on. BTW the same instructions applied to their 3,000,000 BTUH burners. Mine is a little 800,000.

Sounds scary doesn't it, to have an open flame burning in the room........I do it every day on my kitchen gas cook top.

Another thing to "don't try this at home" do is:

I have watched the gas company employees do a light off on furnaces.

There may be 100' of piping that was full of air. They crack the union at the furnace gas valve and turn on the gas cock.

Then listen to the air escaping, the sound changes when the gas shows up. It takes a good experienced ear. You shut off the gas cock, tighten the union and light the furnace.

These were 20+ years veterans of the business.

This is all natural gas....lighter than air....will go up in the room.

LPG-propane is a different animal...heavier than air..... will fill your shoes with gas before igniting.

0 -

-

First of all if you are starting up a new system and you have a gas cooking stove in the house then turn on one of the top burners and hold a match near the burner. When doing this if you listen closely you will hear a change in pitch when the gas starts to pass through the burner. It should light with the match, then go ahead and bring on the rest of the burners to bleed out the remaining air. Then bring the oven on and make sure it lights safely. If it is an older range there may be a pilot in the oven. You will have to lite that pilot with a match. If it has a hot surface Igniter it will eventually safely light off the igniter.

For a water heater and house heater follow the 5 minute rule which states that if you attempted to light the pilot and it did not light wait 5 minutes then attempt lighting again. The 5 minute rule is for both natural gas and LP waiting 5 minutes means you will in both cases with natural and LP you will be below the lower explosive limit. LEL for natural gas is 4% gas and for LP 2.1%. If after about 10 minutes it will not light then you may have to bleed the main gas line. At that point I will go to the end of the gas line and look for a tee, hook up a hose to the tee and run it outdoors open the gas cock up stream a very small amount just enough to let a little escape. If you have a combustible gas detector then test what is coming out of the hose for percent gas either LP or natural. You could also loosen the pilot tubing nut at the control slightly and hold a match near the tubing nut until it lights then make the nut back up and check with soap and water for bubbles there should not be any.

Much the same thing can be done on the gas valve for the house heater.

For systems over 400,000 BTU's it usually should be a two man job, one person inside controlling the gas shut off on the area closest to the end of the gas line. The other outside also with a shut off opening and closing it until the gas lights. Do not trust odor as sometimes you can get odorant fade especially with all new pipes.

Be careful with LP as it tends to linger and disperse very slowly and keep in mind it is also heavier than air so it will accumulate on the floor.

Hope this helps.2

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements