Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Radiant help-flow problems?

Options

er1k

Member Posts: 9

Hello everyone,

I am having a problem that I hope you can help me out with. I have an open direct system that I think is not getting enough flow with the pumps. The people that I bought it from seem to think that flow is fine, though. The problem is that I left it on for 24 hours on 67 degrees. When I went to the house today one zone on the thermostat was reading 60 and the other 63. The temp outside is 25 degrees Fahrenheit. So I think that when they are both on it does not flow fast enough. It almost seems like there is air in the line or it has some flow restrictions. When I stated it up the well did have a lot of black mud or something in it which I have since fixed. I've taken the pumps off to see if there was anything in them but with no avail. I will post everything that I can to see if I have something wrong. Can you guys look at my design to see if it's right? Are my pumps sized enough? Or anything else? Here's some more info:

I had a company design the system for me...so here are their numbers:

Zone 1, 750 sq ft, 130-150 fluid temp, flow rate 3gpm, medium pump selector, energy factor .05, temp difference 65, 24375 btu heat required

Zone 2 862sqft, 130-150 fluid temp, flow rate 3.75 gpm, medium pump selector, energy factor .05, temp difference 65, 28015 btu heat required

My actual flow is (on the highest setting)zone 1-1.8 gpm, zone 2-1.8gpm, together at the same time 2.2gpm

My delta t is 140 out and 107 in...it is 25 deg Fahrenheit outside.

My pumps are grundfos ups15-35sfc 0-12ft head range, 3 settings

I have two zones, 1/2 pex with my manifolds 23 feet away from the pumps with 3/4 pex-a

My loops are zone 1-250ft, 260,255, 267, and 290. Zone 2 is 260, 275, 260, and 275.

So my actual flow is 2.2 gpm through both zones. Is that enough?

Also, one of the pumps is making a funny noise. I have a video but can't seem to upload it.

Thanks, Erik.

I am having a problem that I hope you can help me out with. I have an open direct system that I think is not getting enough flow with the pumps. The people that I bought it from seem to think that flow is fine, though. The problem is that I left it on for 24 hours on 67 degrees. When I went to the house today one zone on the thermostat was reading 60 and the other 63. The temp outside is 25 degrees Fahrenheit. So I think that when they are both on it does not flow fast enough. It almost seems like there is air in the line or it has some flow restrictions. When I stated it up the well did have a lot of black mud or something in it which I have since fixed. I've taken the pumps off to see if there was anything in them but with no avail. I will post everything that I can to see if I have something wrong. Can you guys look at my design to see if it's right? Are my pumps sized enough? Or anything else? Here's some more info:

I had a company design the system for me...so here are their numbers:

Zone 1, 750 sq ft, 130-150 fluid temp, flow rate 3gpm, medium pump selector, energy factor .05, temp difference 65, 24375 btu heat required

Zone 2 862sqft, 130-150 fluid temp, flow rate 3.75 gpm, medium pump selector, energy factor .05, temp difference 65, 28015 btu heat required

My actual flow is (on the highest setting)zone 1-1.8 gpm, zone 2-1.8gpm, together at the same time 2.2gpm

My delta t is 140 out and 107 in...it is 25 deg Fahrenheit outside.

My pumps are grundfos ups15-35sfc 0-12ft head range, 3 settings

I have two zones, 1/2 pex with my manifolds 23 feet away from the pumps with 3/4 pex-a

My loops are zone 1-250ft, 260,255, 267, and 290. Zone 2 is 260, 275, 260, and 275.

So my actual flow is 2.2 gpm through both zones. Is that enough?

Also, one of the pumps is making a funny noise. I have a video but can't seem to upload it.

Thanks, Erik.

0

Comments

-

1:Abandon the open system before you kill yourself or someone else with Legionnaire's disease is my first thought.

Second, 2.2 GPM at a 33 degree delta is 36,300 BTU so no, it's not enough if the heat design you listed is accurate.

Third, you'll need primary/secondary piping to overcome the high head of the tankless (what model is this?)

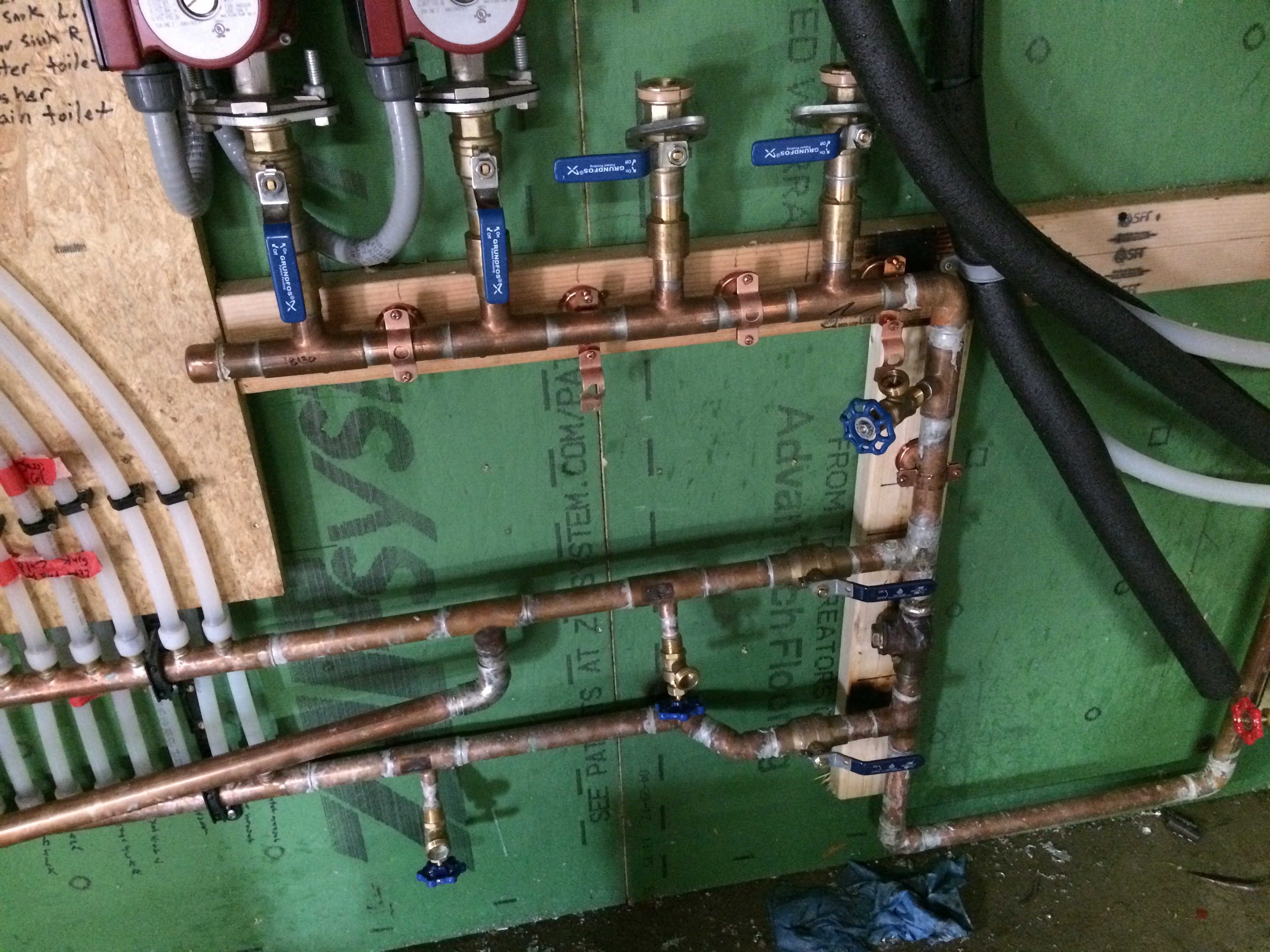

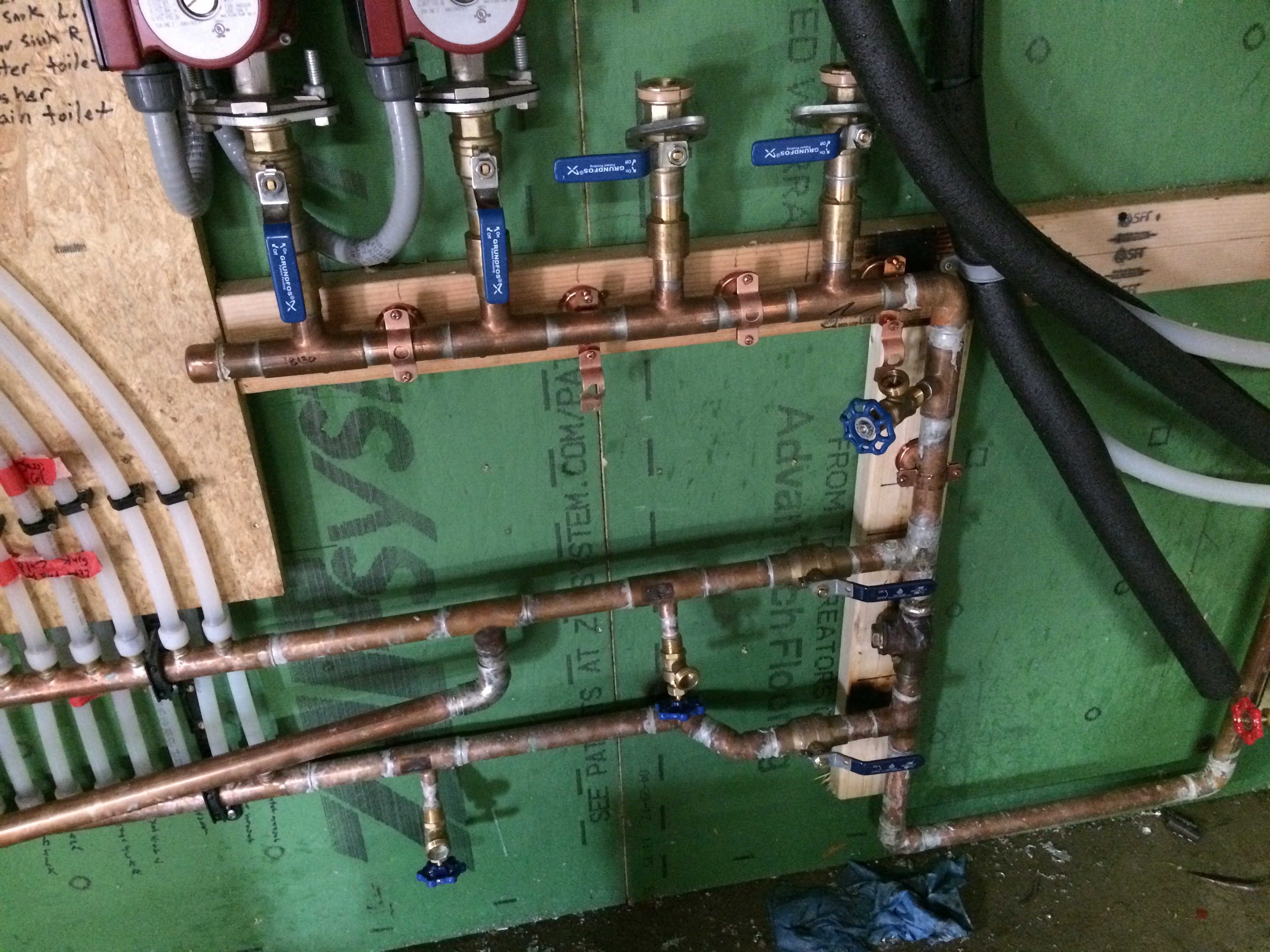

4: It looks like your incoming cold water is tied into the hot supply header, judging by the filter.

1 -

-

Can you post the design drawing.

What you have there is (more than) a bit of a mess. I don't think you are going to fix it without a re pipe. As long as you are repiping, adding a heat exchanger and creating a closed loop is a must.

I know there is an online supply company that claims that there has never been a case of legionnaires from open radiant systems. I would be happy to introduce you a couple victims who will tell you differently. It is not something you want."If you can't explain it simply, you don't understand it well enough"

Albert Einstein4 -

It won't work like that. There's far too much head (resistance to flow) in the heat exchanger of a tankless for those circulators to overcome it.

As GroundUp said, it will have to be piped p/s with a very large circ on the heater loop.

I would also second what he said about the open loop and legionella, as well as a host of other issues.

A tankless is not designed, controlled or approved to be used as a boiler. If a tankless could take the place of a boiler, there would be no need to make boilers. Someone has sold you a bill of goods.

If you're gonna be there for the long haul, you'd be better off making it a closed loop and installing a boiler. I've seen open loops that clogged with biological growth in little time.

You can research p/s piping in the resource center of this site.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.3 -

Hi zman, I can post a diagram of the system soon. As far as the legionnaires...do you know of cases where they contracted it from the open loop system?

Hi Ironman, why would a tankless hot water system not be good for a radiant set up?

Thanks.0 -

0 -

Question 1. Legionairres. Yes, folks have gotten it from open loop systems. And from cooling towers. And from water heaters running at less than 140. And... and you don't want it. It isn't 100% fatal, but it's well up there -- and there are quicker, slicker ways to go.

A tankless water heater is designed for a very large temperature rise -- typically the design is for 80 to 100 degrees -- on a relatively low flow -- typically no more than 2 to 3 gpm -- ramping up from no heat to full output in only a few seconds. It is also typically designed for a 30 psi pressure drop through the heat exchanger. All of which means that the heat exchanger has many, small passages to get large heat transfer rates. A boiler, on the other hand, is designed for a rather small temperature rise -- typically 30 to 40 degrees at the most -- at higher flows -- depending on the boiler, upwards of 5 gpm -- and does not need to ramp up to full output particularly rapidly. They are also designed for a very small pressure drop -- a few PSI at the most. Therefore the heat exchanger is completely different -- wider passages, more contained volume.

They are designed an built for completely different purposes -- not unlike a comparison between my wife's Chevy sedan and my Chevy K2500 super duty.

Using the wrong tool for the job is rarely a way to success...Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England4 -

A tankless with out a heat exchanger built in is worthless. The craftsmanship is completely sub standard. With incoming cold water in the system you lose efficiency due to the temperature rise. It could be reworked but I would go after the person who installed the system. If their not a contractor you going no where. By the look of the work it looks like their not. If you tried to save money by having some hack do the system it’s an exspensive lesson.0

-

Yes I do know people who have contracted it from an open system.er1k said:Hi zman, I can post a diagram of the system soon. As far as the legionnaires...do you know of cases where they contracted it from the open loop system?

Hi Ironman, why would a tankless hot water system not be good for a radiant set up?

Thanks.

Your circs will never be able to overcome the heating loops and the water heater resistance. It would be pretty easy to add a heat exchanger and close the heating side."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

Ok. How should I redesign the system? Buy a boiler? Buy a second tankless? I still don't know what a primary secondary piping is.0

-

And how do I calculate how much btu my radiant is producing?0

-

"If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

GPM x Delta T x 500 = BTU/hr.er1k said:And how do I calculate how much btu my radiant is producing?

2.2 x 33 x 500 = 33,600

The reason for the low flow is that the resistance in the loops, associated piping/components and hot water heater is greater than what the pumps are designed for.

If you paid someone for that design, you should ask for your money back. The math is bad.

Is your radiant installed with heat transfer plates? Even with plates, the 32 btu/ft as designed is optimistic. Without plates, it is impossible."If you can't explain it simply, you don't understand it well enough"

Albert Einstein2 -

Hire a pro?er1k said:Ok. How should I redesign the system? Buy a boiler? Buy a second tankless? I still don't know what a primary secondary piping is.

Steve Minnich1 -

I think you are looking at a do-over.

A room by room load calc

A design indicating heat emitter sizing and required flow for each zone

Equipment sized and selected to the actual load calculation

A combi boiler or other heating specific appliance.

I'm not sure how salvageable that system is. Perhaps the heater could be used for a dedicated DHW source and install a boiler sized to the heat load calculation.

You could run a load calc and at least get a start on a proper design, here is a free ap.

https://www.slantfin.com/products/virtual-heat-loss-calculator/Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

ZMan-yes I do have the aluminum plates. 33600btu is not enough. I don't understand. I called the company and I feel like they are giving me the run around. Wouldn't they see that the low flow is not producing enough btus?

The pumps get really hot which I think because they are working so hard. My feeling is that they won't last that long. But I really don't know for sure.

Hot rod-thanks for the app. I just downloaded it.

Is there a way to do the math or have a gauge to figure out the head resistance of the tankless and/or everything else?0 -

It seems the votes are in.....this will never work as such.

I have never dealt with any type of tankless heater and most likely never will.

Could you all help me, the HO poster and perhaps the designer of this set up understand the basic problem?

They calculated he needs 6.75 GPM for heating the house.

They spec a tankless that will do 10 GPM.

(for the moment lets assume these two numbers are correct)

Are they overlooking that that 10 GPM is achieved by the house water supply pressure of 50-80 PSI is pushing water thru the heater to deliver the domestic hot water??

But in the heating mode these small circulators (which can produce only a few PSI) will certainly not deliver the GPM needed because of pressure drop??

Is it a good guess that this happens a lot?

2 -

No easy way to figure out head loss mathematically for something like a tankless -- but it's really easy with a pair of gauges. One on the outlet, one on the inlet. Subtract. Voila. Same idea for any other length of pipe or appliance.

The company is not giving you the runaround. If all the flow you are getting is 2.2 gpm, the heat from your radiant system is going to be about 33K BTU for your delta T. That's physics, and you can't debate the matter. The low flow is the result of a pump not having enough head to push any more through the circuit resistance. That's a characteristic of the pump, and you can't debate that, either -- but you can put in a bigger pump with a different head vs. flow characteristic. Most typical circulators for heating systems, though, aren't designed for the high head conditions found with tankless heaters; you'll have to look elsewhere.

Bottom line: though the company may not be giving you the runaround, whoever created the design -- tankless heater, pumps, expected radiant floor output -- did not do a good job.

I think you need to go right back to square one. Do the heat loss calculation, room by room. Assess what is in the floor, and determine if it can meet the heat loss of the room. Do NOT go over 20 BTUh/square foot of heated (not gross) floor area. From that find which rooms are going to need additional heat -- baseboards, radiant wall panels, radiant ceilings, whatever. Add up all your heat losses and select a boiler based on that heat loss (a boiler, not a water heater). Get someone to design and build the necessary primary and secondary pumping, manifolds, piping, and controls.

You can salvage your tankless for your domestic hot water, if it's adequate.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

There is usually a filter screen somEwhere in a tankless heat, be sure that is clean to get as much flow as you can, maybe limp through this heating season.

3 steps

Load calculation, room by room

heat emitter selection sized to each room, or the tube an plates.

Expect somewhere in the mid to high 20 BTU per square foot with properly installed radiant. Rooms with higher load may need additional heat emitters.

Select a het appliance to match the total load calculation

Pipe and zone the system to best practices regarding pipe size, air and dirt elimination, expansion vessel and location, safeties, fill system, etc.

You have a bit of work to do, you or you can hire some of all of it out, starting with a load calc depending on your skill and comfortable level.

My company has a whole series of technical journals available for free! these will step you through each component of the sizing and installation, except the load calc.

This is a good starting issue, the rest are pdfs on our website.

https://www.caleffi.com/sites/default/files/coll_attach_file/idronics_12_0.pdfBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

With that bar napkin piping schematic. I’m curious, as to what happens when there is a heat call, and you are using the cold water at a fixture simultaneously? Have you tried that?

Not that it would have anything to do with the performance of what you have there.....

Gordon Ramsay rhetoric uncut, is ringing through my head with that near boiler piping, and heat source.

Options.

Get a HX for the radiant, and repipe accordingly properly.

Use the tankless for domestic, and get a dedicated heat source for the radiant. Preferably not another tankless...... repipe accordingly.

Or ditch the tankless and get a combi to service both. That system you have now is no way to go through life.

1 -

So I am real busy spackling the house I don't have time to really dig into this system. But I have been messing with the temp control on the tankless. I set it up to 150. It goes to 160. I can achieve 25k btu when only one zone is on...25k is what I am looking for per zone. If the equation gpm x delta t x 500 is true. So when I run one zone at a time I get about 1.8 gpm. But when I run 2 at the same time I get 2.2. Why? Why wouldn't I get 3.6? Too much head pressure?

I think that it might work when only one comes on...but when both do it's hard for it to get up to temp.

0 -

To much head0

-

Hey Jamie hall. So what gauges would I use to measure the head pressure?

As far as not enough flow when the two zones turn on...i do have an extra zone built into the zone distribution manifold...what if I split one of the zones up and put another pump there? So my one zone is 4 loops...split that into 2 zones of 2 loops with separate pumps.0 -

Centrifugal pumps do not just happily double the flow when you hook up two pipes. The flow will go up -- but not double -- as you have observed.

Your fundamental problem is that you have more head loss than your pump can pump against at the flow you want out of the pump. The only way to fix that is a pump capable of the flow you need at the head loss you have, or reducing the head loss.

As to gauges -- any good pressure gauge intended for hot water will work, provided it has the range you needBr. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

So since fresh cold water runs through your space heating lines prior to being heated, what happens to the flow rate and delta T if you open a hot faucet while both zones are calling for heat? Long story short, you gotta re-pipe this thing primary secondary at the very least. To eliminate Legionnaire's disease from the equation, you need to separate the radiant from the domestic. Whether that means a heat exchanger or a boiler or even a combi-heat type unit, is up to you. But it will not work like this, no matter what you do; the head through the tankless is far too high1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements