Replacing Low Water Cut-off (float type)

Comments

-

I'll call Hydrolevel tomorrow, to see if I can get a circuit diagram.Jamie Hall said:Anybody have access to a circuit diagram? Not just the attach this wire to that screw, but the actual internal circuit diagram? I have a dismaying suspicion that the Safeguard simply won't work unless there is a continuous ground and bonding, but I don't want to say for sure without the circuit diagram...

ThanksWeil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

I tried reversing the 24 volt wire to no avail. I'll try running a ground wire between the LWCO and 24volt transformer box.EBEBRATT-Ed said:try running a ground wire between the low water cutoff and the box the transformer is mounted on. Even a temp jumppper wire and see what happens. You could also try reversing the 24 volt wires

ThanksWeil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

Update: I returned the SafeGard 400 LWCO and replaced it with a McDonnell-Miller PSE802-24, Electronic 24V Low Water Cutoff with Auto Reset .

https://www.supplyhouse.com/Mcdonnell-Miller-153927-LWCO-PSE802-24-Electronic-24V-Low-Water-Cutoff-with-Auto-Reset-Steam

The good news - the PSE802-24 works as far as recognizing a LOW water condition - turns ON showing green power light and red low water light. When water hits the probe, red light flashes then turns OFF . Exactly what it's designed to do.

The bad news - when turning up the thermostat to get heat - the burner fires for a mere second then cuts off. Not surprising since I only connected the Hot wire and Neutral to see if the probe recognizes a low water state. Therein lies my problem about where to go from here.

Wiring instructions for 24V LWCO

Given my bolier was installed in 1985 - current wiring instructions don't conform exactly to my configuration. The only existing wiring for the boiler comes from

1) 24V transformer

2) Thermostat

3) Gas Valve 36C03 Type 422 ( see below) (standing pilot)

TH- white wire

TH-TR ( middle red wire isn't connected to anything - never has been)

TR-blue wire

Thoughts appreciated.

Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

-

No teflon. I used thread sealant, very sparingly. Then I removed all of sealant, still didn't work.HVACNUT said:Did you happen to use teflon tape on the threads of the Safeguard?

Soft compound only.Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

-

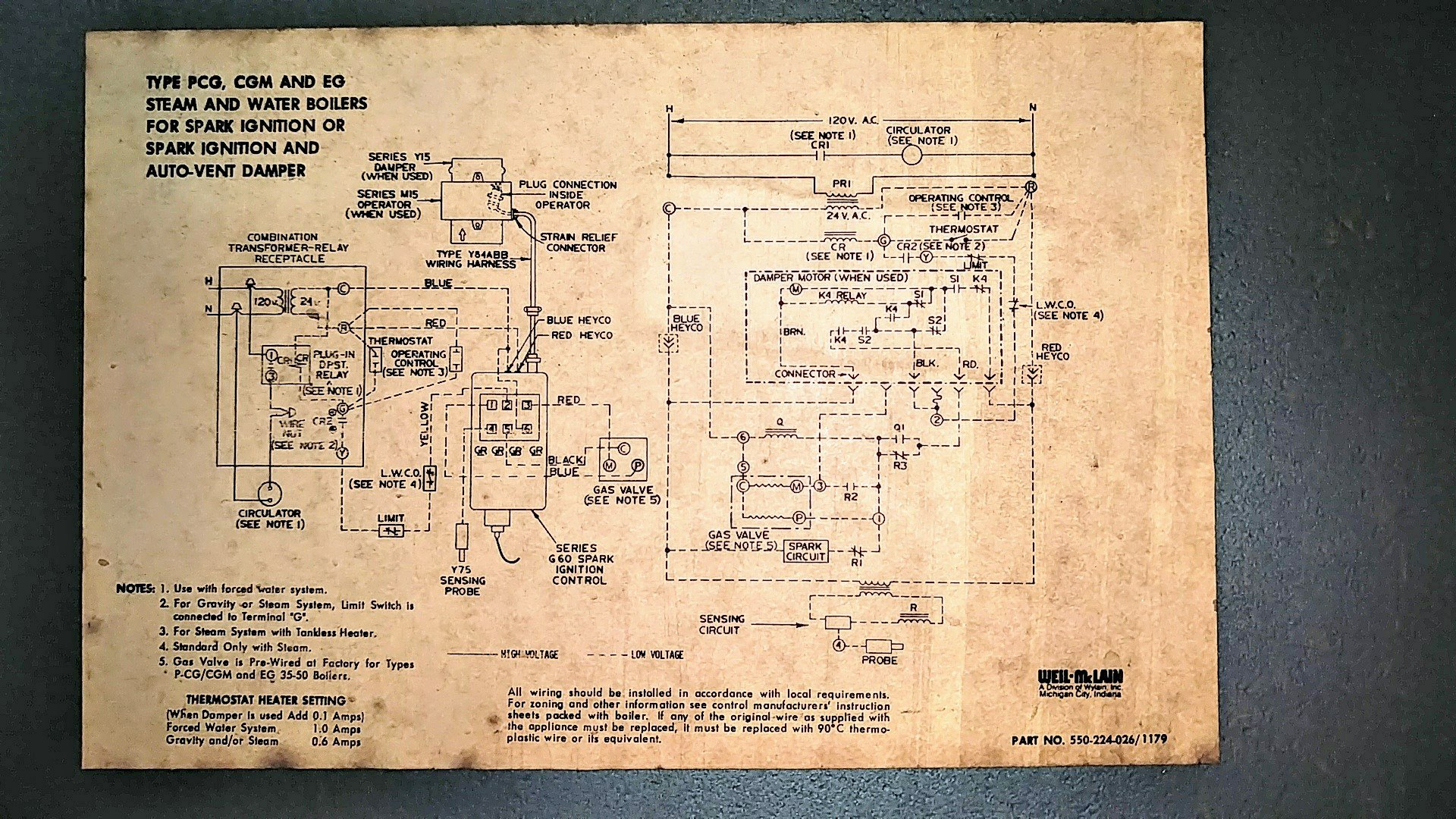

@JUGHNE Thanks for the suggestion. Attached is the diagram, but it looks like it the wrong cover was placed on the boiler. The diagram is for spark ignition but mine is a standing pilot. At any rate, I'll draw a wiring diagram that worked with the old Model 67 LWCO. Maybe that will help.JUGHNE said:Do you have the original wiring diagram that came with the boiler? It might be on the inside of the door.

If you have several diagrams it would be the simplest one shown.

Picture of it if you have it, please.

Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

Re-cap, I swapped out my SafeGard 400 for McDonnell Miller PSE-802 24 volt LWCO probe. The install was pretty straightforwad and it works. But, there was a problem - the Burners would not recognize the thermostat temperature reduction to turn off the bolier. The LWCO would shut down the boiler with low water, no problem. At first, I called a local repair guy from a usually reliable company. Never again. He initially told me I needed a 120 volt line for my 24 volt system. After re-configuring the wiring, he diagnosed a "bad probe." However, the probe works. On the bright side, I became more motivated.

First thing was to totally un-do the faulty wiring and start from scratch. I spent a bunch of time drawing up diagrams and finally settled on one I figured would work. Initially it didn't work. A big problem was the boiler firing up even though the thermostat was turned way down. The problem was mis-wiring the TH terminal wire to the Thermostat wire. Took a lot of trouble shooting to finally figure it out. Going back to the diagram, the TH terminal wasn't tied into the thermostat properly

Anyway...I just completed the wiring - and it works! Temporarily, for testing purposes, I left off pressure limits, making it easier to diagnose any issues.

Testing results:

1. LWCO shuts down entire system in a low water state.

2. Boiler starts back up with proper water level.

3. Thermostat functions properly, - boiler starts and shuts down based on the temperature setting.

Intallation steps taken. (Standing pilot, White-Rodgers 36c03 Gas Valve Type 422, Weil-McLain EG-55 boiler installed in 1985; McDonnell Miller PSE-802 24 volt LWCO probe for steam)

1. Ran 24 volt lines (hot and neutral) from 24V transformer directly to terminal "H" & terminal "N"of LWCO

2. Connected gas valve TH terminal wire to Thermostat wire - we'll call it wire A

3. Ran hot wire from terminal B of LWCO to other Thermostat wire - wire B

4. Connected Gas valve TR terminal wire to N terminal of LWCO.

Sounds simple, but for me it was daunting for a first-timer. But thanks to you guys - success! You guys are GREAT. Maybe this experience will help someone else.

Whew!

Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

Attached is my updated wiring configuration. I'm about to add the Vaporstat and Pressuretrol to the current wiring configuration and wanted feedback based on my diagram. Any thoughts appreciated!

Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

Oh yeah Special Thanks! to @Jamie Hall @Steamhead @Fred and anybody else having a hand in all of this!Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

That looks right.

After wiring everything, you should manually trip the pressure controls (gently lift the lever at the bottom with a screwdriver until you hear it click) to make sure they do indeed shut down the burner.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

@Steamhead Will do. Thanks!Steamhead said:That looks right.

After wiring everything, you should manually trip the pressure controls (gently lift the lever at the bottom with a screwdriver until you hear it click) to make sure they do indeed shut down the burner.

Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

@Steamhead Tested both pressure controls. Passed!! Tonight when it gets cooler outside, I'll add some steam tablets, fire up the boiler and test once again. Thank you!!Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

Update: thanks to all the fine experts in this forum, I made it through the heating season successfully! Temperature down to 50 degrees tonight, will do seasonal shutdown, fill up boiler and add addt'l steamaster tablets this evening.

To refresh- EG55 Weil McClain steam bolier

new parts installed:

Vaporstat Controller (Steam) L408J1009

Pressuretrol PA404A1033

PSE802-24, Electronic 24V Low Water Cutoff with Auto Reset

(Steam)

Big Mouth Air Vent

0-3 PSI pressure gauge

0-30 PSI pressure gauge

Water Gauge Glass Cocks / with new sight glass

Header Insulation with covers

Final two photos attached.

Thanks again. Much appreciated!Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents1 -

Egad, now you maybe just need new near-boiler piping?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

This. Look at the instruction manual to see what we mean. Whoever piped your boiler obviously did not.ethicalpaul said:Egad, now you maybe just need new near-boiler piping?

All Steamed Up, Inc.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

@steamhead Thanks. The near bolier cast iron piping directly into the boiler is new. When installing new boiler sections, the installer wet near boiler piping after filing and leaving a plug left open, rusting the surface.Steamhead said:

This. Look at the instruction manual to see what we mean. Whoever piped your boiler obviously did not.ethicalpaul said:Egad, now you maybe just need new near-boiler piping?

Weil-McLain EG55 2 pipe Vapor System

Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

-

Rust is not the concern. The configuration of those insulated pipes is wrong and will likely result in a lot of water getting thrown into your main steam lines, water hammer, low-water issues during firing due to the bullhead tee.

It may be the angle of the picture, but is there an equalizer?

You want to see something like this:

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

-

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

@JUGHNE Will do re more pics. The boiler was installed in 1985. I assume the piping was done at the same time. I wasn't the owner at that time.JUGHNE said:What they refer to on your piping at the boiler is that it is wrong.

The sequence of piping is incorrect.

How old is your boiler?

Please take pictures from farther back so we see piping from floor to ceiling on all sides.Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

@ethicalpaul Thanks. I found the EG-55 manual, this the configuration prescribed for this boiler. Note I have a parallel-flow system. Actual pics to follow.ethicalpaul said:Rust is not the concern. The configuration of those insulated pipes is wrong and will likely result in a lot of water getting thrown into your main steam lines, water hammer, low-water issues during firing due to the bullhead tee.

It may be the angle of the picture, but is there an equalizer?

You want to see something like this:Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

@Steamhead @JUGHNE @ethicalpaul @Fred

Thanks. About to send pics of all piping starting from right to left of the boiler. Then left to right. No pics for right side of bloiler - no pipes or connections on right side.

(1) front and side view showing main at top from 2 risers

(2) left side view (pipe to main)

(3) left side continued (pipe to main)

(4) Main making first turn - goes around entire basement

(5) Looks like radiator pipe returning water to condensate flow pipe -- which runs in parallel with the entire main around the basement. It is a 2 pipe system.

(6) Going from Left to Right showing piping from boiler traveling to the right.

a) water supply connected to piping

b) end of run

Click the last 3 photos and they will display properly.

Weil-McLain EG55 2 pipe Vapor System

Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

@EdwinD , The way your boiler is piped is totally wrong. Look at the picture from your manual again. It only uses one riser out of the boiler. It is piped, Riser (out of Boiler), Riser to Steam Main, Equalizer at the end that goes back down to below the boiler water line.

When you use both boiler tapings , the configuration should be: Riser (out of the Boiler), Riser (out of the Boiler) , Riser to the Steam Main and then Equalizer, at the end, back down below the boiler water line.1 -

@Fred Thanks. Yes, its pretty obvious its wrong . And it's been configured incorrectly for quite some time. In 1987, when I bought the house, it came that way, and unfortunately there was no Internet.Fred said:@EdwinD , The way your boiler is piped is totally wrong. Look at the picture from your manual again. It only uses one riser out of the boiler. It is piped, Riser (out of Boiler), Riser to Steam Main, Equalizer at the end that goes back down to below the boiler water line.

When you use both boiler tapings , the configuration should be: Riser (out of the Boiler), Riser (out of the Boiler) , Riser to the Steam Main and then Equalizer, at the end, back down below the boiler water line.Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

@Fred There is a bullhead teeFred said:I don't see a bullhead tee but I do see the riser to the Main in between the two risers out of the boiler. That is a no, no. The configuration should be Riser out of boiler, riser out of boiler, riser to main(s) and an equalizer after that.

Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

@ethicalpaul No equalizer.ethicalpaul said:Rust is not the concern. The configuration of those insulated pipes is wrong and will likely result in a lot of water getting thrown into your main steam lines, water hammer, low-water issues during firing due to the bullhead tee.

It may be the angle of the picture, but is there an equalizer?

You want to see something like this:Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

Will the steam main and condensate piping need replacing or the near boiler piping, or both? I'm trying to figure how far to go with this. I may end up installing a regular furnace and be done with it. Frustrated isn't a strong enough word.Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

If the house heats well....and there is no water hammer.....and water does not spit out of the big mouth air vent.....and you can run the system in ounces?? I would leave well enough alone until the day to change out the boiler.

Then only the piping at the boiler would need to be corrected.

Presently you have quite a bit of vertical rise height with the two steam risers and the main riser. That height lets the water fall out and go back down into the boiler. Not the best scenario but there are a lot worse piped boilers than this one that somehow work.1 -

You're going to have to point out the Bull head Tee cause I sure don't see it.EdwinD said:0 -

Keeping up with the dust blowing around the house will certainly distract you enough to forget about any piping. Your situation is not at all frustrating. I don't see anything wrong except the near boiler piping and that looks like an easy enough fix. And, as @JUGHNE said, if it heats and isn't hammering or creating a lot of wet steam and has worked since 1985, what's to complain about? You probably would be on your second hot air furnace by now.EdwinD said:Will the steam main and condensate piping need replacing or the near boiler piping, or both? I'm trying to figure how far to go with this. I may end up installing a regular furnace and be done with it. Frustrated isn't a strong enough word.

2 -

Many older boilers were siamese-piped in such a way, and their more generous steam chest enabled them to work, however, the lack of an equalizer is more of an impediment to dry steam.

So just correct it all whenever the boiler must be replaced, and make sure the EDR of all the radiators has been calculated for the best match.—NBC1 -

@FredFred said:I don't see a bullhead tee but I do see the riser to the Main in between the two risers out of the boiler. That is a no, no. The configuration should be Riser out of boiler, riser out of boiler, riser to main(s) and an equalizer after that.

See attached without insulation covers.Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

@JUGHNE Thanks. I don't get water hammer, but it seems I'm having to add more makeup water than i should. From OCT to March I had to add water about 4 times. I think thats too much.JUGHNE said:If the house heats well....and there is no water hammer.....and water does not spit out of the big mouth air vent.....and you can run the system in ounces?? I would leave well enough alone until the day to change out the boiler.

Then only the piping at the boiler would need to be corrected.

Presently you have quite a bit of vertical rise height with the two steam risers and the main riser. That height lets the water fall out and go back down into the boiler. Not the best scenario but there are a lot worse piped boilers than this one that somehow work.Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

@Fred Correction, there's no bullhead tee.Fred said:

Keeping up with the dust blowing around the house will certainly distract you enough to forget about any piping. Your situation is not at all frustrating. I don't see anything wrong except the near boiler piping and that looks like an easy enough fix. And, as @JUGHNE said, if it heats and isn't hammering or creating a lot of wet steam and has worked since 1985, what's to complain about? You probably would be on your second hot air furnace by now.EdwinD said:Will the steam main and condensate piping need replacing or the near boiler piping, or both? I'm trying to figure how far to go with this. I may end up installing a regular furnace and be done with it. Frustrated isn't a strong enough word.

Thanks.

Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

@JUGHNE @Fred @nicholas bonham-carter @ethicalpaul

@Jamie Hall

A little background. New cast iron sections were installed a year ago. With my minimal knowledge I knew more than the installers - not good.

Here's my question, I'm thinking of the following configuration which wouldn't require moving the boiler.

It will require abandoning the left riser -- and adding a slightly longer left header (from the tee) - just enough to add more space between boiler and drop down piping -- then add an elbow and adding a reducer bushing to elbow to accomodate the recommended 1 1/2" piping to a hartford loop with equalizer and the condensate return -- similar to what's shown below.

Thoughts?Weil-McLain EG55 2 pipe Vapor System

OP Pressure .10 -.25 oz

8-Way Boiler Water Treatment

Barnes & Jones Big Mouth Vents0 -

> @EdwinD said:

> Will the steam main and condensate piping need replacing or the near boiler piping, or both? I'm trying to figure how far to go with this. I may end up installing a regular furnace and be done with it. Frustrated isn't a strong enough word.

Abandoning a really good heating technology because of something a clueless installer did 30 years ago seems strange 😅

If you are adding makeup water a lot, you may get a chance to have that piping done correctly sooner rather than later. Check it or have it checked for leaks this summer. 30 years is a nice run.

Edit: After posting I saw your above post on the next page, sorry about that. I like your idea. Did you check to see if your boiler can perform OK with a single riser?NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

IMO, going to one riser would involve re-piping almost as much as doing a drop header and correcting everything.

If you can keep your pressure very low, your water clean and have no hammer then I would leave well enough alone. There are plenty of worse systems that work, not as well as yours, but still function.

Be concerned about losing water.

You can overfill/flood the boiler up above the riser 90's.

Leave sit for a day, looking for leaks on the floor.

If none then drain down the sludge out and refill and fire up to steaming to drive oxygen out of the water.

Are any of your returns under the floor?

The return line near the chimney cleanout door looks to have a check valve installed. That could be a cause of slow return water but not loss of water. I do not think you need it there. You can unscrew the top and remove the guts then replace the top.

Do you have an idea of the amount of water added?

I assume manual addition.

You could mark the sight glass, add water for the same amount of valve open time you use to add water during the season.

If you can approximate that addition 3-4 times then observe the sight glass.

Drain out water to return the sight to your original marking.

Measure the gallons of water you drain out. That will give you an idea of loss.1

Categories

- All Categories

- 87.4K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 121 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 115 Geothermal

- 168 Indoor-Air Quality

- 3.8K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.8K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements