Checking circ sizing in existing system?

However, I have very little confidence in the previous owner's math skills and his ability to have selected the appropriate circ sizes for the heating. Does anyone have any tips for measuring an existing system to verify whether or not the pump sizing is close to what they should be?

Is it as simple as measuring all the baseboard runs and accessible pipes/adding up the valves and other inter-pipe connections that are visible and coming up with a head calculation?

I understand that to be more accurate, I'd need to do a heat loss calc and not just use the max BTU rating of the boiler (HTP Munchkin M80) to determine the necessary flow rate, right?

My boiler currently outputs to a Taco 009 then to three additional circulators for each zone; 2x 007 and one more 009. The zone circulators are controlled by a t-stat triggered Argo AR861-3II.

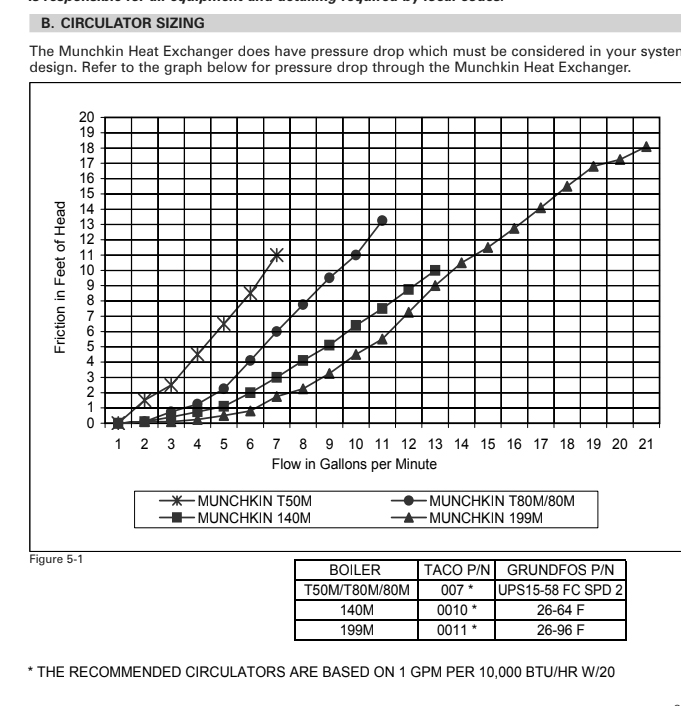

I've attached a picture of the circ sizing recommendation from the HTP boiler manual:

- HTP Munchkin 80M R1 (DOM 11/04)

- Taco 007,009 on Argos

- DHW Bradford White RG2PV50T6N 50-gal

Comments

-

009s and 007s have wildly different performance curves . Those 2 models randomly ending up in the same job would almost suggest someone knew something . Could you attach a couple pictures of the near boiler piping and boiler ? You might be asked about some math tooYou didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38331 -

Rich,

I'll get some pictures. I don't mind math. I'll at least check to see if there is math involved and either figure out the proper calculations or find someone more experienced than me to do before committing to a project.

In this case, I'm just doubting the previous owner's work. He was an HVAC guy who seemed to use cast-offs in his own home. Kinda like the shoe-maker has no shoes lol

My heating system does function, but I have no confidence that it's working as well or as efficiently as it could.- Dan G.

- HTP Munchkin 80M R1 (DOM 11/04)

- Taco 007,009 on Argos

- DHW Bradford White RG2PV50T6N 50-gal0 -

If you can get temp & pressure measurements, that would alleviate the need for cyphering things up.0

-

Here’s the guts of my system- Dan G.

- HTP Munchkin 80M R1 (DOM 11/04)

- Taco 007,009 on Argos

- DHW Bradford White RG2PV50T6N 50-gal0 -

I misspoke, there is a 009 on the inlet side of the boiler.- Dan G.

- HTP Munchkin 80M R1 (DOM 11/04)

- Taco 007,009 on Argos

- DHW Bradford White RG2PV50T6N 50-gal0 -

GPM = btu / 20 x 500,... head is 6 ft per hundred ft of pipe,//so if you have a 100000 btu boiler thats 10 gpm so any pump that can pump 10 GPM will work with 6 ft of head that is"The bitter taste of a poor install lasts far longer than the JOY of the lowest price"0

-

If it were me, I'd first slap pressure gauges on either side of the heating pump using tap saddle valves and get a true pressure differential with all zones calling. Then I'd take the furthest zone from the pump and do the same thing. In fact, I'd recommend doing it to ALL individual zones.

You can then take this pressure differential and convert it to feet of head by multiplying the PSIG reading times 2.307.

Then, take the manufacturers performance curve, and plot the known head and see how many GPM you are moving at those points in time, with a given zone calling.

Now, take the heat emitters, and compare them to the known flow to make certain you are moving adequate fluid flow (assume a 20 degree temperature differential).

If flow is adequate ( yes), then you know where you need to be flow rate and pressure drop wise. If not (no) then you at least know what the pressure drop for a given flow is, and using the Bell and Gossett System Syzer, you can calculate the required flow and pressure (head) required.

If the rooms are not heating correctly, then a full blow loss calc needs to be done (recommended anyway) and emitter capacity checked against demand.

ME0 -

Mark,

That all sounds like a great procedure, however, I'd be concerned about the saddle valves eventually leaking - so am not sure how to address that.

- Dan G.

- HTP Munchkin 80M R1 (DOM 11/04)

- Taco 007,009 on Argos

- DHW Bradford White RG2PV50T6N 50-gal0 -

Well, if you are handy at soldering (which I probably wrongly assumed you are not) then cut in two tees with 1/4" female by sweat bushings and install the gauges (2 of them) before and after the pump. Or, install two tees, two ball valves and one gage. Open one valve, then read gage, then close it, then open the other and read gage, make note of difference, do math, convert to head and be done with it.

Sorry for my assumption...

ME0 -

Mark,

Not a problem. It's often hard to evaluate anyone's expertise particularly if they're just a homeowner like myself.

I have soldered copper before and am not entirely fearful of cutting into my system

The harder part is justifying it to my significant other - Dan G.

- Dan G.

- HTP Munchkin 80M R1 (DOM 11/04)

- Taco 007,009 on Argos

- DHW Bradford White RG2PV50T6N 50-gal0 -

Are you allowed to mount the brown pump shaft vertical as it is currently? Or did the photo just post 90deg off?0

-

I have installed many HTP 80M boilers. First never use a ECM pump on the boiler circuit. The 80M must be installed on a primary (boiler circuit) / secondary (heating circuit) circuits. HTP tells you to use a Taco 007 or a Grundfos UP 15-42 F on spd-2 on the primary circuit. The Taco 009 is used on the Indirect H/W tank, specifically the HTP Ultra-Stor tank. The indirect tank, if you have one, is part of the primary circuit and should not use an ECM pump. Use an ECM pump on the secondary circuit (space heating) only, if applicable. This boiler needs hydrolic separation.

Never mount a pump in a vertical position except where the pump motor is above the pipe and the pressure is above 45 psi. Your Taco pump should be mounted horizontally.

You need to take some pictures that show the whole setup.0 -

This installation is something a homeowner did. It reeks of homeowner. The solder job alone says as much. This is a terrible installation.

And...concentric venting, to, Gasp! Is that a crack in the exhaust vent or just a drip of pvc primer?

You are getting awfully close to the 10 psi shut down pressure and an Pr0 error code.1 -

I do see closely spaced tees, so it appears to be a primary/secondary system. But, what professional would mount tees like that?

The pump on the boiler circuit is a 009 and should be a 007. The pump curve on the 009 is a steep curve and the flow and head are at the bottom of the curve . The 007 has the flow and head in the middle of the pump curve, where it should be. The 009 is a 1/8 hp pump with a 1.4 amp draw and the 007 is a 1/25 hp with a .71 amp draw and they both do the same work.1 -

Why not an ECM on the boiler circuit? If, in one of the fixed speed it matches the boiler flow spec, why not. You at least save 50% or more electrical use.HomerJSmith said:I have installed many HTP 80M boilers. First never use a ECM pump on the boiler circuit. The 80M must be installed on a primary (boiler circuit) / secondary (heating circuit) circuits. HTP tells you to use a Taco 007 or a Grundfos UP 15-42 F on spd-2 on the primary circuit. The Taco 009 is used on the Indirect H/W tank, specifically the HTP Ultra-Stor tank. The indirect tank, if you have one, is part of the primary circuit and should not use an ECM pump. Use an ECM pump on the secondary circuit (space heating) only, if applicable. This boiler needs hydrolic separation.

Never mount a pump in a vertical position except where the pump motor is above the pipe and the pressure is above 45 psi. Your Taco pump should be mounted horizontally.

You need to take some pictures that show the whole setup.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

A fixed speed pump is half the price of an ECM. Are there boiler manufactures that actually recommend an ECM in the boiler loop? What's the energy savings advantage of ECM over a fixed speed pump in a Mod/Con boiler circuit if the fixed speed pump is matched to the flow and head with the lowest HP? The Taco 007 is about 80 W compared to the Alpha2 at about 30 W on speed 2.

I was told this by a manufactures engineer when the ECM's were first coming on line. Perhaps new thinking has changed that.0 -

Best get used to ECM circulators. They will become the mandatory minimum in the next few years. It's already the standard over in Europe. Regarding boiler manufacturers, I believe Lochinvar has the ability to put out a 0 to 10 VDC signal to control the boiler pump, and if memory serves, there are others.HomerJSmith said:A fixed speed pump is half the price of an ECM. Are there boiler manufactures that actually recommend an ECM in the boiler loop? What's the energy savings advantage of ECM over a fixed speed pump in a Mod/Con boiler circuit if the fixed speed pump is matched to the flow and head with the lowest HP?

The net reduction in KWH is pretty significant, and can not be ignored, which is why all of the major pump supplier have introduced them into the market. Wilo has one that uses one watt, and is used to replace TRV's on individual radiators.

Also, to the OP, if the pump in question is pumping away from the PONPC and is reasonably close to the PONPC, you can probably get by with just one gage on the pumps discharge. Inlet pressure should equal fill pressure.

ME

1 -

Mark are you suggesting, I should give up my 'horse and buggy' thinking?

I use a lot of ECM pumps, but never on a Mod/Con boiler circuit. I'd be interested in the views and comments of those who have used one on the boiler circuit.0 -

Let’s clarify. An ecm circulator does not have to have a variable flow rate in the boiler loop.

I believe that is what Holmer is alluding to.

An ecm circulator will use less watts at same curve as a plc type circulator. Heck in my old system I switched from a B&G 100 HV to a B&G PL 36 wet rotor that alone saved 60 watts both PLC circs. The 36 actually increased flow rate slightly.

Circulator selection can be overbearing across brands, and curves, ecm circs make life a bit easier now days. There are some gaps where they may not fill.0 -

I will add that someday boiler manufacturers, and pump manufacturers will get on the same page. That page is for plug, and play 0-10vdc with out third party hardware. Result variable speed ECM circulators matching flow rate output to modulation output. HTP is on the right path with the UFT, leave the circulator out of the package, and let the designer choose one to suit the systems needs, but that’s another discussion.1

-

One more step that can be done with circ pump sizing.

Develop the system curve over the pump curve and find the actual OP operating point. Basically the head loss curve for the circuit, or boiler loop.

Some of the boiler manufacturers give you a few points in their literature to do this. I think Lochinvar shows the pressure drop in the boiler including some piping and fittings.

Here is an example of a Weil Ultra to show a troubleshooter why this pump was selected.

Idronics 16 takes you through the steps to create the system curve and how to use it.

https://www.caleffi.com/sites/default/files/coll_attach_file/idronics_16_na_0.pdfBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream-1 -

Interesting you mention using one gauge Mark...Mark Eatherton said:

Also, to the OP, if the pump in question is pumping away from the PONPC and is reasonably close to the PONPC, you can probably get by with just one gauge on the pumps discharge. Inlet pressure should equal fill pressure.

ME

I was verifying the GPM display on my Alpha last weekend with two mechanical pressure gauges, I am PONPC and my pumps are reasonably close to the PONPC.

I found exactly what you mentioned... on both the Alpha and my indirect 15-58 pump both had no pressure change on the inlet side of the pump while in operation. Certainly makes testing easier and faster by just using one gauge!

Read/record static pressure, read/record pressure in operation.

FWIW- if my observations & subsequent calculations are accurate- the GPM display on the Alpha is not very accurate.

Used the formula here: https://sciencing.com/convert-psi-gpm-water-8174602.html

0 -

Gordy, now you're talking. Why do you need a fixed flow rate of 8 gpm when you are at a the lowest turn down and at 15K BTU's instead of the high rate of 80K BTU's. Functionally, you're better off, all the way around.

You guys are so smart!0 -

The Boiler needs a smaller circ. Using one of the 007's would work. An ECM designed for your flow rate would also work well.

The incorrectly installed gold 007 is a bronze pump designed for exposure to domestic water. The bronze is not a big deal, it needs to be flipped so the shaft is horizontal.

If you provide some info on what the zone circ serve, we can give you an idea what circ is appropriate.

I don't think tapping and measuring pressures in a residential heat system is worth the effort. If you can provide the pipe size and approx length, it can be estimated."If you can't explain it simply, you don't understand it well enough"

Albert Einstein1 -

ZMan I have this two pipe monoflo/diverter tee setup. Can the correct pump selection be confirmed by this method?

I'm not sure if the factory installed 007 is adequate. I plan on moving the pump to the supply and begin pumping away.

I'm considering getting an Alpha, the features are appealing to me as a technician.0 -

ME

Interesting you mention using one gauge Mark...

I was verifying the GPM display on my Alpha last weekend with two mechanical pressure gauges, I am PONPC and my pumps are reasonably close to the PONPC.

I found exactly what you mentioned... on both the Alpha and my indirect 15-58 pump both had no pressure change on the inlet side of the pump while in operation. Certainly makes testing easier and faster by just using one gauge!

Read/record static pressure, read/record pressure in operation.

FWIW- if my observations & subsequent calculations are accurate- the GPM display on the Alpha is not very accurate.

Used the formula here: https://sciencing.com/convert-psi-gpm-water-8174602.html

@NY_Rob

The formula in the link is intended for an open system. Even for that application, I think it is suspect.

I am sure it will not accurately model pump performance in a closed system."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

HomerJSmith .

I cannot even remember the last time I used a PSC circ in the boiler loop or anywhere . You make yourself sound as old as me , not quite as old as M.E . The dinosaurs could not adapt , see many of those around in the last few decades ? My uncle is 78 , still working and using ECMsYou didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

Ha!! I never thought that the day would come that I'd be called an old manRich said:HomerJSmith .

I cannot even remember the last time I used a PSC circ in the boiler loop or anywhere . You make yourself sound as old as me , not quite as old as M.E . The dinosaurs could not adapt , see many of those around in the last few decades ? My uncle is 78 , still working and using ECMs You young whipper snapper!

You young whipper snapper!

Dino-soarer for sure. GET OFF MY LAWN (practicing)

ME

2 -

Yeah, I can dead head mine and it still shows 4 GPM... I think the technology is still being refined and fine tuned. Delta T can't lie, much...NY_Rob said:Mark Eatherton said:

Also, to the OP, if the pump in question is pumping away from the PONPC and is reasonably close to the PONPC, you can probably get by with just one gauge on the pumps discharge. Inlet pressure should equal fill pressure.

ME

FWIW- if my observations & subsequent calculations are accurate- the GPM display on the Alpha is not very accurate.

Used the formula here: https://sciencing.com/convert-psi-gpm-water-8174602.html

ME

0 -

It's bad when an old man calls you old huh Mark ? PS Federici's survived , just ate there yesterdayMark Eatherton said:

Ha!! I never thought that the day would come that I'd be called an old manRich said:HomerJSmith .

I cannot even remember the last time I used a PSC circ in the boiler loop or anywhere . You make yourself sound as old as me , not quite as old as M.E . The dinosaurs could not adapt , see many of those around in the last few decades ? My uncle is 78 , still working and using ECMs You young whipper snapper!

You young whipper snapper!

Dino-soarer for sure. GET OFF MY LAWN (practicing)

MEYou didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38331 -

I tried looking around for a better formula, but that was the best I found.. maybe not so good though?Zman said:

@NY_Rob

The formula in the link is intended for an open system. Even for that application, I think it is suspect.

I am sure it will not accurately model pump performance in a closed system.

I tried the simple method of converting the PSI differential to head (PSI * 2.31) and then using the manufacturers pump curve chart to find the GPM rate.. but the results were kind of odd, especially on the CP modes on the Alpha where there is no fixed curve to follow.

If anyone has the correct formula to determine GPM in a closed system I'd love to give it a try.

I have the pipe ID size, and differential pressures for the Alpha and for the 15-58 pump.

0 -

Yikes!Mark Eatherton said:

Yeah, I can dead head mine and it still shows 4 GPM... I think the technology is still being refined and fine tuned. Delta T can't lie, much...NY_Rob said:Mark Eatherton said:

Also, to the OP, if the pump in question is pumping away from the PONPC and is reasonably close to the PONPC, you can probably get by with just one gauge on the pumps discharge. Inlet pressure should equal fill pressure.

ME

FWIW- if my observations & subsequent calculations are accurate- the GPM display on the Alpha is not very accurate.

Used the formula here: https://sciencing.com/convert-psi-gpm-water-8174602.html

ME

I've deadheaded my Alpha and it does drop to zero GPM after 30 sec or so... but it's still off by a significant amount if my calculations were correct.

Alpha Display....... Calculated using DIff Pressure

....2GPM......................4GPM

....4GPM......................8GPM

....6GPM.....................10GPM

On the upside... at least it's under reporting flow

0 -

-

I'm glad to have seemingly spurred much debate and thought on the circs and my system. I'm not sure what I'll actually do since I'm not sure how to quantify whatever advantages there might be to doing any measure of pump and/or pipe reworks.

Unfortunately, my system isn't easy to photograph as it's tucked into an alcove under a stairwell (depicted). The bulk of the plumbing is attached to the alcove wall with one zone circ for the small utility room being fed straight out from the wall. The 007 circ for the utility room zone is actually hung from the underside of the stairs.

Yes, the soldering quality is messy and by the looks of it, I knew straight away that the install wasn't necessarily done for the best performance or by the book and I'm not even a plumber. However, my wife will argue that the system produces heat and unless there is some more meaningful way to convey the necessity of "breaking" the system open to make changes, it'll probably be insisted that I leave it alone.

That said, I still want to learn what it should be so at the first moment a major component fails, I'll have a more clear opportunity to make appropriate corrections.

As listed above, this is the best two pictures I can get of the "whole" system:

The circulator on the bottom left of the first photo (bottom center of the next photo in the background) is on the Input side of the boiler.

The circulator in the middle top of the photo is for my 1st-floor living area heating circuit.

The circulator on the top right of the photo is for my 2nd-floor living area and is seldom ever turned on.

The last circulator pictured in the second picture under the stairs supplies the heating circuit for the small utility room where this boiler and my hot water heater live. It's never turned on and I actually have the circuit supply valve closed.

I realize both the circs for the utility room (mounted under the stairs) and the one on the inlet side of the boiler should have their housing rotated so the electrical guts aren't on the bottom. I'm not sure how or if I can easily do that without making a mess or having to replace seals.

The boiler runs on ODR and doesn't have any connection to my domestic water supply. That's handled by a Rheem PowerVent hot water heater.

The rest of the pictures in my previous post show closer views of the various sections of the system.

One of my intentions was to actually map out the system. I have yet to do that, but I thought that by doing that it would further illuminate issues that I could then develop a correction plan.

Ultimately, I may hire one of the local contractors who is a member of this site to come out and take a look and give their in-person assessment and also perform a combustion analysis since it's been about 5 years since I last had one done.

And, the pressure/temp reading I gave earlier was while the system was not active.

Also, no, the concentric intake/exhaust piping isn't cracked. It's just stained from the PVC cement. My wife and I rebuilt the piping since the original K-diverter had cracked and was leaking condensate into the room.

We replaced it and put together all new piping following the recommended specs by HTP. Working with the PVC cement, putting the pipes together and twisting everything just right in the tight space was a real relationship challenging experience...mostly between me and the pipes. My wife was awesome and did most of the work while I was freaking out I'm very lucky! - Dan G.

I'm very lucky! - Dan G.

- HTP Munchkin 80M R1 (DOM 11/04)

- Taco 007,009 on Argos

- DHW Bradford White RG2PV50T6N 50-gal1 -

Variable speed is coming to residential primary pumps for sure. We do it all day long on almost every building commercially but often have expensive VFDs, DP pressure sensors and high quality flow meters to ensure flow requirements are being met.

Over pumping the primary dilutes your return with hot supply, killing efficiency. I was happy to see Lochinvar offering a controls signal for a variable primary pump.0 -

After having had an amazing consultation with Rich McGrath of Langan's Heating/Plumbing, he advised on using a single circulator, the Taco VT2218. It looks like a great option for us when/if the existing boiler circ dies.- Dan G.

- HTP Munchkin 80M R1 (DOM 11/04)

- Taco 007,009 on Argos

- DHW Bradford White RG2PV50T6N 50-gal0 -

-

The Grundfos Alpha by pushing a button can be set up on seven different speed, pressure or automatic modes. You can experiment and pick the mode best for a given system. It is more practical than playing with pump curves. Replaced a B&G series 1000 with Alpha works great Have a vensuri Tee system that need plenty of flow0

-

I have used an taco ecm in a khn085 modcon and done it without primary secondary, and for the past two years it has only been running one manifold of 4 loops while i work my way down decommissioning the old system floor by floor so its doing on a relatively light heat load 1100sf. its one pump and for now one active zone valve eventually 4 one for each floors manifold. I bought it hoping for delta t setting but found the boilers modulation and the pumps delta tee would parry back and forth no lockout just swing up swing down. I put it into steady speed mode and will when i had the other zones swap it for their delta pressure type. The near boiler configuration is "well sized headers" no bypass. works fine. wish i could say as much for the lochinvar in its second year but that has nothing to do with the pump.

its true when i came up with the idea of a one ecm pump there was a lot of trepidation here particularly since im not a plumber im a tin knocker but with everyone's help and Patience with me i took the chance. did not need a buffer tank even with low temps and one zone only.

the loch does allow 0-10 volt pump control and that would be a way to do delta t but in a residential size there's no 0-10 v ecms commercial ones start close to a grand. they exist in europe and hot rod will tell you all about them but don't let him because you'll just feel inadequate from then on.

No i dont think the variable speed the delta P will have will do what the delta t pump did the delta p will only be adjust a constant pressure in response to opening and closing zone valves. the delta t was trying to adjust the speed in response to the boilers modulation not the valves which will be a steady open or closed. what happens is the DT pump would slow or speed up because modulation had increased or decreased raising or lowering temps. and the boiler would sense that and then counter back and forth in a rather gentle oscillation never locking out but not settling down either. the KHNs 0-10 is supposed to address that possibility by having the boiler control both but i felt the advantage of ecm efficiency was going to outweigh the 0-10v volt magnet motor efficiency and also these guys made me understand i could control DT without DT pumping and they were right it wasnt a problem dt settles in at about 13-17 close to where i wanted it.

make sure you heard the part where i said im not a plumber or an mech engineer just a pain in the website0 -

Ill ad there was concern about minimum flow across heat exchanger without P/S and ecm its not really an issue they cant actually pump that low0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements