Main vent enough?

Comments

-

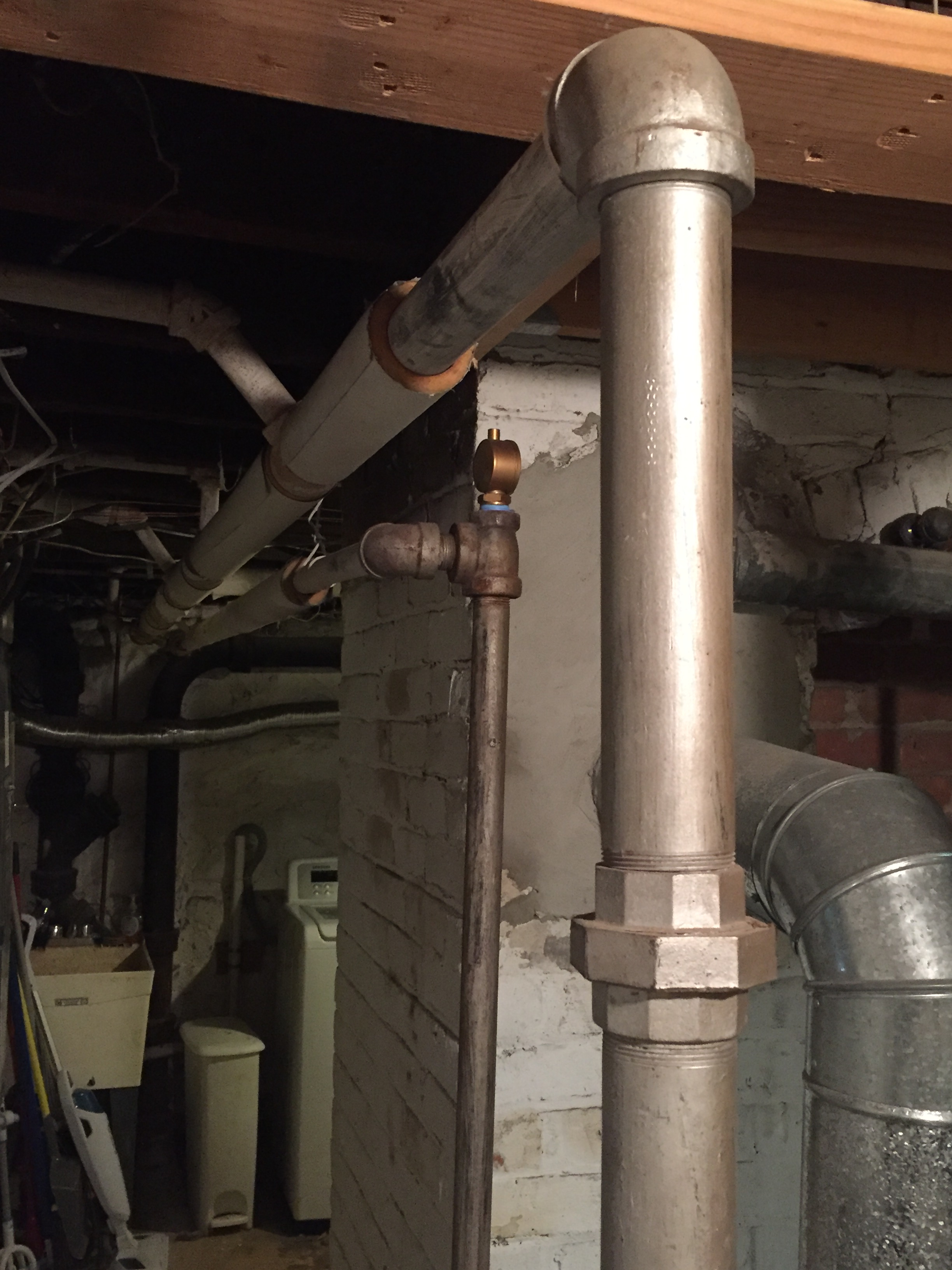

You have two mains. Each should be vented. That one vent, in your picture is a Gorton #1. Probably not nearly enough venting capacity. How long is each Main? Where is the return for that second Main?0

-

Just a guess from the pictures, but it looks like you have one counter flow main, and one parallel flow main. The counter flow main should have it's vent at the end of the main, and the parallel flow main vent (pictured) is too small.

But having said that, I don't see a drip for the counter flow, nor do I see a second return should it not be counter flow.

New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

Isn't there usually a drip on the main somewhere near the boiler on a Counterflow @New England SteamWorks ? I see what I think is a wet return on the floor, behind the boiler that is coming from the direction of that front main. I'm wondering if that main is also a parallel flow but the return drops to the floor at the end of the main???1

-

New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com1 -

-

That’s kinda what it appeared to me too @Fred but it’s dark and can’t really tell.Fred said:Isn't there usually a drip on the main somewhere near the boiler on a Counterflow @New England SteamWorks ? I see what I think is a wet return on the floor, behind the boiler that is coming from the direction of that front main. I'm wondering if that main is also a parallel flow but the return drops to the floor at the end of the main???

Also @MissButters your pressure is set too high, that should be down to .05 and inside the wheel should be 1.DL Mechanical LLC Heating, Cooling and Plumbing 732-266-5386

NJ Master HVACR Lic# 4630

Specializing in Steam Heating, Serving the residents of New Jersey

https://heatinghelp.com/find-a-contractor/detail/dl-mechanical-llc

https://m.facebook.com/DL-Mechanical-LLC-315309995326627/?ref=content_filter

I cannot force people to spend money, I can only suggest how to spend it wisely.......1 -

Looks like the gas linethat drops down to the water heater to me, with a Tee and a plug in it.0

-

I might have spotted the other end of the second main.

1916 two-family, now condo. Top floor. 970 sq. ft. of ‘well ventilated’ space. One-pipe, parallel flow, gas fired steam heat. 27’ of 2” main (un-insulated) vented via Gorton #2. 27’ 1 1/2” dry return (un-insulated) vented by Dole #5. 7 HB Smith Princess 2 col. radiators (38” tall) & 1 ARCo 30s era thin-tube 6 x 8 sec. (32” tall) = total radiator EDR 244. Using Maid-o-Mist radiator vents, sized by calc. & 14 winters tinkering. 1980 HB Smith G210-S-5 rated output 120,000 btu, poor near boiler piping.1 -

I think you are right @FinishGuy . If @MissButters can confirm that that pipe drops to the floor and runs over to a pipe that runs into the boiler, then that's where another vent needs to be installed.0

-

I am goin with @FinishGuy , I think there both parallel supply return and that tee drops to a wet return the one that runs behind the boiler.

Not a fan of "gastite"

But I am so excited

The installer did the header right!!!1 -

Looking at the original posted photo, I think the shadow of a vent is visible.

There is also this.

1916 two-family, now condo. Top floor. 970 sq. ft. of ‘well ventilated’ space. One-pipe, parallel flow, gas fired steam heat. 27’ of 2” main (un-insulated) vented via Gorton #2. 27’ 1 1/2” dry return (un-insulated) vented by Dole #5. 7 HB Smith Princess 2 col. radiators (38” tall) & 1 ARCo 30s era thin-tube 6 x 8 sec. (32” tall) = total radiator EDR 244. Using Maid-o-Mist radiator vents, sized by calc. & 14 winters tinkering. 1980 HB Smith G210-S-5 rated output 120,000 btu, poor near boiler piping.0 -

-

I hope @MissButters does return. It would be nice to hear how her travails are working out, but something else has caught my eye.

Miss, I am a finish carpenter by trade. I have done some framing though, mostly by way of working for others over the years. Something is amiss with the built-up beam in your photos and your basement.

I suspect the old carrying beam was strengthened by sistering a new piece of 2x lumber along its length on both sides, most likely nailed and lag bolts used, the heads of which can be seen.

The 2x on the flat, on the bottom, has moved down and away from this built-up beam. I am uncertain about what purpose it served. As currently constructed perhaps it was meant to prevent twisting of the new assembly? It never provided much in terms of weight bearing ability to the built-up beam.

The concern is that it might fall off. It looks to be a goodly length and therefore heavy and likely to hurt would it hit someone. It may have been like this for decades or maybe not.

Please have a carpenter look at this. If it is indeed an integral part of the beam it can be jacked up and securely attached. Just not with nails going straight up and no adhesive.

1916 two-family, now condo. Top floor. 970 sq. ft. of ‘well ventilated’ space. One-pipe, parallel flow, gas fired steam heat. 27’ of 2” main (un-insulated) vented via Gorton #2. 27’ 1 1/2” dry return (un-insulated) vented by Dole #5. 7 HB Smith Princess 2 col. radiators (38” tall) & 1 ARCo 30s era thin-tube 6 x 8 sec. (32” tall) = total radiator EDR 244. Using Maid-o-Mist radiator vents, sized by calc. & 14 winters tinkering. 1980 HB Smith G210-S-5 rated output 120,000 btu, poor near boiler piping.0 -

@FinishGuy , it actually looks like the flat board is, it actually looks like the flat board, on the bottom may be securely nailed to the old timbers and that they may have sistered new 2X6's along side maybe 2X8's. Not sure why they even bothered with the flat board on the bottom, unless they were trying to hide some termite damage or other damage.0

-

So, I did go and verify that it looks like it is two parallel flows, and the pipe does drop to the floor behind the furnace. Are we missing a vent on what is labeled Main B? We did put a bigger vent on Main A. Would not having a vent on Main B cause the convectors that it goes to first make large hissing noises?FinishGuy said:I might have spotted the other end of the second main.

Thanks!

0 -

Missing or inadequate main vents will make the radiator vents hiss, and make the system unbalanced, with some radiators getting steam long before others.

It’s not enough to have a small vent on each, and think you are done, as you will be burning extra fuel to squeeeeeze the air out of constipated little openings.

Put a low pressure gauge on, and add vents until the air escapes at less that 2 ounces, as steam begins to rise.—NBC0 -

You all know I hate to make a counterpoint haha but I daresay the Gorton #1 is big enough in this situation as it is.

This is because with uninsulated main pipes, the steam does not move fast on cycle start. It has to heat the pipes and it condenses as it goes making for a very slow advance.

I’ve been monitoring my uninsulated main with my hand and monitoring my Gorton #1’s performance during many heating cycles over the last 2 heating seasons. The only time I can even feel more than a whisper of airflow from the vent is when the steam is progressing down the last 7 feet of 1-1/4 pipe between the last radiator takeoff and the vent. That is 5 seconds out of the 7-8 minutes it takes from first steam generation to steam hitting the vent.

I hope to require more venting when I finally install my insulation.

Back to this case, definitely vent the unvented main but don’t panic about the existing vent until/if/when the main is insulated. My 2¢NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

-

It looks like she got up and posted at quarter to eight this morning. ¯\_(ツ)_/¯Fred said:This is a two year old post. Not sure MissButters is listening anymore.

Just another DIYer | King of Prussia, PA

Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-242 -

Wow, @Hap_Hazzard , you are right!0

-

It happens.Fred said:Wow, @Hap_Hazzard , you are right!

Just another DIYer | King of Prussia, PA

Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-240 -

Autumn brings people to Strictly Steam!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el2 -

We put a Gorton #1 (cause that's what we have at the moment) on the Main B vent that seemed to be missing. I'm curious if it is going to help some of the convectors not hiss as much and if it helps one of our radiators towards the end of the line get warm. Thanks everyone!0

-

It will definitely be better than no vent. Did you lower your pressuretrol to .5 psi as suggested earlier? That will reduce hissing and save wasted fuel too

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I would add a Barnes and Jones Big Mouth to each main. They are the same price as one Gorton No.2 and vent almost three times as fast. The more main venting you have the less you will hear the radiator vents. Just put them on a 10 to 12" nipple if possible since having any vent on the drop down 90 is not ideal.

They should be installed at least 18" before the drop.

Have you insulated your mains? That will also make a huge difference in steam distribution.0 -

Unfortunately, I don't think we have the clearance to put them up 10-12", but I'll check when I get home. We have not lowered the pressuretrol to .5 (silly question - is that the slide switch)? I think one of the mains is insulated, but the other is not. Lastly, would not venting the main enough cause one radiator at the end of the line to not get completely hot? We noticed our office on the side off Main B is cool and the radiator only has the first half of the sections get warm. Thanks again!0

-

@MissButters , I'm with @ethicalpaul on this one. Not that there is such a thing as overventing a system -- there really isn't -- but there is such a thing as enough venting, and in my humble opinion you are just fine with that #1 on that main (Cedric, the dragon in the main place I care for, is vented with 1 Gorton #2 and a Hoffman #76 -- for almost 200 feet of 3 inch main. And it's ample). As several have mentioned, though, insulation of the mains is really important.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Thanks again. For the insulation, do we start insulating the mains starting at the vertical pipe off the header, or wait till the next horizontal pipe?0

-

It's not a slide switch, it's just an indicator. You move it up and down with the screw at the top of the device. But you, or whoever is doing it should have some sense of what they are doing. There is also a dial inside the device that should be checked.MissButters said:We have not lowered the pressuretrol to .5 (silly question - is that the slide switch)?

You or whoever does this should have some sense of electricity and general "handiness". You should get the book "we've got steam heat" from this site's store if you want to learn, and you can learn a lot from this forum, but there is a lot of information coming at you so it can be a little overwhelming.NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Everything that carries steam, except radiator runouts in living spaces (or hidden in walls!).MissButters said:Thanks again. For the insulation, do we start insulating the mains starting at the vertical pipe off the header, or wait till the next horizontal pipe?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Thanks! Book has been ordered through this site!ethicalpaul said:

It's not a slide switch, it's just an indicator. You move it up and down with the screw at the top of the device. But you, or whoever is doing it should have some sense of what they are doing. There is also a dial inside the device that should be checked.MissButters said:We have not lowered the pressuretrol to .5 (silly question - is that the slide switch)?

You or whoever does this should have some sense of electricity and general "handiness". You should get the book "we've got steam heat" from this site's store if you want to learn, and you can learn a lot from this forum, but there is a lot of information coming at you so it can be a little overwhelming.0 -

If you were lucky enough to have a two-pipe system you could have relatively small main vents, because the venting is serial; whereas a parallel flow one-pipe system is vented in parallel with the radiator vents, and so needs more capacity.

Putting more main venting on will reduce the hissing of the radiator vents, and make sure all radiators receive steam at the same time.

One Gorton #2 is good for 20 feet of 2 inch main.

Having a low pressure, verified by a gauge calibrated in ounces will help as well.—NBC1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements