In-floor radiant heat constant circulation issues

I currently have an old Burnham boiler running off of an on-board aquastat (Low fire on 140, cut off 165, climbs to 175). Primary circulator (Taco 007) runs full time. Radiant zone is piped as a secondary circuit connected with 4 way mixing valve and a Tekmar 360. The secondary circulator runs full time and is an Grundfos Alpha 15-55F. The Tekmar outdoor reset (for the mixing valve) is configured with values from LoopCAD where I did as close to a heat loss analysis as possible.

Indoor temp desired: 70

Outdoor temp: 10

Water temp required: 160

T-T jumped and secondary circulator runs constantly

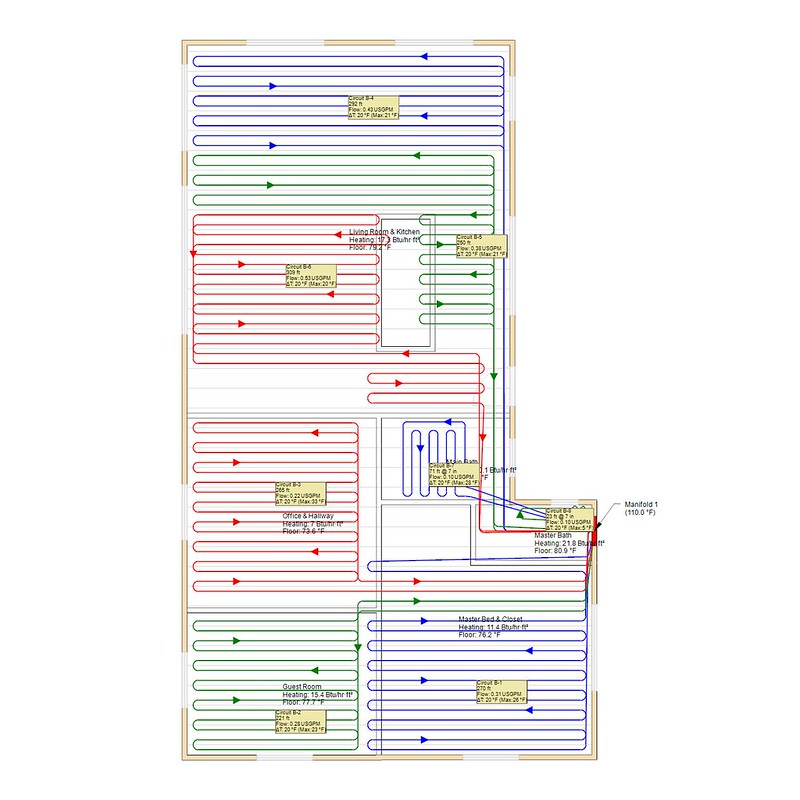

I have the indoor feedback sensor for the Tekmar installed in my largest room with the most heat loss (most windows, 12' ceilings) which is located at the top of the below drawing.

My issue is I'm having a lot of trouble achieving an even 68-70 throughout the house utilizing just the flow control valves (Uponor EP manifold). Some days it seems I have it then instantly days later it changes drastically. What commonly happens is the bedrooms (three rooms at bottom of the drawing) overheat to 72-76 and the large great room (top of drawing) sits at 64-66.

I think this has to do with outdoor temperature change- the heat loss of that large room is ~3-4 BTU/HR more than the bedroom with the most heat loss. One thing to consider is the lower level of this home has no insulation at all. Additionally when I use the flow control / balancing valves on the Uponor EP manifold I can dial in the flow LoopCAD tells me to, but 45 minutes later I will find the loop's flow meter level at nearly 0 GPM. I have found more success last night opening the balancing valves all the way then using the caps on the isolation valves to control the flow. Not sure if this is a good method or not.

My theories:

1. The construction in the basement (70% above grade), lack of insulation and temperature swings are causing a slow responding system (suspended tube) to work even worse / harder to retain setpoint.

2. The inside temperature sensor being in the room with the most heat loss, but also the most sun exposure is providing incorrect feedback to my controls. I had the sensor in the middle of the house (hallway), but experienced the great room to get very cold at night.

3. I should have bought thick heat emitting "joist trak" plates so I don't have to run 120-130' water just to keep the house at temperature.

3. I'm considering buying parts to go with zone control instead of constat circulation. (Tekmar thermostats with floor sensors, Uponor actuators and a Tekmar zone controller). Is this a band aid or the correct solution?

Any advice is appreciated!

Comments

-

It will always be a challenge to run constant circ when your radiant floor design is not matched closely to the heat loss of the space.

Those manifold balancing valves can be frustrating. I have found that if some of the valves are too far open, you get some erratic behavior.

I would put the alpha on constant pressure 3 with all the valves open. Then close the valves one at a time to the point where the indicator starts to move. This will mean that the valve actually has some control over the flow. Then close the loops in the overheating rooms to the desired settings.

If some of the valves are wide open and some are throttled, the water will decide to take the easier path and stop flowing to one loop. The alpha in auto adapt mode can also do some undesirable things."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

"I choose to DIY remove my older in-wall radiators and install a suspended pipe radiant heat system a few months ago. The tubes are 1" from the subfloor and 2 per joist bay, 2" air gap, staple in reflective radiant barrier and R13 insulation in the joist cavity. I have 3/4" T&G subfloor with 3/4" hardwood on top of it."

Are you saying the tubes are hanging 1" below the sub floor? If so, there's your problem.

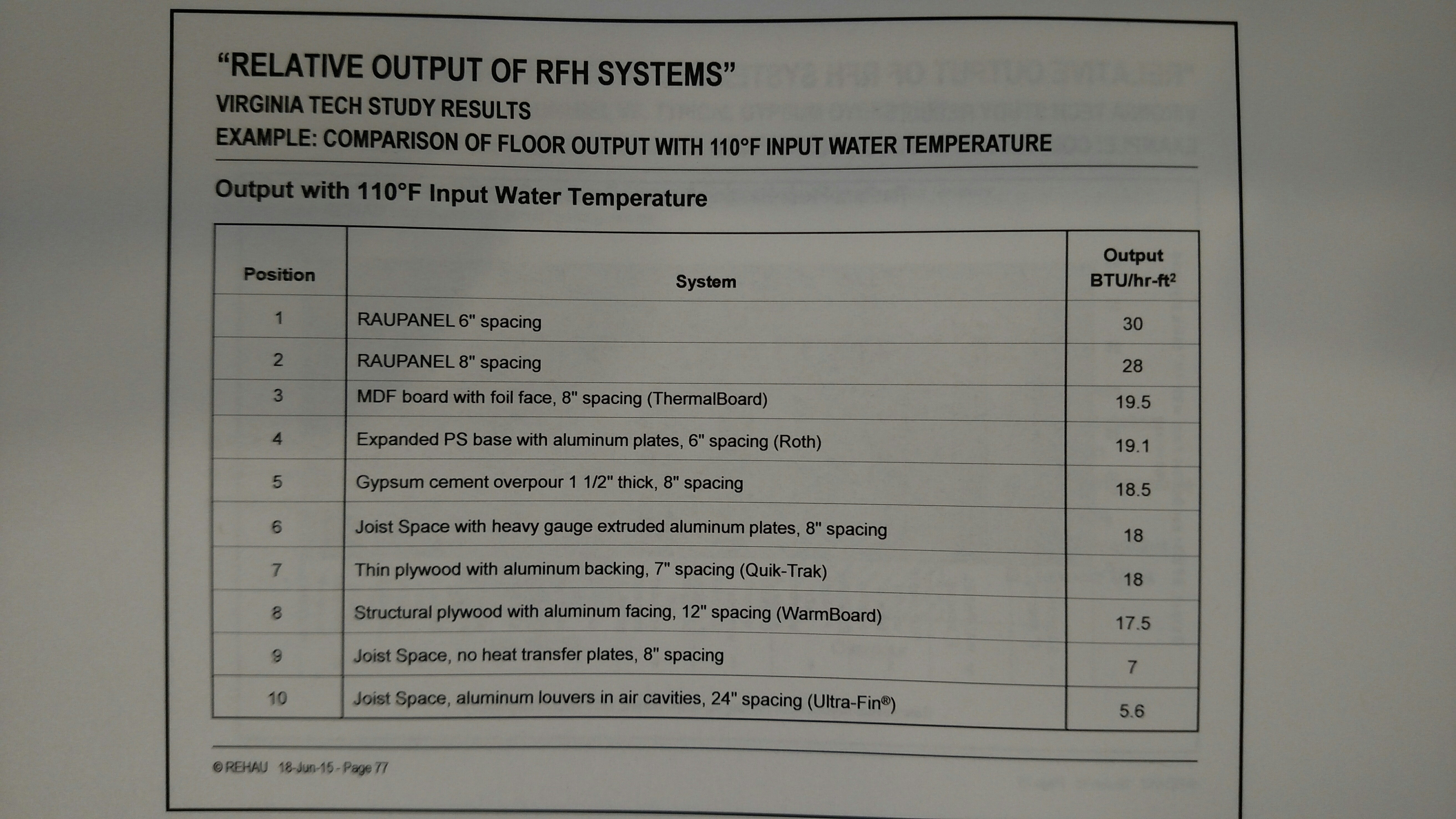

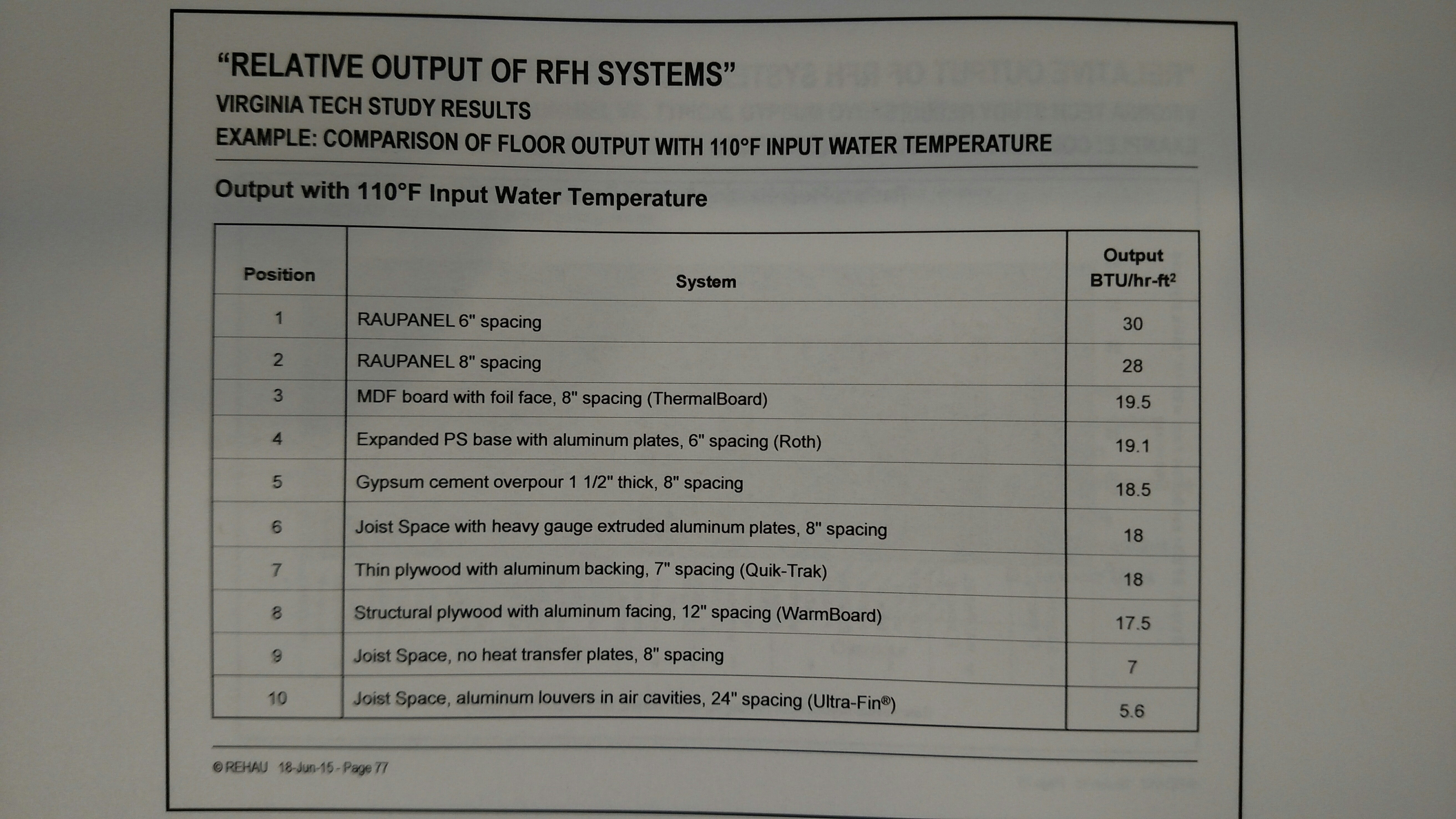

You should have used extruded aluminum heat transfer plates to conduct heat to the floor, not suspend the tubing below it. As it is now, you'll get about 7 btus per sq. ft. output from the floor - at best. That's nowhere near enough to heat your house in cold weather.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

Ironman said:

Are you saying the tubes are hanging 1" below the sub floor? If so, there's your problem.

You should have used extruded aluminum heat transfer plates to conduct heat to the floor, not suspend the tubing below it. As it is now, you'll get about 7 btus per sq. ft. output from the floor - at best. That's nowhere near enough to heat your house in cold weather.

Yes, I did suspend the tubes using Pex clips 1" from the subfloor. I have installed radiant heat like this with success in my parents 3000+ square foot home (with micro-zoning) and in a friends house.

I avoided the Extrude plates due to:

1. Lack of contact. I have flooring nails sticking out everywhere I had to hammer flat. I don't think the plates would make good contact with my subfloor.

2. Cost. At just over $2700 for plates I was willing to sacrifice some efficiency if I could still heat the home.

3. Noise. I was told plates will make noise especially if I zone each room off and the heat system becomes and on/off instead of a continuous circulation.

Am I wrong on the floor contact with nails? This is my biggest concern.

While fine tuning the valves I have noticed quite a bit of air in the system. Although I had no air in the system when I put it in service, I think the old taco air scoop might be letting air in instead of just letting it out- I will replace the valve and bleed the system again this weekend.0 -

No plates, no heat. Clipping the nails is part of the process to assure the proper transfer of heat from the pex. Budget issues considering the cost of the plates always seems to be part of the ongoing problems with plateless jobs. You can't ignore the laws of physics and heat transfer. Running the boiler and the loops at high temps simply won't work. Radiant software has been designed to eliminate the guesswork in all radiant applications, which has been discussed at great length on this site.2

-

Forget about the controls for now; your main issue is a lack of heat transfer from the tubing to the floor because there's nothing but air in between. Dead air space is a very poor conductor of heat. 'Radiant heat" does NOT mean that we are trying to radiate heat between the tubing and the floor; it means that the floor surface radiates heat to the structure. Every thing else is done by conduction. Conduction is by far the most effective means of heat transfer.

Not to be unkind, but please tell me what good it does to save $2700 if the system doesn't work?

You grind the nails off before installing the plates, not bend them over.

You've skipped one of the most crucial steps in the design and installation of radiant floors: heat transfer. No amount of control work will compensate for that. The only thing you can do short of installing the plates is crank the water temp up, but that will drastically lower your efficiency and also have other consequences.

I feel for you and wish you had come here first. Every pro on here would have told you to use extruded plates.

I'm gonna try and attach a summation chart from a study done by the engineering department at Va Tech which shows the output of various types of radiant floors. Pipes stapled directly to the sub floor give an output of 7 btus @ 110* SWT. Yours would be less because they're not contacting the floor.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

Cutting the nails and grinding them flush is worth the trouble to be able to use extruded plates. I did this when putting up radiant under the kitchen of my 1890 Victorian. It's a pain, but you don't have to cut every single nail - the plates are about 5" wide in a 15+" joist bay, so anything right in the center of the bay or within an inch of the joist can be left alone (except where the tubing exits the plates and loops around). You just need the surface that the tracks touch to be nail-free.0

-

Luckily I still have the ceiling open downstairs...

What are the best plates to purchase? Uponor's joist trak plates seem to be only 3.5" wide. It was my understanding wider is better for even distribution- are there plates that hold two pipes parallel?

$2-3k doesn't seem like much, but I just completed a very large renovation (gutted 75% of home and rebuilt all DIY) and I'm currently putting myself in debt to complete it. I know most projects go over budget, but I'm way over and I'm on the younger side too.

Thanks for the advice guys, I'll be looking into whatever plates are recommended.

I have trouble understanding the no plates, no heat concept when I have had heat on days where the weather is in the teens. My floors are 74-80' with an IR gun and I spent ~12 years of Long Island winters warm in my parents house with suspended tube. I know it isn't as efficient but someone has to admit that it does work.

Looking at my acurite sensors my house is currently:

Outside temp: 38.7

Great room: 69.9

Guest room: 68

Office: 67.6

Master Bed: 70.6

Unconditioned basement: 56.3

Unconditioned attached garage: 51.20 -

Could you recommend extrude plates to look into?

Luckily for me I still have the basement ceilings open- I would just have to take the insulation down and put it back up one room at a time.

The Uponor plates are only 3.5" wide and it's my understanding that wider plates = better heat distribution. These plates are also on sale at Supply House this weekend so without recommendations they might get by business.

I find it hard to understand how I have lived with a suspended tube system for ~12 years growing up and never once felt cold. Also my house is warm right now so suspended tube obviously provides heat someone must be able to admit that? I have seen days in the teens outside where I have had heat...

My sensors currently tell me:

Great room: 69.8

Master bed: 70.6

Guest room: 68.1

Office: 67.4

Basement: 56.1

Garage: 51.0

Both basement/garage are below home and are 100% unheated and uninstalled as I am still in construction.Zman said:

I would put the alpha on constant pressure 3 with all the valves open. Then close the valves one at a time to the point where the indicator starts to move. This will mean that the valve actually has some control over the flow. Then close the loops in the overheating rooms to the desired settings.

If some of the valves are wide open and some are throttled, the water will decide to take the easier path and stop flowing to one loop. The alpha in auto adapt mode can also do some undesirable things.

The above advice was very sound - thank you. I had the pump on constant 3, but I had 3 of the loops wide open. Following your procedure it seems I was able to re-balance the whole house last night.0 -

The problem is not that suspended tube will not work in the right scenario. It still has draw backs. One is higher water temps to do the same job as a plated install. Second is response time. Suspended tube depends on convection to heat the floor then the space. You are adding another step in the heat transfer process. In doing that it's a delayed response. Then over shoot.

Hopefully you did a good job with the insulation detail under the floor, and did it right. Particular attention to the rim joist area with insulation, and sealing. The rim joist can kill the output of any radiant floor. More so a suspended tube when it depends on convective heat transfer.1 -

You could add ultra fin to the suspended tube. This would lower water temps.0

-

The addition of ultra fin or plates in strategic locations may help your problem.

Ideally the design of the radiant assembly would vary by room depending on the heat loss of the space. This is especially critical if you are trying to do constant circulation."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

You're not the only one with air lock problems. After you repair your major problems you can research a hundred year old solution. Involves a well elevated expansion tank under vacuum.It's pressure difference rather than pressure that causes circulation.doooglasss said:Ironman said:

While fine tuning the valves I have noticed quite a bit of air in the system. Although I had no air in the system when I put it in service, I think the old taco air scoop might be letting air in instead of just letting it out- I will replace the valve and bleed the system again this weekend.0 -

Wait a second everyone, yes plates do add considerable effectiveness and lower water temps and everything that you all say they do.

But, that is not the problem here, @doooglasss has been heating the house but wants more control over the system. Right now its on constant circulation with an RTU in one room and some rooms are over heating and other are under heating.

Before dropping $3k on heat transfer components and all that does is make the water temp lower and the heat transfer faster, the end result will be the same. Just gonna do it more efficiently and faster but the end result will be rooms are going to be warmer or colder than desired.

Balancing on the manifolds have helped, but is not going to get you the desired results since your heat loads from room to room and floor to floor are wildly different.

My opinion is to add zoning, add thermostats. They don't need to be floor sensing but I do suggest that the be designed to work with radiant floors, i.e. low differential, pwm.....

I just saw some cool stuff from Uponor at the AHR show that can really help your situation out almost exactly. They have wireless thermostats, a controller, and actuators that can add the zoning you are looking for and self-balancing at the manifolds. I haven't seen it in action yet, but its capabilities sounds really cool.

Also, yes, the Alpha in the Auto mode is not doing anything for you and could be hurting. Since there is no change in pressure (no zone valves, no actuators), it may run too slow. My suggestion is to put it into the constant speed mode on High. When and if you do add zoning. then change it to constant pressure and let it do its thing.

There are places for plates and there are places for no plates, I have both in my house and it works just fine as long as the math works.

Dave H.

Dave Holdorf

Technical Training Manager - East

Taco, Inc

1 -

Dave thank you for the reply with a second opinion.

Actually, right after making my original post I ordered Tekmar 519 Thermostats w/ floor sensors, Uponor actuators and a Tekmar 306V zone controller. I realized if I was having trouble balancing now I was going to need some type of zone control once I install radiant walls in the lower level. I'm not sold on the plates, but I will be looking into them if controls don't level the house out.

I am very curious how you run plates with higher water temperatures? It's my understanding that if I run my high temp water through a floor with plates it will overheat my floor above the plates.

I ask because I have one large room that is causing my design temperature to be 20' F more than the rest of the home requires. I would be open to spot platting that room to provide more heat and strategically place the plates so I heat the places people will have their feet- kitchen, in front of couches, walkway, under table.

Update: Thank you for the Uponor link. This thing is affordable and looks to have a little more tech than a basic relay system. I called supply house and just changed my order.0 -

Here's the Va Tech study that scientifically shows the output you can get. Notice that with the tube stapled directly to the sub floor, you only get 7 btus per sq. ft. output. Most newer houses need about 20 - 24 btus per sq. ft. ; older ones can be above 30.

Do you know what the actual heat loss of your house is? Was a room X room heat loss calculation done before you undertook your project? That's the foundation for everything and no amount controls will compensate for lack of proper design.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.3 -

Here's the easiest and effective plate that I know of:

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

if the math was done, and applied to proper tube density in the design. You would not need all the fancy controls either......0

-

A plated system will use anywhere between 20 and 40 degree lower water temp than a staple up. So yes I agree with that chart above, but it also has one thing omitted to say that you can get more heat out of a staple up system, That chart only shows heat output using just a 110 F water temp. Water temp is not the limiting factor when it comes to RFH, its all about the surface temp not to exceed certain parameters; 80-82 for hardwood, 85-87 everywhere else

The heat loss and radiant design will determine what water temps are needed.

In my own home, I have a mix of both, but running the same temperature. I determined if I used plates in some rooms and staple up in others, it allowed me to use one water temp for ease of piping and distribution. My second floor is setup this way with a remote manifold and its own mixing valve on outdoor reset. However, the response times are quite different so the other requirement is zoning. I do not have a plated room on the same zone as a staple up, they need their own zone control.

Yes, I love what a plated system can do but if I plated everything, then I would have had a second manifold, a second mix valve and a heck of a harder time installing everything. My first floor is on another manifold with its own mix valve.

You can adjust the design with and without plates and try to get the water temps close to each other and understand the install and design parameters.

Dave H.Dave Holdorf

Technical Training Manager - East

Taco, Inc

1 -

@doooglasss,

Here's an article by one of the most respected knowledgeable men in our industry: John Siegenthaler. It deals with this very issue.

https://static.squarespace.com/static/50de4c94e4b0a05702aac0fb/t/511a6e48e4b0735b6626ef38/1360686664633/PlatelessInRadiantville.pdfBob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

I will also ask. Dave are you pushing btus through 1 1/2" of flooring?

What's your heat source? Is it a mod/con, or ci boiler?0 -

I have seen @Ironman post this several times. I like this chart it's an apples comparison of several radiant details at one water temp.Ironman said:Here's the Va Tech study that scientifically shows the output you can get. Notice that with the tube stapled directly to the sub floor, you only get 7 btus per sq. ft. output. Most newer houses need about 20 - 24 btus per sq. ft. ; older ones can be above 30.

Do you know what the actual heat loss of your house is? Was a room X room heat loss calculation done before you undertook your project? That's the foundation for everything and no amount controls will compensate for lack of proper design.

It shows how tube centers help increase output, and how plates increase output.

Naturally in all the panel details raising water temps increases output.

The op has a ci boiler. Even though it is not a mod/con using the lowest possible water temp to off set loads still saves energy.

To me a quick responding system is everything, and curbs the appetite for controlling it. The faster the btus get to the space which is the ultimate goal. The faster the space reaches setpoint.

Now about rooms that have varying loads. This can all be compensated for with tube density.

Sorry I'm all about keeping the system as simple as possible. It's been done for decades. It seems like the more bells, and whistles that hit the market the more people think they have to be used. I personally see them as band aids for bad design.

My old house had radiant ceilings, and floors through out. Some rooms had both. All imbedded in concrete, or plaster. Simple ci boiler with a taco paneltrol from the 50's. That systems supply water temp never exceeded 115 degrees at design which is -10. That system over the years has also seen -27 several times, and never had an issue with maintaining a 72 degree set point.

One thermostat, one pump. Amazing they could even pull it off back then with so little technology.............

2 -

@Gordy I believe simplicity in design was/is accomplished by good design. Back in pre-pex days of soft copper tubing radiant those guys didn't just throw it up and call it good. They installed it according to experience.

Also with most all things old, only the stuff that worked and stood the test of time is still around for us to marvel at. There are countless systems which were abandoned or supplemented with another emitter.

Radiant done right is the most even and comfortable. Controls are sometimes overused to compensate for not doing the homework upfront. Like the OP there is different heatloss in different areas, so tube spacing and plates/no plates can and should be used to compensate for that. Then there is not a need to split up zones. Match the emitters output to a constant water temp and the space will hest evenly.

This is only accomplished by a room by room heatloss upfront and designing the emitters for that particular heatloss of that space.

Pay now or pay 3x later and be uncomfortable inbetween.Serving Northern Maine HVAC & Controls. I burn wood, it smells good!2

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 19 Recall Announcements