New radiant system questions. 1 zone + domestic hot water... same temp or 2 temp system

http://www.radiantcompany.com/wp-content/uploads/opensolartie.jpg

any help/advice is appreciated. i cannot afford a prefab panel and have to do this myself

Comments

-

Two temps are needed to get the most performance out of your indirect. Radiant floors will need much lower temps.

Boiler type?0 -

If you don't have the Polaris yet, I'd recommend that you consider a mod/con instead.

But to answer your particular question: no you can't use the temp of the indirect, it will be too hot for the slab most, if not all of the time.

A slab is high mass which means it takes a long time to heat up and a long time to cool down. It's called the flywheel effect. You need a smart control that varies the slab water temp based on outdoor reset.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.2 -

-

bob, where can i look up "smart controll for radiant"? im just finding thermostats. im assuming you mean a controll box of some sortIronman said:If you don't have the Polaris yet, I'd recommend that you consider a mod/con instead.

You need a smart control that varies the slab water temp based on outdoor reset.

0 -

Tekmar's 356 or Taco iSeries valve.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

TYPICALLY, we don't wanna see concrete water temp go above 110*. That's NOT saying that's the water temp that you should use.

As I stated before, you need a smart control that will VARY the water temp based upon outdoor temp. It's called outdoor reset. You don't want the surface of the floor to get above 84* in a living area (except bathrooms).

In order to know what supply water temp is needed at design temperature, proper calculations are necessary. There's no pat answer. These calculations involve a heat loss for the structure; the amount of insulation; the size, length and spacing of the tubing; the square footage and thickness of the slab; the flow rate; and the R value of the floor covering.

From these the SWT is determined and the outdoor reset curve is plotted in the control.

There's a WHOLE lot more to doing radiant than just laying pipe in the floor. If PROPER design is not done and followed, then your gonna be another one that joins the chorus railing on radiant when the problem wasn't the radiant floor but the lack of proper design and installation.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.2 -

"TYPICALLY, we don't wanna see concrete water temp go above 110*. That's NOT saying that's the water temp that you should use." -- Ironman.

I have a radiant slab downstairs and an indirect-fired hot water heater. On warm days like today (outside temperatures above 50F), I put 80F water in the slab if the thermostat calls for heat. And that is enough.

Design day temperature is 14F around here. On such a day, I put 116F water into the slab. I rarely see the outside temperature go below 9F, but last year it went down to about 2F and I had to set the reset curve to go up to 130F if it gets down to 0F outside. The floor temperature is less than the water supply temperature, but I do not remember what it got to that day.

My indirect is supplied with 190F water when it calls for heat.

I also have baseboard upstairs with oversized baseboard units. The house originally had 3 feet of baseboard in each of two rooms, and they were always too cold. I now have 14 feet in each of the two rooms. I supply 120F to 150F water to these, depending on outside temperature.

The radiant zone takes 24 to 48 hours to recover from a temperature change, so I can forget about setbacks there. The baseboard zone does not recover from setbacks very well either because the outdoor reset delivers just enough heat to maintain the desired temperature, but not enough to recover. The controller does have a boost feature, and that helps somewhat, but I just run upstairs at a constant 68F all the time, and downstairs at 69F.

So I actually have three temperatures from my boiler (one temperature at a time) in a very small (1150 square foot) Cape Cod type house in New Jersey. Clever controller can manage that with one extra relay.

0 -

Guys, thanks for taking the time to explain all that. it helps me alot. do you know where i could get a piping diagram of a system like i need. 1 zone for heat and a second zone for DHW? since i am not a boiler guy i dont know which valve types go where.0

-

You need more than a diagram, you need proper design based upon an accurate heat loss calculation. THAT is the foundation for everything.

You can go to SlantFin and download their free heat loss app. If you put the correct info in, you'll get the correct calculation. Start there.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

-

You're welcome!

Please don't disregard the "study" I mentioned. Each system is a snowflake, no two are alike. The generic piping layouts are a starting point, & need to be tuned to your particular installation for the sake of efficiency & safety. However, with patience (& pictures!) the fine people here can give you advice & suggestions that will rival an expensive engineering survey.

0 -

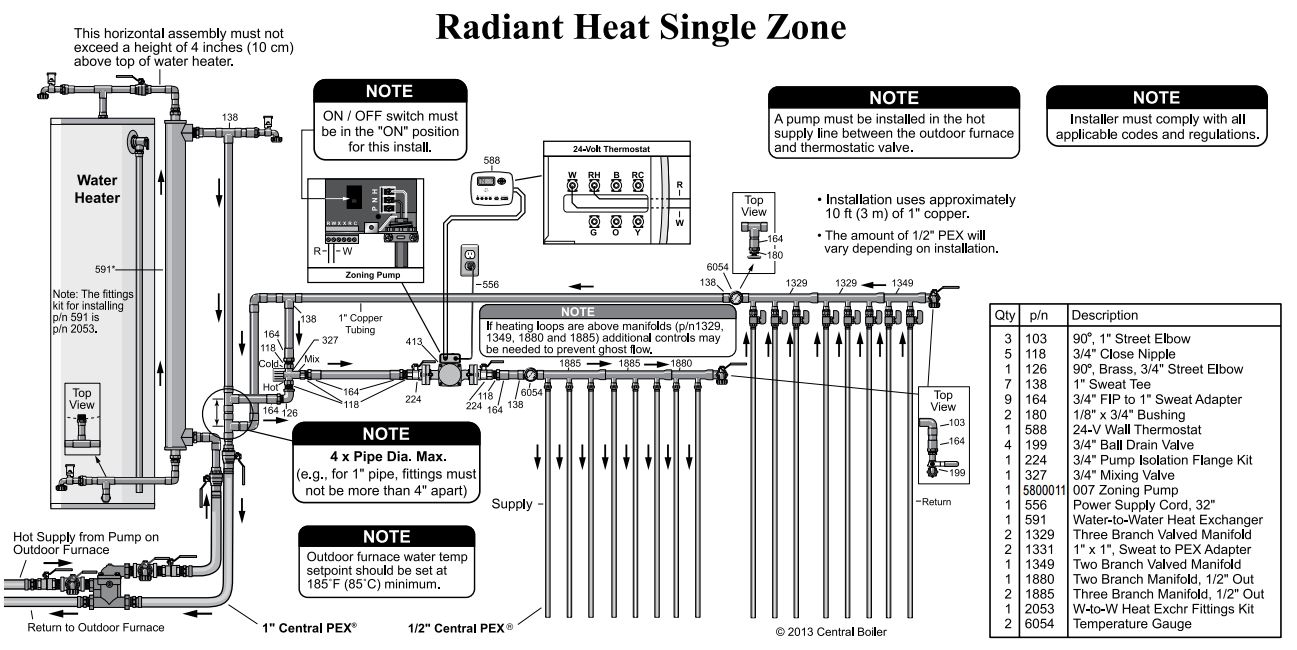

That Central boiler diagram is about worthless. It shows a radiant floor connected directly to an unpressurized outdoor wood boiler without proper means to control slab water temperature.

Please heed what I'm trying to relate to you: you don't need a diagram at this point. You need to know what the actual heat loss of the structure is before doing anything else. This is the starting point, not a diagram. From this, everything else is determined: the output of the floor; the pipe sizing and layout; the circulator size; the controls to be employed, the size and type of the boiler. If solar is used, how many panels and what percentage they can contribute to domestic and space heating. Everything designed into the system is based upon a heat loss calculation.

As Ratio said, no two systems are exactly alike. There's no generic, simplified way to approach this if you want the system to turn out right.

If you'll do the heat loss calc and post the numbers here, then we can begin to give you some specific design criteria.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

Ironman said:

That Central boiler diagram is about worthless. It shows a radiant floor connected directly to an unpressurized outdoor wood boiler without proper means to control slab water temperature.

Please heed what I'm trying to relate to you: you don't need a diagram at this point. You need to know what the actual heat loss of the structure is before doing anything else. This is the starting point, not a diagram. From this, everything else is determined: the output of the floor; the pipe sizing and layout; the circulator size; the controls to be employed, the size and type of the boiler. If solar is used, how many panels and what percentage they can contribute to domestic and space heating. Everything designed into the system is based upon a heat loss calculation.

As Ratio said, no two systems are exactly alike. There's no generic, simplified way to approach this if you want the system to turn out right.

If you'll do the heat loss calc and post the numbers here, then we can begin to give you some specific design criteria.</blockquot

It does show a 3 way thermostatic mixer, for the radiant, and what is that device under the water heater, is that some sort of HX to isolate the open boiler from the house side?Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Hot Rod,

Yes, I saw the thermostatic mixing valve, but I'd hardly consider that the correct mixing device for a slab.

The pex is non barrier. The radiant side shows no fill valve, expansion tank or relief valve. So, I can't see how it could be pressurized. I don't know what the device is in the lines coming from the ODWB, but since there's no circ between it and the side arm, I think we would be safe assuming it's not a heat exchanger that's isolating the ODWB from the house. That means the drawing is showing the radiant floor directly connected to the unpressurized ODWB.

Unless you see something that I'm missing, that makes the drawing useless.

This is not the first time I've seen that drawing, but my opinion of it has always been the same.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

That thing in the lines from the ODWB seems to be some kind of thermostatic valve. The notes call for a pump at the ODWB, & the thing beside the water heater is a heat exchanger, it seems the intent of the water heater is supplemental heat? No sign of make up water to the water heater, nor provisions for any kind of thermal expansion. At least the T&P valve is shown, that may keep it from exploding.0

-

ratio, that's a side arm heat exchanger so the ODWB can heat the domestic water.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Is it? I didn't see any obvious attachments to the domestic water indicated. At first, I thought those things at the inlet & outlet were air vents, but maybe they're a side view of a ball style boiler valve?0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 52 Job Opportunities

- 19 Recall Announcements