Memes

I forgot about them until this morning. The first one is one of my favorites.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

Comments

-

-

Chris those radiators are piped incorrectly, there are no runouts or swingjoints lol...................DL Mechanical LLC Heating, Cooling and Plumbing 732-266-5386

NJ Master HVACR Lic# 4630

Specializing in Steam Heating, Serving the residents of New Jersey

https://heatinghelp.com/find-a-contractor/detail/dl-mechanical-llc

https://m.facebook.com/DL-Mechanical-LLC-315309995326627/?ref=content_filter

I cannot force people to spend money, I can only suggest how to spend it wisely.......2 -

-

Speaking of, I wish I could find a superheat spec on a flooded evaporator. Seems like it doesn't matter as the headers in built into the evaporator are expected to handle that.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Don't all flooded evaporators have accumulators, different conditions could have some serious liquid refrigerant flow back to the compressor, and that would be bad............. I assume a standard SH chart will suffice.ChrisJ said:Speaking of, I wish I could find a superheat spec on a flooded evaporator. Seems like it doesn't matter as the headers in built into the evaporator are expected to handle that.

DL Mechanical LLC Heating, Cooling and Plumbing 732-266-5386

NJ Master HVACR Lic# 4630

Specializing in Steam Heating, Serving the residents of New Jersey

https://heatinghelp.com/find-a-contractor/detail/dl-mechanical-llc

https://m.facebook.com/DL-Mechanical-LLC-315309995326627/?ref=content_filter

I cannot force people to spend money, I can only suggest how to spend it wisely.......0 -

Mine originally had a high side float and headers built into the evaporator

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-

-

Yah, I had a few cases where the head reached 600 psi then the comp cut out. Bad txv, bad indoor fan etc0

-

That's insane.

No highside pressure switch or is that what the switches are set to?Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

600 is the high pressure cut out. 120 lo/325 hi would be a typical snapshot average conditions0

-

-

The sink one isn't mine but is good enough to share. I think I've posted at least one of these here before but can't remember.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

9 -

-

-

-

410 may be operating at a higher pressure differential but it also has higher enthalpy. Does more work on per mass flow rate.0

-

Pardon my ignorance, what is a snubber?0

-

Basically a restrictor that stops gauges from responding as fast to pressure change.makinsteam said:Pardon my ignorance, what is a snubber?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

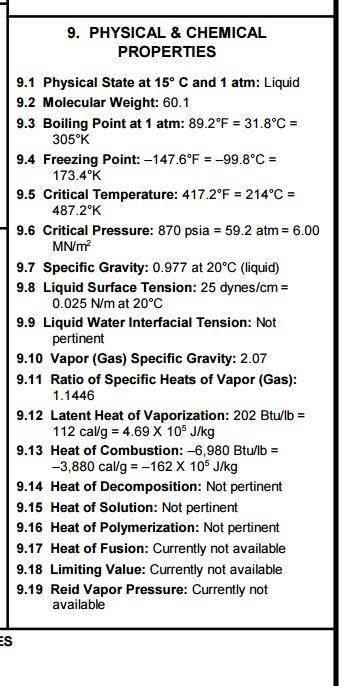

Here are the specifications on methyl formate, the refrigerant my 1933-34 refrigerators use.Harvey Ramer said:410 may be operating at a higher pressure differential but it also has higher enthalpy. Does more work on per mass flow rate.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-

Chris, I think I need this. My Gauge fluctuates with the waterlevel. Do you have a link to any further info?ChrisJ said:

Basically a restrictor that stops gauges from responding as fast to pressure change.makinsteam said:Pardon my ignorance, what is a snubber?

p.s. In case you haven't gathered, you are becoming my heating rolemodel. lol.1 -

Harvey,Harvey Ramer said:Chris

You should find an enthalpy chart for this refrigerant and plot your actual system performance to the chart. It would be interesting to compare to a modern refrigerator on 134.

Did I do my math right? I came up with methyl formate having 17 times the enthalpy as R410A?

As far as I am aware right now, methyl formate's benefits are it is not a greenhouse gas and does not deplete the ozone. It's also a fantastic refrigerant.

It's downsides are it's very flammable, slightly toxic and breaks down rapidly when it comes in contact with moisture. It also breaks down when exposed to high temperatures over time. This is why these machines may need to be burped of non-condensibles from time to time.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Thanks.makinsteam said:

Chris, I think I need this. My Gauge fluctuates with the waterlevel. Do you have a link to any further info?ChrisJ said:

Basically a restrictor that stops gauges from responding as fast to pressure change.makinsteam said:Pardon my ignorance, what is a snubber?

p.s. In case you haven't gathered, you are becoming my heating rolemodel. lol.

You may need to wait until I try mine as I just guessed at the size. If you go to Mcmaster.com and search for snubbers they come up. The number I went with is 3820K27 and 0.015" size, but I don't know if that's small enough or not yet.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

You may need to wait until I try mine as I just guessed at the size. If you go to Mcmaster.com and search for snubbers they come up. The number I went with is 3820K27 and 0.015" size, but I don't know if that's small enough or not yet.

Ok, great. I'll wait for your feedback. I can get McMaster items through work, so this is great info.0 -

Ok, great. I'll wait for your feedback. I can get McMaster items through work, so this is great info.makinsteam said:You may need to wait until I try mine as I just guessed at the size. If you go to Mcmaster.com and search for snubbers they come up. The number I went with is 3820K27 and 0.015" size, but I don't know if that's small enough or not yet.

Actually, what gauge are you using?

When I was using a 3 PSI Wika I never had a need for a snubber, especially with it isolated big a pigtail. Even my 16" Dwyer doesn't need a snubber. The needle vibrating or bouncing a little isn't a big deal in my opinion. The problem is with my 0 - 2" Magnehelic gauge. If it piped in directly without a pig tail and without a snubber it vibrates so fast you almost can't see the needle.

This is the best I have on youtube to show what I consider, appropriate gauge operation. This is with a 1/4" ball valve almost completely closed to slow the gauge down. https://youtu.be/hH36luC9GKU

https://youtu.be/hH36luC9GKU

This is what I mean by without a siphon. The 3 PSI Wika in this video is reading in the negative the entire time even though there is clearly a positive pressure. https://youtu.be/XEJ4JD6ojjg

https://youtu.be/XEJ4JD6ojjg Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

@ChrisJ, I think it's worth reposting one of your memes that struck me particularly funny.

Re: refrigerants, I'm a fan of R290 and R290/R600A blends. Never studied R611 before now. There's a lot to like about it.Terry T

steam; proportioned minitube; trapless; jet pump return; vac vent. New Yorker CGS30C

4 -

R611 is really nice in many ways including the fact you can literally pour it out of a glass jar into the system via a funnel.ttekushan said:@ChrisJ, I think it's worth reposting one of your memes that struck me particularly funny.

Re: refrigerants, I'm a fan of R290 and R290/R600A blends. Never studied R611 before now. There's a lot to like about it.

Thanks for resharing that, I forgot about that meme.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-

Well that's way before my time time I tryed looking some of it up. Not much came up, but the GE part.

I'm waiting to see how long 410a makes it.0 -

I don't know if you did or not. Very possible. I would compare the refrigerants on a pressure enthalpy chart. I am not familiar with Methyl Formate. I was talking more along the lines of the way people always flip out about the pressure differential on a 410 system compared to a 22 system without realizing that the 410 does more work per cycle. Not advocating for 410. Miserably high pressures.ChrisJ said:

Harvey,Harvey Ramer said:Chris

You should find an enthalpy chart for this refrigerant and plot your actual system performance to the chart. It would be interesting to compare to a modern refrigerator on 134.

Did I do my math right? I came up with methyl formate having 17 times the enthalpy as R410A?

As far as I am aware right now, methyl formate's benefits are it is not a greenhouse gas and does not deplete the ozone. It's also a fantastic refrigerant.

It's downsides are it's very flammable, slightly toxic and breaks down rapidly when it comes in contact with moisture. It also breaks down when exposed to high temperatures over time. This is why these machines may need to be burped of non-condensibles from time to time.0 -

People are scared of change I guess. Im not really sure how much more efficient 410 is over 22, but we are seeing a lot more scroll compressors and larger coils for efficiency.

We where just talking about this the other day at work. We are starting to see less and less semi hermetic compressors and more scrolls compressors.0 -

Ah I see.

What I found interesting is when Freon came out in the 1940s it was said to have a far lower latent heat of vaporization than other refrigerants like SO2 and this was seen as a benefit as it was easier to control. Many methyl formate units have destroyed float valve seats which seems to be from wire drawing.

I had to convert mine to a capillary tube as the float valve was really bad.

I remember when R134A first came out for cars everyone said how bad it was, and it was warmer than R12. I converted an R12 system that used a fixed orifice and cycled the compressor to R134A and swapped the low side switch to a lower pressure one which resulted in 36F vent temperatures.

I never had any complaints about R134A when it was used properly.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements