At last! Or... not quite!

Comments

-

-

Your story is really interesting @BobC and I'm glad you had the good sense not to flood water into a red-hot boiler. I suspect this is in fact what caused a good number of boiler explosions back in the day (and could still do so today in the case of a LWCO failure). In fact one of my "clients" called me with a case of a failed boiler that had resulted in that same "hot" smell that someone noticed—and we see a few people writing into this forum with similar situations. They all have Hartford Loops, and yet still their boilers dry-fired. No one ever seems to notice except for me. I try my very best to let it go, but sometimes I have trouble.

I never did see how just dry firing (without the introduction of water) could cause an explosion. A fire, possibly, but how does a dry firing boiler explode unless someone throws the makeup water valve open in a panic? And this is why I remain quite skeptical that it was the Hartford Loop that made some kind of dramatic reduction in boiler explosions. I just can't connect the dots. I have never heard anyone say they could connect the dots either, they just seem to take it as gospel that the Hartford Loop was the salvation of the problem.

You mentioned the Delco boiler didn't have a Hartford Loop. Would you see a different result in your story if it did have a Hartford Loop?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

If you had an oil fired boiler correctly sized you could install it with no LWCO, no Hartford, no pressure control and no burner primary control and no safety valve.

If nothing ever goes wrong it might run 100 years without an issue.

I have see steam boilers converted from coal that never had a lwco (don't know when they became mandatory)

I have also heard of a "technician" that removed an oil primary and ran the burner with no safety and nothing happened until another tech found it that way and corrected it. It ran that way for a year.

If the boiler is correctly sized you shouldn't need a pressure control either as it shouldn't build pressure so why need a safety valve?

But things do go wrong. Coal fired boilers had no LWCO or pressure control or thermostat or burner safety control. All they had was a safety valve and maybe a Hartford loop.

Many steam boiler don't have and don't need a Hartford loop if they have a boiler feed tank they are not required.

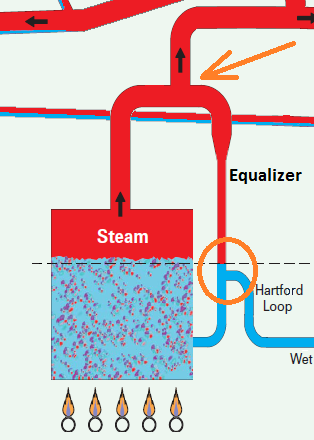

The most important reason for the equalizer and HL is to drain the header.

0 -

It's a shame steam heating systems haven't really been looked at or improved in what………80 years?

It sure would be nice to see some new boiler designs, new controls etc.

Wifi linked radiator vents etc. Improved vent quality………Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

1 -

Not enough market share. Those of us in the NE in boiler country (or what's left of it) don't realize that most of the country is gas warm air or heat pumps. The steam boiler market is a replacement market unless its process steam or high pressure etc. Residential steam is a fraction of the market that drops every year as systems get scrapped for warm air or heat pumps or converted to HW. Look at the boiler mfgs for residential steam:

HB Smith…gone

Slant Finn…gone

That leaves

Utica Dunkirk

Burnham and clones Force, Crown etc

Weil McLain/Williamson

Peerless even they are slipping into the Burnham thing.

1 -

That is the reason there is less innovation on steam boilers, oil burners and coal shovels. Less and less people are using them.

But if you want to get in on a real moneymaker…. I have this idea for a shoelace tip restoring machine. Don't you hate it when you have a shoelace that the tip falls off of? You can never get it to go through the lace hole in the wingtip shoes everybody was wearing in the 1950s. With a shoelace tip restoring machine in your very own home, you don't need to stop at Walmart on your way to the sock-hop dance to pick up a new set of shoelaces. Just pull out your tip restoring machine and your laces will work just like new ones. Everyone will want more than one in their home

I think this will take off and be a real hot item next Christmas. The gift for the man that has everything. I'm looking for investors, any takers?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

-

-

My laces break before the tips come off.

This reminded me of an old story. My boss at the oil company was loaded with $$$ but was cheap. I guess that why he was loaded.

We had a guy working there as an oil tech. He wasn't the best. There were 3 of us there at the time I was the oldest at 23 and the other two were 3 years younger. We all started at like $2.25/hour.

Because this guy wasn't so hot he hadn't had a raise in a while. One day he was walking past the owner's office to the shop out back.

Later the owner came to me and said "He has his work shoes taped together with duct tape, I guess I better give him a raise".

0 -

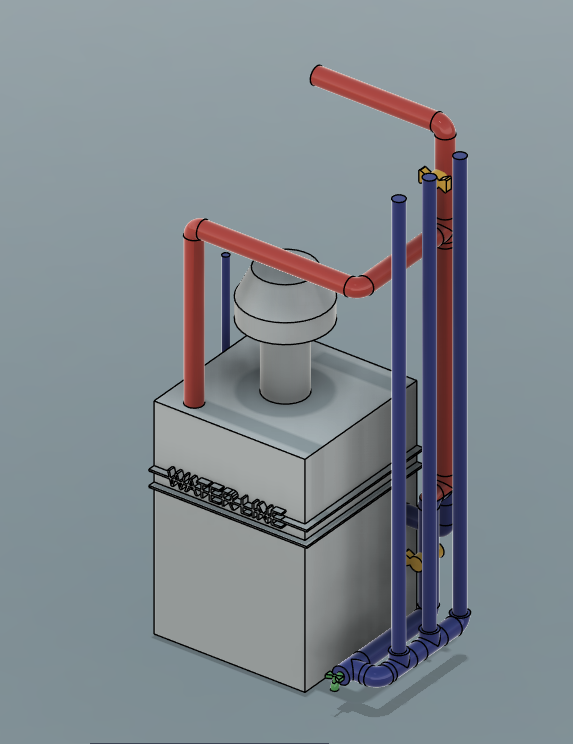

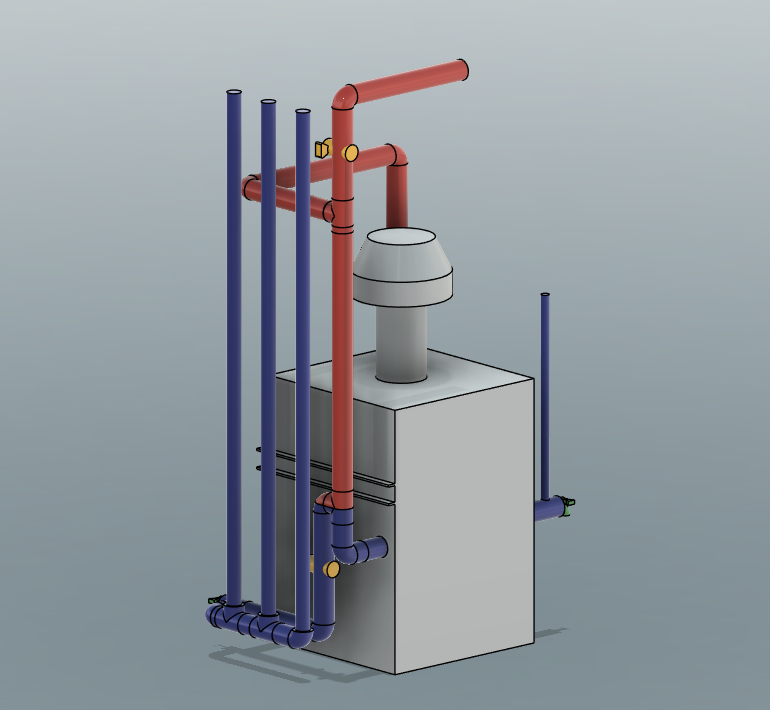

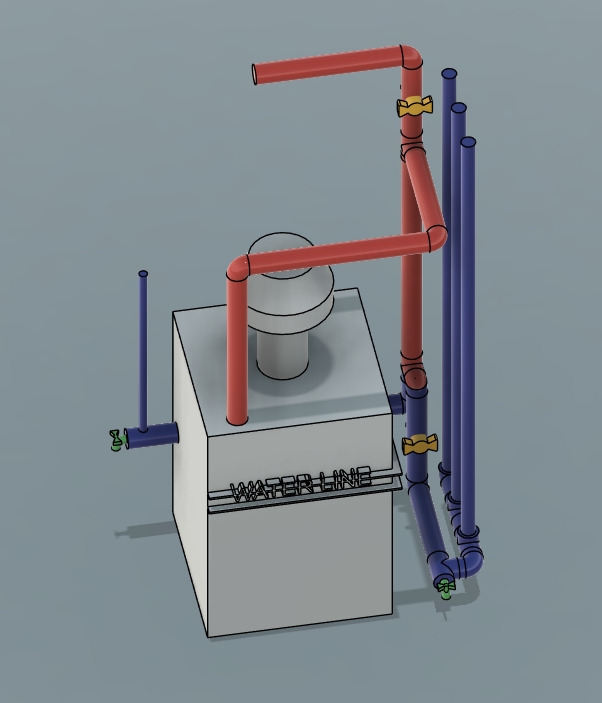

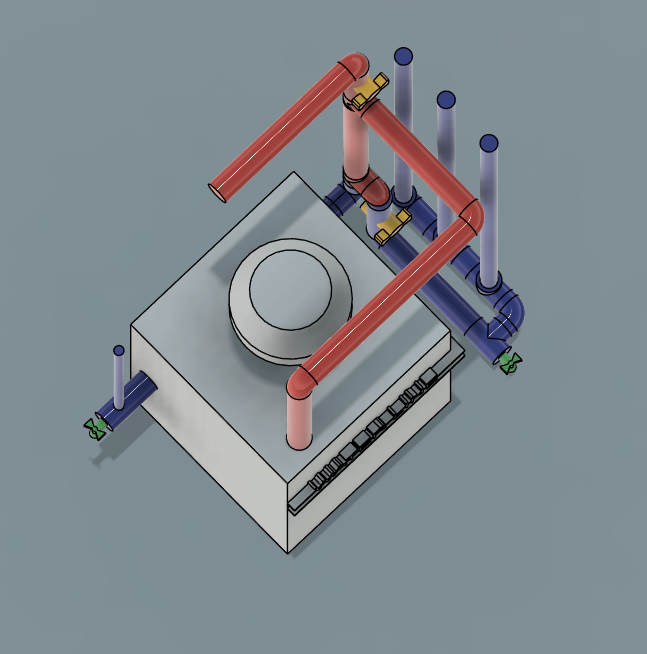

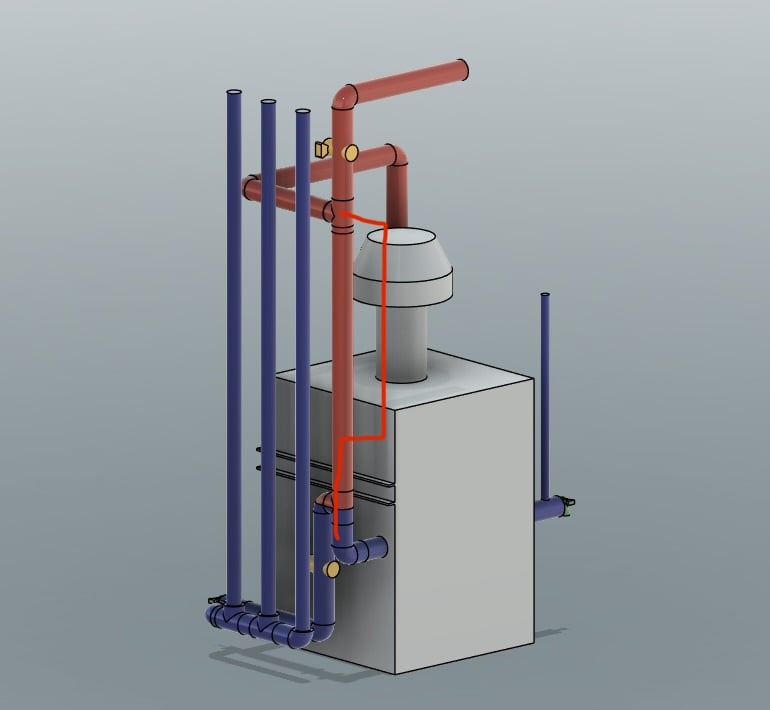

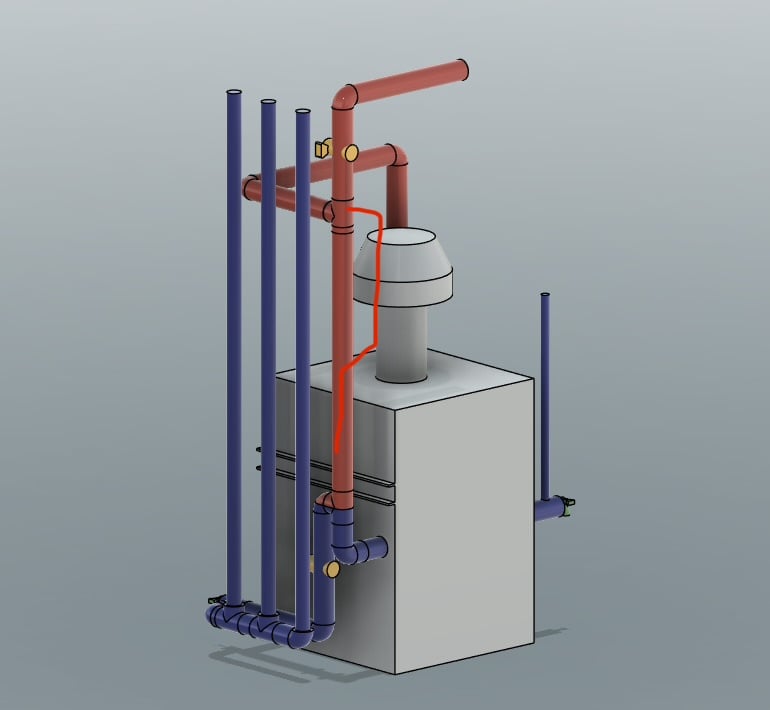

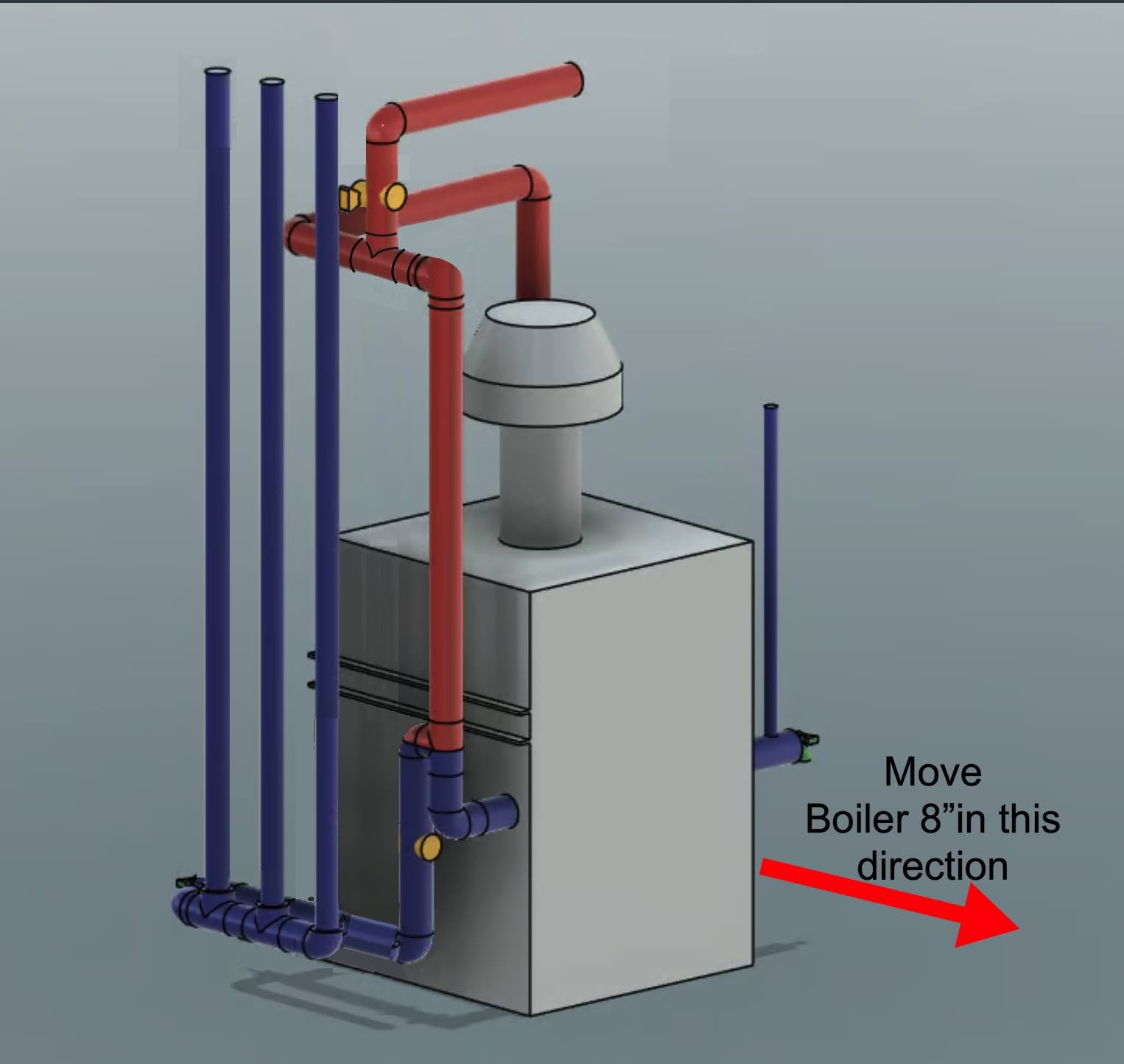

The technician and I teamed up to do a CAD of the next pipe rework. Thoughts?

Any issue with the tee in the equalizer pipe vertical position?:

0 -

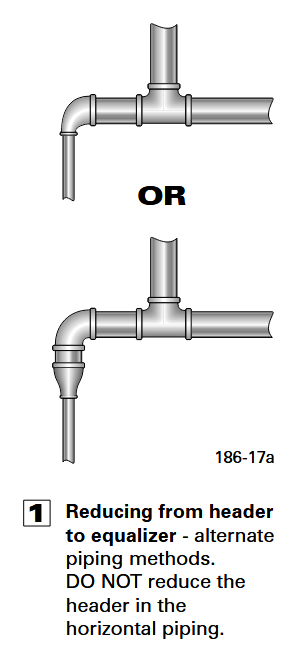

the header isn't right, the main should connect to a horizontal tee in the header then the end of the header should turn down to the equalizer. the horizontal tee where the main connects encourages any water to continue on to the equalizer. what you have now forces the water to turn when it hits the tee and it will tend to divide between the steam traveling up and gravity pulling it down to the equalizer.

0 -

-

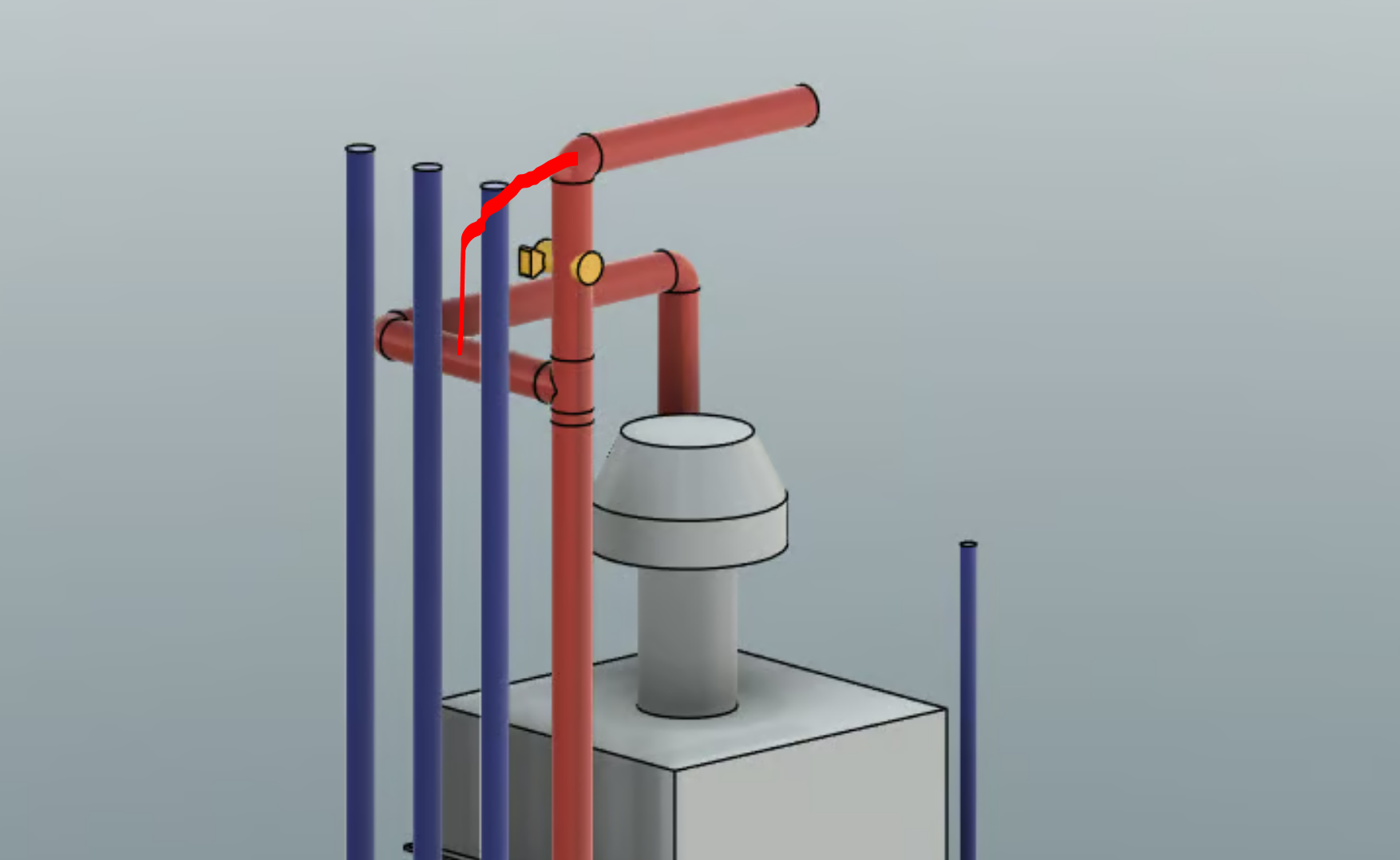

Could we come past the horizontal tee the into an elbow then down into other elbow to keep the placement of the exiting vertical in the picture:

0 -

you could if you make the offset in the equalizer with 45s so it doesn't have a horizontal section or you make sure the horizontal section has pitch and is above the water line. what would be better would be to use 2 45s and offset the riser to the main if you have the distance to do it. or 1 45 in the riser and turn the ell at the end of the main at a 45.

0 -

perhaps?

0 -

These are the issues I have with the CAD rendering.

Maybe the color change is not accurate.

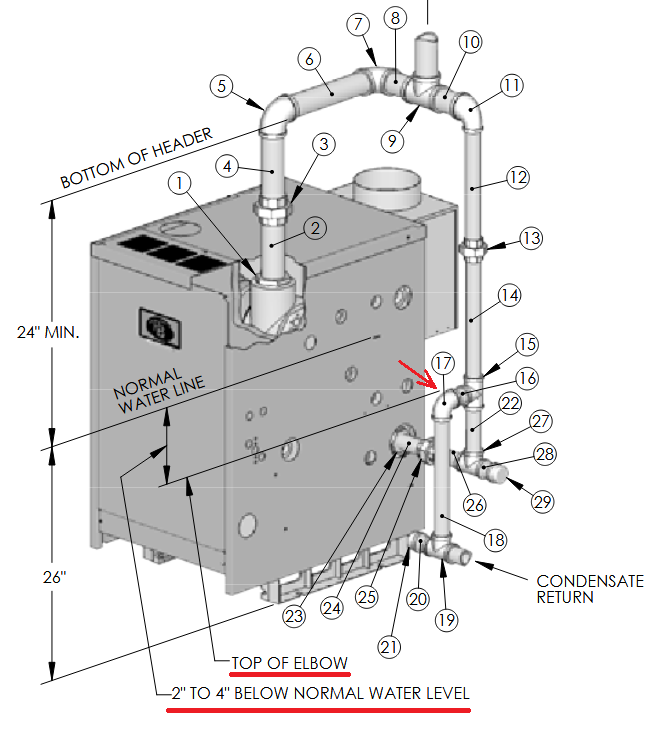

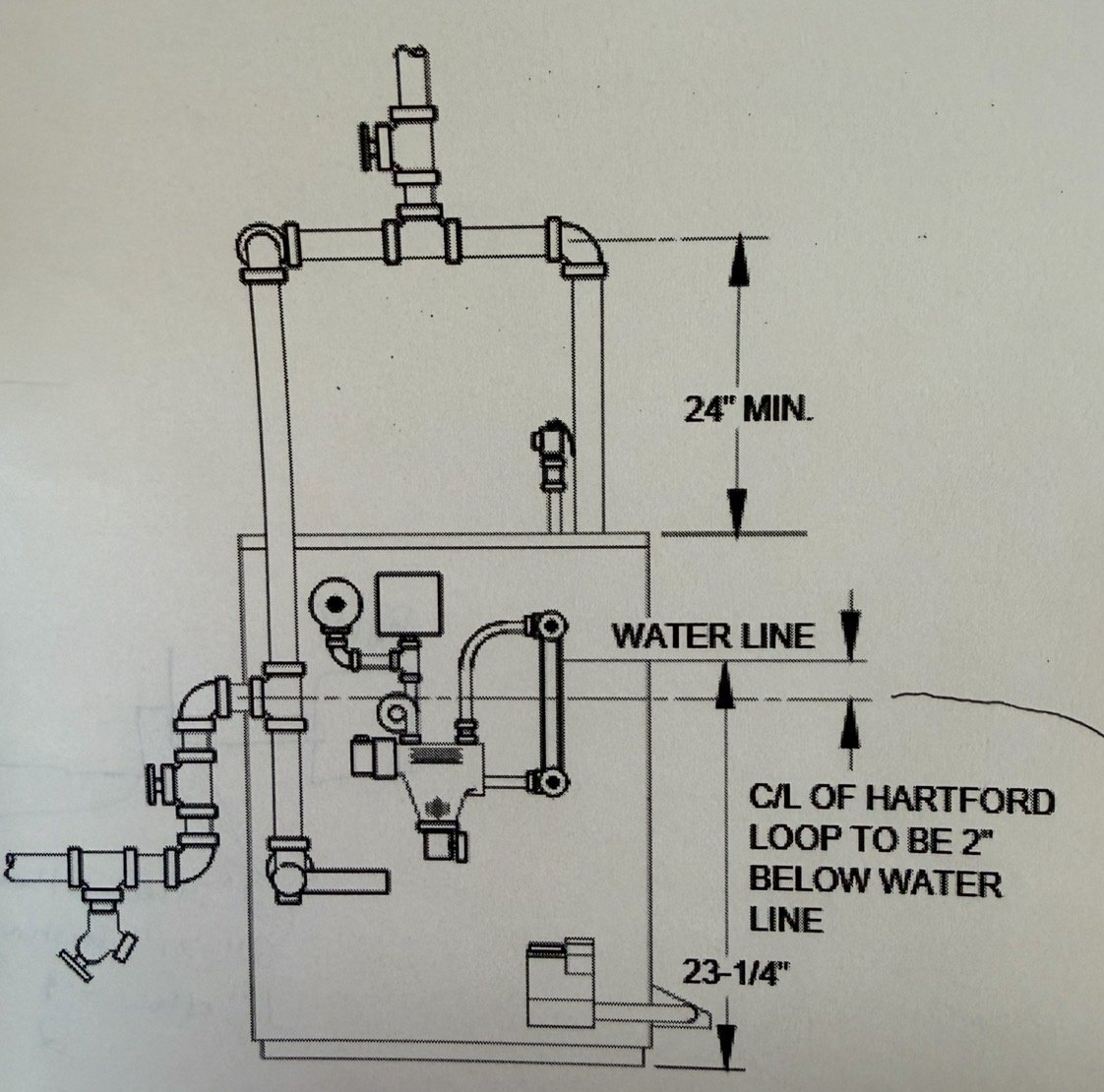

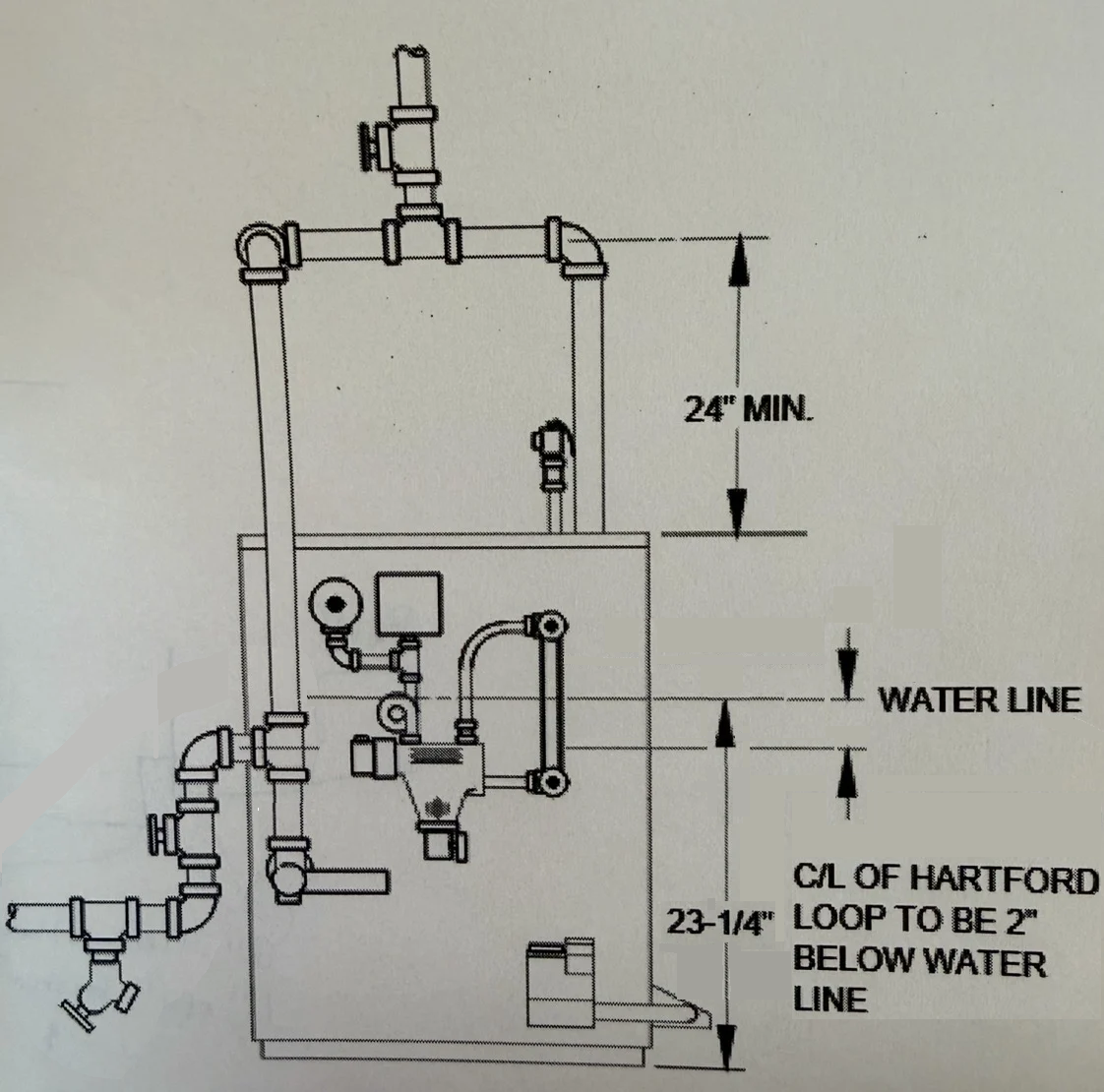

From a Weil McLain manual.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

-

Cannot move this direction without getting boiler too close to wall sadly.

0 -

It’s a color misplacement in the CAD, the elbow is positioned at 2 inches below water line to center of the elbow.

0 -

Looks to me if your are going to go with the pipe center it would be more than 2 inches. That 2 inches would be to the top of the pipe. I think the idea is the have that short horizontal section of pipe always submerged or full of water within the boiler's usable water level range. If steam can't get in there there won't be any water hammer.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

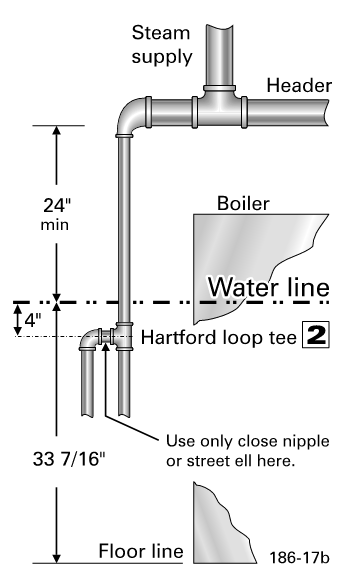

Interesting, we went from the HB Smith (manufacturer of this boiler) diagram:

0 -

OK, I can't fault you for that. Did you actually measure the 23-1/4" ? The water line in the boiler's drawing seems kind of high the way it is drawn.

I would have thought it would have been more like this.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

the model in the CAD is not to scale of this boiler as it’s taller. All measurements will be followed per the HB Smith diagrams and documents.

0 -

When people know how to pipe there is no need to 'line things up".

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements