At last! Or... not quite!

Today return piping at boiler was corrected and vents added to other steam leg and dry return:

Two hours of running the the system heats quickly, no water hammer and the pressuretrol is working correctly. The old piping had severe build up as pictured.

Still a few adjustments to make but the system is finally operating near correct. Many thanks for all the input and knowledge!

Comments

-

i would like to see an autopsy of whatever that is blocking the tee. it could be scale that came loose from somewhere but it kind of looks like a piece of sheetmetal or something that got in there or came loose from something somehow and got plated with rust.

0 -

-

Well I'm glad to hear it appears to work better. Probably not being clogged up may help.

However we clearly failed with the other thread !!! So I will try again. Since I'm not sure where it all went wrong.

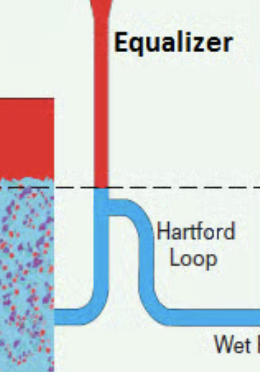

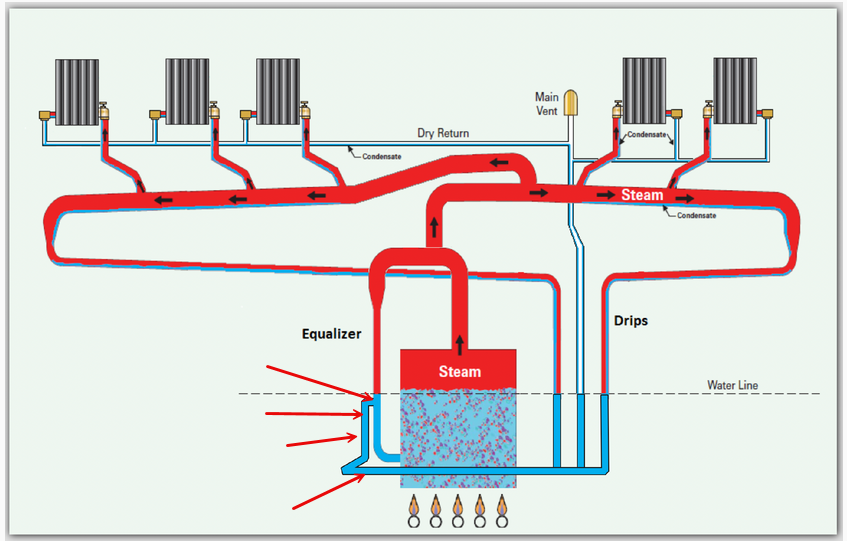

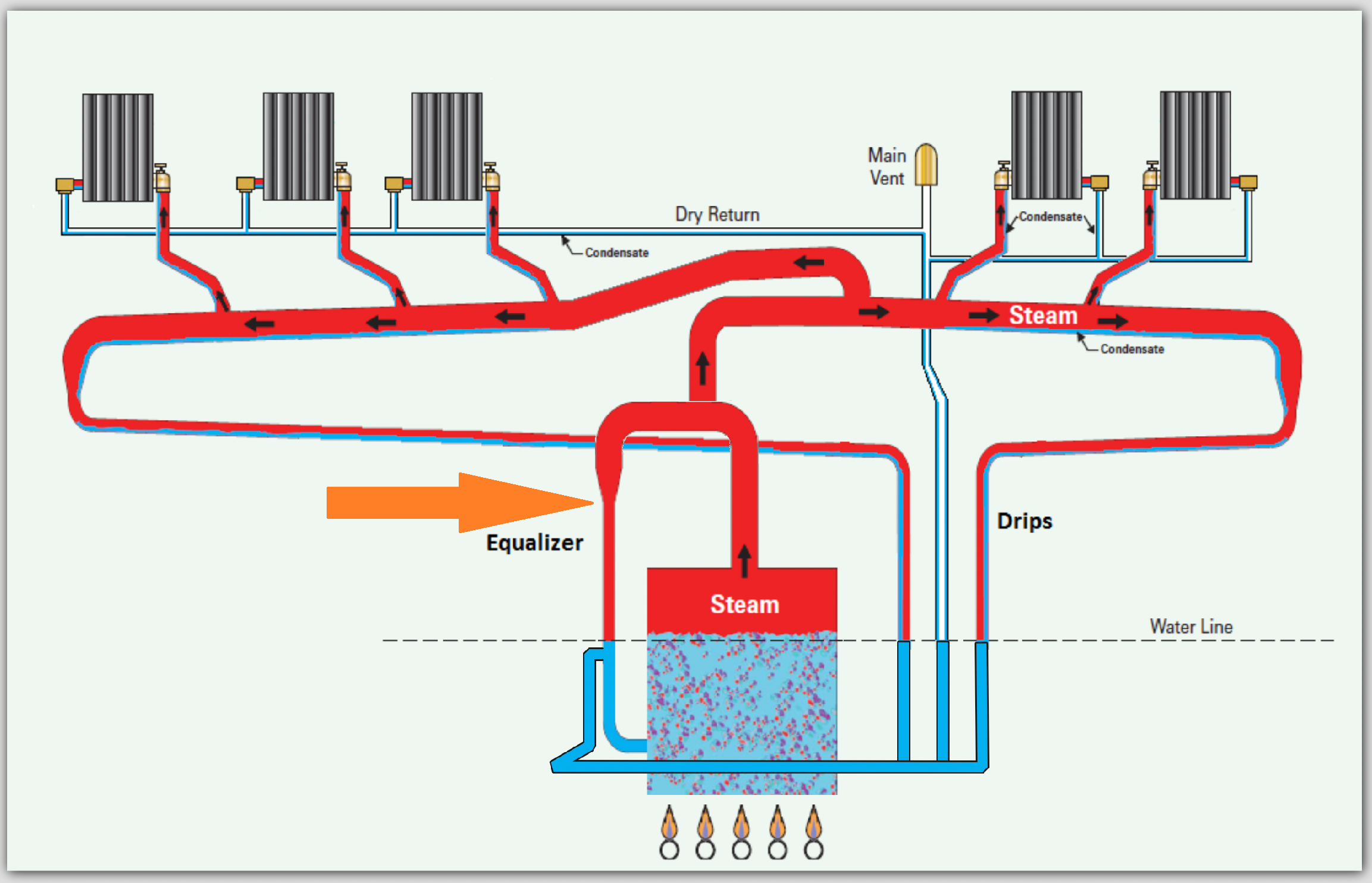

All three vertical pipes (Yellow arrows) should be Teed together at the level of the wet return which is at the level of the pipe at the Orange arrow, all Tees well below the water line. Also the (kind of) Hartford loop is kind of useless since it looks like the equalizer is not connected to it. So if there was a leak at the level of the Orange arrow there actually is no siphon break.

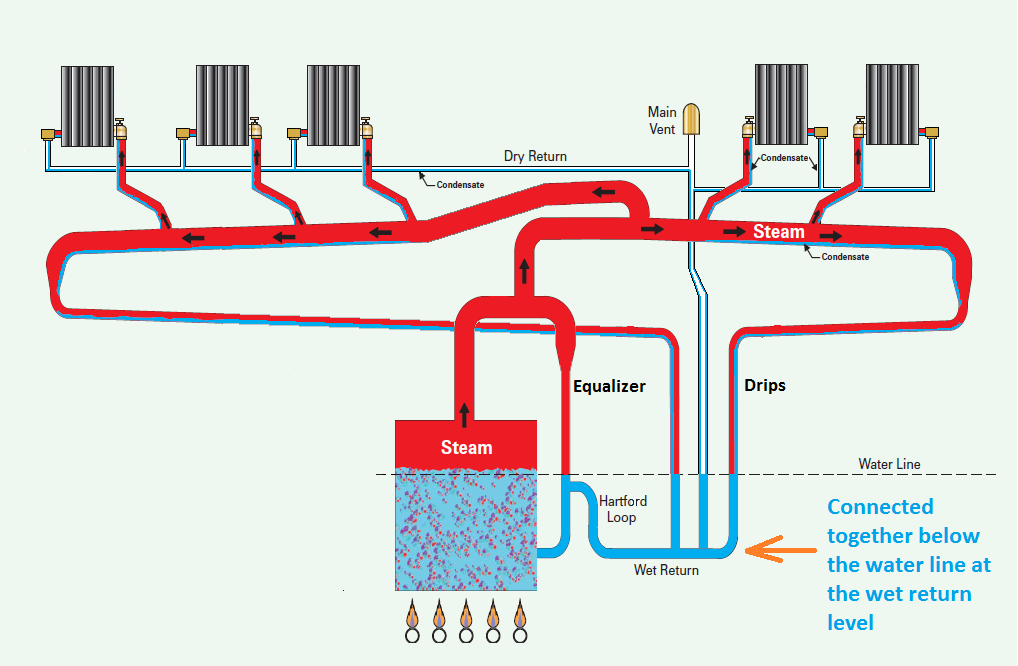

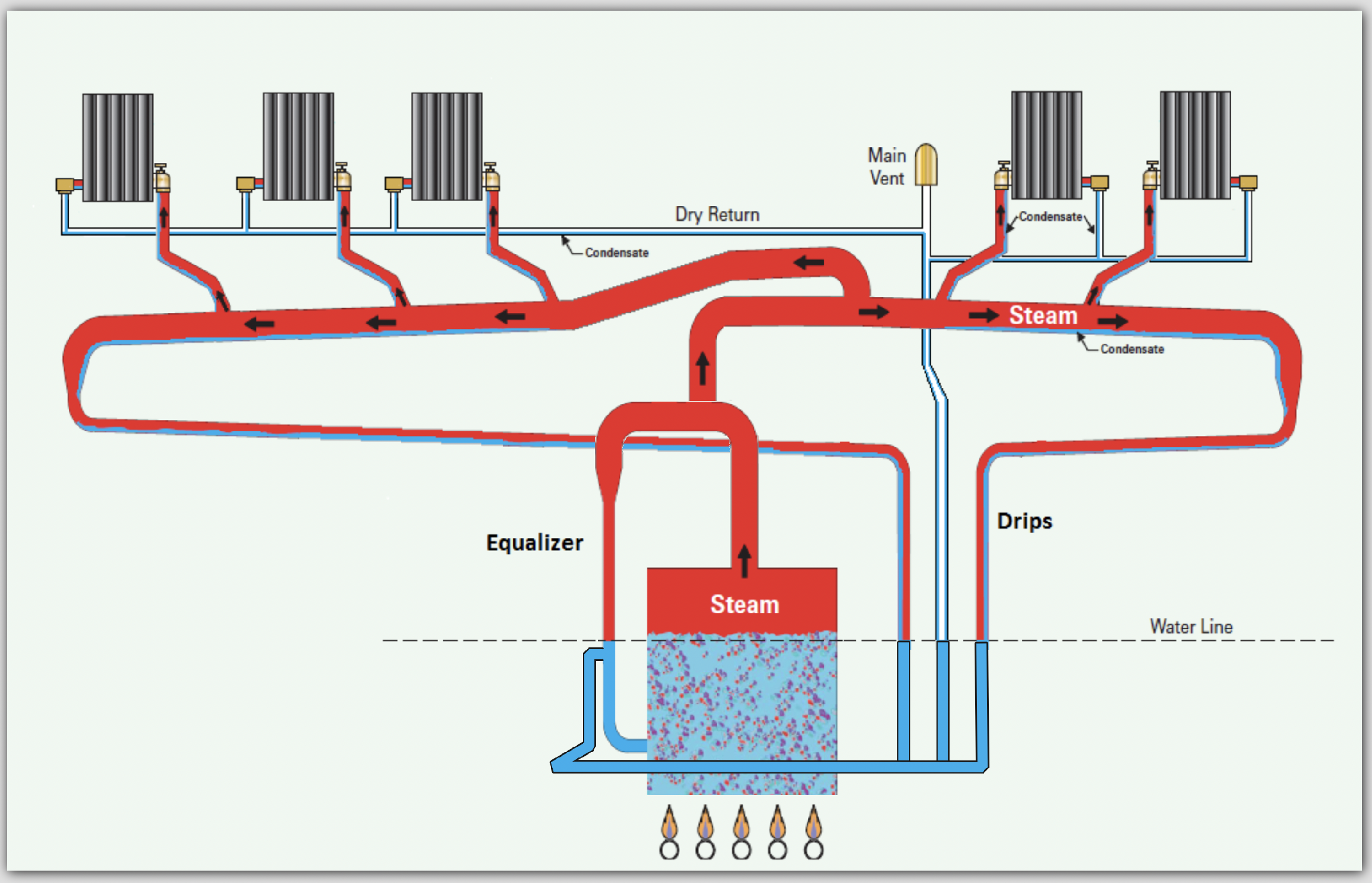

I thought I posted this image example below in the other thread (I have not gone back and looked yet). Look at the piping below the water line (it provides isolation so steam can't pass) and the Hartford loop to the equalizer connection (siphon break).

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

So...just did a lot of reading to find out what I missed. Looks like the tech did some fine pipework, but not what was needed. The level of the tees where the steam mains, and the dry return drip still connect above the water line (so steam could still back up into the dry return and shut down the venting) and the Hartford is still on the other side of the boiler with the equalizer. Am I missing anything?

0 -

I don't see the proper Hartford Loop piping arrangement in that photo

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

It's true there's no syphon break, but why do people ignore that the boiler will drain itself even with a syphon break by … wait for it… creating steam that then gets delivered to the leaking return

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

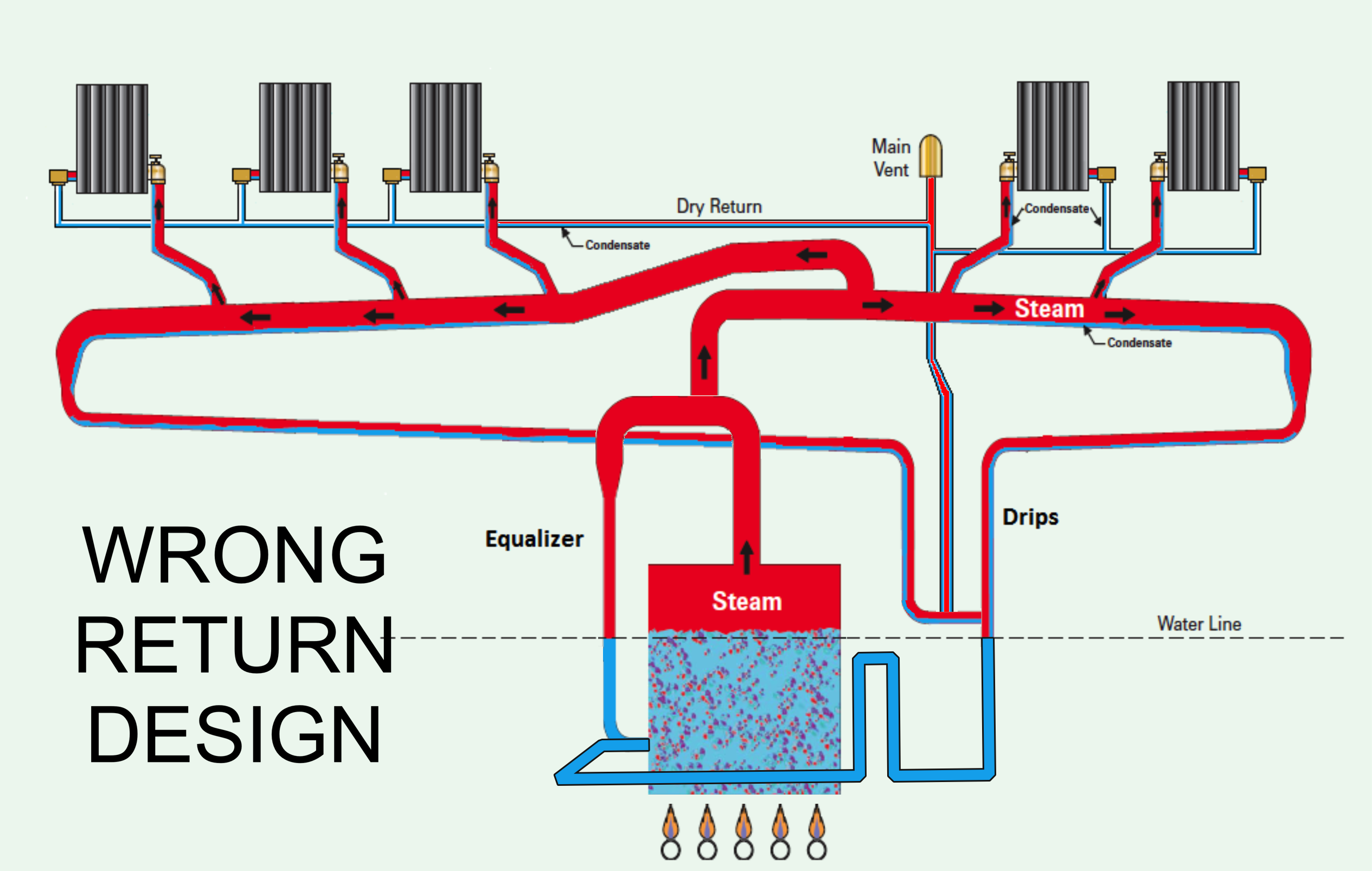

This is what you have pictured.

There is no true Hartford Loop if that raised portion of the wet return does not tie into the equalizer just below the boiler water line (and above the minimum safe water level). In your current design, steam or air cannot break the siphon if the wet return fails.

In the @109A_5 yellow-arrow photo, the three return drops are above the water line, which allows steam to pass from one return drip to another. They need to connect below the water line so a water seal prevents that cross-connection.

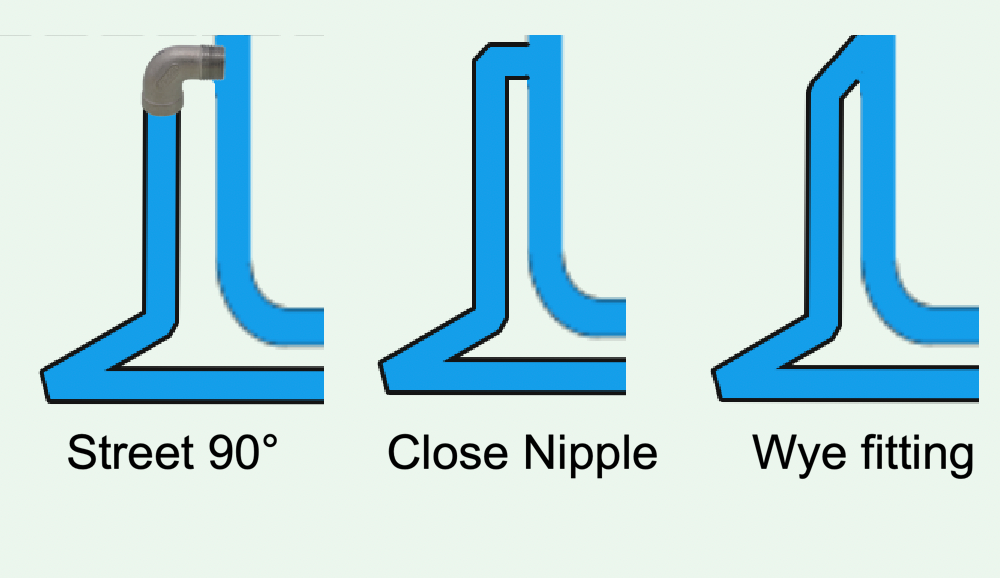

And don't forget the connection at the Hartford loop should be a close nipple or street elbow, or a Wye fitting.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

-

I get it, but what's the fastest leak you've seen in a wet return? Has anyone ever seen a leak that would drain a boiler that fast?

And any leak will eventually end up with a dry boiler even with a Hartford Loop, assuming the LWCO is out to lunch which all these conversations about the importance of the Hartford Loop seem to require.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

As we have talked about before @ethicalpaul, the Hartford loop is a proven technology from a time gone by. That design reduced the amount of boiler failures by the thousands. But that technology was for a boiler that did not have a LWCO or a pressure limit because there was nothing electrical to turn off. Hand fired boilers were blowing up at a rate of 2 boiler every 3 days in the 1880s and 90s. That little twist un the pipes stopped a lot of boilers from failing.

Does @markmarlatt need a proper Hartford loop? Will that technology ever save that particular boiler from a failure? Probably not. That boiler has a well maintained LWCO and pressure shut off switch on a well maintained pig tail. Just look at the photos of the inside of those pipes. Well maintained over the years.

If that technology is so obsolete, then why do the manufacturers still require if in the installation instructions? And try to get boiler insurance for a commercial steam boiler without one. It just ain't happening.

I say if your are going to do it at all, you may as well do it right! Or ,like your boiler install with two risers into a drop header. Way overkill in my opinion.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

-

I'm not Paul but I'd have to ask what kind of boilers were exploding and stopped with the addition? Were these small residential systems or huge fire tube boilers etc. What other changes happened around the same time etc.

The small residential systems I've seen in person from the 1920s didn't have a Hartford loop or even a header. I have to think many do, but the ones I've seen didn't. I'm sure we've all seen plenty of snowmen with no header or anything on here as well.

Me? I read the book and do as it says and Ed is right, it needs to be piped per the book.

But it's good to question the book too.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

1 -

Thank you much. The tech will be returning to rework the piping as described in the picture and will tie into the equalizer line instead of the boiler itself

0 -

Go here:

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting3 -

and will tie into the equalizer line instead of the boiler itself

It should tie into the equalizer in addition to the boiler itself

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Wow, that is some terrifying stuff!

0 -

Did anyone see in that document any cases where the Hartford Loop or lack thereof was involved? Most of these cases are hot water tanks it seems.

Was there something about wet returns back then that caused thousands of them to catastrophically fail every year??

This case is indicative of what I believe were most of the explosions. Simple human error or inattention:

This guy was apparently experimenting to see how fast his pressure would increase…kind of like what I do in my videos haha

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Right now the piping is connected to the second 2" port on the boiler rather than the equalizer line. This will be reworked to tie into the equalizer pipe which itself returns to the boiler on the left 2" port of the boiler. The right 2" port will be converted to have only a drain valve.

0 -

-

You are right about the 500 comment thread, but when the topic comes up, it comes up. Has anyone ever seen a wet return "break"? In my short experience I've only seen them drip (including mine!)—that makes homeowners call a plumber or DIY it.

I agree fully about mains being tied together above the water line, that's no good.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Paul, do you own a fork lift? have you ever driven that fork lift into a steel pipe? That fork lift can do some real damage to a steel pipe even if it isn't rusting away

But I bet your question really asks "Has anyone ever seen a wet return in someones small residential basement "break"? and does not consider that some homes may have systemas that were designed and installed before the requirement by code to include the LWCO, Pressure Control, and the Hartford Loop. But those radiator system still need to be heated with boilers that are installed today.

I believe that if you are a hammer, everything looks like a nail …and if you have a steam boiler in your basement with glass pipes that every other steam boiler is exactly like yours.

Reminds me of the story of the electrician helper that had a frozen pipe and he tried every electrical repair he could think of to solve his no heat problem

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Well the old tale says that thousands of boilers were exploding every year all over the place and so an insurance company had to swoop in and solve the problem. I don't think the root cause was forklifts, but I could be mistaken.

This insurance company mandated their solution (reportedly) in all homes in the US including mine so I am indeed trying to make sense of it in residential context.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

-

@ethicalpaul asked:"Did anyone see in that document any cases where the Hartford Loop, or lack thereof, was involved? Most of these cases seem to involve hot water tanks."

As a matter of fact, Paul, I don’t believe there are any actual records of boiler failures avoided as a result of installing a Hartford Loop. That would be a 'non-event,' and I don’t believe there are records of 'non-events'—only records of actual events.

Now, you could research the number of events where the Hartford Steam Boiler Insurance Co. (HSB) paid for boiler failure claims in the years leading up to the requirement to have that piping arrangement, and compare it to the number of claims that occurred after the requirement was enforced. That would be the definitive answer to the question about the effectiveness of that piping arrangement.

The problem is that the only historical reporting of boiler failures prior to 1919 would be in local newspapers that reported a boiler explosion in a given location. You might need to look up several—or even hundreds of—newspapers in public library archives to find out how many boiler failures were documented before 1919. HSB does not have this information in a cataloged format prior to 1919. The Smithsonian does have HSB records from about the mid-1930s to the 1950s that can be researched.

Our host, Dan Holohan, has done a lot of this research, and I am willing to take his word for it. According to his statements in many a steam seminar, it appears that boiler explosions were reported (not if, but) by how many occurred in a given week in some large metropolitan cities—like baseball box scores. They were a way of life at the turn of the century, just like seeing the farm report, or the weather forecast for tomorrow, or which horse and buggy ended up in a collision with one of these new-fangled horseless carriage things. The news of the day always included the number of boiler explosions that were going on in the places we lived.

That's why we need boiler insurance!

I asked AI if there were any documentation for these statics on this before and after 1919 and there are none that are easily accessible. And since you like this stuff Paul, I think that it would be a great project for your next video to see if you can take a field trip to Hartford and go thru the pre 1919 boiler failure archives and start to document and catalogue your findings and have them published. Perhaps your findings will help us abolish the need for the Hartford Loop on all future Steam Boilers in residences with 10 radiators or less. Especially if they have glass pipes

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

The equalizer pipe size is 2" and the drips and dry return are 1.5". Question; where is the best place to reduce from 2" to 1.5"?:

- At the tee in the equalizer pipe

- After the street elbow coming off the equalizer tee

- The vertical after the street elbow

- The horizontal at the floor

Thoughts?

0 -

Any of those are fine. As long as you don't reduce it in the horizontal in such a way that it can trap water(and in an equalizer even that is less important) you can do it whatever way works out best.

0 -

The HSB company did not mandate that every home in America must install a Hartford loop. and the fork lift has nothing to do with the mandate of the Hartford loop either. Where the mandate came from is HSB to their customers. Not to you (or your great grandfather if he lived in that house). If that person did not elect to purchase HSB insurance, there was no requirement to install that piping. You are putting the cart before the horse with this statement "This insurance company mandated their solution (reportedly) in all homes in the US including mine so I am indeed trying to make sense of it in residential context."

The truth is that HSB mandated in 1919 that all boilers they insured must have this piping arrangement, known as the Hartford loop. Boilers that were uninsured between 1920 and 1940 still experienced failures and were not required to have Hartford loops. Factories continued using forklifts and operating boilers, with or without an HSB insurance policy.

About 20 years goes by, as a result of HSB’s success in preventing boiler failures, local code officials began to notice that this piping arrangement was effectively saving many insured boilers. They then said to themself, “SELF, Let’s make this Hartford loop requirement mandatory for all steam boilers, whether they are insured by HSB or not.” One local code adopted it, then another, and another, until eventually it became standard practice just about everywhere. Boiler manufacturers followed suit and included the Hartford loop in their instructions.

And that is how we got here today.

So, you can tell the story down the lane by saying that in 1919, every boiler was required to have this piping arrangement because some insurance company said so. Which is only half true, but you can tell it that way if you like.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Thank you, its looking like just after the street elbow in the vertical will be the best place given the spacing.

0 -

Often the reduction is in this area (Orange arrow) I forget how old your boiler is. If there is an install manual available for the boiler that information of the manufacture's recommended pipe sizes would be there. Bigger won't hurt so if it were reduced just above the Hartford loop connection that would be fine too.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

As a matter of fact, I replaced one in a church in October that had a catastrophic break in a wet return. The boiler had been decommissioned before I was brought in so I had no idea what had gone wrong. Replaced boiler, put on an auto feed with a counter. Left for about 14 hrs after firing and the boiler had filled 128 gallons. After opening the cement around the only wet return that went under ground, we found about a 2" section of 1 1/2 steel just missing. It had rotted away, probably at least a year prior. There was a sump pump pit about 2 feet away and about 16 inches lower in elevation that they told me later had been running nonstop the prior heating season. Without a counter, without a Hartford loop, and a stuck m&m 67, that would have become cherry red. I've also seen some substantial rot outs when the underground return isnt wrapped or at a minimum painted to protect it from the cement.

2 -

Thanks for that story, but that catastrophic leak was years in the making, as you said.

Without a counter, without a Hartford loop, and a stuck m&m 67, that would have become cherry red.

The hartford loop came before counters, and before m&m 67s, so let's imagine… you don't have to tell me because I know, but ask yourself, "how would the hartford loop do anything other than postpone that underground leak drying out the boiler for more than an hour or two of steaming?"

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I think the difference here is not so much how fast the boiler empties, but who gets the blame. When a professional installs something for a consumer and doesnt take as many precautions as possible to prevent a catastrophe, and a catastrophe occurs, guess who gets the blame. If you are a homeowner who DIY'S your steam, its ok, do what you want...I dont think you can file suit against yourself even in NJ. I bet your wife could though. You are right that water will eventually leave through a leak in one direction or the other, but im pretty sure the Hartford Boiler Insurance company knew that then, and knows that now. Im also aware of the order of the invention of safeties and controls, but when you are (as a professional) called out to homes and businesses during the heating season who have no heat and frozen pipes, and you need to get them fired up as quickly as possible, you still dont skip installing a Hartford Loop because wet return leak will eventually dry out a boiler through boiling and condensating.

0 -

@4GenPlumber Actually, both my boiler and Paul's were inspected so they needed to be correct.

Paul has never said someone shouldn't install the Hartford Loop, not once. People seem to interpret him questioning it, as him saying don't use it.

Perhaps on an older installation he's suggested the owner shouldn't be concerned about it being wrong, or missing but I'm pretty sure he wants all new boilers to be installed per the manual and all local codes.

What I think he is saying is it's not the safety net people think it is.

This may be important because for example fake security cameras have been found to be, to an extent, dangerous because they make people feel secure and safe not realizing they're fake. Just an example.

There's also the fact of correlation does not imply causation. I'm sure during the late 1800s early 1900s there were many changes made to heating boilers and heating systems besides the addition of the Hartford Loop as well as the people operating the systems. When you hear your neighbor blew up you'd probably start paying a lot closer attention to your boiler. Sometimes a little fear is a good thing.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

2 -

The Hartford Loop plus LWCO plus one of these water alarms is pretty foolproof imo, although it would be better if it were powered by an AC/DC power supply instead of 9V battery.

0 -

The boiler can and will still dry fire if the LWCO fails and the boiler is neglected, even without leaks.

Nothing is fool proof. Even two LWCO's can still have issues if ignored.

You could say a gas or oil fired boiler is even more dangerous because they get ignored. No one is watching the fire and feeding the boiler. With a coal boiler, even without the LWCO someone was checking it throughout the day.

Not the case now.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

1 -

That water leak detector I mentioned can have the sensor placed at the low part of the floor by the wet return and the actual alarm unit can be placed up in the living space where anybody who isn't totally deaf will hear the 110dB alarm. I have one in my sump pump sump, one in my water heater pan, and one by my wet return.

Obviously someone has to be there since it doesn't have the ability to shut down the boiler automatically and obviously you cannot "neglect" the boiler.

0 -

The Hartford loop, was instituted back when boilers had substantially more water. The margin between the safe operation and dangerous operation due to low water, was probably greater. Back then, the Hartford loop probably bought you some more time than it does now. Talking residential boilers here. In addition, I would assume that people used to check the boilers a few times a day. Like everything else that was probably more Hands-On, back in the day. In this day and age, the probably does not provide much in the way of protection. Just for clarity. Absolutely positively, install a Hartford loop on every boiler installation. Just saying....

1 -

I've seen a few cast iron boilers with Hartford Loops run out of water and continue to fire. Until dry. And hot. They cracked and once cooled they leaked. I've been in cellars that only got visited once a year, by me. There's no accounting for neglect.

Miss Hall's School service mechanic, greenhouse manager, teacher, dog walker and designated driver

1 -

-

In the late 1970's I was living on the first floor of a 2 family house. One day I noticed a "hot" smell in the kitchen that seemed strong in the back hall and stronger still when I opened the door to the cellar stairs. I went down cellar and saw a glow on the back of the boiler for the second floor. I went around and killed the power to the boiler and moved everything close to the boiler away from it to be safe. I realized feeding cold water into a glowing boiler was not safe.

These were old Delco D4 steam boilers with hot water coils from the 40's, no Hartford loop and no LWCO. I called the landlords daughter and told them what I found and that they should have the boiler checked before trying to use it. That boiler was replaced with a Burnham V74 a week later.

Bob

Smith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements