steam Whac-A-Mole

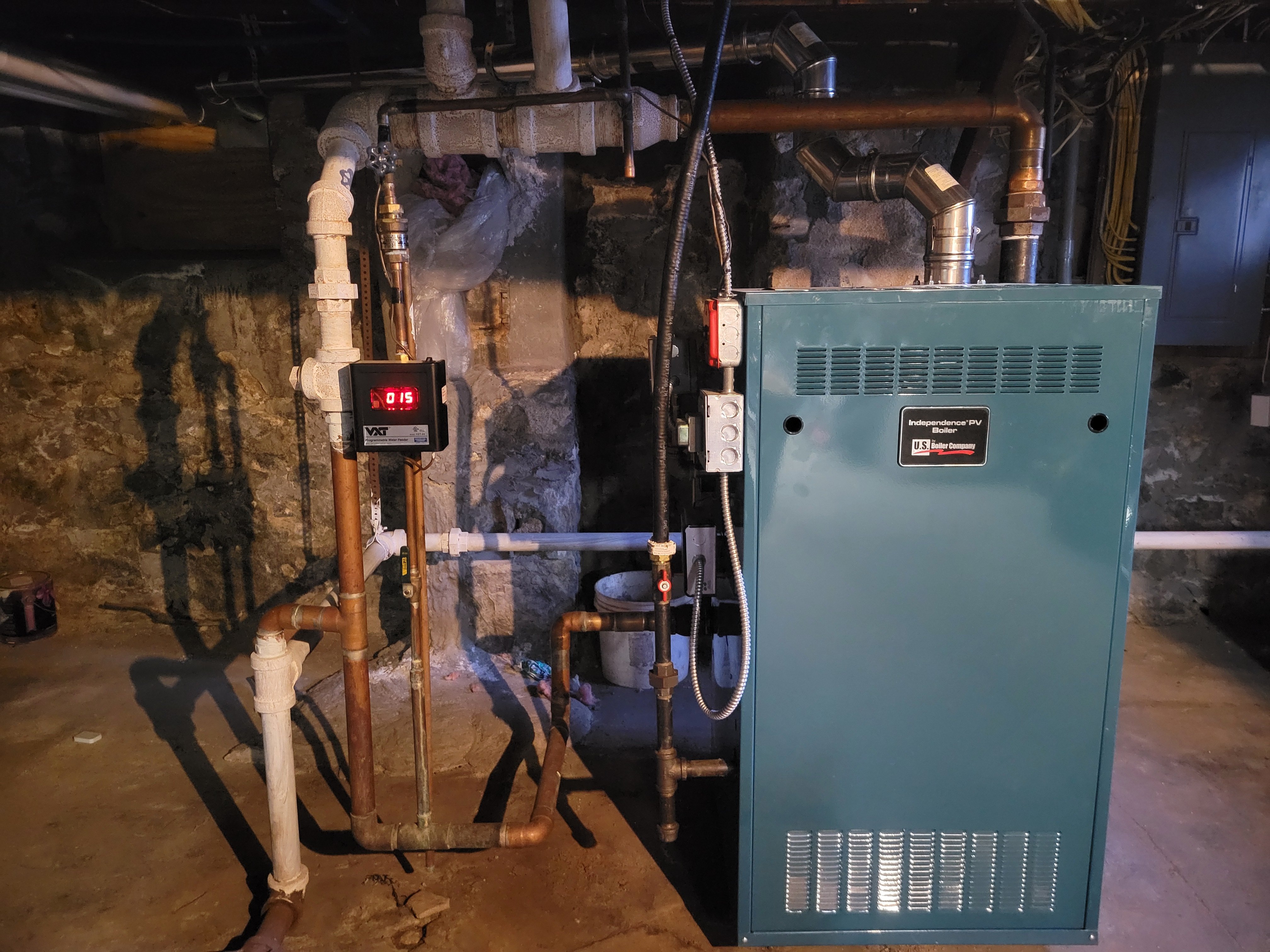

Hi folks, I'm hoping for some help getting a handle on very inconsistent heating. I have a Burnham Independence boiler, installed about a year ago. The guy was not a true steam guy and reused an existing copper header (I know, I know), but it seems to still conform to the mfg minimum height-above-waterline requirements and not an inch more (again, I know that's not great to go off waterline). It utilizes a single 2" riser off the 2" tapping with an elbow to a 2" copper header section, which subsequently expands to a 3" black pipe header section just before it hits two 2" risers to the mains, then drops to a 1.5" equalizer. Water level is quite stable in the sight glass (though occasionally i see a drop of water drop from the top of the glass within the glass itself). I have a pressuretrol set to 1.5 with a 1 diff. Pressure generally seems to be somewhere between .5 - 1psi for the most part, though it's a 0-30 so imprecise. It doesn't seem to cut out except for when it's checking water level periodically. I have two roughly equal length mains at about 60 ft ea - one running primarily through the open basement and another that is largely running through a much shorter (in height) crawlspace that gets quite warm. The mains are not insulated (again, I know). The main that runs through the crawlspace has a Gorton #2 at the end and the one that runs through the open basement has a vent antler I built, consisting of a #2 along with two #1s. Pitches seem correct on the mains (more than 1" per 20ft). The crawlspace main has a mostly dry return, and the open basement main has a wet one.

Here's where things get strange - the crawlspace main heats about 2 mins faster than the open basement main, despite the extra venting on the open basement main. Not coincidentally, I assume, those radiators generally get hot quicker than the ones on the other main. Unimpeded, they get much quicker, even at the very end of the main. I have several of them throttled back to just over a #3 setting on adjustable Vent Rites, and then the rest with Gorton #5. The primary basement main uses Gorton #4s on its respective radiators (where thermostat is) with #5s the rest of the way. At the end of that run is a room with two equal sized radiators. the one furthest presently does not get warm. the one nearest gets hot as anything. Pitch on the far radiator seems fine, as does the pitch on the riser that runs to it from the main. That riser gets extremely hot quite early and then just hits a wall and stops to a near crawl. I remove that radiator vent entirely and occasionally a puff of air comes through.

The above is just how things are going now. It seems that when I make the slightest adjustments to vent rite settings on the hot side everything starts to change. That far radiator I mentioned actually was heating up fine a few days ago - pretty much in step with the other one in the room, but I suspect it was because I had been throttling the vent rite at the other end of the house to hardly anything. Once i touched that setting (opened it only enough to start venting) the radiator at the other end of the house stopped heating. Even now, I adjusted a couple of radiators on the "hot" side of the house simultaneously - one is still heating and the other has totally stopped, despite them also being in the same room and the same vent rite setting.

All of this to say - I do something barely noticeable in one place and suddenly something in an entirely different area goes lights off. Could all of this be due to the near boiler piping being done just to minimums? Could it be uninsulated piping? Neither seems the observable culprit (e.g. boiler doesn't seem to be surging and both mains seemingly fill ok). My boiler is slightly undersized (e.g. edr sits pretty much right between the two burnham sizes (IN6 and IN7) - but only after i had shut off one of the larger radiators I didn't seem to need based on heat loss for that room (turned the vent upside down to kill it).

I realize this post is as all over the place as my heating seems to be, but i just can't seem to get a handle on what's going on and it's driving me crazy.

Happy to provide any pictures or other details that might be helpful.

Comments

-

I don't think that the near boiler piping being just to minimums has much to do with it, though I doubt that it helps much, either.

On the radiator with the riser that gets very hot and then just stops, or almost completely stops. Does it stop in the length of pipe somewhere, or at the inlet valve? If it's along the pipe somewhere, check the pitch of that pipe very carefully. There may be a puddle in there which isn't draining. If it gets to the valve, check and make sure that that valve is really fully open.

Otherwise, I expect you have discovered the fun part of one pipe steam! : you adjust something in one place, and something over in the next country changes. Patience. You need to adjust just one thing at a time and see what it does —and then be able to change it back if it messes things up.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

@Jamie Hall The one that gets very hot and stops has a vertical riser off the main, then a sloping section of about a foot and a half, then another vertical riser up to the inlet valve for the radiator. It makes it about 80-90% up that sloping section and then stops to a crawl. Eventually it might make it up into the inlet valve but we're talking like 45 mins - 1hr after that first radiator was hot all the way across. The inlet valve is 100% open and it's new (i replaced both the valves in that room last month, along with both the radiators - all new). I feel worth mentioning - the air sputters out of that radiator when i remove the vent. a very slow occasional puff of air to a semi-frequent sputtering once it finally hits the inlet valve. That sputtering/ unevenness of airflow concerns me but maybe unjustifiably so.

.

0 -

I'm wondering how long it would take the steam to get to that inlet valve if you disconnected the radiator.

Before doing that though I think I would be extra careful in checking the main every foot or so for pitch, with a shorter magnetic level. You have it easy since you have no insulation. If there is a puddle that could be killing the steam.

1 -

@Captain Who at the very start of that main it is just the right side of level (image attached), but that's about as bad as it gets. This is not a particularly long level - what's the max length you'd go with? Also to note:

- I don't have any water hammer

- all the other radiators on that line heat up fine (for now, at least). and that radiator actually did heat up pretty well until i made a small adjustment elsewhere.

- one of the radiators on the other main, a radiator that historically has been blazing, stopped heating almost entirely when i slightly adjusted the vent rite a bit earlier today to try to balance things better with this other problematic radiator on the other main.

I think it's the extreme volatility that's throwing me off here. I didn't think such minute changes would have such dramatic impacts - especially within the same room - but maybe i just need to sit with things for a few days and see if they find their balance?

0 -

Let's see a picture of the near boiler piping. There's no bullhead tee arrangement or anything like that?

I use a very short level, maybe 3 in. long and magnetized so I don't miss any puddling sections.

0 -

No, nothing like that. It ain't pretty but it's pretty much mfg. spec, with the exception of some missing valves on the return side.

0 -

@morgtheborg , what pipe sizes are your mains? What main vents are on them?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Why is that return so much higher than the other one? Does the waterline ever go below that?

What is the spec for the diameter of the riser out of the boiler? Even my small Peerless 63-04L is 2-1/2 in. minimum.

60 ft. mains are extremely long. Twice what my longest one is, and mine are fully insulated. Pretty long main to have no insulation.

Aside, that flue vent looks very small to me, and all those bends are not proper.

0 -

@Steamhead mains are about 60' each - one has a Gorton #2 and the other I made an antler with one #2 and two #1s. Originally they both had #2s but because one main was several minutes slower to heat (several minutes) I figured the antler would help. honestly, it didn't really make much difference. Mains are 2"

@Captain Who that "high" return is actually wet the whole way, as far as i measured off the floor. I think the other is so much lower because they dropped it to the floor after it leaves the elevated crawlspace and hits the open basement. I have a water heater in that corner so i suspect they simply did that for clearance and accessibility purposes. and yep - it's a 2" tapping and calls for a min 2" riser and header. - just edited to reflect your edit: should i worry about proper venting then with those bends? i imagine not related to the issue at hand but something to address for health or boiler longevity? And re: insulation - so maybe that is the issue after all?

0 -

Apologies: I just remeasured - mains are about 40-45' each

0 -

I'm confused on how your boiler pressure is averaging 0.5 to 1 psi with one radiator not even getting steam, let alone it's vent ever closing? You should be getting no pressure. Oh, you are going by that internal syphon code compliant piece of garbage 0-30 psi one? They always clog unless they are on a pigtail. It is probably giving a false reading and reacting to the temperature, not pressure.

0 -

@Captain Who assuming that's the case and i should be getting no pressure, that wouldn't necessarily point to any one issue, correct?

0 -

No I wouldn't expect it to fix this particular problem but you really need a 0-3psi gauge alongside your pressuretrol teed on the same pigtail.

If somehow it were reading correctly then that would mean there is some clog in the piping leading to your troublesome radiator, like the valve maybe, even though you believe it to be fully functional due to being new. We have to start thinking a bit outside the box maybe.

1 -

I think you are wasting some of the available steam during each boiler cycle (unless you want the basement and crawl space heated). Since the steam is limited " My boiler is slightly undersized ".

Since your mains are not insulated you are reheating the mains with each boiler cycle slowing the steam propagation down along the mains to get to the far ends. So the far ends become a choice, one or the other. Even with way over zealous main venting reheating the mains slows the steam propagation.

The more efficient the steam distribution system is the more control you will have to balance the system.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System2 -

@Captain Who what I don't understand is that it was just working a few days ago until i slightly opened up a vent on the other side of the house. And now, another radiator in another room - the "hot" side and not even the end of that run - is not warming after slightly reducing the opening on the vent rite to the same degree as a radiator alongside it, which remains very hot. The end-of-run radiator is an issue but it seems like the the overall system is acting erratically and unable to be balanced or deliver across the entire runs.

0 -

@109A_5 thanks for that - I suspected that might be the case (and purchased the insulation to do the job) - I know from Dan that not insulating pipe means an "undersized" boiler in a sense, so i guess that just compounded what was an existing borderline issue. i just wanted to see if anyone had a different thought before i started wrapping pipe and might need to unwrap it after the fact for one reason or another

0 -

If you do a long burn that results in every single vent in the system closing, and this troublesome radiator is still not getting steam then there has to be a blockage or major amount of water trapped inside the radiator/near radiator piping, even with an underpowered boiler. One more reason to get a proper pressure gauge.

1 -

The radiator that gets hot and then stops does the pipe come off the main with a 90 or a 45. It matters. On 1 pipe you should use a 45. A 90 will cause the condensate to kill the steam. You don't have condensate until after the initial heat up. That could be why it stops working.

0 -

You might not even be developing any appreciable pressure in the radiators that are getting filled with steam, if your boiler is very undersized. I doubt that you factored in the EDR of uninsulated mains (and yours are pretty long) and supply pipes and near boiler piping. Your boiler could be a lot more undersized than you realize for this situation. If adjacent radiators are actually at a vacuum due to condensing steam within and the boiler not replenishing it fast enough, the steam will want to go there even if you take the vent off of the radiator that isn't heating because a vacuum beats 0 gauge pressure present at the vent opening. I'm not saying there absolutely isn't some sort of trapped water situation on top of this.

Try throwing a blanket over each of the other radiators that share the main with this troublesome radiator and see what happens just as an experiment.

0 -

@EBEBRATT-Ed pipe comes off the main vertical, then about 1.5' sideways with a backpitch to the main, then vertical to the radiator valve.

@Captain Who that's interesting and explains why nothing really wants to exit that radiator even without a vent. It also explains the seeming randomness of radiators coming offline. I did an EDR calc and got about 504 (some radiators were hard to match, but I think I was pretty close). And again, that's the number after shutting off one of the larger radiators in a bedroom that already had 2 large radiators - it was also based purely on the radiators themselves. This Burnham indicates 454 Sq Ft. Perhaps the pipe insulation will offset heat loss just enough to allow everything to fill properly? I imagine that's all I can do at this point short of replacing the whole boiler 1 year into things. I quoted with 4 different companies last year - not a single one of them made any indication that a sizing should be under consideration - all simply wanted to replace what was there. I assume they went with the IN6 because that's the largest power venting model that Burnham offers, but it could just as easily have been a matter of wanting to swap like for like as that was what was already here (and started an above water line leak - after less than 10 years!). I'll try the blanket test a bit later and see what that yields. I imagine this intense cold isn't really helping things.

1 -

Yeah do the blanket experiment. I'm interested in hearing what happens. I think in your case I'd go with the 1.5 in. thick insulation. Part of my steam main was done with that stuff and the rest was the inferior 1 in., and some of that got destroyed when that part of the main leaked and had to be repaired umpteen times until I figured out how to replace it. I will definitely be going with the 1.5 there too. It is important to insulate as much of the supply to the radiators as you can too, at least where it is exposed in the basement.

Two 45 ft. 2 in. steam mains would have an EDR of 87 sq. ft. So if you add that you have 591 sq. ft. EDR and the boiler is good for 454. That doesn't take into account the near boiler piping either. Your header alone could add another 12 sq. ft. easily, so make that 600 sq. ft.. This doesn't factor in the uninsulated supplies to the radiators. If you had 3 ft. exposed in the basement per radiator could be another 18 sq. ft. there, so say 625 sq. ft. total EDR.

0 -

@morgtheborg , also check the cycling adjustment on your thermostat. Most digital thermostats come set for 5 cycles per hour (CPH) which is good for scorched-air but not for steam or hot-water. I generally set them for 3 CPH, this takes advantage of the thermal mass in these systems. Some instructions tell you to set for 1 CPH on steam, but this should not be needed unless the system responds very slowly.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements