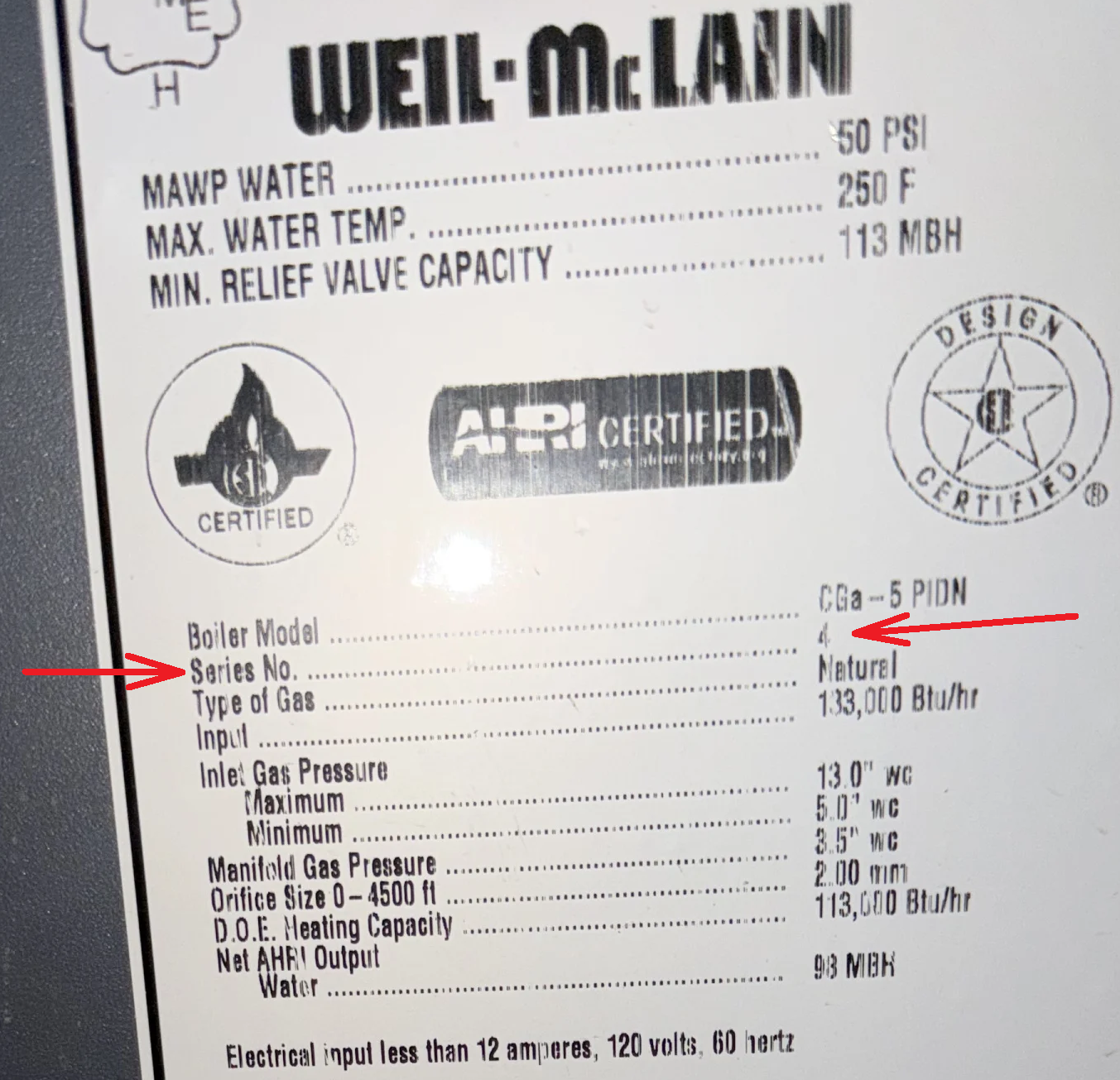

CGA weil mclain

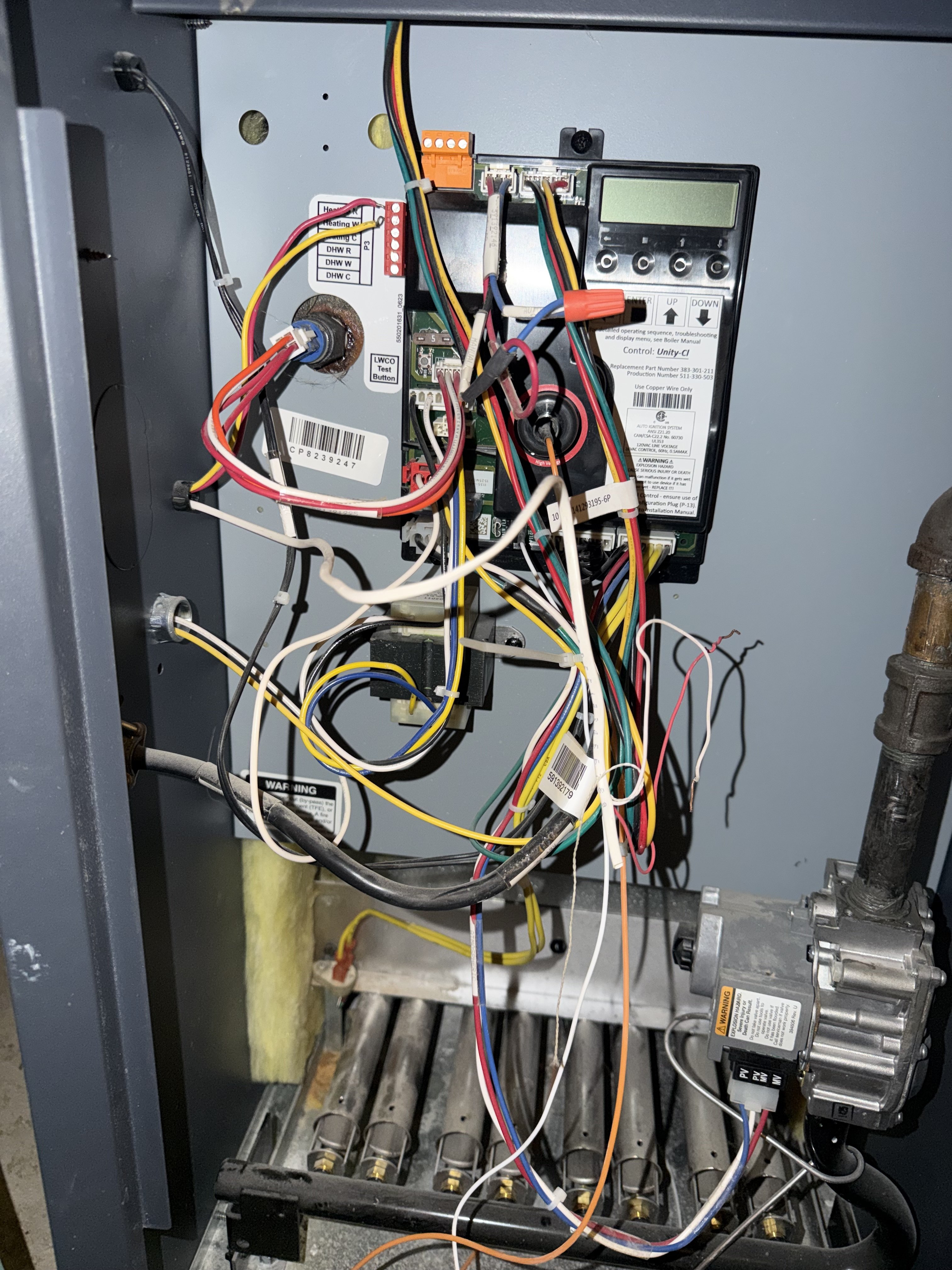

got a new boiler installed recently and today it threw a fault false flame. the installer came a notice there is water on the plug. the plug on the upper left and it leaks to the safety switch on the lower left. What do you call this plug? This was installed in the summer. Is it fixable?

Comments

-

Was the installer who came out the same one who installed the boiler this summer? What did he think?

Trying to keep Bernie burning!

0 -

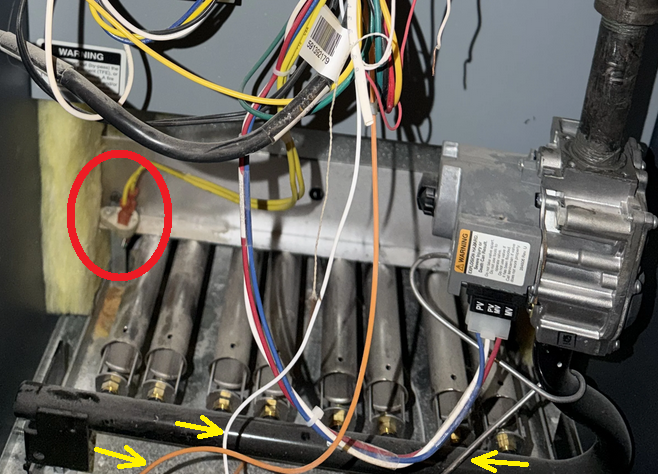

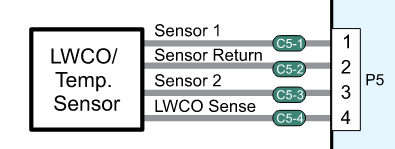

The 4 pin plug with the 2 reds, a yellow, and a white is the Water Temperature/LWCO sensor.

And it leaked to the bottom left? The Rollout Switch with the yellow wires?

Once the Rollout blows, its done. It needs to be replaced.

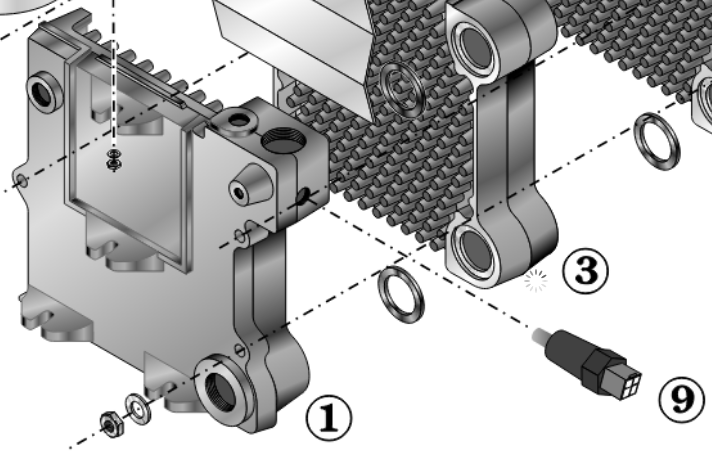

As far as the sensor, I wouldn’t assume that's where the leak generated. I'd look at the 3/4" tap in the block on top of the boiler, behind the supply pipe. There should either be an air eliminator there, or it should be capped. Something is leaking from up high and trailing down between the block and the jacket.

I would start by shutting off the power. Fix the leak. Disconnect everything from the board, and dry everything well. Use a hair dryer if you want. Disconnect the sensor and dry the area and the connector. If the Rollout is still good, plug everything back in. Turn OFF the gas. Turn on the power. Raise the thermostat and see what the board does. If it goes through the whole trial for ignition sequence (without actual ignition, of course), then try with the gas on. ONCE!

WM would have the resistance specs on the sensor if needed.

1 -

The guy who installed the unit came out last night and tighten the temperature sensor and it worked whole day today. This evening it through the error again. I reset the boiler and it came back online.

it looks like there is moisture around the teflone tape around the temperature senor.

behind the supply pipe, it has an air eliminator.

Will have them air eliminator.

0 -

I turned the heat off and i can see water sipping out from teflone tape around the LWCO plugin.

0 -

If it is that sensor is leaking at the threads and not something up higher, at some point you probably will have to drain (or partially drain) the system, remove the sensor, inspect the treads (sensor and block), and if all looks good put it back in with tape and dope. This should be done before it turns into a corroded mess.

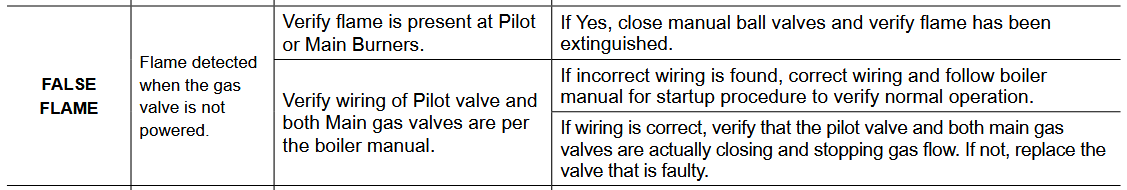

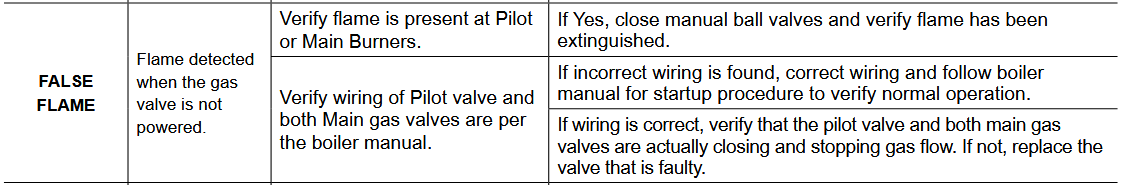

The other thing is the "false flame" error means there is a flame when there should not be and the sensor leak may have nothing to do with that.

https://www.weil-mclain.com/wp-content/uploads/CGa-Series-4-Boiler-Manual-0425.pdf

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

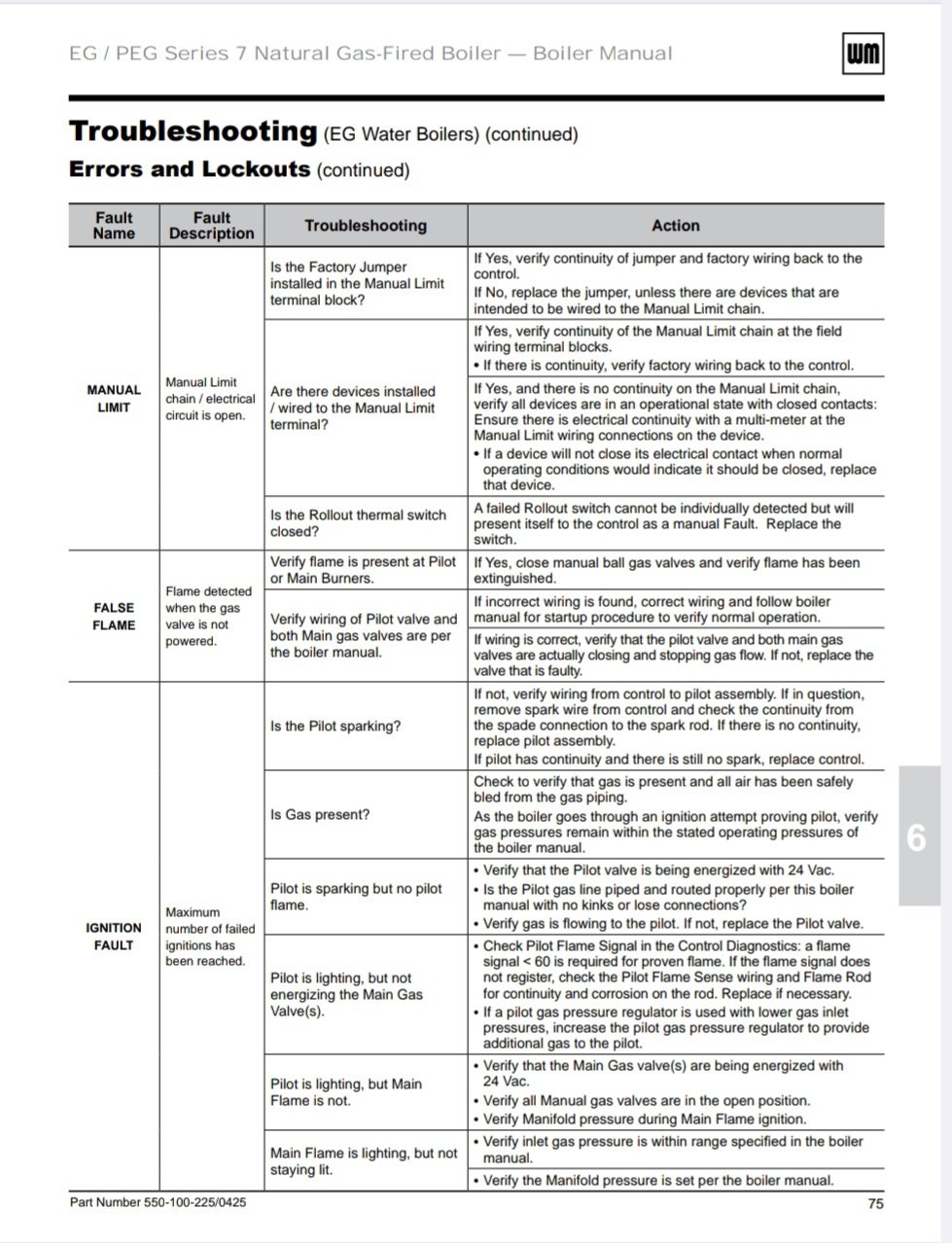

this is helpful. what could be the cause of the false fire and how to debug it. i can reset the fault and it will do a cycle and then the error is triggered.

also noticed there are 4 wires coming out from the guard dog low water device but only 2 wires are connected. it is connected to the transformer. where should the other 2 wires be connected to. please share any diagrams if you have it.

many tganks

0 -

Its pretty rare that a factory installed fitting is leaking. Could be, but rare. Start looking higher.

0 -

yes have the contractor coming out again. As the boiler already have a LWCO, is a separate guard dog still necessary. I don't believe that device is completely connected because there are 2 wires that aren't connected to anything.

From the manual for the boiler, looks like I can connect to the p4 limits. There is auto-reset and manual-reset. What is the recommended approach for the guard dog?

Regarding fittings from factory, It make sense that it shouldn't have any issues. Was watching a video on youtube of Mikey Pipes, he was assembling the same unit and the nipple on the supply line was not proper secured and didn't have proper dope on it. I guess it could happen.

0 -

contractor came and re-apply dope on the LWCO sensor. so far it is ok and don't see any water.

0 -

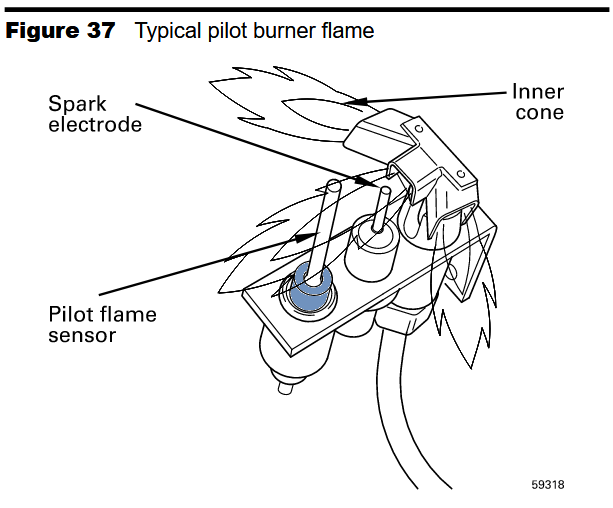

don’t sessions any more water leak but it threw the same error again. where is the flame sensor located for the cga 5.

0 -

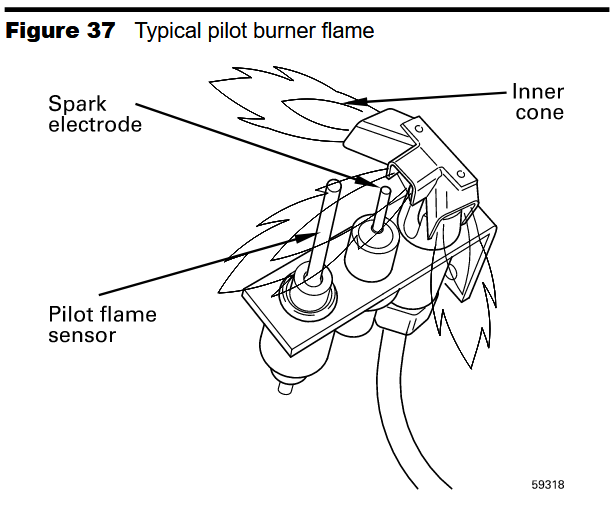

Down in the burner compartment attached to the pilot assembly.

The boiler is new, so unless its been burning terribly, I wouldn’t think that's the issue. What code is being displayed?

0 -

According to what someone posted, the flame error is saying flame when there shouldn’t be. I haven’t worked on the series 4 yet but to me that means something isn’t closing the gas valve after the boiler is supposed to to shut down. Allowing the pilot or flame to stay lit. Have you tried cleaning the pilot assembly and checking it looks ok?The Temp/LWCO probe may have just been a separate issue happening at the same time

0 -

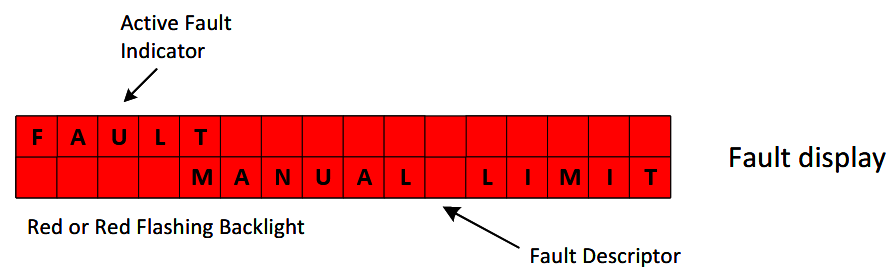

The LCD turned red and it said fault false flame. I don’t recall seeing any code. Is the code on the lcd panel?

0 -

-

thank you for the picture. super helpful. If the wiring is in question, would it cause intermittent faults? What is the most likely cause when it is intermittent?

It would work for several hours with multiple cycles and then it would stop working. A reset will make it work again and the cycle repeats.

0 -

I'd inspect the wiring for abrasions, being crushed or pinched and secure connections. I'd also inspect the insulation on the sensor probe for contamination or damage (the area of blueish shading in the image below), clean or replace if needed.

If you have the proper test equipment (a multimeter or equivalent capable of DC microAmps) Flame Rectification current could be measured also.

All assuming the flame goes out when actually expected every time, if a gas valve (main or pilot) is sticking open you may have to catch it in the act.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

-

In my case, the leaking was from the LWCO and it was clearly visible. When it is under warranty, does it cover the contractor cost?

0 -

What is the fault code when the rollout is tripped? Would it also indicate false flame?

0 -

No. My WM Pro Tools app doesn't have the CGa Series 4 listed yet, but the CGi uses the same Unity-CI control board.

You can turn off the power and remove the plate that the Rollout is attached to and set it aside so you can see if the pilot flame goes out when it's supposed to. When you turn the power back on to check, be careful to set the plate so the Rollout isn't touching anything but air. If it shorts out, its done. They used to give you a spare Rollout. You also should have the manual.

0 -

thanks for sharing. i also remember seeing manual limit, is that another fault? need to pay close attention if it happens again.

0 -

The Rollout thermal switch is actually a Thermal fuse. When tripped it would have to be replaced (Red Circle).

These wires and aluminum tube (Yellow arrows) go down to the Pilot / Flame Sensor assembly.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I called tech support and they were pretty helpful. Because the boiler is new, they said the most likely cause is the gas pressure. Will need to hire a person who was trained by Weil Mclain to do some diagnostic.

0 -

tech recommends checking the gas pressure. I live in NYC and we use gas from Con Edison. How does one check that pressure?

0 -

A Tech should easily able to test the Gas pressure with a Manometer. And it should be verified if not to just rule it out.

The thing is, the way I see it, the way gas valves are designed so the inlet pressure would actually help the valve close not keep it open. To me the only way the pressure would keep it open is if the pressure is so high it can actually open (or keep the valve open) against the solenoid's spring pressure. Maybe the internal regulator is bad, but still the incoming gas pressure should not be that high.

And if the pressure was that high the burner may have other combustion issues.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

Gas pressure should not be throwing false flame signal. When does it happen? Early morning, mid day or evening? once a day? Many times? Suspecting may condensation dripping down during cold start maybe. Just sleuthing a bit.

0 -

It started last Saturday. contractor came and noticed there was water around the thread of the LWCO sensor. contractor tighten the sensor but then it tripped again but it didn't stopped the leak. contractor finally took the sensor out and apply dope and put it back in. immediately the next morning in tripped again but didn't see any visible water by the sensor. I reset the boiler, and since the reset, it has not trip again.

When it had the leak, I can see water dripping on to the burner tubes. Also I can feel the water on the insulation behind where the circuit board was mounted.

I hope that was the reason it tripped the false flame. Many thanks for everyone's wonderful suggestions.

2 -

Just keep doing what you're doing. Keep an eye on it.

I wonder if there are more boilers that shipped with loose sensors. Sealant issue? Bad tap in the block? Or is this singular?

0 -

the good news is that I haven't seen a fault for more than a week now. however noticed a weird situation as if the boiler threw a fault but eventually reset itself and came back online. I keep the temp at around 63 at night, when the temp goes below it fires up the boiler, noticed from 3-5AM last night, the temp dropped down to 61 as if the boiler wasn't running. Also just now, the boiler is running however the temp in the boiler drop down to 100.

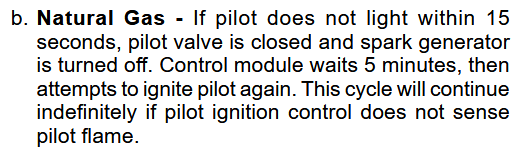

What is the behavior when the boiler can't ignite? According to the documentation, it'll try multiple times and with some exponential backoff.

0 -

does the cga series 3 have a temperature differential lockout?

0 -

With that controller is it a Series 3 or Series 4 ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

Looks like a Series 4 to me. Curious, why do you think it is a Series 3 ?

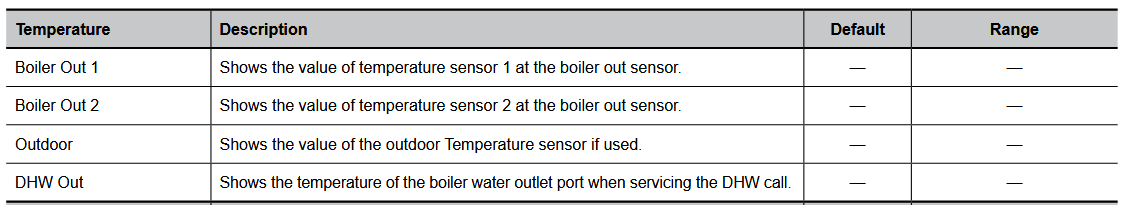

The only two temperature sensors I saw in the diagram were in the LWCO sensor assembly. I believe they are for a sanity check, although I could not find an error message if one has an implausible reading or the differential is too wide.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

you are 100%, i missed read that as serial number.

again it threw the false flame and the red panel blinked 5 times.

0 -

That control is new to me. I thought WM was going with a universal U-Control to use throughout their line of boilers. And like I mentioned earlier, the Series 4 isn't even listed on the WM app yet. And it was updated 12-25. I can find your boiler with a CP# search, but I can't bring up any manuals on it.

0 -

As far as the 'False Flame' error, is the boiler still under warranty ? If not the things mentioned previously in the thread should be checked, some of which may need some diagnostic equipment.

For some reason the controller apparently thinks there is a flame present when their should not be. The actual presents of the flame may or may not be true.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

The boiler was installed Oct 2025. It should be under warranty, I hope. I got a contractor in the weil maclain site to come and diagnose the problem.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements