Need Help - Pulling Air In

Hey guys. Plumber here, but I replaced my boiler about 6 weeks ago after doing a lot of research and asking several questions on this site.

Problem I seem to be having is I can't bleed the air out and on further thought I think I might be pulling air into the system through the seperator.

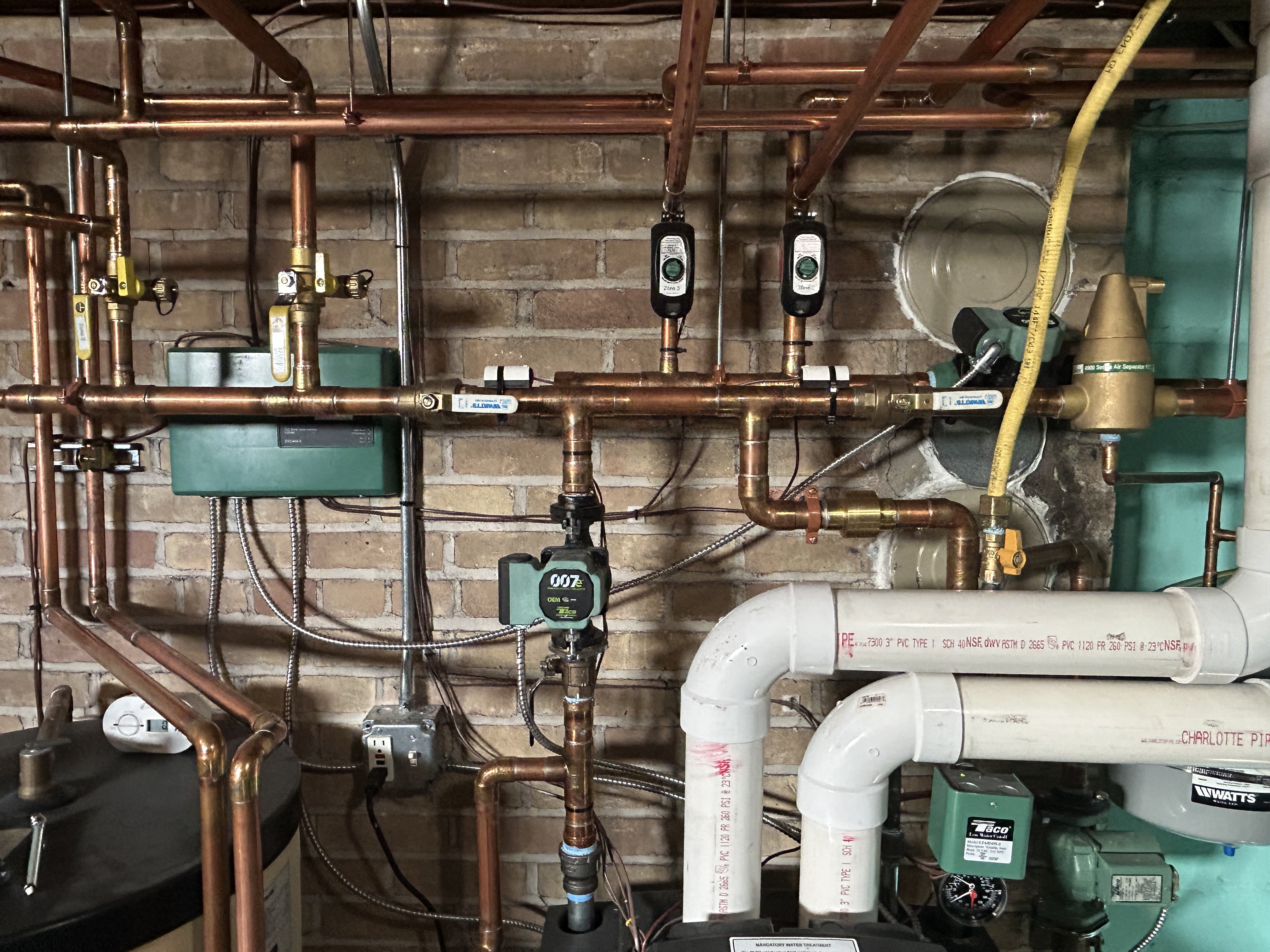

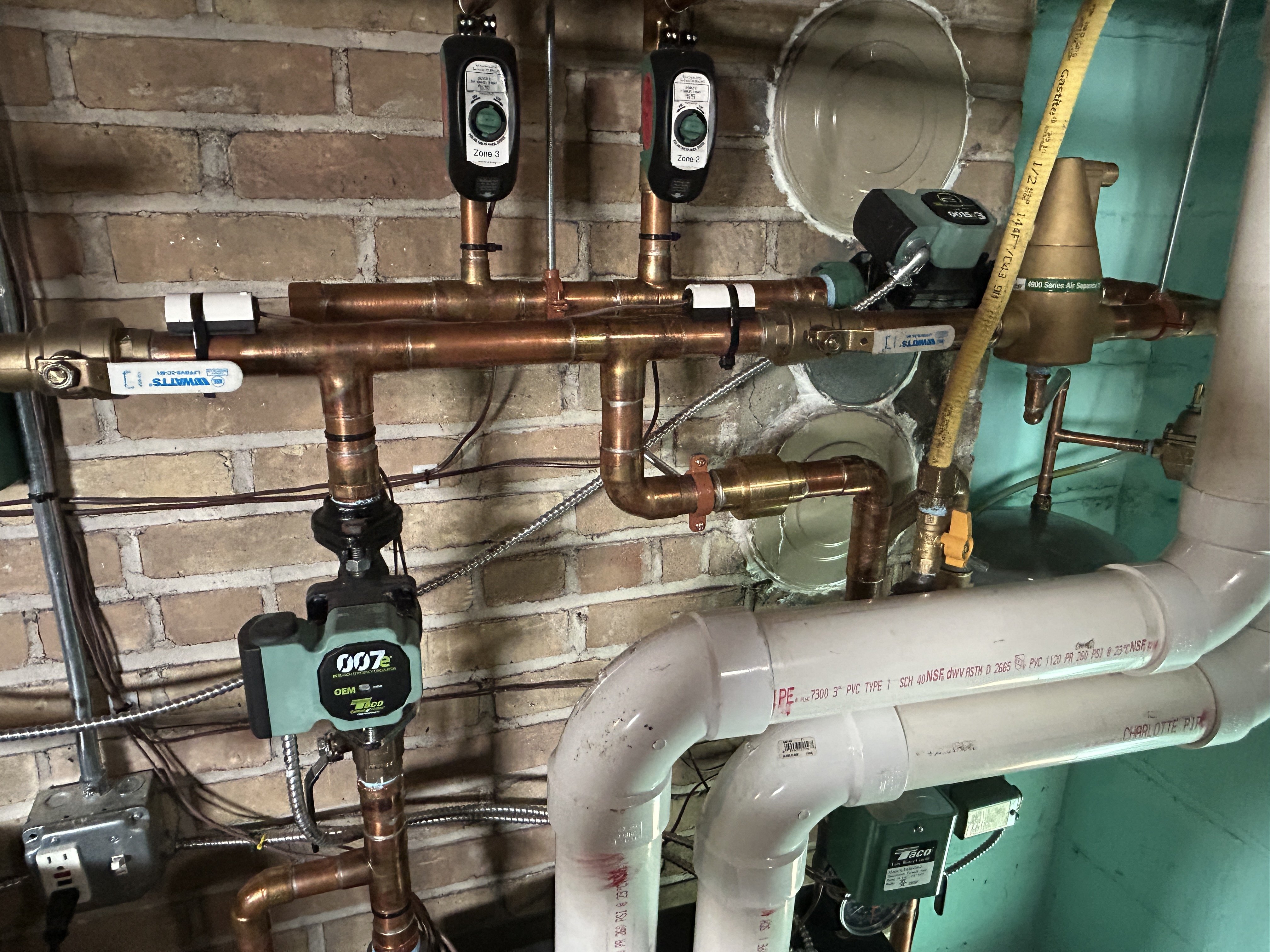

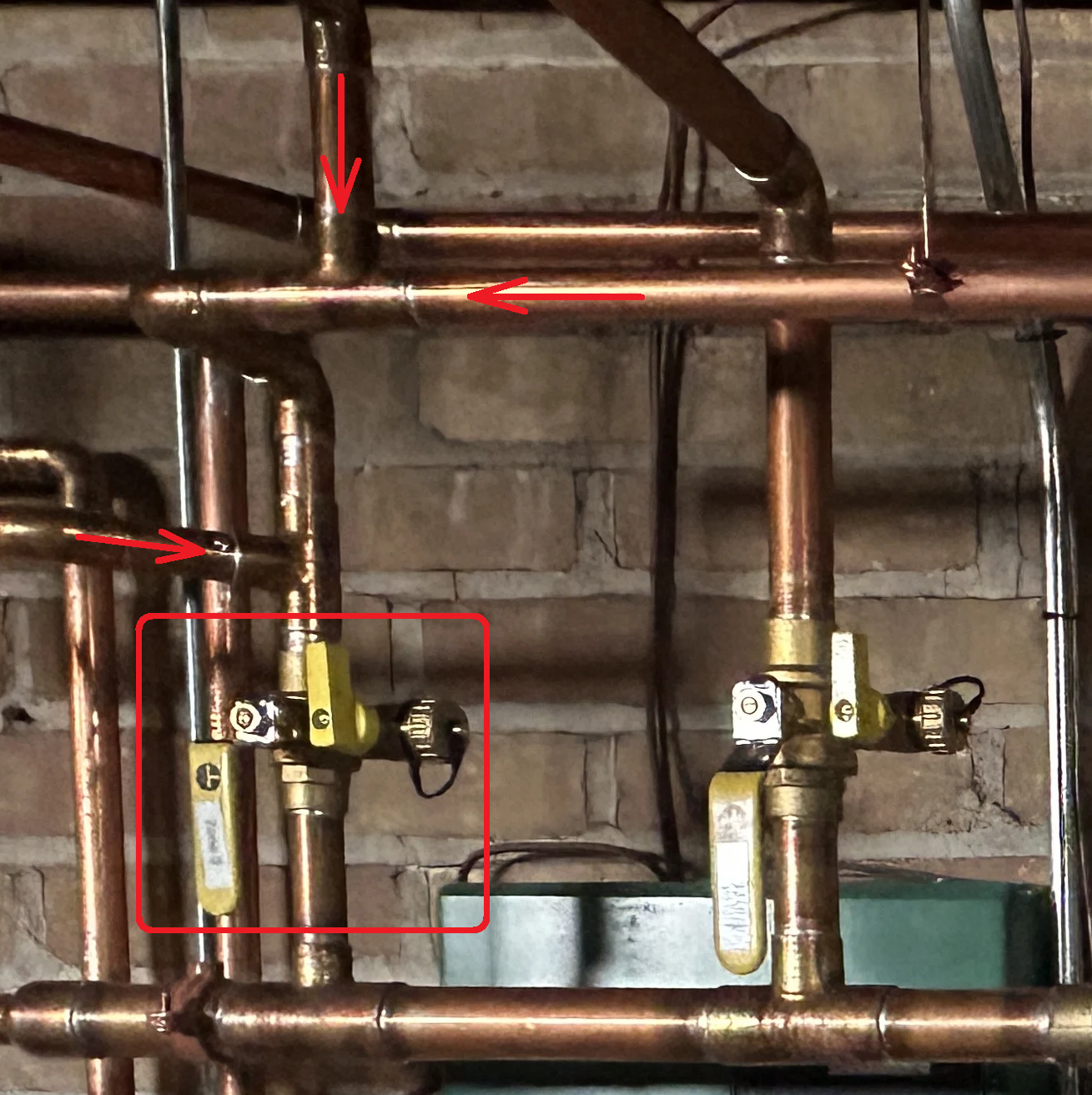

I followed installation instructions to the best of my understanding and was careful on my layout, but I might have a negative air issue near the seperator and system pump. I'm attaching some photos here so you guys can see my set up and would appreciate any direction as to tests I can do to be sure or how I might adjust things so it operates properly.

Also since you won't be able to tell from the picture there is 17" between the seperator and the system pump.

Also, system pump is a 0015e3. I had it set to medium most of the last month but had since changed to low to see if that didn't pull as hard. Seem to have same issue.

Also, if I did anything else stupid please point it out! Thanks in advance!

JTM

Comments

-

Well now, you can't pull air in if your expansion tank is reasonably close to the INLET of the main circlation pump, and if the system pressure — and tank precharge — is adequate (probably around 15 psig cold).

So… where is the expansion tank in relation to the system pump — I can't make it out in the pictures — and what is the system cold pressure?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

I'm not a hot water hydronics guy, so I may be way off in the weeds with this. But is there multiple loops on one zone with no way to isolate each loop to purge the air out of each loop independently ? Or are the valves just not in the picture ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Maybe it is the picture angle, it looks like access to the zone control box is very awkward.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

The circulator is mounted wrong, but the piping appears to be correct. If you are keeping the correct pressure in the system, it's impossible for it to be pulling air in. Sounds like a proper purge is in order, but I don't see a purge station or even a way to do that aside from the auto-fill which isn't always adequate. Hopefully there are some high point vents?

2 -

@Jamie Hall Hadn't checked in a bit but I have a watco 911 combo fill valve regular which I thought was set to 15 psi but my boiler hasn't run all day currently and while it's not cold cold it's sitting at 11 PSI. The expansion tank might be overcharged as a result.

Sorry about pic angles but between pics 2, 3 and 4 you can see the expansion tank in relation to the automatic air filter. It has almost exactly 27" of piping between the bottom of the seperator and the top of the expansion tank. That plus the 17" between the air seperator and the system pump is 34" of piping.

Only guidelines I saw were a required minimum distance between those components not maximums of how close they should be. Insight appreciated.0 -

@GroundUp I think I need to check system pressure matching expansion tank and that might be where my issue is.

Aren't the purge valves on the zones themselves adequate for purging air with the fast fill valve? Beyond that I thought I would bleed any remaining air at the radiators.

What sort of different purge station would you have added? I have boiler drains on both ends of the header and purge valves on each zone?

Thanks!0 -

Not individual purge stations for each loop but just a full port ball valve on each loop so each loop can be purged out individually. Only one valve open at a time to purge that loop. Once all loops in that zone are purged, all the loop valves are opened for normal operation.

The way I see it, what guarantee is there that the purge water will flow through all the loops in that zone to purge out all the air ? Doing one loop at a time forces each loop to purge.

I would think full port ball valves are less expensive than purge stations.

EDIT: Are there individual radiator valves that can be closed ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

What type of radiation do you have ? If it is old Cast Iron radiators are there air bleed valves on them ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

@109A_5 Yeah you might be right, I'm not sure. I didn't see a lot of piping schematics showing that additional detail so I guess I didn't think of it. But yes, fast fill I'm just hoping to get the bulk air out and then at each cast iron radiator I have shut off or bleed valves where I get the air that rises. Unfortunately many of the shut off don't work at all but I was planning to deal with that in summer time. All the air bleeders work.

0 -

OK, I was originally thinking you had baseboard. With cast iron radiators with air bleed valves you should be able to get the air out that way. As long as there are no high spots trapping air.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I don't like using the fast fill for purging as it generally doesn't have enough velocity, so I generally use something like a Webstone purge and fill valve in the main and then purge each zone individually. Not saying your fast fill method doesn't work, it would just need to be verified. How many vertical feet above the boiler is the highest point in the radiation? 11 psi may not be enough to lift that high, which would pull air in the high point vents if applicable

1 -

@GroundUp About 12' or 13' to maybe from the header/main but maybe 14/15' from the boiler itself.

I acutally hadn't checked that an had assumed system was at 15psi from the preset on the watts fill/regulator. I adjust that and then took the pressure off and set the expansion tank to match at exactly 15. Seems to be running well and getting between 18 and 22 psi when running.

I fast filled again and purged (maybe it doesn't work that well, I never hear glugs of air coming through the hose through the zones) and then bled the radiators twice again while it was cold.

So far so good. System pump still hasn't air locked.

Why is my circulator mounted wrong? Will that impact performance or just the orientation you mean? Being an amateur at this my layout didn't quite work like i envisioned so i had to orient it that way but I understood it can be mounted in any direction.

Last question (thanks!): I only have manual bleeders on the radiators, would it be wise to add an automatic one up there on the second floor somewhere? One radiator tends to get the most air because of its location.Thanks!

0 -

The motor needs to be horizontal, per the manufacturer. That won't cause air infiltration or anything but it will cause premature wear on the bearings and potentially allow an air pocket to be trapped in the volute. Manual vents are preferred, as long as time can be taken to properly bleed each one. Auto vents at high points generally are not a good idea as a low pressure scenario can draw air back in

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements