Beckett Burner tripping

For approximately the past month, the burner on my New Yorker boiler has been intermittently tripping. Typically, resetting it is easy: pressing the red reset button on the Honeywell ignition control will restart the burner, often with just a touch. However, on occasion the reset button alone does not work.

When this happens, I’ve observed that gently tapping on the transformer will cause the burner to start. Based on this behavior, I suspected a bad transformer and replaced it.

But, replacing it, did not change anything!

What the heck is going on!

Comments

-

You may have a dead spot on the motor. if there is power to the motor and the transformer and the motor does not operate then the tap may get the motor to start and off you go. The problem with that repair is: if my guess is incorrect then you now own two good transformers and two good motors. and you still have teh problem.

Have you thought of calling a professional oil burner technician?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

4 -

I have to ask : why not Becket designed and built a brushless DC motor for their burners?

At least the 24 volt version I know of.

And why no big(above 10Kwh) burners use a brushless DC motor?

They seem to be very reliable in many commercial things(cars and electric motorcycles beeing one).

Plus one can very gradually adjust speed of fan or oil pump unlike present AC motors...

0 -

-

@Gabriel82, Yes, I believe it can be easily done.

But you'd need more than just a modulating burner. Picture the scales for setting combustion air, pump pressure, and the "Z" dimension as 1 to 10 settings. High fire is 10. Low fire is 1. Every adjustment to modulate down can't always be 9 on air, 9 on pump pressure, 9 on Z. 8 and 8, and 8, and so forth. The actual combustion would need to be constantly monitored, and feed that information to the burner to make proper adjustments to the ratio to stay clean burning through the whole range.

They probably have a prototype out on Highway 61 next to the forty red, white, and blue shoe strings, and the thousand telephones that don't ring.

1 -

I just had the same issue on a Honeywell R8184G controller running a Beckett on a recent property acquisition on a freezing (of course) Sunday night (of course). When the reset was pushed, nothing would appear to happen but the safety would pop after 45 seconds.

I disassembled the controller and found a dime size hole burned in the PC around a relay contact that powers the burner motor. To repair, I removed the relay, Dremeled out the burned area, filled with epoxy, drilled a new hole, installed an extension wire to replace the relay pin burned below the PC level, and reinstalled. At some point I'll update the controller to a Carlin 70200.

If yours is intermittent, it could be a bad solder joint starting. Once the gap widens, it starts an arc which will burn a hole in the board.

One thing you don't want to do is keep pushing the reset unless you figure out the problem.

1 -

On @Gabriel82 thoughts about motors. Quite right. In the last decade or so brushless "DC" motors (they are actually rectifying AC motors, but we'll let that go) have become the go-to. But we still use AC induction motors for a lot of applications. Why? Cheaper. Long life spans (decades). Reliable. Run on crappy power. Perfectly satisfactory for constant speed applications (which includes domestic oil burners). If it ain't broke…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England4 -

-

Cost

If you understand how a fuel pump create pressure then you would know that adjusting the speed of the motor will not produce the desired effect. that being a change in the pump pressure to the nozzle in order to change the BTU input in some way that can be matched by change in air flow that a fan might produce when the fan rotation speed is changed.

To your point, since Gas input can be adjusted by way of a variable negative pressure at the gas valve, the DC motor IS being used in just that manor to offer variable input burners incorporated into many condensing boilers that operate with Natural and LP Gas.

You should do more research with liquid fuel burners to see if you can invent one that is cost effective with a DC motor that can also adjust the liquid fuel pressure to match the variable combustion air input available with such a DC motor option. Let me know how that works out.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

@MaxMercy said: "I disassembled the controller and found a dime size hole burned in the PC around a relay contact that powers the burner motor. To repair, I removed the relay, Dremeled out the burned area, filled with epoxy, drilled a new hole, installed an extension wire to replace the relay pin burned below the PC level, and reinstalled."

This situation is extremely concerning. While I understand how this modification may appear to function properly—and may even be considered acceptable by the building owner—it presents a serious and unacceptable liability risk. Anyone who assumes responsibility for a system that has been altered in this manner becomes exposed to significant legal and financial consequences if any failure occurs, even one completely unrelated to the modification identified here. That risk alone can be catastrophic, potentially resulting in severe financial loss, loss of licensure, or criminal liability—all in the interest of saving a relatively small amount of money.

Safety controls that are certified by a recognized testing agency are approved only as manufactured, and only when installed and maintained according to factory specifications. Once a control has been altered—by adding epoxy, additional wiring, solder, or any other non-approved modification—it is no longer covered by that certification. At that point, all liability transfers to the last individual who serviced the equipment, regardless of whether they performed or were even aware of the original unauthorized modification.

This is the most alarming aspect of the situation. Even if I were to perform a routine and otherwise unrelated service—such as replacing a nozzle, a relief valve, or another component—I would be assuming full responsibility for the risks created by an improper modification that should never have been made in the first place.

Max, this control must be replaced immediately with a properly listed and approved unit. This is not optional. Please obtain a replacement control as soon as possible.

I think of my dealing with Lennox Industries on a job in Avalon NJ. Nothing to do with solving the problem but Lennox washed their hands of the job as a result of a modification I thought was just perfect. Read this post:

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

I appreciate your advice as always Ed, but there was no modification made to the control, only the repair of the printed circuit and the replacement of one pin of the relay. I should have taken some pictures (and I did think of that after I finished, but I was more concerned about pipes freezing). For some context, I am a retired electrical engineer that has designed and/or built hundreds of prototypes going back to the 1970s when I used to free hand resist draw, chemically etch, and drill prototype printed circuits.

Worst case scenario is that it fails, the burner motor won't run again. The repair did not in any way alter the original design or affect the safeties in the controller (I pulled the yellow cad cell wire after I reinstalled the control and it locked out in 45 seconds). I will replace that controller as time permits with the Carlin controller because it features diagnostics and it's shorter lockout time, but I assure you the repair was proper and safe.

1 -

Well, maybe I want to use the burner/heater boiler while on the move just on battery, 12 or 24 volt...

As is, with AC I have to have a pure sine wave inverter with enough power "resistance"on top of what is the maximum that AC motor will draw(Amps)...

And if I blow up in smoke the inverter I still cannot use the burner AND I need a new inverter...

😑🤔

not fun...

0 -

@MaxMercy replied: I appreciate your advice as always Ed, but there was no modification made to the control

So you are saying that the control comes from the factory with epoxy and wire identical to the epoxy and wire you provided? I think not.

Perhaps I didn't make myself clear. The fact that your modification has nothing to do with a subsequent failure where there is a catastrophic failure (for instance a relief valve that fails to release and the a section of the cast iron explodes off the side of the boiler and damages property causes an injury or causes a death might happen**) will have no bearing on the insurance companies determination, the boiler manufacturer's determination or even the relief valve manufacturers determination that the problem was not their responsibility as a result of the unauthorized repair of the primary safety control.

When in front of a judge… that went to law school and never picked up a wrench in her life, that has no practical knowledge of what we actually do for a living, and your background as an electrical engineer, … hears that you put wire and epoxy on a control that is called "The Primary Safety Control" from another lawyer… that has never picked up a wrench in her life, that has no practical knowledge of what we actually do for a living, and your background as an electrical engineer, and they see how much you are worth, …what do you think the judge will decide?

I'm not saying you are wrong or did anything dangerous, I'm just giving you the facts from the several court cases I have been witness to. The real world is out to get us MAX.

I don't believe you need to replace that control because you made the repair, and in your situation I might have done the same thing. The difference is that the next business day I personally would be purchasing the replacement control and installing it ASAP.

Just some ramblings of an old man with a wrench

** I actually saw a boiler in Stone Harbor NJ, with the relief valve outlet plugged to stop it from leaking, when giving an estimate for new equipment. A few weeks later that same person asked me if I could fix the boiler and when I arrived a 12” x12” section of cast iron was embedded into a cinder block wall next to the boiler. I guess it over pressured as a result of a control defect and a relief valve that did not discharge the pressure that built up. I was surprised at the sheetmetal cover of the boiler being torn away like you might see on a Saturday morning cartoonEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

I'm on it 😁

Right now I do suspect two DC brushless motors would be needed!

One for the oil pump and one for the combustion fan.

I almost managed to buy a diesel heater that had two brushless motors(one for combustion fan ,other one for cooling the heat exchanger,since it's air heater).

Someone else bought it faster than me...

This setup is for higher efficiency since combustion fan/motor can run for optimum efficiency and the other one can have a higher rpm so that air can be circulated over the heat exchanger.

So more energy is extracted from same quantity of fuel . Up to a point ,since diesel fuel needs some heat and air to burn properly!

Brushless motors are small,can pack up Power, are adjustable by voltage, hell even electric bicycle have them...

Why not an oil burner?

Since the oil pump has a coupling part to fit the same motor that spins the centrifugal impeller.

AND ,since you say it in a comment above ,a DC small voltage would be safer than 115AC, or 230AC...

As for the ignition part ,well yeah, that still is dangerous...

But ,I managed to shock myself in an old Bmw M20B20 plug wires...

By accident... about 20000 volts 😂

Hurt a bit.

All I'm saying ,as history proved it ,even oil burners can be improved!

Motors, Fans, combustion side, heat exchanger(condenser ones and corrosion resistant alloys, 316L, 904L, AL29-4C,etc...) .

All for the benefit of the customer(who wants higher fuel bills or never ending parts orders?!).

0 -

"So you are saying that the control comes from the factory with epoxy and wire identical to the epoxy and wire you provided? I think not."

You're correct, it didn't come that way, but it is also in the realm of what is considered a proper printed circuit repair. It's analogous to sectioning a part of a rusted out automobile quarter panel and welding in a new patch panel.

I get that the world is out to get us - we have more lawyers than doctors, and that gap continues to widen…

0 -

@MaxMercy, Defending your experience and technical skills in a court of law, when someone was injured or worse, will fall on deaf ears. You are absolutely right as you are taken the the cleaners by some slick lawyer

But you can feel better with the knowledge that I also agree with you.

Here's another story from 2013 where the person that is responsible for a disaster was not punished at all, but the innocent were to blame since they have deeper pockets. That is how the legal system works here.

This happened in my neighborhood in 2013.

- An elderly couple switched from LP to Natural Gas.

- There was gas left in the LP tank

- The contractor that installed the new gas lines (Shore Guys) left the unused LP pipe in the crawlspace

- The propane company did not collect their LP tank in a timely manor

- The gas fireplace could not be converted to natural gas

- When the handyman Neighbor heard that there was gas left in the tank and that the fireplace gas log could still burn LP GAS, he did the friend a favor and tried to light up the fireplace by opening the valve on the abandoned gas tank.

- When that was unsuccessful because the LP Gas line was disconnected and abandoned under the home, he gave up and forgot to close the LP Tank valve

- The next time the well pump under the home sparked on, the house was gone!

Who made the mistake? the neighbor. Who got blamed? the Contractor and the LP gas delivery company.

But this won't happen to you MAX. That stuff happens to other people!

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

@Gabriel82 says:

I'm on it 😁

Right now I do suspect two DC brushless motors would be needed!

One for the oil pump and one for the combustion fan.

You will need to redesign the fuel pump pressure regulator or have an electronic orifice size adjusting mechanism. That is because changing the speed the fuel pump rotates does not change the pressure sent to the nozzle.

If the fuel pump rotates too slowly, the pressure valve will not open at all, which means that there will be no fuel at low fire speed. So how will that work for you? Low fire = No fire

Once the pump rotation speed reaches the minimum speed to open the pressure regulating valve you will get the fuel at the pressure that adjustment is set for. (100 PSI For example) As you increase the pump motor speed the pump gears will force more oil into the pressure regulating chamber and the pressure regulating device will continue to deliver 100 PSI pressure to the nozzle, and all the other oil will be bypassed back to the tank or the inlet of the pump.

So the faster you go, the more air you will force into the combustion chamber, the more oil will be bypassed to the tank or pump inlet, but the amount of oil will remain the same as a result of the pressure regulator in the pump being set at 100 PSI and the nozzle orifice being fixed at the same GPH rating no matter what pump motor or the fan speed is turning.

But What do I know?If it were that easy, someone would have already done it!

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

-

-

You can do whatever you want regarding controls repair, re solder or whatever monkey business you want. If something happens you will be responsible

Those of us that went to some type of trade school and obtained heating, AC or electrical licenses basically were forewarned not to monkey with safety controls and control repairs. It's not worth it or the liability involved.

No matter what good intentions you have the judge will put you away.

I have an example:

In the old days before many electronics vacuum tubes were common in burner controls. Honeywell had the RA890 burner control used on oil or gas burners (commercial) Common in the 50s & 60s

One fault this control had was that a match book was the perfect size to hold the flame relay closed to keep the burner running instead of locking out. Not good but that's not my story.

Honeywell specified that you should only use Honeywell vacuum tube #####. That being said when you needed tubes you just went to the electronics store and bought a tube that crossed referenced over. For all practical purposes it was the same exact tube.

But not as far as a Judge and Honeywell were concerned. There were many burner failures that Honeywell got out of because of a substituted tube

0 -

Can someone tell me if these motor/rotor problems happen in the 24V dc beckett burner?

Around here,in Romania Riello and some german brands(with blue flame low nox) are the most seen in oil or natural gas boilers.

In all honesty I haven't even seen a Beckett burner.

Although the way is designed seems a lot simpler to service than many other brands!

Thank you!

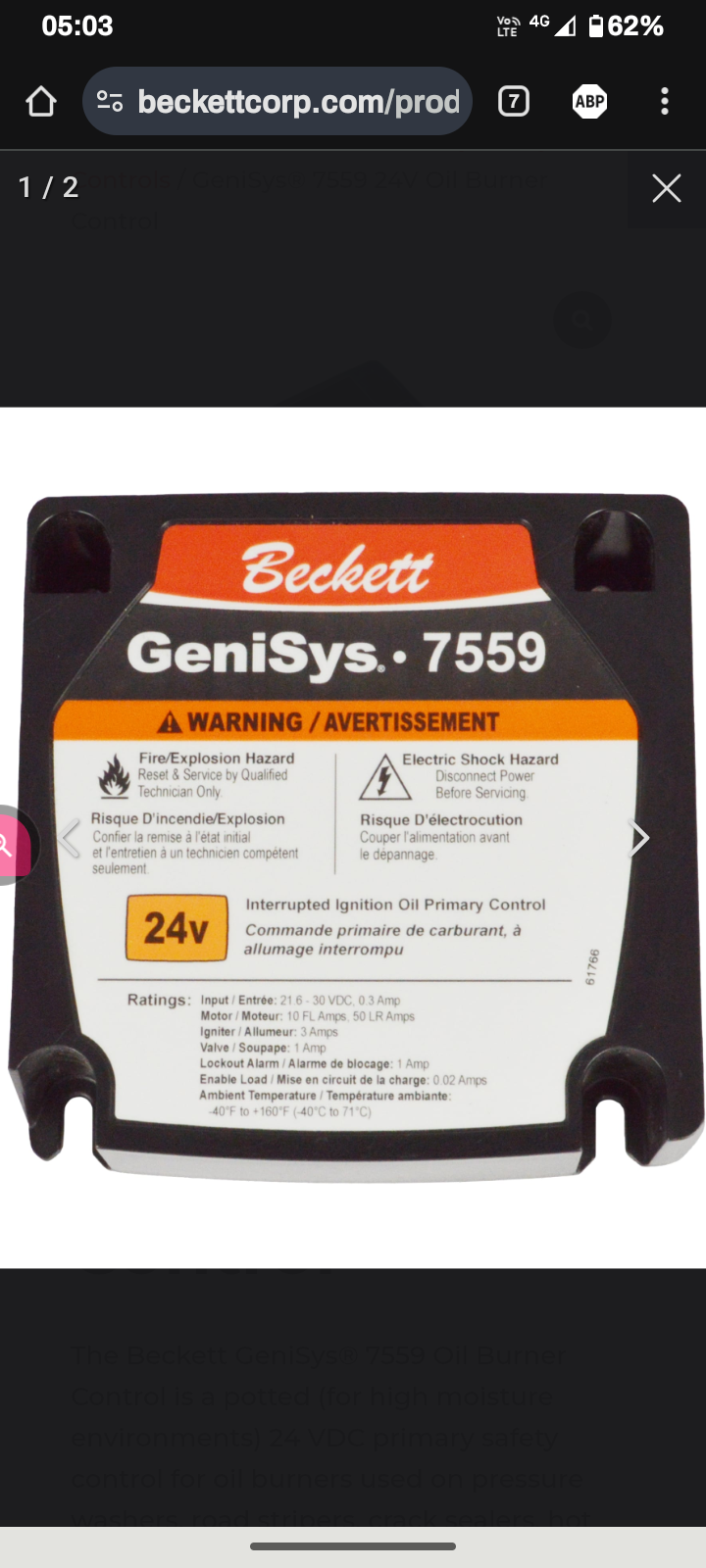

Beckett GeniSys® 7559 Oil Burner Control

https://www.beckettcorp.com/product/genisys-7559-24v-oil-burner-control/

0 -

In the U.S., we are mostly still using 120VAC PSC (permanent split capacitor) burner motors. Genisys 120VAC primary, 24VAC secondary. Igniter 120VAC primary, 14 to 20 thousand VDC secondary.

The German blue flame is likely the Buderus G125BE. They were offered here for a while but didn't sell well due to cost. It was a lot of extra money for a small gain in efficiency over their G115 boiler with a Riello burner. Beautiful boiler and burner, though.

0 -

Fair question - it was Sunday and I didn't have access to a new control, and given the 2F temp, I was concerned about freezing pipes, so time was of the essence. My back up plan was another older Honeywell control that I know I have somewhere buried, but I didn't know what box it might be in much less what building it was in .. 😏 That might have taken a few hours to locate.

But repairing electronics is as easy and natural to me as an advanced skill that you have that I don't possess is to you. Honestly, it took longer to R&R the board and drive it back to my shop to repair it than it actually did to repair it. The longest time was the 15 minutes I had to wait for the epoxy to set (I had some coffee). There was nothing extraordinary about the technique or the effort. The actual time spent on the repair of the board was 30 minutes including the epoxy dry time.

Years ago I had to repair a broken (dropped) circuit board from a large European machining center for a machine shop. It took probably 10 hours of working under a 3D microscope to repair the dozens of tiny traces that were severed. The board was not available from the manufacturer and the "repair" would have been to fly out a technician to replace the board. The cost to the machine shop would have approached $10K. He was thrilled to pay me a twentieth of that. That was an extraordinary effort, but I digress.

When the weather warms up and when time allows, I'll put a Carlin 70200 in it. If we decide to flip the property before then, and even thought I know that repair is proper and will last forever, I'll replace that Honeywell anyway with a new controller so I can sleep at night after Ed scared the beejezzus out of me… 😁

2 -

@MaxMercy , "under a 3D microscope...". That's pretty cool. You must have the patience of a Saint working so small.

I changed out and relocated a zone panel with (3) 75 va transformers for the radiant actuators today. The panel and one transformer were bad. They were mounted behind the indirect water heater. Inches away. I had to use stubby tools to get in there. Its surrounded by a 120 gallon indirect, a 40 gallon buffer tank, and the boiler. There's pipes everywhere. I had to duck under and pop up to get to the area. Once you're there, its like you're in a coffin with booby traps. Relief valve at my left elbow. Primary circulator at my right. At one point I hit the power switch by mistake (yes, it's in the same terrible location), and the wire for the isolated end switch to the boiler was touching the electrical conduit. So of course it blew the 3 amp fuse in the boiler. I was so proud of myself I didn't curse once. Nobody home, so I could've let it fly if I wanted to. What really pisses me off is the meatball that installed it in the first place. The whole installation was real sloppy. Patience.

2 -

Hey, I really feel that I need to follow through with this.

Thank you all for the information and wisdom that you provided.

Years ago, I replaced the boiler in my previous home because it was rusting out. Just something about standing near it and seeing flames whenever it turned on gave me concern.

Anyway, I took off the burner and saved it for parts. So when I read EdTheHeaterMans post about the motor I remembered it and knew I could try this repair for free.

It's only been 24 hours but the used Beckett motor does seem to have fixed the problem. The motor that was on my boiler was an Emerson but they are both part number 2456. It's my opinion that the Beckett is more quiet. If it's not, it has a tone that is easier on my ears.

Thank you all for your help I deeply appreciate it.

0 -

Just to chime in regarding the board repair,, I agree with Max. I've done the same in a few cases. I've taken apart controls and repaired boards. Most times it's just a simple solder joint.. I have also fixed the tracers on boards as well..

I do understand the legal concerns about repairing or modifying a mfg part. But to me it's called a "REPAIR". And it's not necessarily modifying anything. It's just repairing what has already been designed and assembled.

Years ago, people used to REPAIR things all the time. Nowadays, it's simply REPLACE.

What ever happened to the guy that would REPAIR a toaster? Or an old TV ?

"My father is a television repair man and has a massive set of tools" 😁

2 -

I'm back.

My burner is tripping, requiring me to press the reset button, only when calling for domestic hot water. AKA showering! It has been notoriously cold this winter where I am in the northeast and the boiler has been running fine otherwise. I do have a mixing valve installed and I have never tinkered it so presumably it is at 125 degrees.

Any thoughts?

0 -

I just heard someone using the shower so I checked on the boiler and sure enough its tempurature was low so I rapped the motor with the most convenient thing I could find, an aluminum cat litter shovel, and it immediately fired up.

Is it safe to assume that the old replacement motor that I had sitting around isn't much better than the one it replaced?

If that is the overall best guess, is there a particular brand suggested?

Is there any brand that is more quiet than the others?

Thanks!

0 -

A couple of miscellaneous musings…

On repairs, modifications, and the like. I'm not sure whether our electrical engineer friend up above is a registered PE or not. Many electrical and mechanicals are not, so the following may make no difference. It also, however, applies to licensed trades. Registered Professional Engineers may only work in the fields in which they are registered. In those fields, they may be and usually are protected by errors and omissions insurance, but this will not be available outside those fields. In any event, the rule is that the last party who made any sort of modification or repair, however defined, owns the liability for the whole, and has the burden, if something goes amiss, of proving that their work had nothing to do with the later problem.

Just sayin'.

On motors. Single phase AC, line voltage squirrel cage motors (there are many flavours) are still used for a very simple reason. They are cheap and reliable. True, they aren't as elegant or efficient as rectified DC motors can be, nor as controllable (they either spin or they don't). But they will run all day for decades on miserable power and never complain.

On oil pumps. As someone noted the oil pressure in a liquid fuel burner or engine is not controlled by how fast the high pressure pump is running. The volume delivered to a free outlet is — but that is not the situation with a nozzle (or in engines, the injectors). The pressure — and hence the flow rate of a fixed nozzle — is set by a pressure regulating valve, and excess volume is returned. In engines the injectors are pulsed, and the fuel volume delivered is controlled by the pulse duration.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I agree but the website is called HeatingHelp, right?

0 -

If you're getting your DHW from the boiler, then the call for hot water should have no more effect on the burner operation than a call for heat.

It seems to be that for you to have struck the burner motor and caused it to start, it would HAVE to be in that 45 second window from when the control attempts a burner start and when the control locks out from the burner not starting. I guess it's possible?

Yes, this is "heatinghelp" but you have to understand that intermittents are notoriously difficult to diagnose, particularly when it's done by correspondence. If you're going to repair this yourself, then you can fire the parts cannon at it - replace all the maintenance items first (filters, nozzle, points, coupler, cad cell) and then move on to the burner motor (new), pump, control, and aquastat… That may not fix it as it could be a broken wire or even your boiler's red switch.

After it's working, it really needs to have the combustion and draft adjusted for safe and clean operation. Either hire a company with combustion equipment or buy it and learn how to use it.

0 -

Max Mercy. I totally agree with all of that.

I understand what you are saying regarding DHW should not have anymore of an impact than a heating call from the thermostat but that was what I was questioning.

I may start this guesswork off by bring over the burner primary control from the burner that I saved when I replaced my old boiler years ago.

I say this because I rested the aluminum litter shovel against the motor to remind me not to press the reset button and I went to grab it, that inadvertent touch was enough to fire it up.

You got me. Anyway, I have the part, it's free and they had worked in unison before.

I don't have an answer as to whether I struck it within 45 seconds or not, sorry about that.

Thank you.

1 -

Same old, same old. The burner runs forever with a call for heat. The washing machine calls for hot water and it doesn't fire up until I press the red button on the now replaced oil ignition control box. hmmm.

I mean I thought this was HeatingHelp but after the musing I too am lost in thought.

It's fine if it's not. I would simply need to move on and ask for my $25 back.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements