HELP!!Is It possible for a Boiler to Run with a Sealed Air Intake, and APS always closed

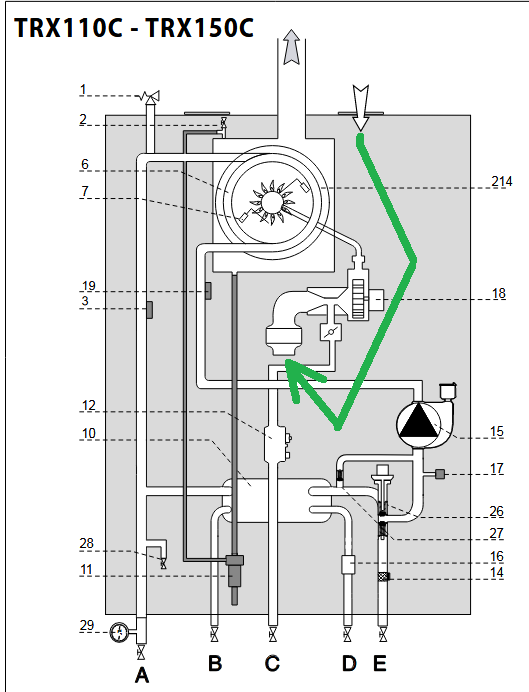

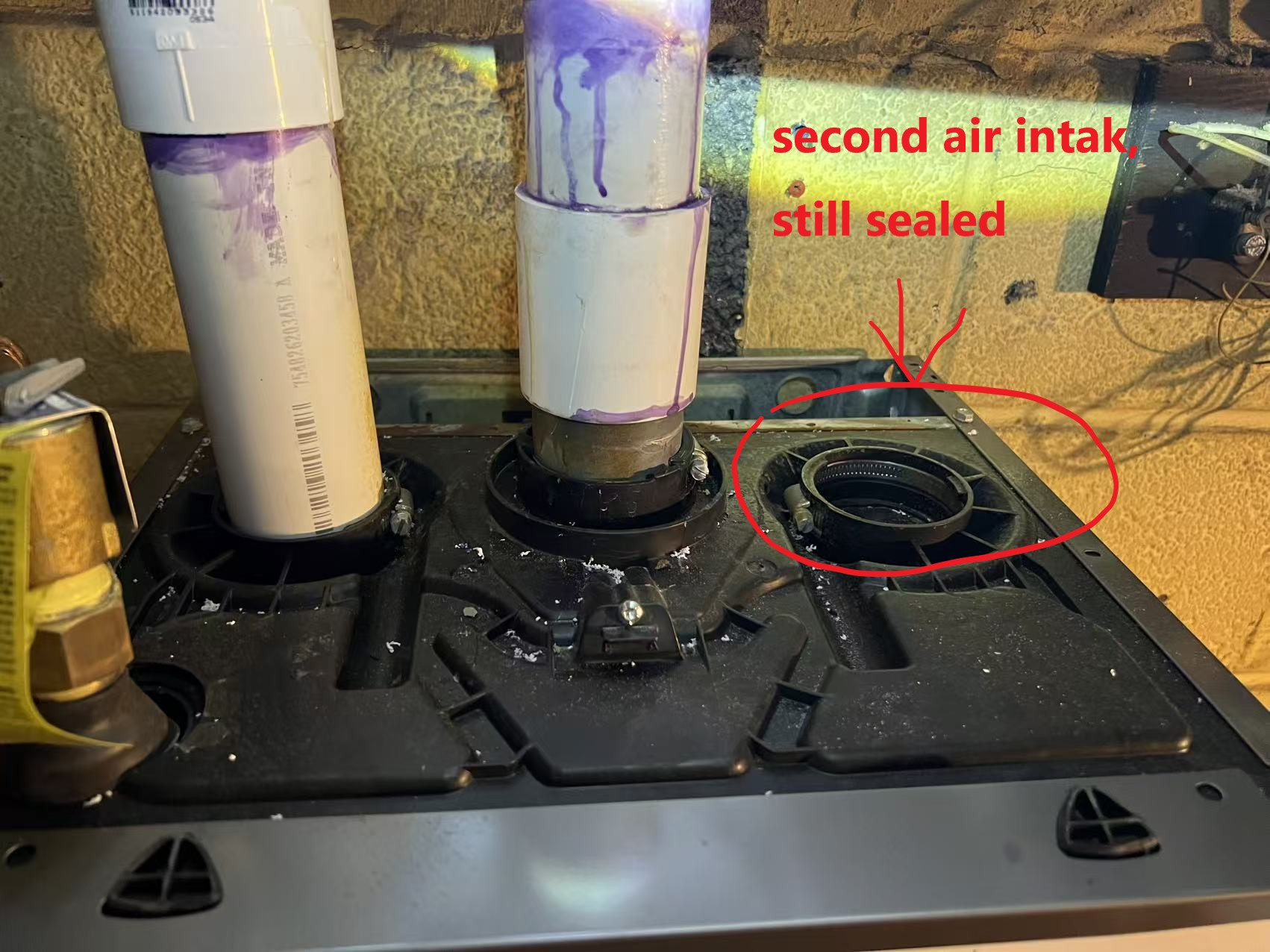

Basically, someone installed this gas boiler in my basement last year..and ever since then, there have been so many things going on. They didn’t take the air intake cap out, the exhaust started to leak, and while I am not a boiler technician, I recently started to do my own research about how the boiler could have been running for about six weeks while the air intake cap had been hermetically sealing the system for so long.

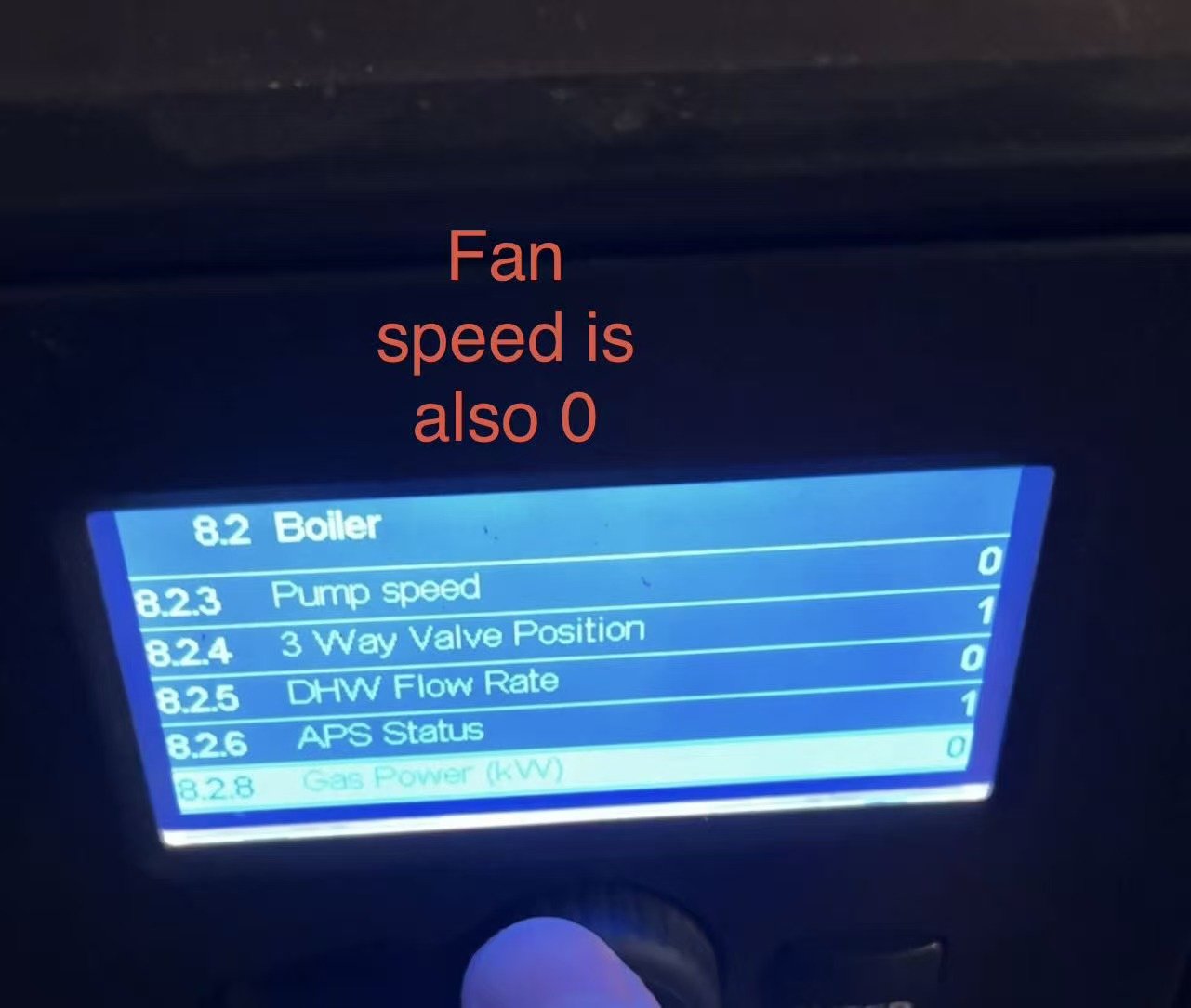

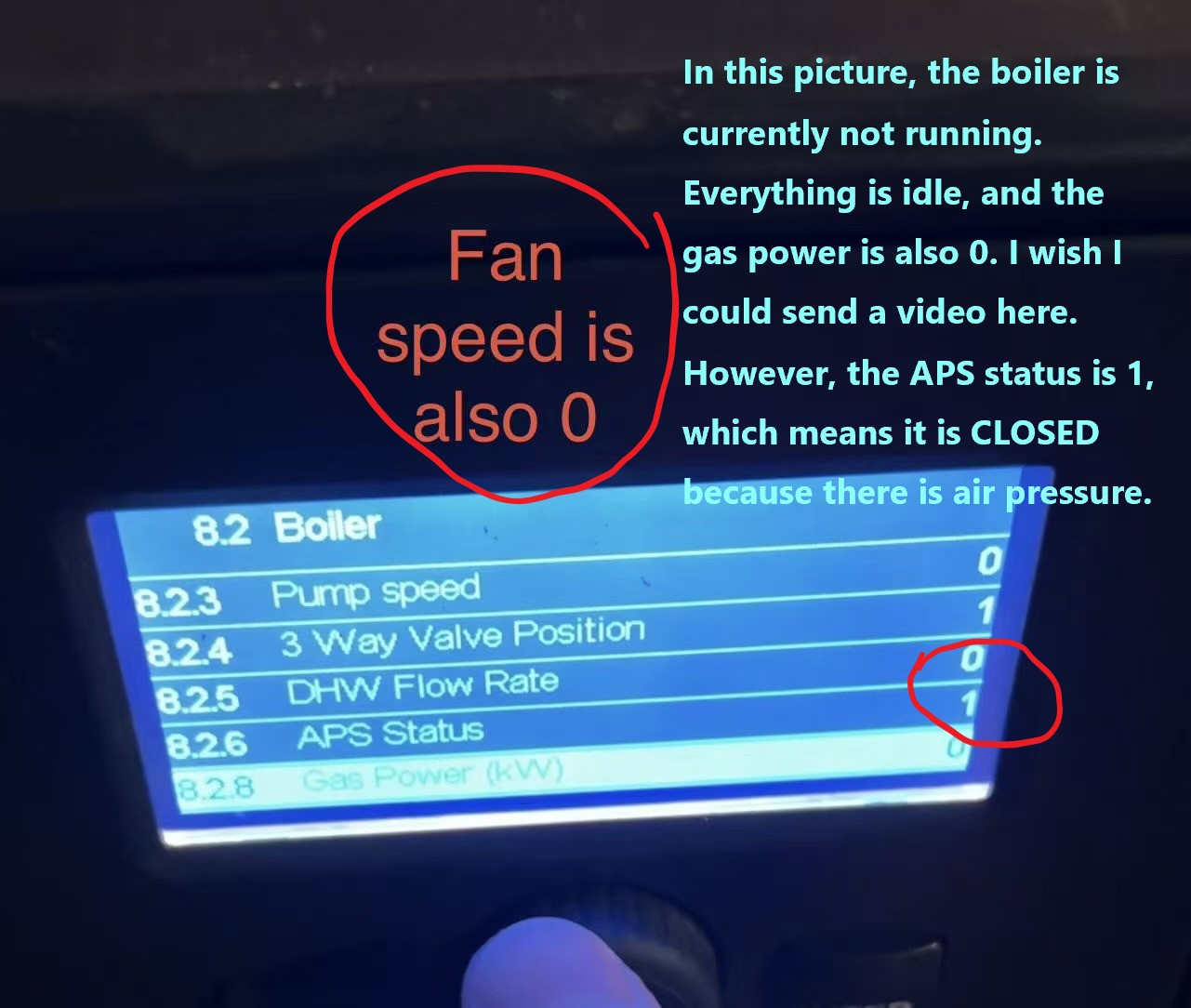

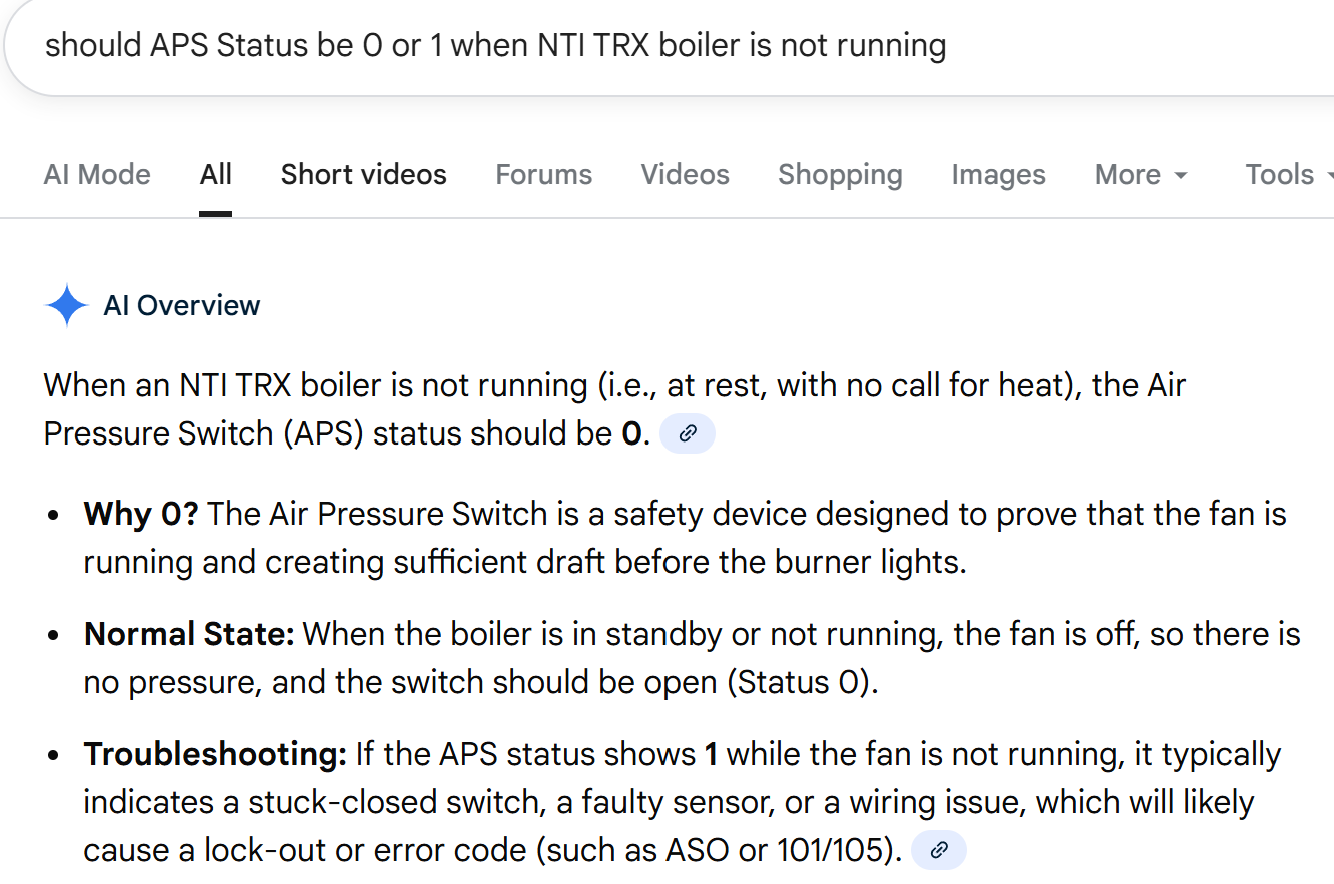

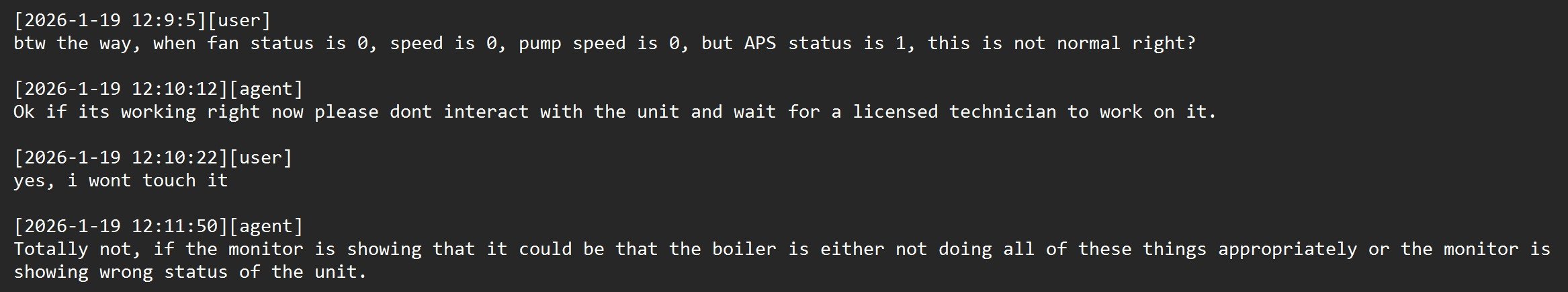

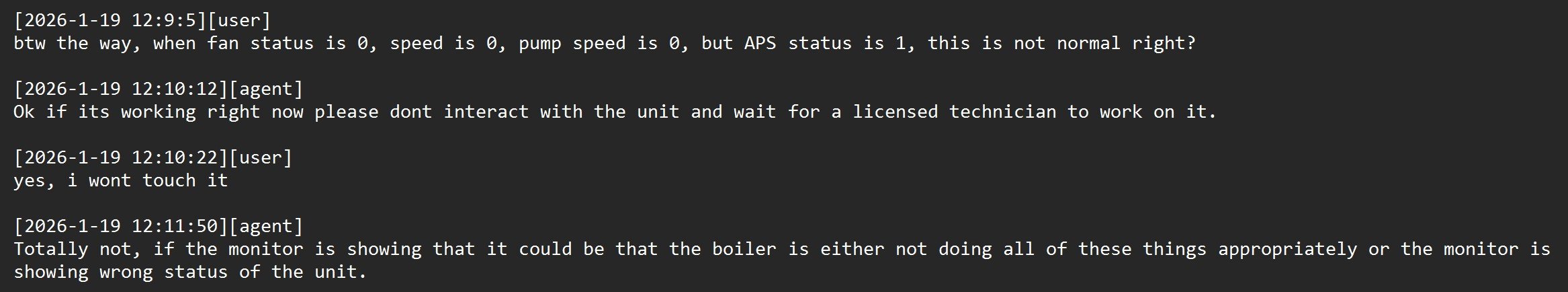

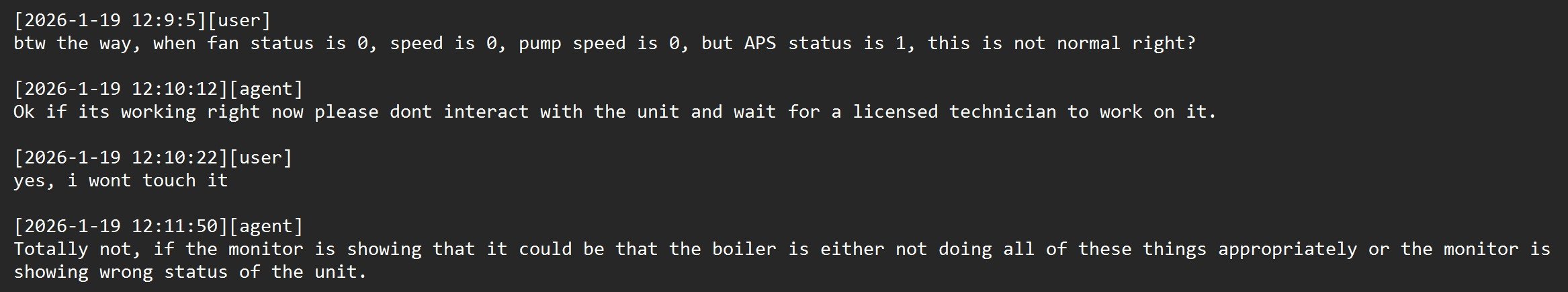

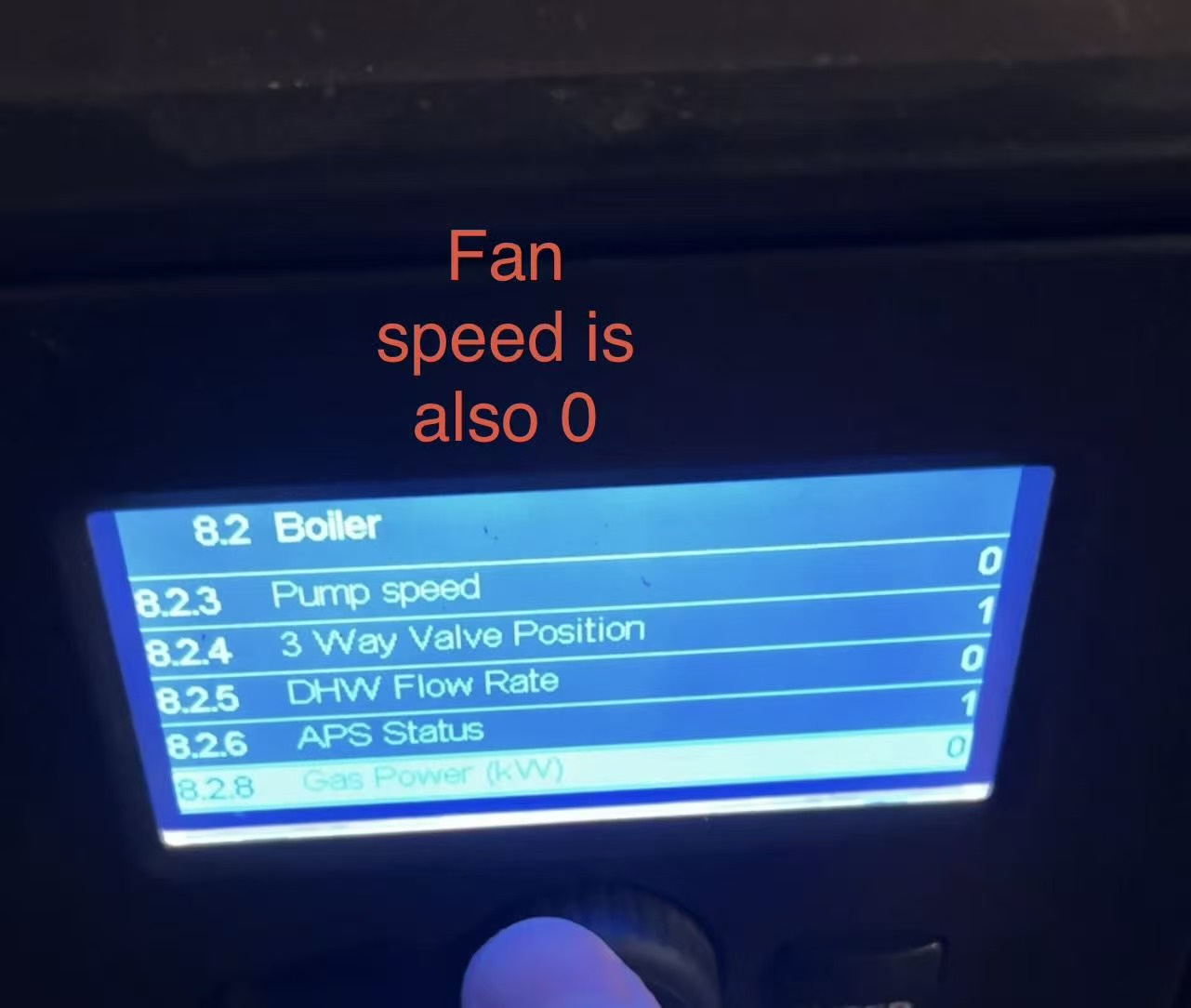

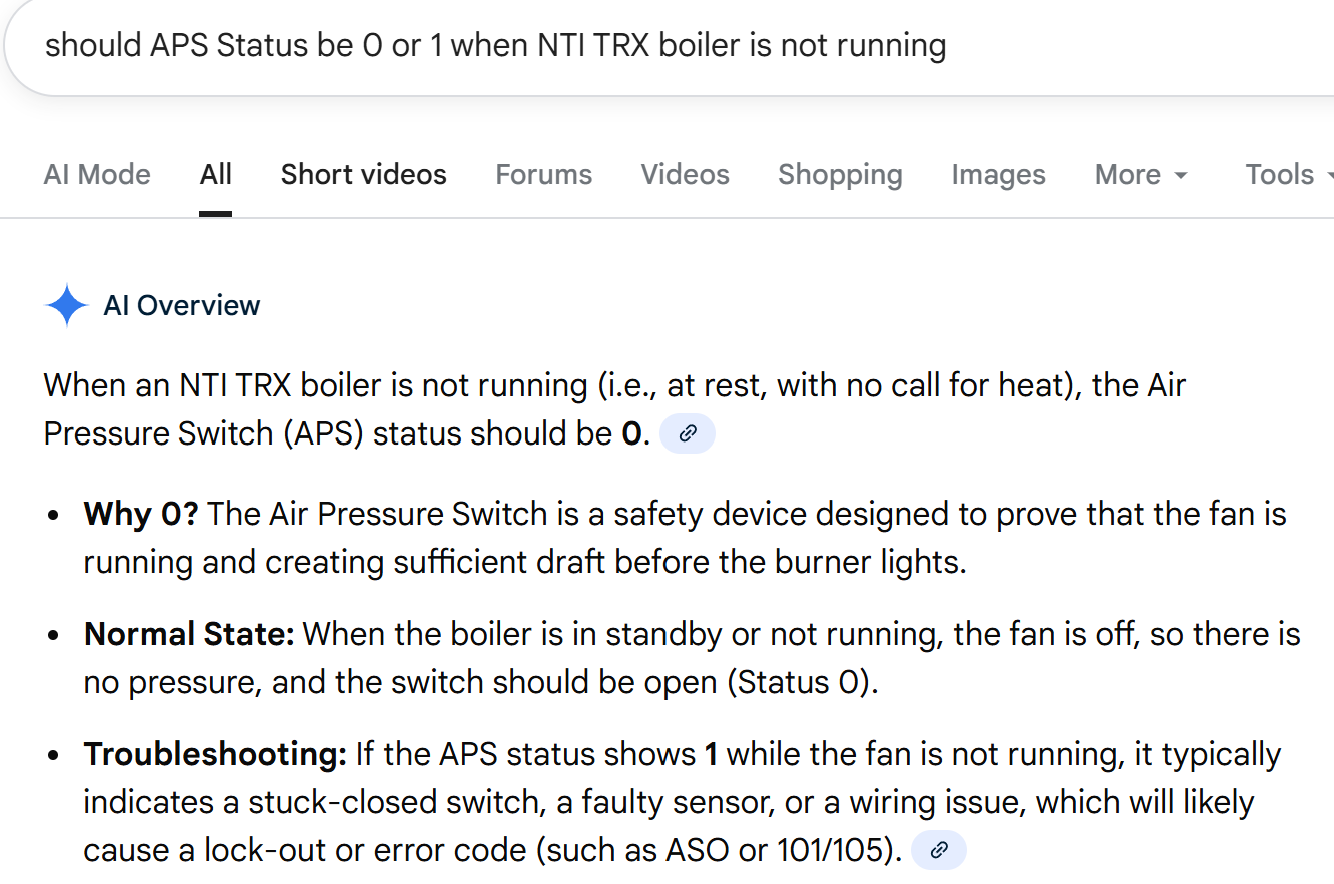

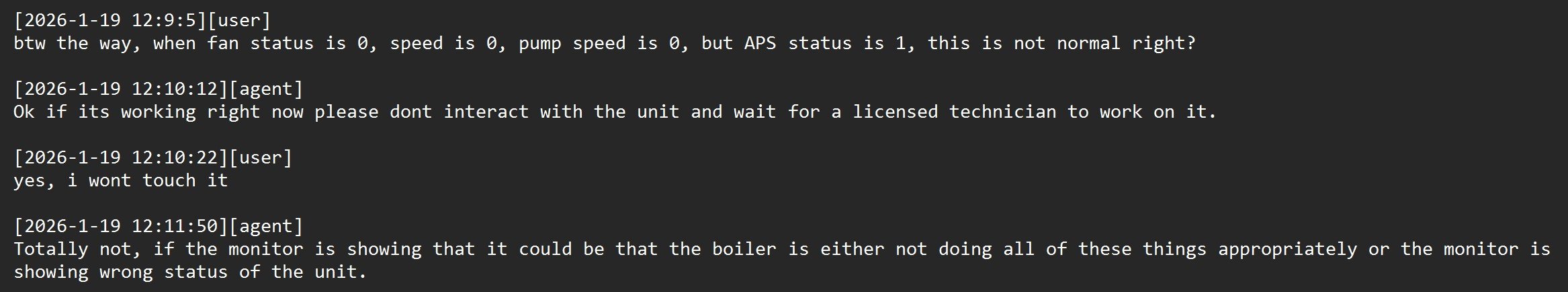

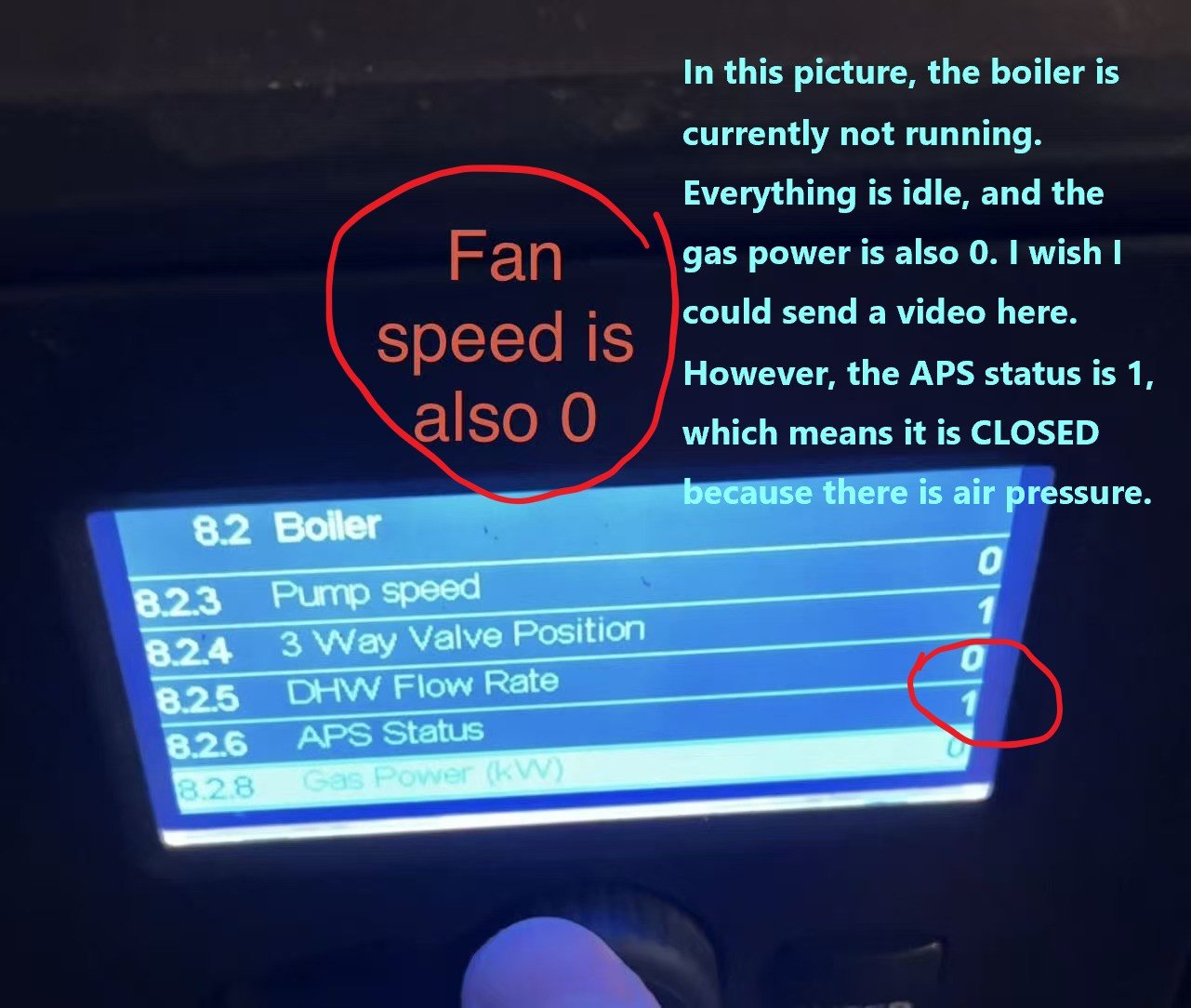

I recently discovered on my own that when the boiler is not running, the fan speed is 0, the gas power is 0, while the APS status is 1, which, based on my research, means the air pressure switch is closed. More surprisingly, there is no error code displayed on the screen.

Is this even possible? Is it possible that they likely manipulated the wires, trying to cheat the air pressure sensor so that it is always closed? Subsequently, is it possible that they also manipulated the main control board to silence the machine from reporting errors?

Also, it is really cold outside right now, and I noticed the exhaust flue temperature is 156, which, based on my research, is a very dangerous temperature for the exhaust PVC pipe as well. Is it possible that they also bypassed something so the boiler never shuts itself down?

This company says "nothing is wrong"...... while it is temporarily working though and I have to keep it on just because it's freezing outside… and nobody is sending me a commissioning report…

UPDATE 1/25/2026:

Thank you all so much for replying to this post!!! I want to clarify a few things. The boiler is currently running and providing heat, and the air intake cap was removed about six weeks after installation. There are no error codes currently being displayed.

The confusing part is that when the boiler is NOT running, it still shows APS status 1, meaning it is CLOSED (because the control board thinks there's air pressure). The boiler is not detecting this as an error, and everything is still working.

Here are some crazy videos….

when boiler is ON, APS is ON

when boiler is ON, APS status is 1

when boiler is OFF, APS status is STILL 1

when boiler is OFF, APS is still ON

Comments

-

You need a real pro. What make and model boiler? Where are you located?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

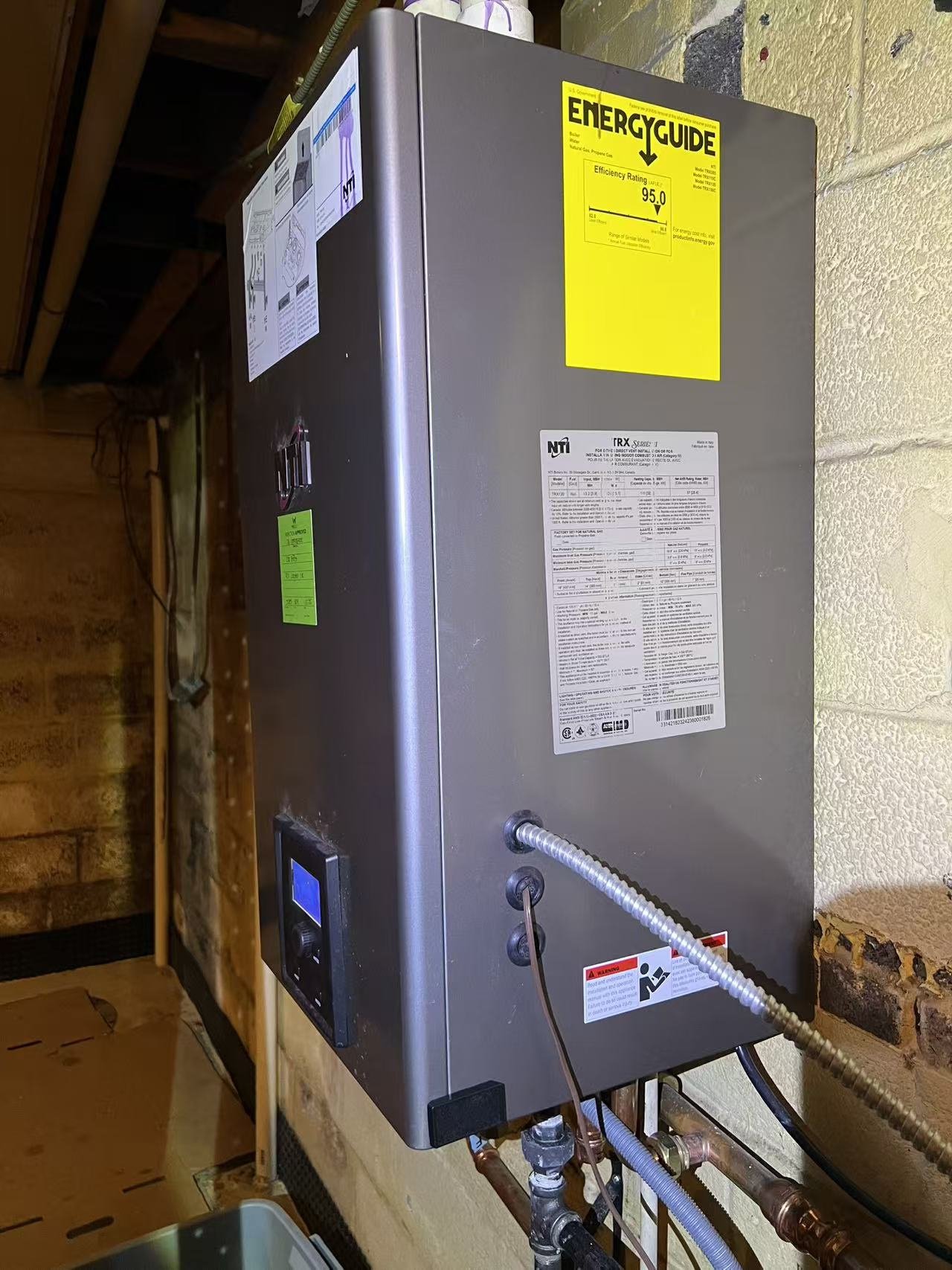

NTI TRX, I'm in MD

0 -

the flue temperature tracks closely to the water return temperature.

What temperature do your heat emitters need.? Staying below 140 will allow the boiler to condense and run more efficiently.

The lower the return, the more it condenses.

Mod cons are used in high temperature systems.

Don’t get started on the PVC pipe compatibility, that concern has been going on for many years

IPEX makes a tested and approved plastic venting product, Centrotherm and a few others.

Impossible to answer your question regarding control hacks

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thank you. My real question is: how could the boiler even run with the air intake cap sealing it? I thought it should have locked itself immediately, unless someone bypassed the air pressure sensor.

Currently when the boiler is not running and there fan isn't running either, the air pressure switch sensor says it is still closed.

0 -

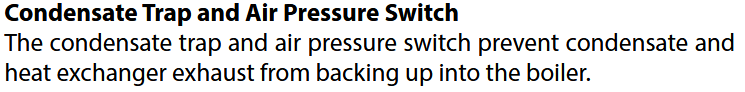

APS = air pressure switch.

The logic, algorithm or computer software built into the boiler control makes it nearly impossible to hack in the way you are imagining. The API must be in the "normal position" (not operating) before the exhaust blower can start. If it is hacked to the "operating position" then the blower will not start.

Once the exhaust blower starts the API switches from the "normal position" to the "operating position" and then allows the burner to fire. (there are a bunch of steps in the trial for ignition sequence before the flame actually ignites). Once the flame is established, if the API gets switched to the non-operating position or "normal position" for any reason, the gas valve will shut off the main burner fuel. That system is pretty much bullet proof for safety reasons.

As far as having the combustion air intake hermetically sealed, if that were the case then the API would never change from the "normal opposition" to the "operating position" because you can't blow air out if there is no air coming in. That is a basic law of physics. A fan only moves air, it can not create air from nothing just by spinning the blades.

There is a real need for a professional here to ease your concerns.

Does this piece of equipment heat the rooms in your home and Domestic Hot Water (you use for showers) also?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

That is exactly my concern… the technician didn’t even remove the intake cap for six weeks, and there’s no way the boiler would have kept running without shutting down. So, I don’t know if something was bypassed. According to NTI support, APS Status 1 means the APS is CLOSED because there's air pressure—but the intake cap was never removed.

and not it's just heat only for my radiators, there's no indirect tank linked.

0 -

does the air intake pipe directly to the inducer fan, or just into the boiler cabinet? Some boilers have air into the cabinet, if so possibly the door was off or leaked enough air for the burner.

I doubt it would even light off with no air at all available?

I’m not sure what you mean by intake cap? Was this on the air intake termination, or at the boiler? What purpose would it have served?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

More pictures would help.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

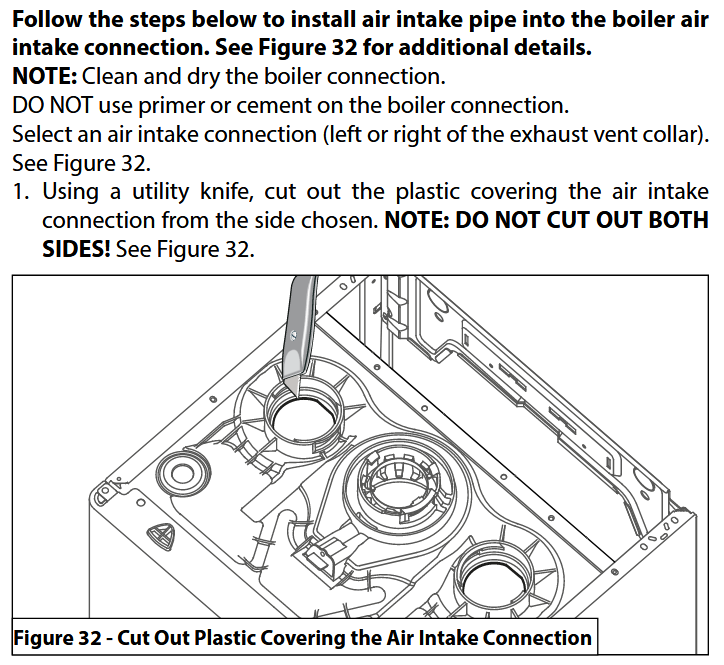

It is an NTI TRX boiler. The intake cap came with the boiler, and someone needs to physically cut it off with a knife, not just remove a plug.

The cap has been cut off now, but I started to get curious, how is it that if there was no air pressure, there were no error codes? The air pressure switch should have shut off the boiler immediately. (Actually, that’s what happened when they first installed the boiler, they couldn’t turn it on.)

By the way, my posts about this on Reddit are now getting banned and deleted. This company must know they can’t put out this fire anymore. I’m already planning to directly ask the government on Monday anyway so I'm just asking here see if anyone knows about NTI TRX boilers

0 -

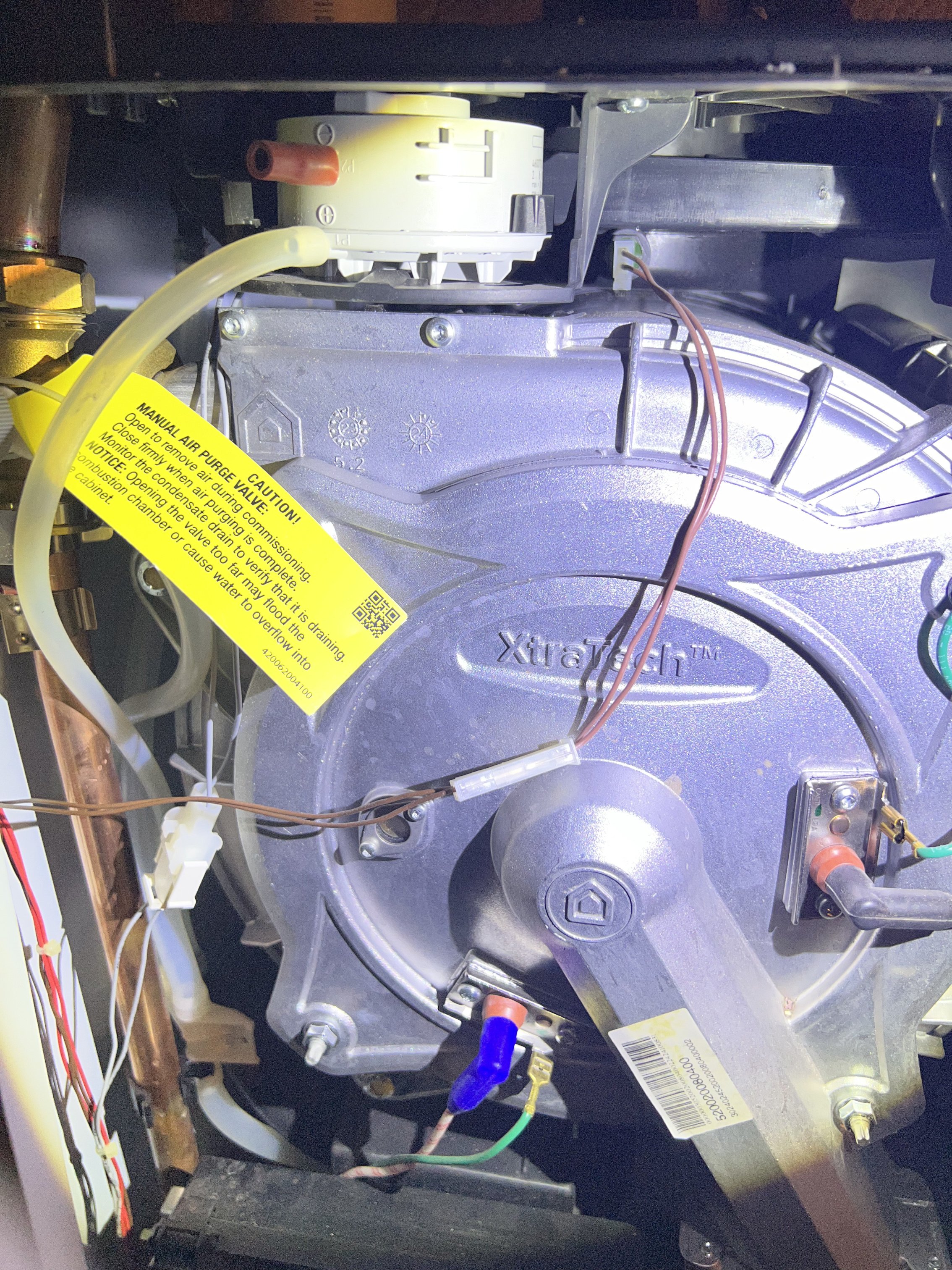

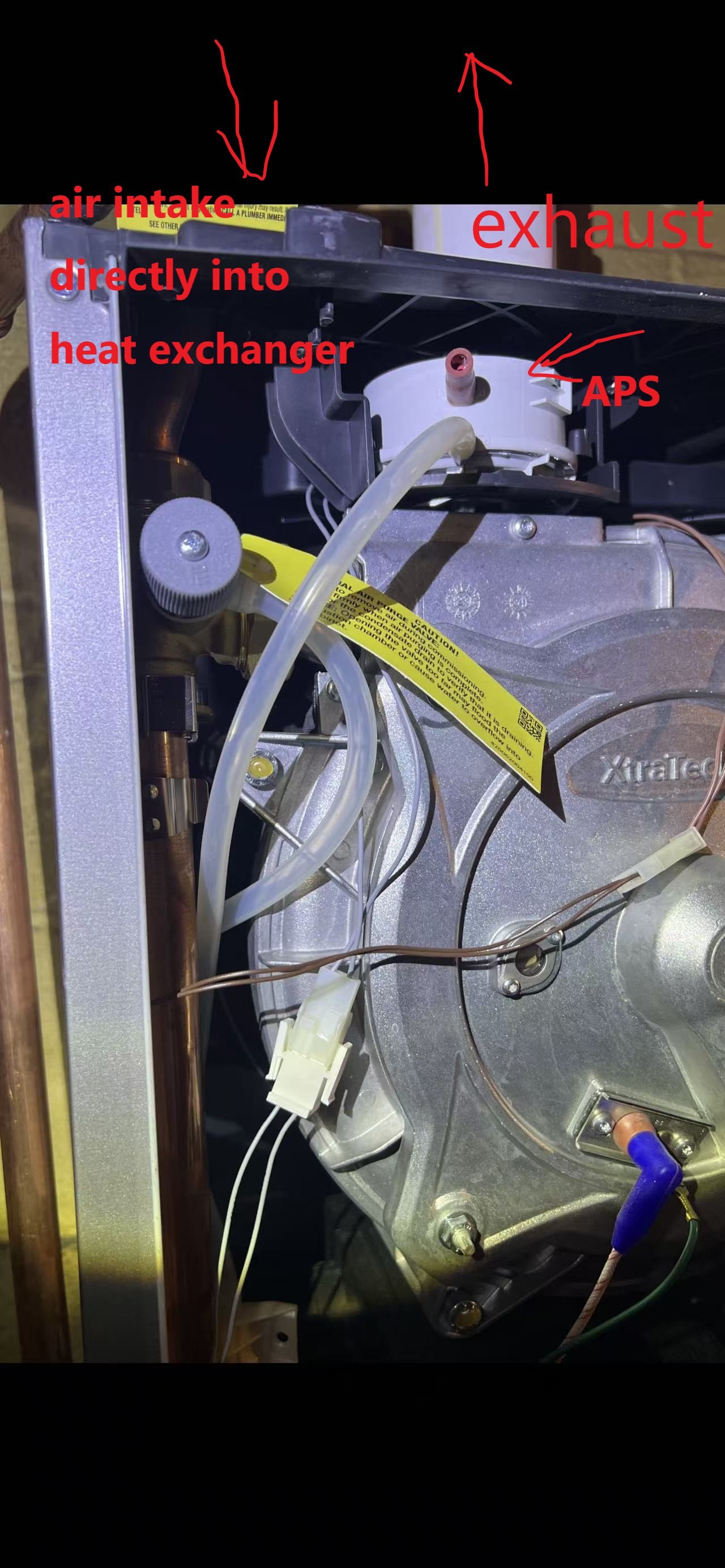

Also, the cap directly seals the heat exchanger, it seems. I overheard the technician say that 100% of the air is coming from the intake pipe. I;m not a technician though

0 -

-

the left one!! yes that's the manual,,, they never cut that thing open…. and the boiler was running for almsot 6 weeks……….. no the right one is not being used

it's open now though

0 -

So they installed the air intake pipe to the outside and never cut out the plastic covering ?

Does it work better now ?

I agree with @EdTheHeaterMan about the pressure switch logic.

Maybe as @hot_rod stated it was getting air from cabinet leakage.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

yes exactly, it is working now, the point is, the first day they started the boiler, they said that something's wrong, and they talked about missing a part of 'coil' or 'board', and i highly suspect they bypassed the APS sensor for it to run, because this boiler is not designed to use conditional air to combust

0 -

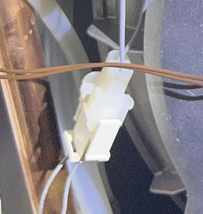

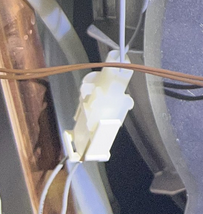

Attached is another internal photo. These two disconnected wires hanging inside the cabinet are highly suspicious. My assessment (again I'm not a HVAC technician at all) is that the Molex connectors were tampered with to manually jump (bypass) the Air Pressure Switch (APS) and the Heat Exchanger signal (maybe related to like a temperature sensor?).

By hard-wiring these connections, they effectively forced a 'Closed' signal to the mainboard, tricking the boiler into firing. Normally, with the intake cap sealed, the air pressure sensor would never close naturally due to the lack of airflow. Without this manual bypass, the boiler would have correctly remained in a safety lockout state

0 -

this is the manual, they never cut the plastic off and attach a PVC pipe to it (the PVC pipe goes to the outside), so there's been no oxygen intake, until this day, I have no idea how the boiler was running, it was definitely producing a lot of carbon monoxide for sure.

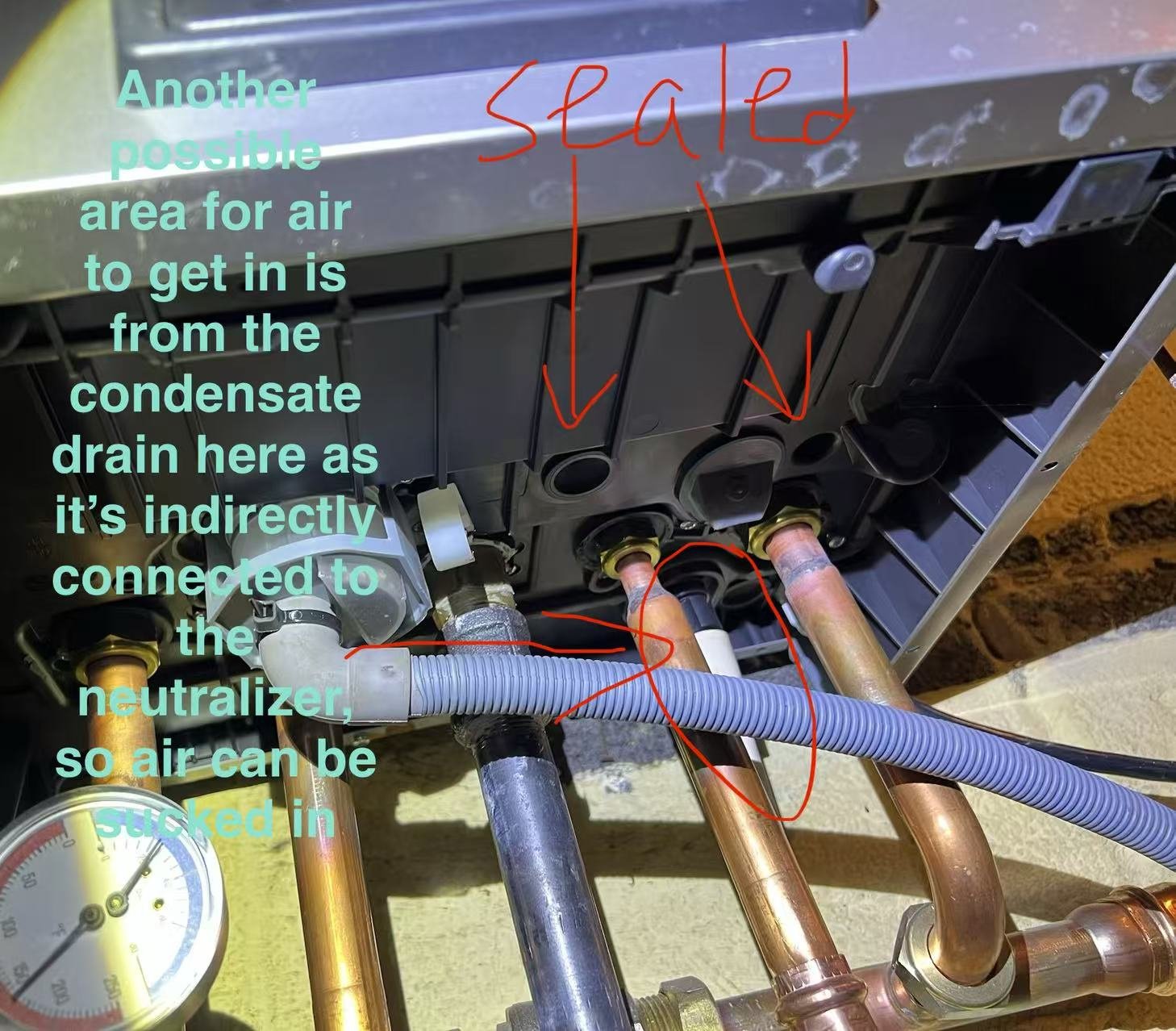

This unit is a sealed combustion system. It is strictly designed to be hermetically isolated from the indoor environment to prevent dust, debris, and contaminants from entering the heat exchanger, I did found out that the technicians intentionally removed a rubber grommet (sealing plug) from the chassis. This was clearly a makeshift attempt to allow unfiltered ambient air into the sealed cabinet to sustain combustion

0 -

I don't see anything disconnected. The connector in the middle of the picture goes to the flue gas temperature sensor.

This looks connected also.

Looks like the air comes into the cabinet. Then into the intake manifold.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

THANK YOU SO MUCH! I think this visual explains it all. If there’s no air coming from the external intake, it must have been drawing air from inside the boiler through a leak. Since the boiler is supposed to be hermetically sealed, this also explains why the APS sensor would have needed to be bypassed, as the only locations that could provide air through a leak wouldn’t supply enough pressure…….

now the second question is… on the boiler screen, if the boiler is not running & there's no air pressure, the APS still says status 1 (which means its closed)

0 -

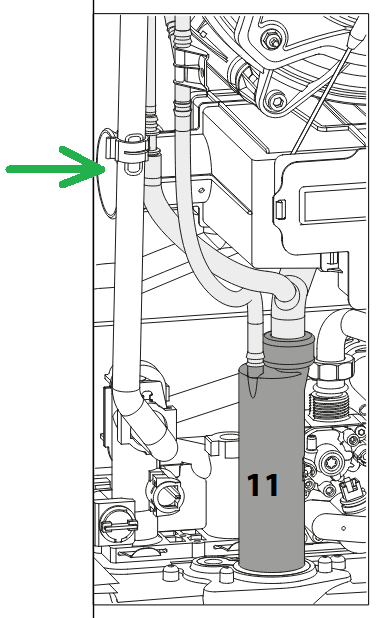

I think the Air Pressure Switch is for a purpose other than (or in addition to) what you think it is for.

Since the condensate trap probably has the proper condensate level in it the Air Pressure Switch is happy.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Some Air Pressure switches have only a normally closed set of contacts, Other APSs only have a normally open set of contacts, and there are others than have a single pole double throw SPDT set of contacts where there is a common wire and one normally open contact and one normally closed contact. Without knowing how NTI wires up their system, it is difficult to say that a switch is open (off) or closed (on). So that is why I didn't use off or on in my previous explanation. But for clarity and not accuracy I will use on and off to describe the condition of the heater flame.

If the flame is off the APS must be in the flame off position in order to start the turning on process. If the APS was jumped, or bypassed to the flame on position, the system can not start.

Once the start sequence turns on the fan, the APS needs to change from the flame off to the flame on position or the gas valve can not open to make a flame happen.

That is why @109A_5 indicated that the APS is "happy". This means that no one has jumped, bypassed or adjusted the APS in order to make the heat operate. There must be another reason for your system operating with both of the air inlet cut outs still in place. It has nothing to do with the APS.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I don't see intake air direct connected to the fan?? Air piped to the fan looks like this. Exhaust directly behind.

Most all mod cons allow you to pull inside air if the room volume is sufficient. Following the manuals requirements form "all inside air"

So the air just comes into the case, as I see it. I doubt the case is hermetically sealed! Every wire and pipe that goes into the case has some air leakage.

I highly doubt that boiler would fire if the fan was getting absolutely no air? How would it push air into the combustion at all if it were 100% blocked. It's really no different than blocking the outlet of the fan, air movement stops.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

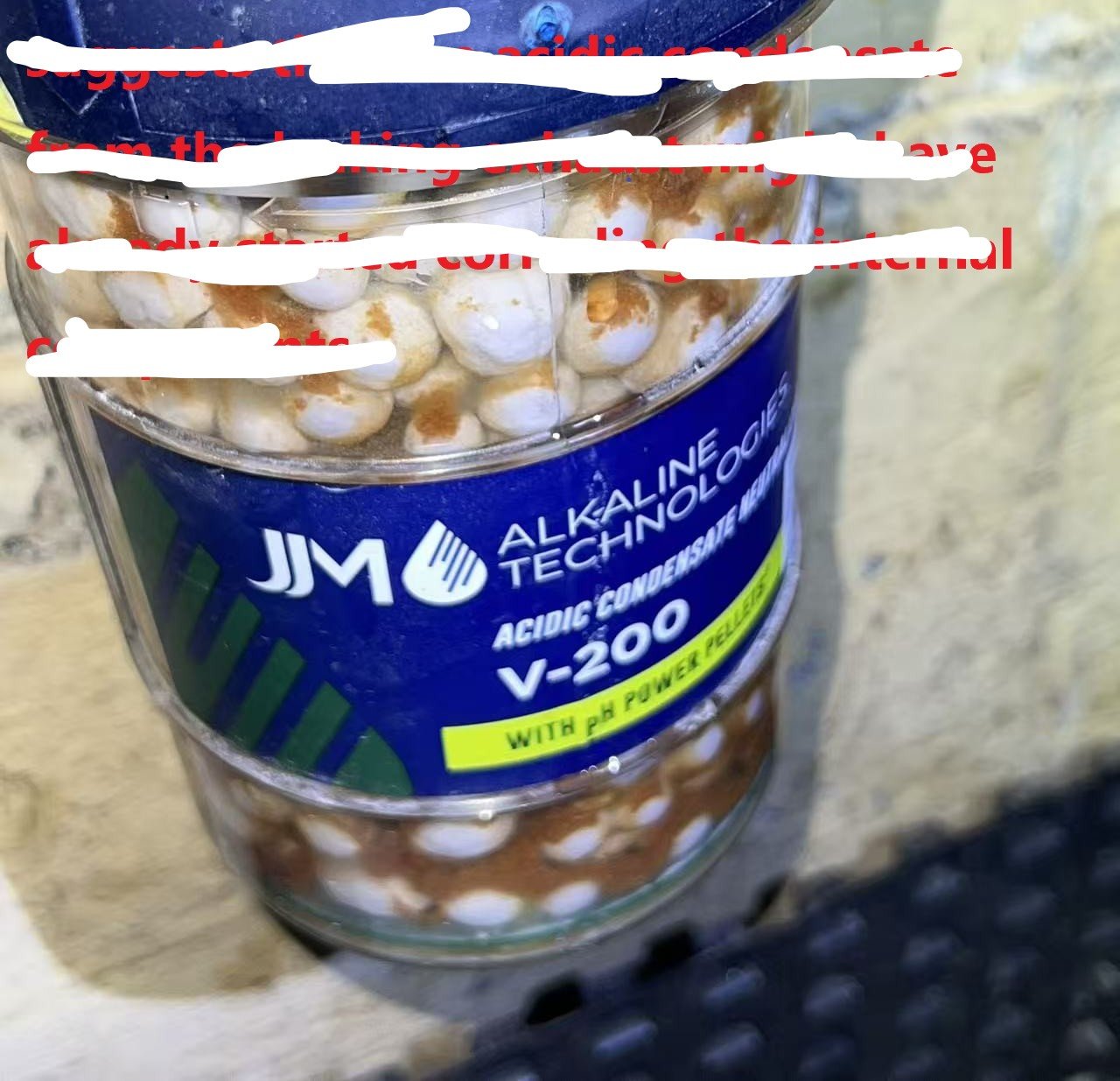

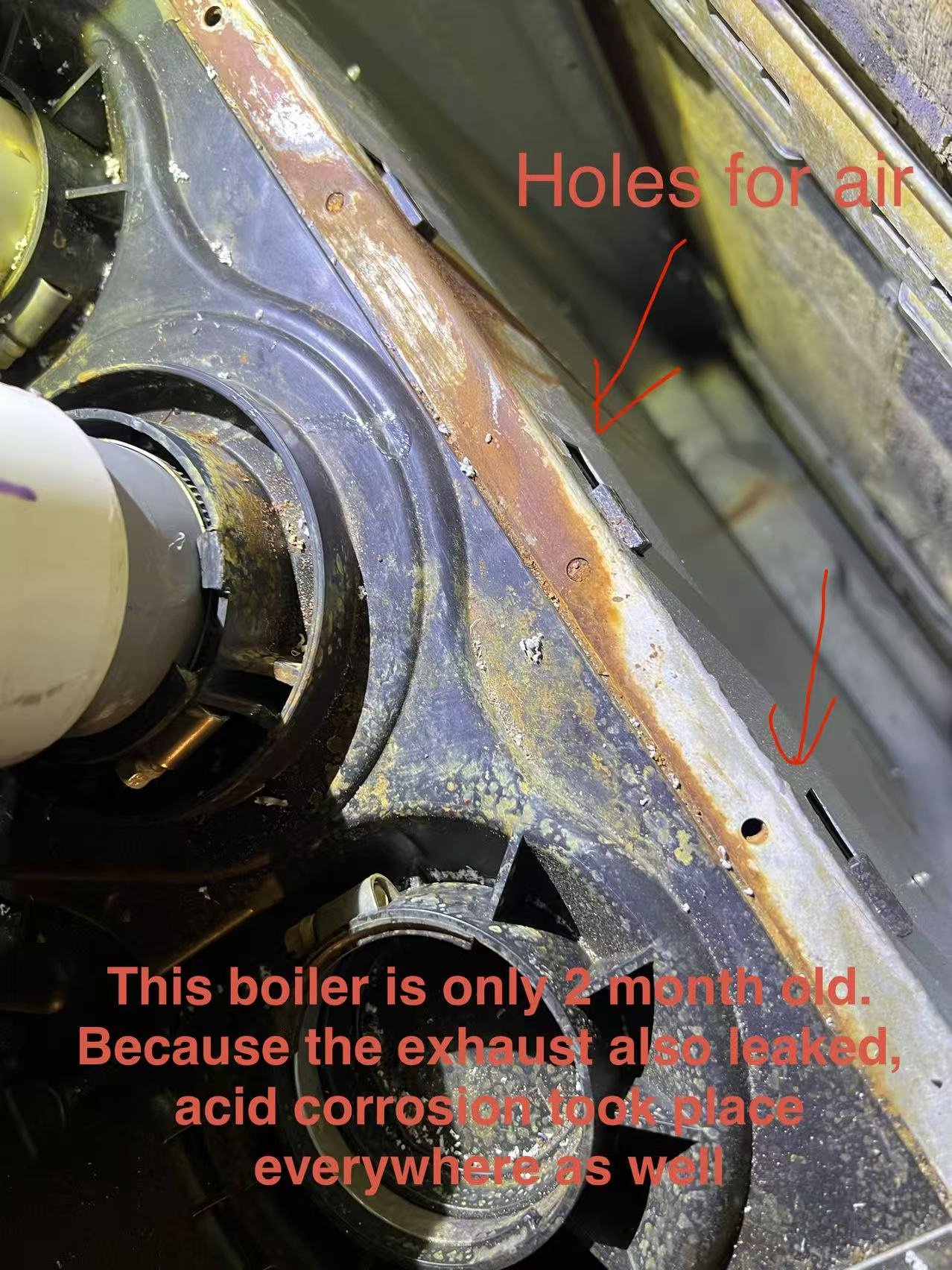

This helps a lot. I really appreciate it. This kind of explains why it was still burning, because it was probably sucking air from the condensate drain. This is how the neutralizer looked after running for about six weeks. That brownish-colored residue definitely suggests that something inside the boiler corroded.

With that being said, I still think someone jumped the APS because right now when the boiler is off, with no air and no gas, the boiler screen still says the APS is CLOSED. I also think someone bypassed some settings in the control board to let the boiler keep running because I got confirmation from the manufacturer that this suggests something is indeed incorrect.

0 -

Honestly, I don’t think the APS is really “happy” 24/7. I confirmed with the manufacturer that this would suggest the APS is always “happy,” regardless of whether the boiler is on or off.

For your reference, APS status 1 for this boiler means the APS is closed.

0 -

@bwu0518 said: "I still think someone jumped the APS"

even after @EdTheHeaterMan said: "The logic, algorithm or computer software built into the boiler control makes it nearly impossible to hack in the way you are imagining. The API must be in the "normal position" (not operating) before the exhaust blower can start. If it is hacked to the "operating position" then the blower will not start.

Once the exhaust blower starts the API switches from the "normal position" to the "operating position" and then allows the burner to fire. (there are a bunch of steps in the trial for ignition sequence before the flame actually ignites). Once the flame is established, if the API gets switched to the non-operating position or "normal position" for any reason, the gas valve will shut off the main burner fuel. That system is pretty much bullet proof for safety reasons."

And @109A _5 said: "I agree with @EdTheHeaterMan about the pressure switch logic."

And @EdTheHeaterMan repeated this: "If the flame is off the APS must be in the flame off position in order to start the turning on process. If the APS was jumped, or bypassed to the flame on position, the system can not start."

I don't believe that @bwu0518 is getting the point. Maybe it is possible for the APS to be in the #1 code position in order for the burner to start. If the boiler is operating then the APS is doing the proper job.

There is something else wrong if the APS is supposed to show zero (0) when in the stand by (OFF) mode. What does the APS monitor indicate when the burner is operating?

And by the way, there is always going to be colored discharges thru the condensate drain. It is the nature of burning fuel. Stuff that is in the air that is not actual air will do funny stuff when it comes in contact with a fire flame. There are also impurities in the gas you are purchasing from the gas company. Nobody is perfect, including the guy that filters the gas before it gets to your home. And the combustion process actually takes the hydrocarbons the gas is made up of, and converts them into other stuff like carbonic acid. That is acid made up of carbon and other byproducts of combustion and does nothing to heat your home but will eat away at the innards of your heater. You may need to replace that heater in about 17 to 29 years as a result of that stuff.

You need to remember your home is not a super clean laboratory and therefore you will get some stuff that is not necessary to heat your home but will get exhausted into the air and the condensation that leaves the boiler.

And you are probably right, the installer that didn't know enough to cut an air intake into your boiler, as explained in the instruction manual, was probably an electromechanical software engineer before he installed your boiler and could figure out how the "Jump the APS, and still make it work. That happens a lot.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I totally understand, and that actually makes sense that there could have been air leaking from inside my basement. My question is, it’s not designed to work like that. From what I can tell, the entire boiler is meant to be sealed by its enclosure. Even though there are many small holes, they are all plugged with rubber caps. And even if there were only this small amount of leakage, the air volume definitely wouldn’t be sufficient. So the air pressure switch shouldn’t be able to detect enough air pressure, and therefore it should refuse to close the circuit and allow the system to ignite.

And here, APS status 1 for this boiler means the air pressure switch is detecting sufficient air pressure for the boiler to start ignition.

0 -

Your persistence in the fact the the installer intentionally did something to the APS, as opposed to a factory malfunction with the display reminds me of the person that posted this query on a Auto Repair DIY site. They insisted there was a problem with the tire valve because the tire would not inflate.

Am I not understanding how this tire valve works? I have been adding air to this tire valve for over 30 minutes and the tire will not inflate. Can someone tell me what I'm doing wrong here?

The someone asked for a picture from farther back. Now we get the real story. A different possibility for the outcome.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Thank you for this detailed information; it’s very helpful. I confirmed with the manufacturer that when the boiler is idle, meaning it is not running, with no gas and no air, the APS switch is still in its “operating” position, indicating that there is sufficient air intake, instead of the “normal” position you were referring to.

0 -

Seems like NTI may be creating more problems then it is solving with the plug in the intake. If it just goes into the cabinet anyways?

I'd be more worried about protecting the exhaust side, as debris in there gets directly into the fan?

Must be some reason they install the plug

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Hahaha, I get your point, and I deeply apologize if I am being unreasonably persistent. This is a brand-new boiler, and there are no openings designed on the casing, not even on the top or bottom.

The reason I suspect that someone may have done something to the APS or the control board, maybe in its "tech setting override screen" or somewhere, is that it seems to let the control board ignore this “no gas, no air, but air pressure switch is still ready” mode. This suspicion is reinforced because the company also told me something vague in a letter, saying “per manufacturer-recommended remedies.”

Regardless, I really appreciate everyone spending so much time explaining all these details to me!

1 -

I follow your logic completely. The intake cap plug was supposed to be removed on Day 1, there is even an explicit manufacturer’s label on the casing instructing installers to 'cut it open.' The technician simply failed to do it.

However, here is the physical impossibility: the boiler continued to operate for six weeks, regardless of whether something was bypassed or not… Given that the unit is a hermetically sealed system, with NTI's original rubber plugs still intact on the chassis, it is technically inexplicable for the boiler to sustain combustion without sufficient air source….. unless there's a manufacture default?

not to mention, this technician did a horrible job, the exhuast was also leaking like gallons of acid everywhere in my basement in the last few weeks, the pipes and boiler are currently already corroded, that's even another story I didn't bring up…

so even there was imcomplete combustion + leaking exhaust pipe, it already produced CO backflow to my basement anyway, even if my persistent suspicion on the APS and control board is incorrect.

0 -

Nobody doubts your finding the plug in place.

If in fact the cabinet is completely tight, the definition of hermetically sealed, how does a flame or fire burn with absolutely no O2 getting in? How is the front cover attached?

Put a match in a small canning jar, quickly screw the lid on, what happens?

The early Munchkins were claimed to be air tight cabinets also, and they certainly weren't.

The inducer fan is basically a vacuum cleaner, it will pull air through the smallest opening, just enough to support combustion, however incomplete.

Fill the cabinet with water to see how well it is sealed :), just kidding.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Look. First, can we all agree on one thing, and that is the answer to your posted question?

Which is, NO.

No fire can run without access to air. It may run poorly, granted, but if it's running it's getting air.

I really don't care how many switches you bypass or whatever — no air, no fire.

So it might be interesting, as a matter of curiousity, to see how enough air can get from the space around the boiler into the boiler to fire the burner. I dare say there are ways…

Now, quite possibly the install was not well done. I'll grant that — though I haven't seen enough in the pictures to tell. It is probably much too late to get the original installer involved at this point to set things right, but it might be worth while to get another tech. in (without telling him what's wrong) to go over the installation.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

It seems to me if the APS ever opens during normal operation that is an error. I don't see any MacGyvering. You could disconnect the connector and see if it make an error, but be prepared to reset the error to restore operation.

Personally I think it only trips if the condensate trap is empty letting exhaust gas into the environment outside the boiler's cabinet. It is not for proving the Inducer Fan. It appears Inducer Fan has its own RPM monitor.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

yes, the boiler casing is meant to seal the entire

I attached more pics. There are indeed spots where air could be sucked in, but not spots where air was supposed to be drawn in. So even if there was combustion, it was definitely severely incomplete combustion thus producing highly concentraded carbon monoxide

0 -

Thank you all for replying again!!!!!!! I genuinely appreciate the feedback, especially since my post has been getting removed from other places for no apparent reason. I took pictures of all sides of the boiler and shared them earlier in a reply. I agree with everyone’s points. If there truly was no air, the unit should not have burned gas or initiated combustion at all. Even so, any locations where air could have leaked through would definitely not have provided enough airflow, so the air pressure would not have been sufficient to trigger the APS to be ready for combustion.

I think we should move on to the next question that needs further investigation. How is it possible that when the fan speed is zero, gas is zero, and the boiler is not running, the APS status still says there is air pressure, the air pressure switch is ready, and ignition can start?

0 -

running without adequate air may have damaged the air prove switch

Its hard to reverse troubleshoot, but you know the corrections that need to be made

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

You can't jump the air pressure switch. With any mod-con boiler when there is a heating demand enabled it goes thru a self diagnostic to ensure that all the safety devices are in their correct position. if any safety switch is in the wrong position it will not allow the boiler to start. it will give you an error code. you can try it yourself by removing a wire from the switch. its to prevent techs from doing just that

0 -

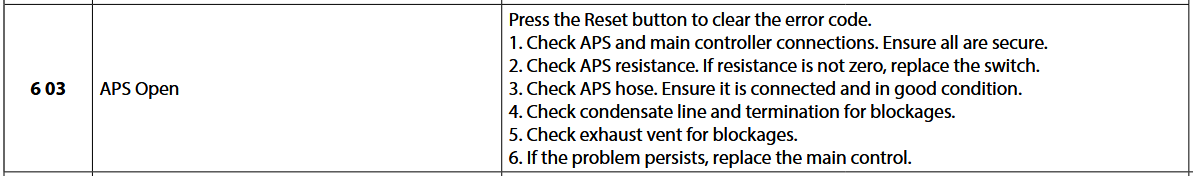

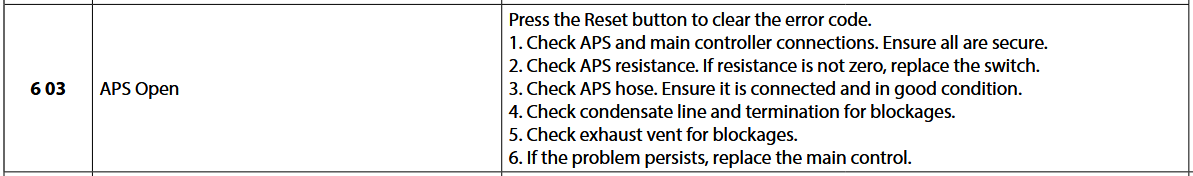

That 603 APS OPEN is exactly the error code I see in the error log history (not currently displayed on the screen). Now it looks like, regardless of whether the boiler is running or not, the APS status is always 1, which indicates it is permanently closed (and not open). This raises my concern that someone may have jumped the sensor. I do not have proof, as I am not a technician, and I have asked the government to inspect it next week. I do not want to hire a third party in case the company claims I am 'tampering with evidence'. Before we discovered that there was barely any air intake, the fan probably could not have sucked in enough air from the leaks for the APS to fully close. So it seems like someone may have forced it to appear as “1” all the time.

0 -

I totally get that. That’s the craziest part right now. When the boiler fan is not running and there is no air pressure, the APS should be in an incorrect position for the situation, and the boiler should not even start. However, the boiler is still cycling on and off normally, with no error codes. Either the APS has been jumped, or it was damaged from the prolonged incomplete combustion. Either way, something is damaged, yet the boiler is still working without anyone’s interference.

0 -

When the boiler was commissioned was a Combustion Analyzer used ? If so do you have the receipt ???

You and AI are are making the assumption that the status should be all zeros, well what about the 3 way valve position ???

And I'll say it again, I believe the APS is not for proving the inducer fan. It is for many units but in this case it seems it is not.

Where does this statement from the manual state the APS proves proper inducer operation ?

Sadly the boiler's manual does not state the sequence of operation (not that I could find).

" something is damaged " claiming something is damaged with no real proof is not very logical. You need a pressure / vacuum source, a Manometer and a multimeter and the APS specifications to test the APS operation, without that you are just guessing.

# 2 below expects the switch to be closed when the unit is not running. Resistance tests are not done with the unit operating.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements