Thermostatic mixing valve and Taco 3 way

bottom line up front - I’m looking for a possible alternative to the thermostatic mixing valve I have installed behind wood boiler.

pictures attached for reference

Switzer 1750 gallon indoor wood boiler. Bosch Greenstar propane boiler backup fuel source and brains of radiant heat system. Wood boiler 1750 gallons of water separated from water that runs through floor and propane boiler by a 100 plate heat exchanger which seems to be surprisingly very efficient.

Issue : thermostatic mixing valve seems very temperamental- very sensitive to adjustment. When wood boiler is operating near max (220 degrees at 30psi), the Taco three way mixing valves (I100u3R-1) across the room near propane boiler flash green rapidly. This apparently indicates that the supply water is near max , or that the valve is moving. When there is a call for heat a pump pulls water from wood boiler loop and heat exchanger through thermostatic mixing valve and brings it over to the taco valves to be mixed for floor heat. Propane boiler recognizes the hot water and either shuts down quickly or never fires up at all (depending on the temp that the propane boiler is registering at the time). When the green lights flash and I have ‘overly sufficient temperature’ supply water I dial the thermostatic mixing valve behind wood boiler back. But then it seems that later when the wood boiler temp is lower, maybe around 170 (where I should be able to get 150 degrees after heat exchanger) - the water temp doesn’t seem adequate anymore and I find the propane boiler running more often. I can’t seem to find the sweet spot on this thermostatic mixing valve.

- Does someone have a recommendation of a better way to mix the water behind the wood boiler? This one seems very sensitive to small movements of the cap. I’d like to be able to give maybe 140-150 degree water to the other side of the room for the taco valves to mix. The dip switch settings on the three way tacos are set for a max temp of 130 degree supply water. When wood boiler temp drops below 140-150 id like it to send max available remaining temps through the heat exchanger across the room, until finally the propane boiler kicks on as backup fuel source (triggered by aquastat registering 120 or less on wood boiler).

- Is it a big problem for these taco valves to routinely flash green rapidly? With 80 degree return temps these valves should be able to take high temp water (right now I’m seeing 175 coming over from wood boiler) and mix it to 130, I would think? That’s why I’m thinking it is flashing rapidly to indicate that the valve is moving. However sometimes I see them flashing for minutes when the water temps are high.

I find myself constantly making adjustments to this thermostatic mixing valve based on the water temperature of the wood boiler.

Thanks in advance

Comments

-

I am having a hard time picturing your system design. To facilitate productive responses can you post a sketch up of your system including heat exchanger, pumps, mixing valves, direction of pump flow, heat emitters, propane back up etc,?

0 -

this (attached plans) is missing the heat exchanger. The 100 plate heat exchanger was an after thought because I wanted to separate wood boiler water from propane boiler water (water going through floor).

As I type this I’m looking at the propane boiler indicating 195 and that boiler hasn’t been fired for a couple hours based on the high temps being brought over from wood boiler. The wood boiler is indicating 205. That 100 plate heat exchanger really seems to work well.

so I keep dialing that thermostatic mixing valve down because I don’t want that hot of water over here. In fact I think 190 is the Bosch boiler high limit. But I dial it down and then all the sudden it’s too much. I think it’s a faulty thermostatic mixing valve maybe ? Although it does cool down and heat up when I adjust it…1 -

The thermostatic valve behind the boiler? Is it for return temperature protection? Or mixing down for the system?

It looks like a fairly large valve, high Cv. Valves over 5 Cv are required by ASSE to maintain + or - 5°, So you could expect to see some temperature variation. Over 40 GPM the listing requires +or- 7° accuracy variance.

220° is extremely hot for a mix valve, most are rated to 200°, some solar specific valves may be 210°

Check the max. temperature for that valve, also the Cv and the listing ASSE number.

Also they need a good flow rate so the thermal cartridge inside is surrounded by turbulent conditions to adjust. Some manufacturers will show minimum required gpm. And of course they need a supply of cooler water on the C port to adjust.

Taco shows 240°F max for that I-valve, maybe you don't need the first thermostatic valve?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

thermostatic mixing valve behind wood boiler (with white cap) is for mixing down for the system. Wood boiler has 1750 gallons of storage and gets to 220 degrees. I only need 140 or so over to the i-valves, which will mix with return water to a max supply of 130 based on dip switch settings.

I figure having that thermostatic valve keeps unnecessary BTUs in the insulated boiler - ( why send 200 degree water over to the I-valves when 140 would suffice?

I’m happy to read that the I valve is capable of 240. That makes me less concerned about the flashing green light. Perhaps that’s ok, and that it’s just notifying me that the valve is adjusting due to high supply temps.

If I can keep the water temps below 190 (Bosch boiler limit) - unsure why - I know the heat exchanger of that boiler is rated for more … maybe I don’t have as big of a problem as I think.

It’s really difficult to properly regulate temperatures with that thing, though. I need to install a temp gauge right beneath the thermostatic mixing valve on supply side. I’ve been adjusting and then going over to propane boiler to get the readout of what’s being brought over.

Not sure what model valve the thermostatic is. Need to check with Gary the wood boiler installer. -15 F in northern Illinois but it’s 75 inside - so I guess I don’t have too much to complain about yet

0 -

Having an electronic controller on a brass body with 240•°F water flowing would make me nervous, I suggest not trying that :)

It would be good to find the data sheet on that thermostatic valve to determine it's capability and limitation. The DN numbers are usually an indicator of European origin. Any name on the knob?

The valve obviously needs a cold return to blend the 220° water down to 140°. A temperature gauge on all 3 ports would give you some info to work with. It's hard to troubleshoot a valve like that without some data. Temperature for sure, flow would be handy to know also. That you may estimate based on the pump and the loop it is flowing through

Even an inexpensive strap on temperature gauge would be accurate enough. Most VOM meters have temperature heads for reading two temperatures if you own a meter of some sort.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Where is the circulator on the Wood boiler side of the heat exchanger?

0 -

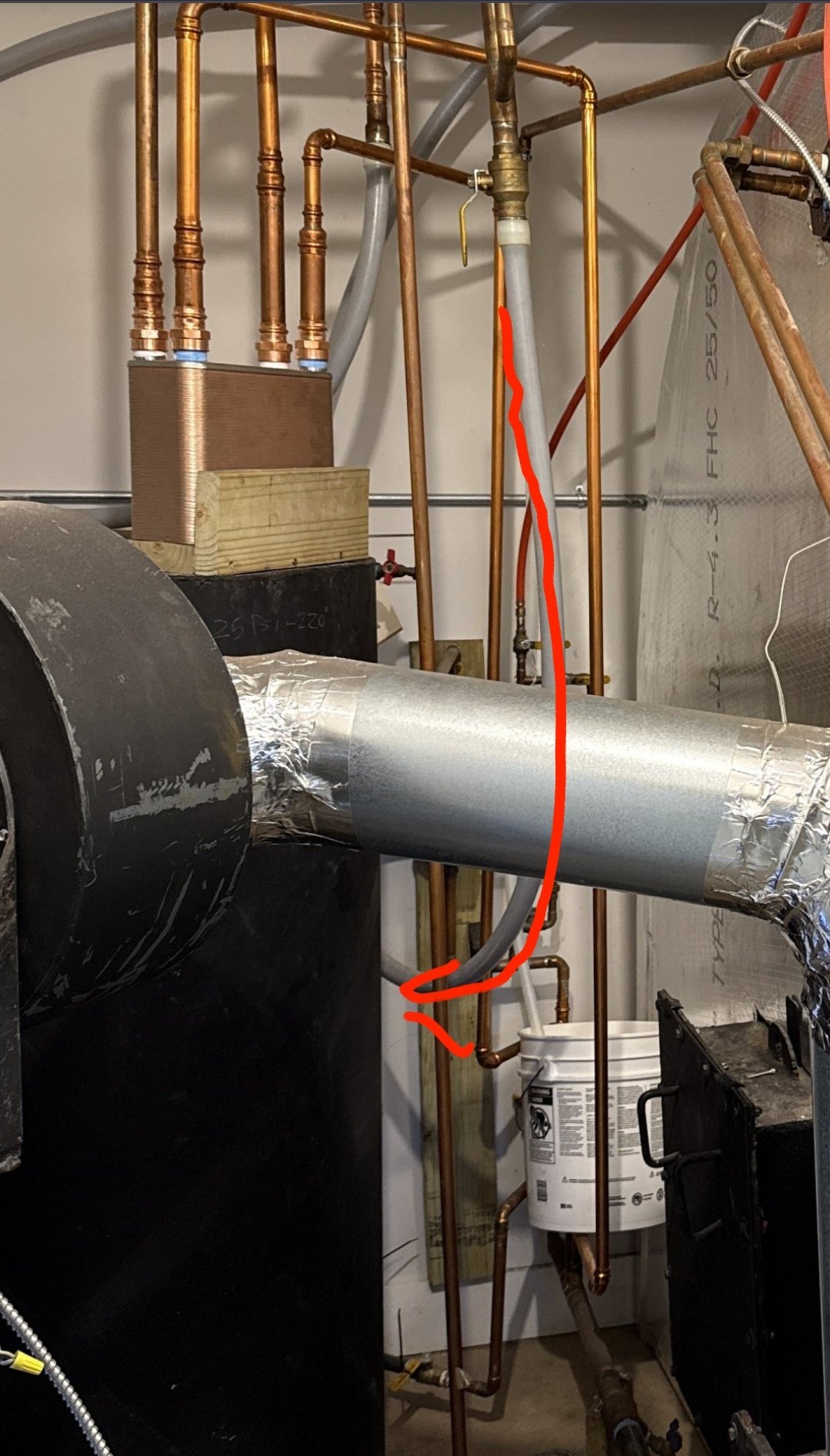

This PEX line, it carries the mixed down heat from HeX and wood boiler?

Where does it go to in the other mechanical room? Can you point out which pipe it is in the other room photos?

0 -

Is there a separate circulator to drive/pull fluid through the heat exchanger on the propane system side of heat exchanger?

0 -

I was thinking coming off the 1 1/4” pex with a Tee and installing a gauge like this:

I actually ordered one of these a couple days ago and waiting for it to get to Home Depot to pick up

0 -

Yes sir,

Red lines continued from your drawing - across the room. the pump on the vertical portion of that copper pipe is designed to come on with a call for heat. The pump on the horizontal portion also turns on, and the propane boiler fires up. However, when propane boiler senses the hot water being pumped by the vertical pump, the propane boiler shuts down. Sometimes when the temps are really high on the wood boiler, the residual water stays in that primary side even when the pumps aren’t running and the propane boiler continues to measure that temp. If the temp is higher than what it would fire up to based on the propane boiler setting / dial, then it doesn’t fire up at all with a call for heat and the pumps simply turn on.

1 -

My initial impression is that the return (and supply) temps coming off the heat exchanger are widely variable, too variable for your current mixing valve. Have you tried any other brands of mixing valve yet? What brand do you have on their now? If you go to replace it, try to find one that can completely close off the hot side of the mixing valve, and of course the appropriate cV value and flow expectations.

Do you know if there is a check valve on the propane boiler loop? If one of your main goals is to keep the propane boiler temp lower when not active, a check valve in that loop will help. Without one the circulator, on the wood boiler HeX loop, can push the heated water retrograde into the boiler loop.

EDIT: I reread your last post. It sounds like both of the boiler loop circulators are always active together. Check valve won't help that then.

I don't see a problem with the supply temps ranging from 140 to 190F. Maybe someone else can point out why that would be problematic. The taco iSeries should be able to handle that range and still provide reasonable accuracy for their own mix.

0 -

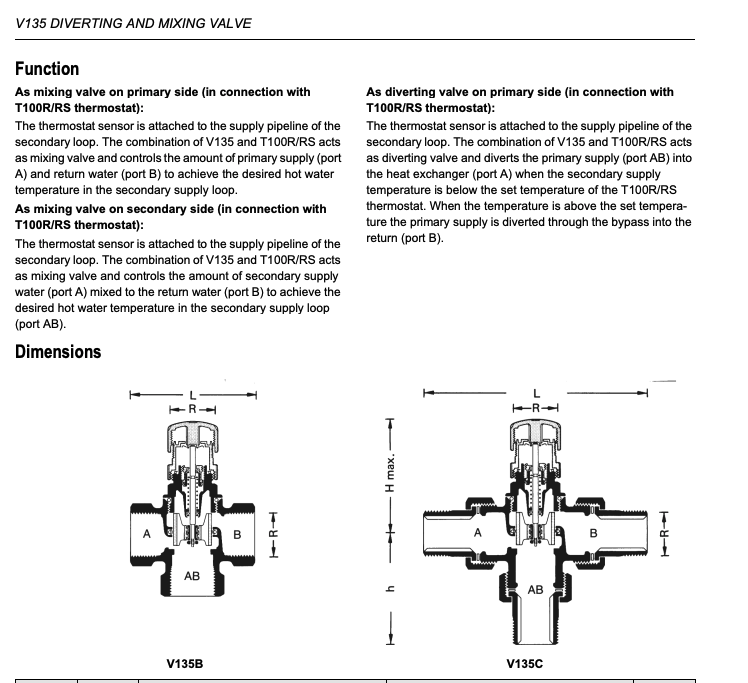

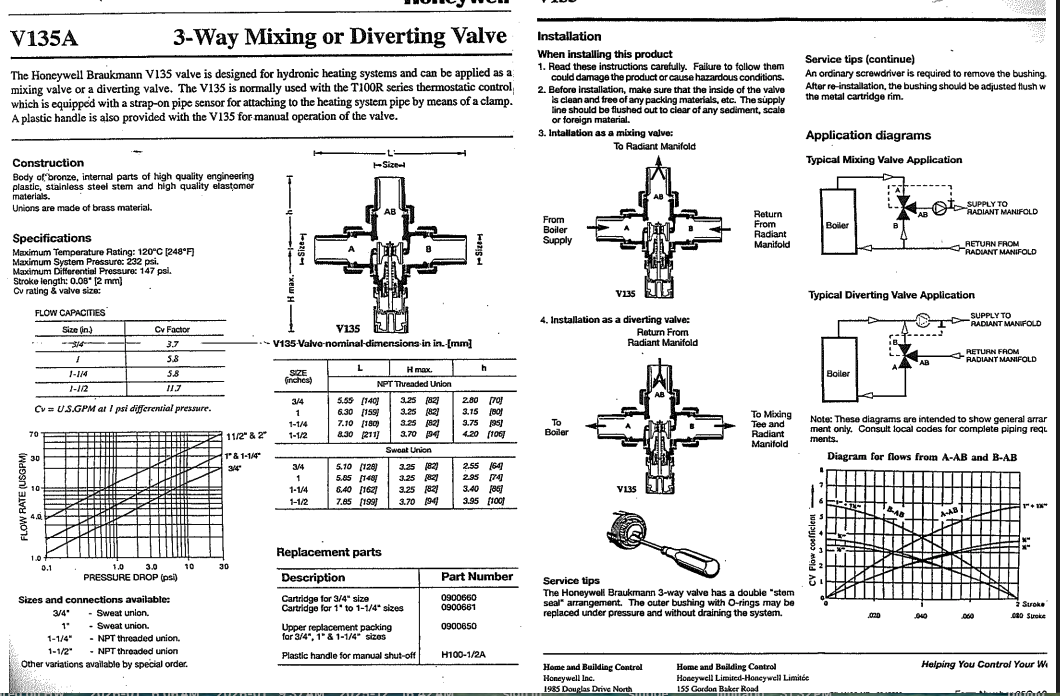

It looks like this V135 cV 5.8

V135A1014 - Honeywell Home V135A1014 - 1" 3-Way Mixing Valve (Female Sweat Union)

0 -

I see that circulator (on the HeX loop from wood boiler) is set to LO. I'm curious if Medium or High will stabilize those temperatures coming out the mixing valve. Have you tried that? As @hot_rod pointed out, some of those mixing valves need a minimum flow.

You have probably tried this already, but turn the mixing valve momentarily full max and full minimum a couple times before dialing in.

0 -

that valve needs an actuator, I believe.

When you turn the white knob do you feel spring tension? If not you probably have a manual 3 way way valve

it will not maintain a constant outlet temperature as supply and return temperature change if it is the valve @bjohnhy suggested, you could get a thermostatic actuator to turn a dumb valve into a smart mixing valve. A valve that responds to temperatureBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

both of those pumps are set to High.

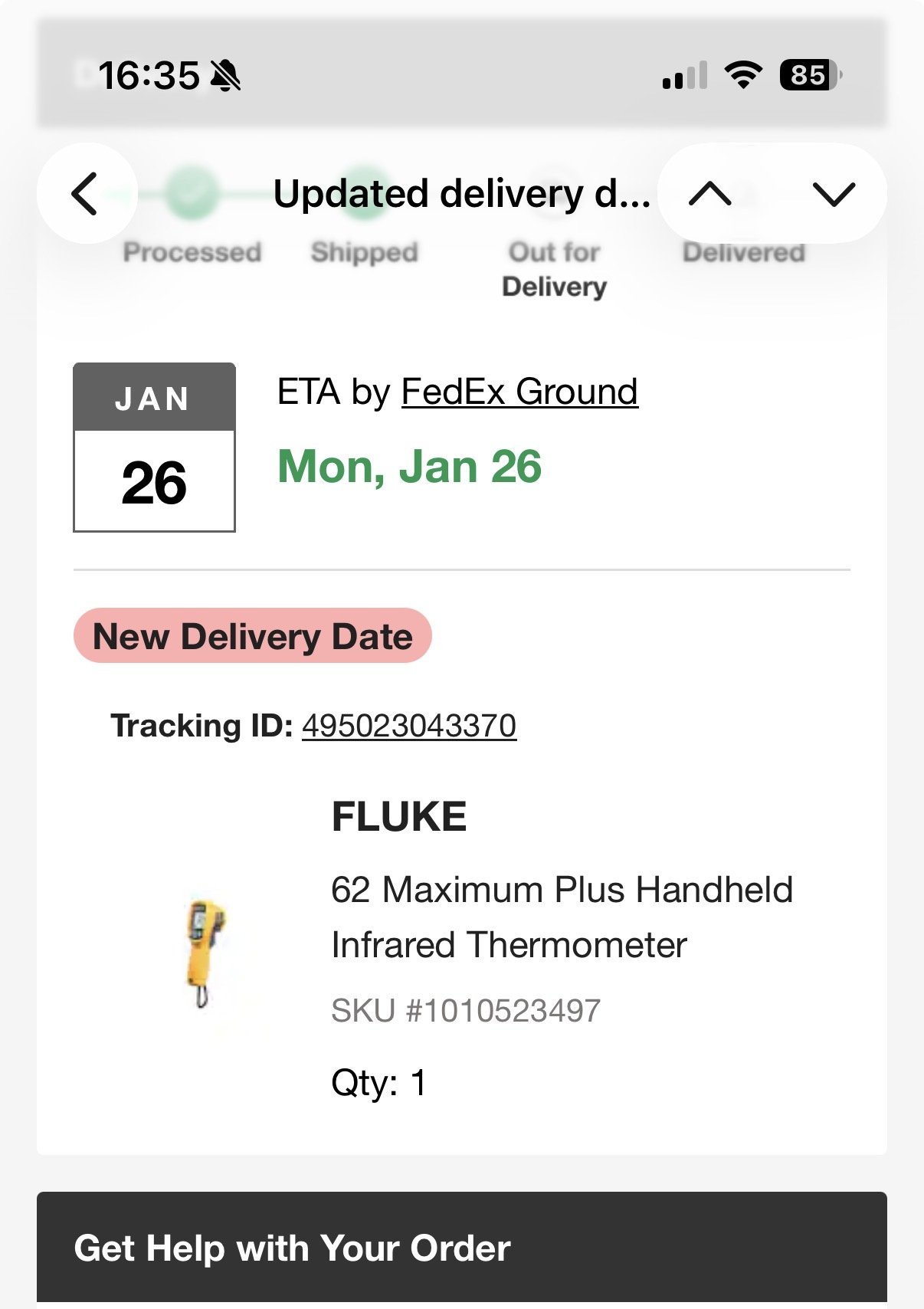

I haven’t looked at any other thermostatic mixing valves yet - I was coming here to see if there was recommendations or a better way to control the temp. When I get this Fluke reader, I’m going to do some experimenting … I’ll see exactly what I’m dealing with before investing in another valve and more work.One thing that would be nice is if I could have the propane boiler take the water reading from a different spot other than what’s sitting in itself. Often the residual water in the primary side in and around the propane boiler gets a lot lower than what’s available not far away and sitting at that vertical circulator that pumps the wood boiler water, and based on the dial / setting on propane boiler it needs to fire up to 120 or so. The boiler fires up and starts heating that water up - that pump kicks on and starts bringing water from wood boiler. The hot water travels through hydraulic separator and down into propane boiler- and then propane boiler realizes it doesn’t have to be running and shuts down. Every time there is a call for heat this happens, unless the wood boiler is really hot and the water sitting in the primary system is over what the propane boiler would fire up to. I’m not sure how to control that…

0 -

Yes sir this was an older thread on the topic when I was asking questions about the thermostatic valve and its capabilities.

Ground up said it’s a v135 and that it’s capable of maintaining a set temp - and I was very surprised at that based on how simple it looks. My troubles adjusting and maintaining temp made me come back and look for a possible different option…

https://forum.heatinghelp.com/discussion/comment/1877533#Comment_1877533

0 -

Does that V135 valve we talked about earlier require an actuator to work as you mentioned ? I’ve been struggling with it a bit, hence this thread.

0 -

For a visual representation of what I was talking about earlier…

Right now the wood boiler temp is at 170.

Without a call for heat and no pumps running the propane boiler indicates 111, the water temperature circled in red.

The water temp circled in green coming over from wood boiler is much higher even with no pumps running just the residual hot water that was being brought over.

If propane boiler measured this water it wouldn’t fire up at all. Right now the next time there is a call for heat the propane boiler will fire up from 111 up to about 120 (based on the dial on the left side of the propane boiler) before it recognizes it has hot water from wood boiler available that passes through the caleffi separator , and then shut down.

A lot of unnecessary cycles on the propane boiler.

0 -

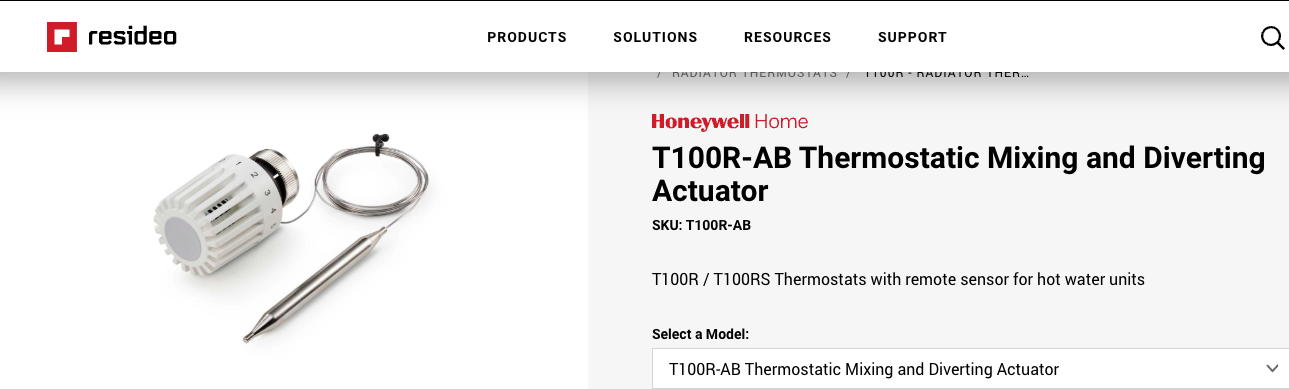

If you have this valve, as far as I can see it needs to have some sort of actuator attached to the top if you want it to sense and respond to temperature.

If not it is just a manual valve that can be set with the white knob adjustment.

SO it can be a thermostatically controlled valve if the T100R/RS is attached.

You need to confirm exactly which valve or combination you have.

If it is just the manual valve, the YOU are the thermostatic actuator :)

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Is the actuator hiding in the box/package somewhere? I'm looking for @GroundUp insight if this actuator is required. He seems to have experience with this model. But it seems like the actuator would solve your current issue.

https://www.supplyhouse.com/Honeywell-Home-T100R1012-Valve-Actuator-with-Remote-Sensor-86-158F

In terms of your boiler short cycling bursts just to find the wood boiler is active.... What is the central control for your heating system?

0 -

The connection thread on a valve like that is pretty universal, various types or brands of actuators could bve used. Adapters are used for snap on type actuators like some Danfoss models.

This would generally be a separate component, not boxed with the valve body.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

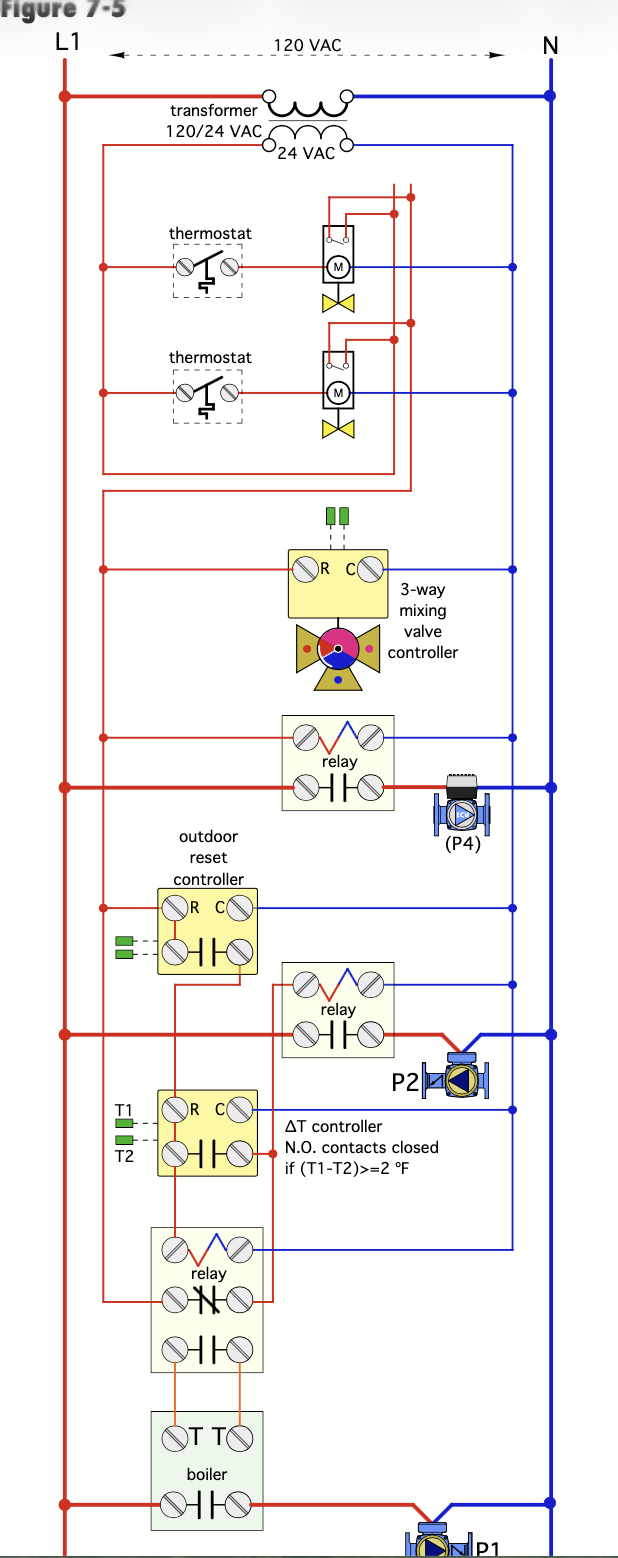

There are so many different ways to control a hybrid system like that from simple to no so simple. It gets complicated blending various boilers and the various control they have, or may not have in your case :)

I like to use a differential controller as it measures temperatures in two locations to make a decision.

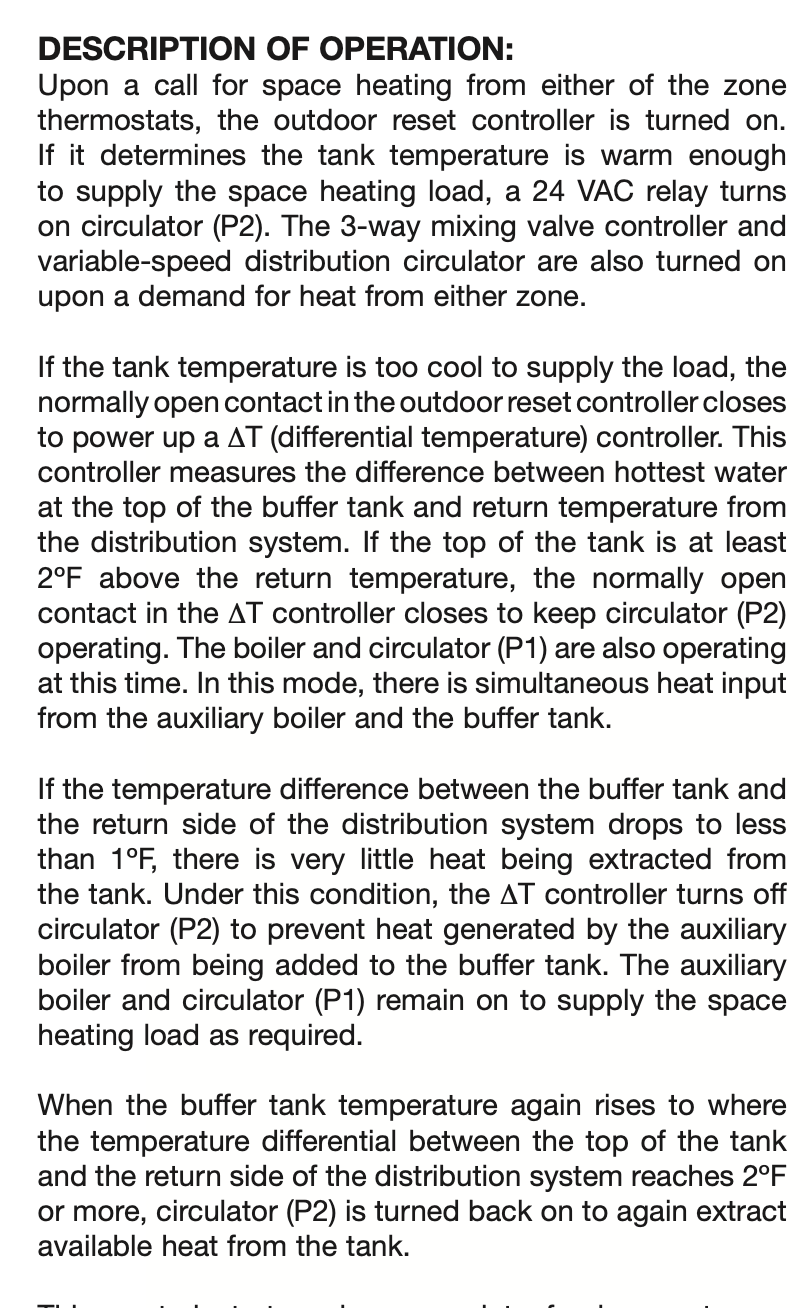

Here is an example close to your system, ignore the DHW component.

You have some good components, you just need better control of them, better decision making controls. IF you want to optimize the system performance and efficiency.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

that would explain why I’ve been having issues., for sure! I had to basically close that cap completely off last night because I was worried about 190+ water running through that propane boiler.

now, I imagine that it doesn’t hurt the propane boiler as long as it doesn’t fire up with that hot of water in it, and it won’t.0 -

I just spoke with Gary the boiler manufacturer and installer, and he can’t seem to remember the model he installed here - so outside of the picture and just looking at it - I don’t really have any info on it. There is no box or anything here…

0 -

re: what is the central control for your heating system ?

I believe it’s the propane boiler. The propane boiler is connected to outdoor sensor, the taco valves and low voltage wires connected to 11 zones. That is, in my mind, the brains of the operation.

I know it needs to know why its own temperature is, which is what it’s measuring, but it would be really nice if it had an additional sensor up at the wood boiler piping or up near that pump and wouldn’t fire up if that temperature was sufficient, even though its own temperature was not.

0 -

You propane boiler may have a high limit sensor, sometimes those are a manual reset style, a red button pops up to indicate it has tripped. You manual would tell you what the high limit protection is.

Ideally, properly piped, the LP boiler would never see that temperature. It would only kick in when the return drops to say 120° The back up LP takes over only if or when the "big boy" has dropped off, cooled down to your lowest useable temperature.

Think of the wood boiler as just a big storage vessel. The very best way to use that energy is to just "sip" off the volume (gpm) and temperature you need to get the job done.

As such, pulling off that big storage with an ODR controlled device, be it a valve or pump, is the way you maximize the use of that big storage vessel.

The very best place to store you energy is in the unburned firewood 🤗.

Once you combust the wood, energy starts slipping away from you with every transfer. So next best place to store it is a very well insulated tank, a thermos bottle.

Lastly use that stored energy as needed, ideally at the lowest supply temperature, lowest flow rate.

You have all or most of the pieces, the assembly and control logic is still not dialed in.

It really comes down to what yo want or expect. I have done systems where the owner just wants a wall switch to turn on the back up.

Others want a more automatic switch should the fire go out or wood bridge and they wake up to a cold home.

How efficient, how automatic comes down to your comfort level as far as control complexity and $$

I'm not clear on why the loads could not be pulled from the tank, or plate heat exchanger with just the Taco mixers. They have the ODR function, so each one could be customized to the load? Maybe the manufacturer has a good explanation for that, or why they send out manual mix valves? Or maybe the actuator got misplaced?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

yes sir everything you said makes sense. This wood boiler does batch burns - takes 1750 gallons of water at 120 degrees and brings it up to 200-220 in about three hours with a full load of good wood. It’s super insulated, and then I built a room around it and insulated the walls heavily with insulation and rock wool.

The system is designed to work as you explained. There is an aquastat measuring wood boiler temp. As long as wood boiler temp is greater than 120, that pump on the vertical section of copper piping is designed to come on with the pump on the horizontal section, thus bringing over hot water from wood boiler. When wood boiler temp drops below 120, the vertical pump no longer comes on and no more water is brought over from wood boiler. The horizontal pump still comes on with propane boiler, and propane boiler takes over as primary heat source.

Everything works great in that aspect except for when wood boiler temps are a bit lower, say around 160-170 - even though it’s still plenty sufficient to do ALL the heating , the residual water around and inside the propane boiler is cooler - say 110. So it thinks at that moment in time that it needs to fire up at the next time there is a call for heat. If it could take a look 6 feet away to that circulation pump for the wood boiler and see that 170 degree water is sitting there waiting to get pushed over to the taco valves - then it wouldn’t fire up at all. Perhaps Bosch makes an additional sensor I could utilize.

But, other than this small hiccup - the system is designed to work as you described. I will say that I’ve been checking the propane tank levels and it doesn’t use a ton of propane to do these cycles and fire up for short periods of time. It’s probably good for the boiler to fire up occasionally - but right now it’s quite often unless the wood boiler temps are 190+, and then the residual temps around the propane boiler seem to spike up as well, and the propane boiler never fires up at all in that case.Thank you again - always impressed by your knowledge.

0 -

That boiler may have an option to add a "supply" sensor, that could be placed in a better location, instead of the internal sensor, to know the systems temperature, and not fire until it is needed.

You are down to chasing tiny % points of efficiency, maybe. Exercising the boiler is not a bad thing as long as LP use is in your comfort range?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

it is… in my comfort range.

One of the main reasons I bought this wood boiler was to teach my boy some work ethic and reward for hard work (heated floors and hot showers after a few hours with the Chain saw and splitter).

I hate to burn propane unnecessarily when adequate heated water is sitting only a few feet away, however, I don’t believe it’s using a lot of propane doing what it’s doing.

One of those supply sensors you’re referring too - if available, might be a really nice improvement, though.

Not as big of an improvement as not having to constantly mess with this thermostatic valve, though! Anxious to get this temp gauge and do some more experimenting.

If this thing does in fact require the actuator , that would explain a lot. I was under a different impression after that other thread, though

1 -

This could work very well in this scenario. Is there a specific controller one could buy off the shelf for this? It looks like it requires piecemeal creation. Especially that Delta T controller/relay.

If the propane boiler was not the Central control, it could potentially be powered down completely. It seems like the wood boiler and work ethic are plenty to keep you all warm.

0 -

I would start with the actuator for the mix valve, since you have that already That should limit the LP getting too hot

Try it, if you want more control, the sky is the limit

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I spoke with a rep at Supplyhouse about that actuator. My question is where it says the sensor temperature range is from 86F-158F. Obviously I have hotter water coming into the valve from the wood boiler. The valve itself is rated much higher.

The rep advised that I better call Honeywell…

I think I'd start with maybe trying to send a maximum of 150 across the room. Wonder what'd happen if I have 200 water coming into the valve but it only senses up to 158…

0 -

The sensor goes downstream of the mix valve, so it sees the mixed temperature. Only the valve H port should see 200°F, the red line on the left of the valve in this case.

Here is how a remote sensor is typically placed on the mix pipe 12- 24" away from the valve. This assures that the return and supply from the M port has blended to get an accurate reading.

A mixing valve will always, must always have hotter water entering the H port, of course.

There are better valves for that application. A fixed temperature thermostatic valve would be better suited, no need to fiddle with it, just select the temperature you want at the mix port and it adjusts accordingly.

If your goal is to have a two stage mixing system? I don't think you are adding much efficiency by mixing from 200 to 170, then 170 to 120 or whatever the final goal is. The system will pull from the tank whatever flow and temperature it needs to mix to the final desired temperature and btu rate. The 200° stays in the big tank until it is needed.

That valve and separate actuator seems like a complicated and $$ way to go about .

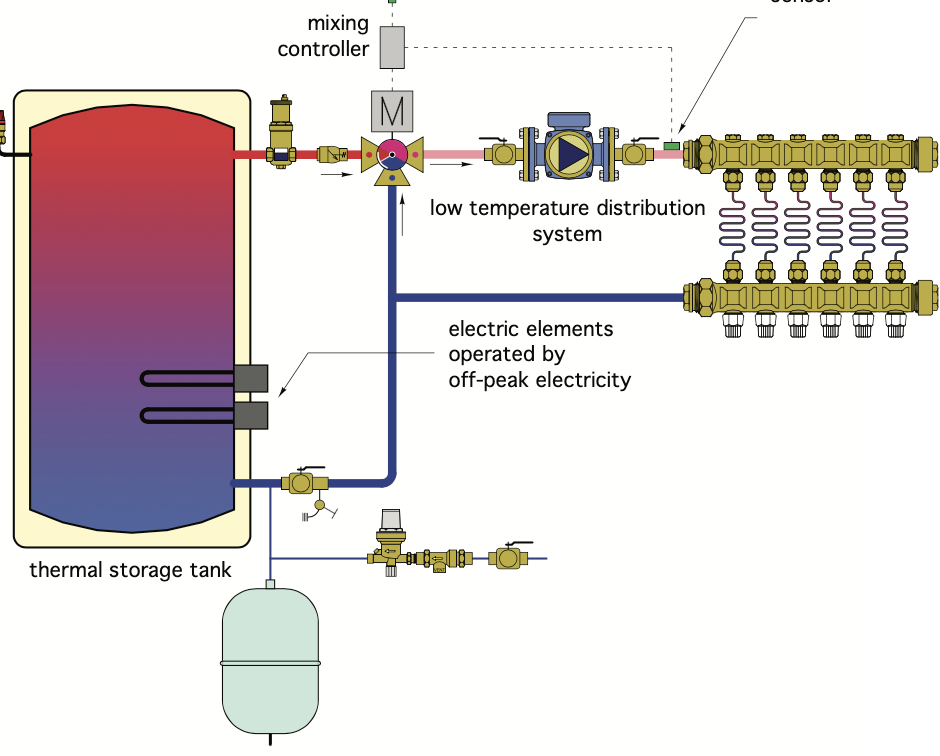

This valve developed specifically for the wood boiler industry, has a high flow rate, simple installation. temperature gauge wells at all 3 ports to monitor what it is doing. It is generally used as return temperature protection, but can also be used in a diverting function.t

But at this point you are only one component away from taming the beast. A simple, non electric, screw on component.

Also know all mixing valves will have some differential, the outlet will never stay at exactly the 170 or whatever you set it, it could vary 3, 5, 8, 12, maybe more. So as you watch the outlet temperature, expect some hysteresis.

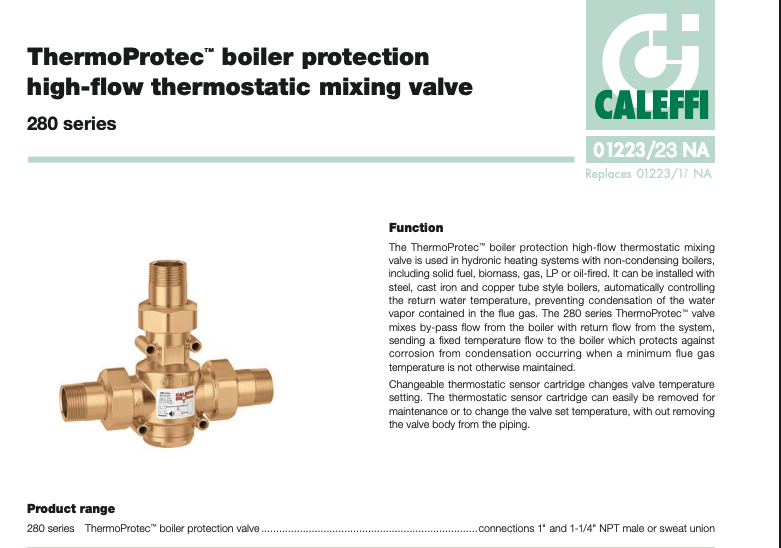

The HW spec sheet on this specific actuator shows a a 158° mix max and a .3C differential.

The M-30 X 1.5 is a common thread size, you might find different temperature range actuators from other brands, although 70C is hotter than most I have worked with. Caleffi is 120f max.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

It's been awhile since I used one, but any V135 I ever installed was thermostatic and did not require an actuator. Perhaps they have changed the recipe or there is a different variety I am not aware of.

0 -

”The sensor goes downstream of the mix valve, so it sees the mixed temperature. Only the valve H port should see 200°F, the red line on the left of the valve in this case.”

Duhhh! I apparently wasn’t thinking this morning - hadn’t had my coffee yet…

I am going to try it - I agree with you only one component away, that seems like it’ll be a simple twist on installation. No cutting pipes, etc.

thanks again!

1 -

The V 135 is a simple basic liner action 3 way valve, fairly low Cv. There is no temperature sensing component inside. It ships with a plastic "manual" knob. Here is an older cut sheet showing how it works inside.

Any M-30 head could be added. These are options that could control that valve, typically used as radiator control. Three of these are, based on air temperature, or the top one with remote sensors strap on a pipe or radiator. I believe this is the type, T100R-AB, HW will supply.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

”If your goal is to have a two stage mixing system? I don't think you are adding much efficiency by mixing from 200 to 170, then 170 to 120 or whatever the final goal is. The system will pull from the tank whatever flow and temperature it needs to mix to the final desired temperature and btu rate. The 200° stays in the big tank until it is needed.”

I guess that is what I’m doing…

Gary had installed this valve when he came out and installed the wood boiler. This is probably standard for him since his boiler produces 220F water.

I guess it makes sense in my mind for a couple reasons, even if the Taco three way mixing valves are capable of much higher temps:

I have 1 1/4" pex tubing connected beneath the mixing valve traveling approximately 100' before it gets over to those Taco Valves. Perhaps I should have run copper over across the room but it was considerable savings to run pex - and at the time I ran the pex I wasn't taking into consideration the fact that 200+ degree water might be a bit excessive to run through plastic. So far the uponor pex has been impressive to me and seems to withstand high temps under pressure, however, for peace of mind I'll be happy with mixing this water down to 150 or so to send 100' across the room where it can then be mixed down to 120.

You're most likely correct about the negligible loss in efficiency, but in my mind since I have 1 1/4" pex running such a long distance to the other corner of the room - there might be enough volume of water there to where sending 200+ degree water through the pex vs storing it in the boiler and only sending the 140-150 degree required to be mixed down by the Taco valves made sense to me.

And - the other thing I was thinking about was the 190 high limit on that Bosch boiler. I think if this actuator can maintain 150 + - 10 or so, I'll be pretty happy with that.

0 -

With that being the case, then using the valve in a manual position prevents excessive temperature to the system.

If the valve gets set manually when the water is 220, then whatever it gets set to, the temperature will never exceed that. Unless the boiler runs to 230- 240 or higher? Which theoretically is possible with 30 psi on it? 274F is possible with 30 psi.

If it drops 5, 10, even 20 degrees as the boiler cools or the load increases, is that a problem? The Taco valves are the final, fine tuning mechanism.

However, if the cost of the actuator is not an issue, it seems a small price to pay to give it some intelligence.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

yes sir the ‘problem’ I’ve been running into is that when I set the valve manually when the temperature is up near 220, it works fine. But then when the wood boiler temp gets down to say 160 or 150 (still plenty sufficient for heating demands) then the valve doesn’t seem to produce hot enough water and the propane boiler seems to run more often. It still sends water over from the wood boiler since that pump runs based on aquastat on wood boiler sensing greater than 220, and I’m sure it supplements what the propane boiler is doing, however, it should be capable of doing it entirely without the propane boiler running at all.

I think and *hope that this actuator is going to be a welcomed addition

I do know what you’re saying, though. The flashing green lights on the Taco valves being associated with ‘max temp’ was driving me to mix the water so that I was striving to get about 150 max to the other side of the room. If I manually set the thermostatic valve with what I have now to, say, 190 when the boiler is at 220 degrees, then that will allow mostly hot supply water in and minimal return, which should give me plenty of hot water for most wood boiler temps. But having a smart valve that will open up more hot water in as the wood boiler temps get to the lower levels will be better I’m thinking0 -

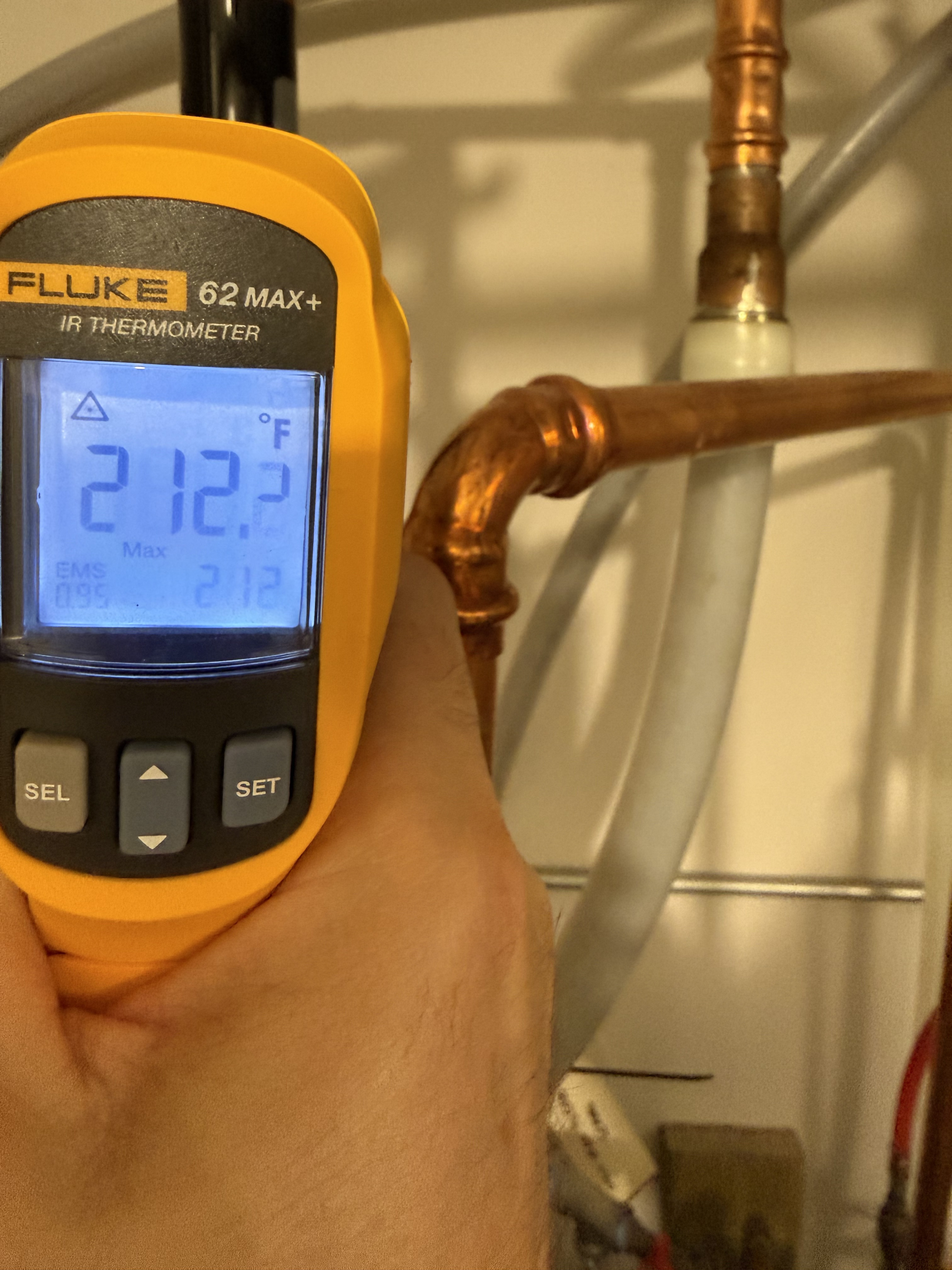

Thought I’d share after doing a little experimenting with this Fluke that I picked up today.

Amazed at the efficiency of this 100 plate heat exchanger that someone recommended to me on here. Badger piping supply in Central Wisconsin.

First pic is of the temp of the water being supplied out of the wood boiler. Second pic is the temp of the water headed towards the thermostatic mixing valve after it returned from the house floors and went through the house side of the heat exchanger. No wonder I’m getting such hot water across the room , I was expecting at least a 20F loss.

wood boiler side a fairly short loop with 3/4” copper. House side 1” that expands into 1 1/4” pex to travel across room.

Gauge seems very accurate - evidenced by when the flashing lights would go out on the Taco valves based on dip switch setting Max)

I did watch the supply side of the Taco I-valves (what taco valves sending to the manifolds). It appears that they reset themselves after each cycle. Call for heat, flashing green lights and initially I get some pretty hot water heading towards the manifolds. Taco valves continue flashing as they adjust down to less than 130F (max based on dip switch settings) , and then the flashing lights go out.

nice to have this gauge so I can see exactly what’s going on….0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements