Newly Commissioned Lochinvar - Blown Gas Valve

This KHB boiler fired right up last Monday and then stopped working two days later. Good spark on the igniter, my manometer showed -1.02” wc on the outlet of the gas valve; 6.5” wc at the inlet. Thirty volts from the circuit board to the gas valve, but no gas coming out of the valve.

Gas valves - especially new ones - are very stable. It’s not often that I have to replace one. So are transformers, but I’m suspecting that the on-board transformer is at fault. Why am I getting 30 volts out of a 24 volt transformer? Is 30 volts enough to fry a gas valve? Incoming voltage is 126 volts.

Two btu per sq ft for degree difference for a slab

Comments

-

-

The 30V reading when there is a load on the transformer?

Maybe check your meter accuracy with another meter to be sure it is not lying to you :)

There is probably a + or - voltage tolerance for the valve coil. A cut or submittal sheet may show that? Lochinvar or the gas valve manufacturer would know

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

126 is about 5% high so the 24 volts would be about 25.2. Don't know why you getting 30v.

This assumes the transformer is rated 120/24. The 24 may be slightly higher with no load on it.

0 -

Did you check the resistance of the gas valves coil(s) ?

Where was the 30 VAC measured at ?

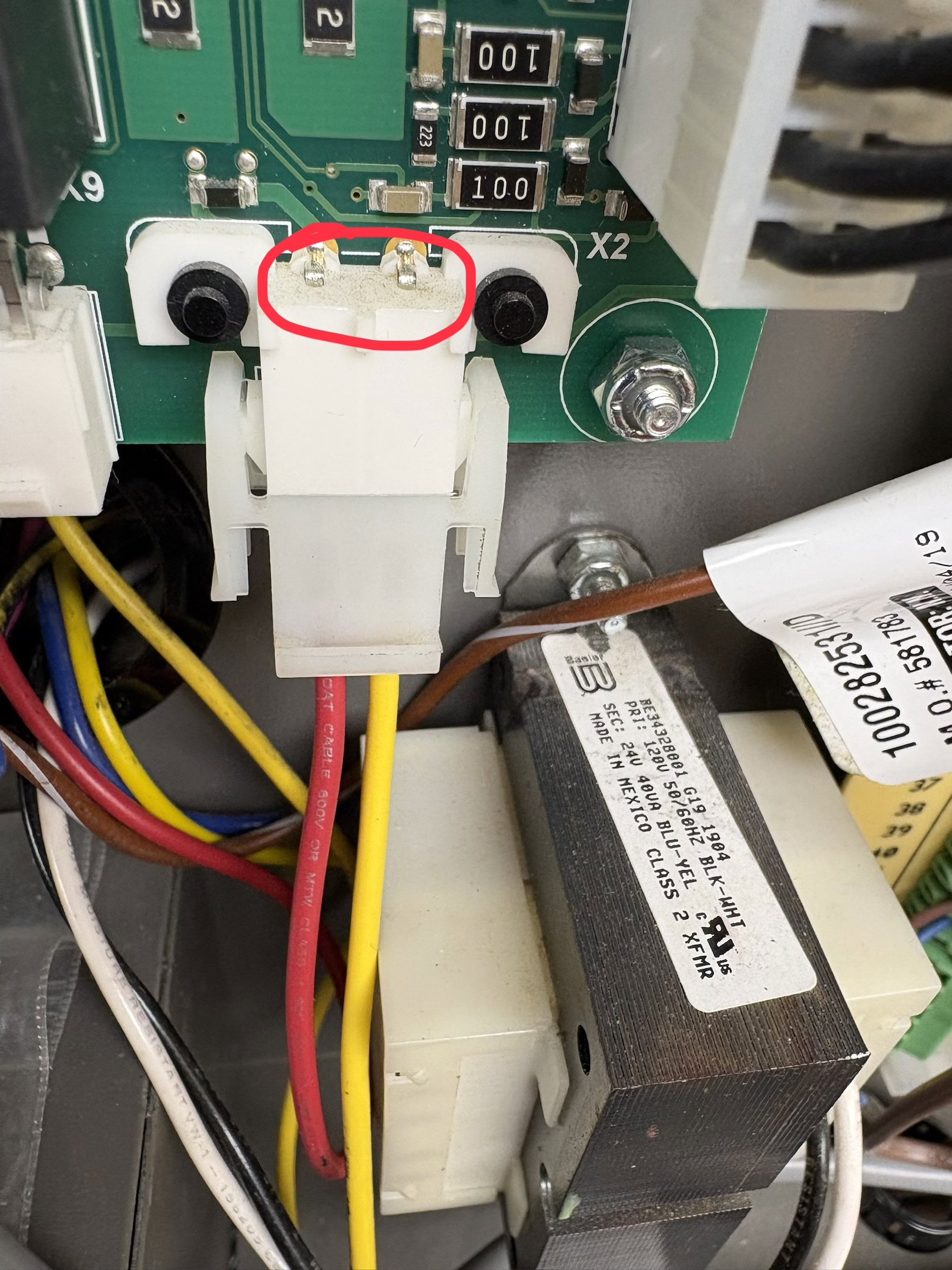

There was a post about bad cables to the gas valve. I suspect the solder joints on the little board in that Gas valve connector in that situation.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

No, no resistance check.

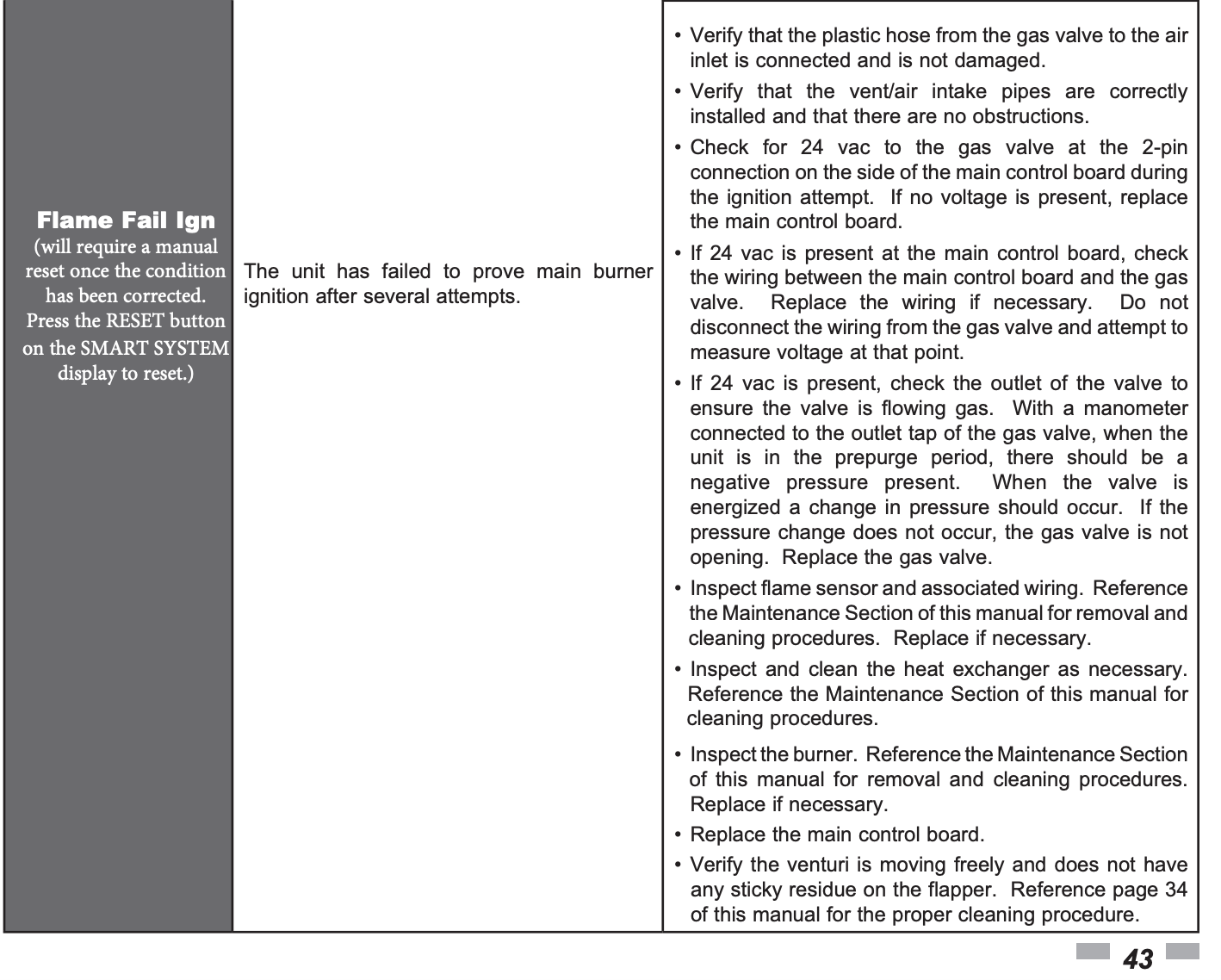

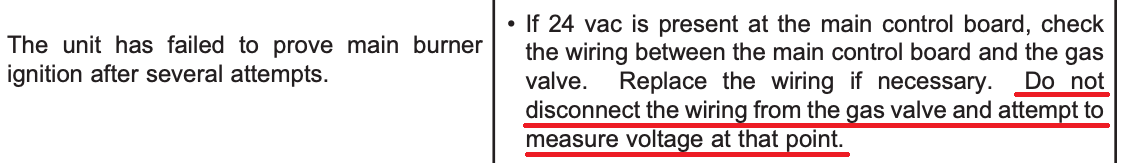

The 30 volts was measured at the circuit board connection to the gas valve molex plug and also at the other molex plug where it plugs into the gas valve even though troubleshooting guidelines says not to for some reason (see paragraph 4).

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

-

@Alan (California Radiant) Forbes, Yes I did see that warning.

It seems quite common these days that the solenoid coils inside gas valves are DC coils and not AC coils like they have been for many decades. Inside that wiring harness connector at the gas valve there is a full wave bridge rectifier on a small circuit board, it converts AC to DC (pulsating DC) or also referred to as RAC (Rectified AC) in this industry. Attempting to measure AC volts on the gas valve side of the connector may give an unexpected reading (multimeter dependent) possibly causing an incorrect diagnosis. Also being a DC coil if the connector is disconnected while energized the collapsing magnetic field can make a high voltage spike that could possibly damage something.

If I saw a lot of these types of issues and I wanted to quickly and accurately diagnose them, I would build a dual load that I could substitute in place of the gas valve to verify the integrity of the cable and the full wave bridge rectifier, and the On-Off switch in some cases. You could also use a spare (verified) gas valve cable to independently power up the gas valve with great caution. I would also familiarize myself with the typical Resistance readings of the coil(s) in the gas valve, since if a coil is open your done. I agree 30 volts should not burn up the coil(s) in two weeks but may shorten the life a bit in the long term.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

The note to not disconnect the value to test is because the system monitors the gas valve coil current. With it disconnected, the system board thinks the coil is open and has failed.

As mentioned, check the resistance of the coil with power off. Remove power, turn off gas. Remove plug into the gas value and with your meter set to ohms, preferably in the 200 ohm range (that is to say don’t use auto-ranging), measure the resistance of the coil. It will measure only a few ohms which is normal. DC resistance and AC impedance are two very different things so what looks like a short for DC resistance will typically be ok when connected to an AC source.

A bad, open coil will have an infinite resistance. That needs a new gas valve, no fixing that.

30 volts on the secondary of a 40va (or smaller) control transformer when unloaded isn’t outside the realm of possible, the lower cost the transformer, the higher the ratio of full load to unloaded voltage will be.Another check that can be made is the actual coil current. If you have a clamp on ammeter, you could measure the AC current when the unit attempts ignition. It will be less than an amp. If you have a Fluke or a meter with a hi-lo capture, use that as the coil is only energized for a few seconds which can be hard to see if it’s not firing and staying on.

1 -

" The note to not disconnect the value to test is because the system monitors the gas valve coil current. With it disconnected, the system board thinks the coil is open and has failed. "

I see no evidence the control module has that level of sophistication. There no faults that identify that type of defect.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

It may not show up as a fault. I've worked on unit heaters that monitor the gas valve like that, all they do when they decide it's failed is turn on the inducer motor. I figured it out when I realized it happened when I turned the gas valve off. IIRC there was no flash code, or perhaps a misleading one. Certainly nothing that said "gas valve open circuit" or anything that could be interpreted that way.

0 -

@ratio Turning the gas valve off electrically or psychically causes other start-up issues. Which are detectable. Having a Gas Valve current monitoring resource within the control module that is monitored by the system logic and it not used for diagnostic fault codes is just silly.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Exactly as Ratio posted. Flipping the switch on a valve to off opens the circuit. No current. No inducer. That’s all. Sure, it could throw a message but many don’t. They just don’t run because the brain knows the valve is off. No gas. No run.

The Lochenvar wall mounts use imported components. The control board, gas valve and inducer motor/fan are a 100% Italian import.

There’s and old saying in the machinery industry about Euro design: The Germans design it to work then figure out how to make it look good, the Italians make it look good then figure out how to make it work.Just sayin’. Logic and reason aren’t always encapsulated in all designs and behaviors.

1 -

@109A_5, ITYM physically. I mean, I am good enough that some believe psychic powers are involved; but I just flipped the switch on the gas valve.

In any case, I can tell you with some assurance that a) turning the gas valve to the off position started the inducer & turning it back on stopped the inducer (no heat call present), and b) any flash code that may have been present made no mention of the gas valve or anything else that would point to the gas valve being switched off or open circuit. Of course turning the gas valve off causes other start-up issues (chief of which is no heat), but that's not what was going on.

It may be silly, but I spent some time figuring that out. Hopefully, knowing that will save someone else some time and hair-pulling.

0 -

The new gas valve and transformer arrive today. I will ohm out the new gas valve and compare to the old one. I also want to compare the secondary voltage of the old vs. new transformers.

I’m also adding an electrical surge protector as the house is on a ridge and when it gets windy, sparks can fly.

I had the utility company check the high voltage (~250 volts coming to the house) and they said they weren’t able to do much about adjusting it down.8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

Which model KHB?

If it is a 110, the WHB uses the same parts. On my WHB110, I have 122V on the primary of the control transformer, 29.4 volts on the secondary unloaded. This with a calibrated Fluke 179.Voltage drops to 27.3 with the gas valve energized, current is 0.70 amps, cut sheet says 0.6 total for both coils (480+120ma). So while a bit higher, I’m not concerned with that whatsoever.

My gas valve coil measures approximately 5.8 ohms DC resistance (again with the Fluke 179). You can measure coil voltage a bit easier at the X2 connection points, just don’t slip with your meter probes.

It would be interesting to see if your replacement transformer has the same Basler part number as mine shown below. Based on what I’m seeing, I would definitely connect the new part to 120v and check the output before going to the trouble to replace the one currently installed, it will probably be the same voltage has what you already have.

0 -

if it is a long run to the house from the rest of the distribution system it is probably boosted a bit to make up for the loss under load over the long line to the house's service.

0 -

I think if you researched it more you would find the control module does not measure the gas valve current as suggested. Think about it, if normal voltage was applies to test the status of the On-Off switch it would open the gas valve if the On-Off switch was closed and the gas valve is connected and in good working condition.

I believe what they do is they send a small current (a fraction of the normal Gas valve current and it may be DC also, a supervisory current) to basically test the continuity to verify the status of the On-Off switch. This is very different than actually monitoring the Gas Valve current.

Kind of like the difference between a pass/fail Ohmmeter and an Ammeter.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

As silly as it sounds, I have had electrical problems that went away after I unplugged and re-plugged the connectors on the boiler circuit boards.

The surge protectors that I have replaced have not been the circuit breaker types. I have used whole house surge protector with surge capacitor that sets in the panel box or mounts on the bottom of a surface mounted service entrance panel. You need 2 breaker spaces for them to connect to. Might try:

1 -

Unfortunately unplugging and re-plugging can change things, poor pin fitment, poor crimps, wiping oxidized or contaminated pins, moving poor solder joints, sadly that happens more than you want it too.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements