0-3 gauge and negative PSI

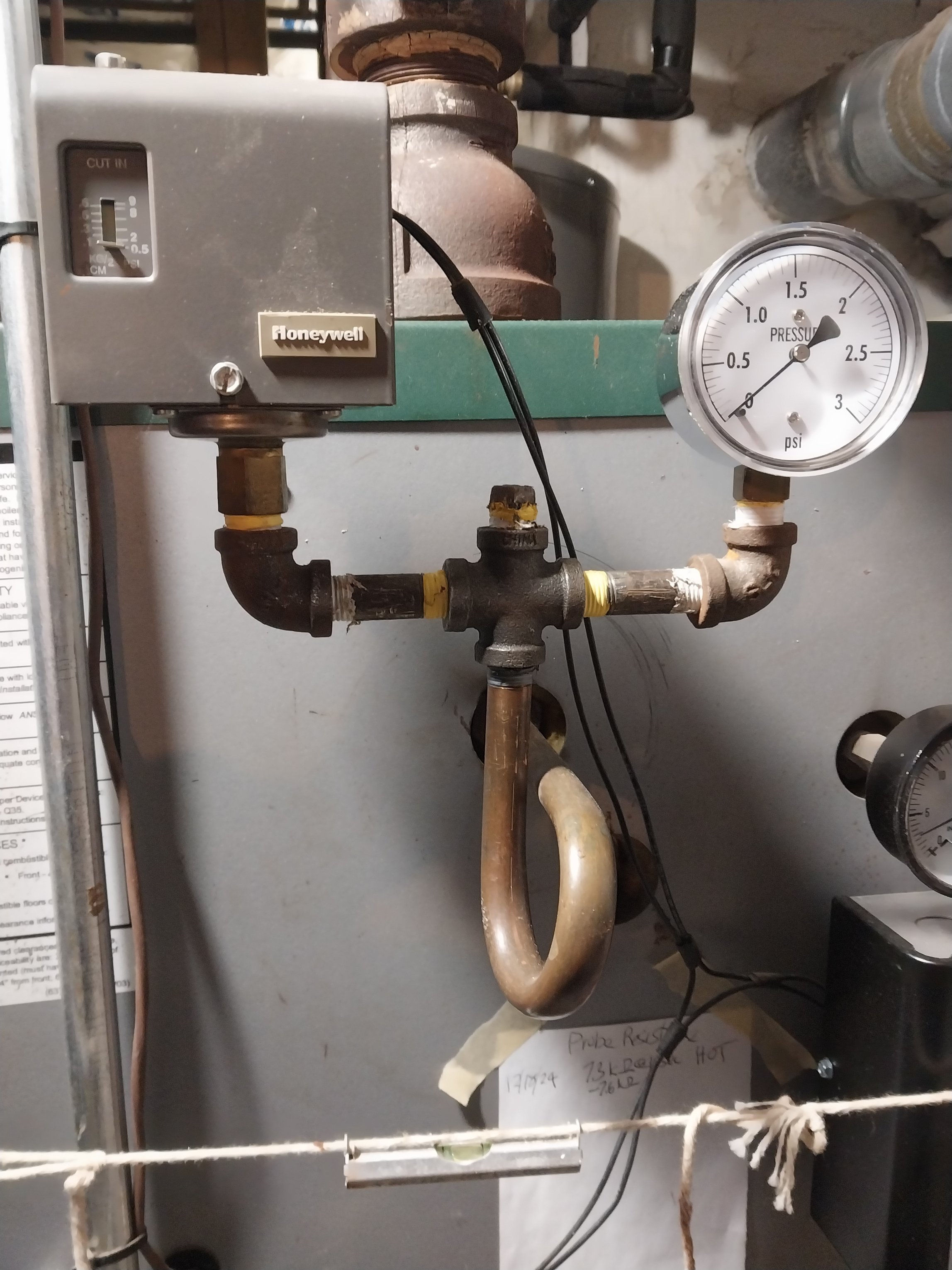

I have a single pipe steam boiler with a hot water loop for one radiator.

When the boiler satisfies the steam call, all the vents are locked because there is steam everywhere. Mains, each radiator vent, etc. So, pressure drops to near zero, but steam is good and nicely heating the house.

one issue tho is that hot water loop. the boiler is no longer calling for steam, but everything is closed. and that hot water pump is actually causing the pressure in the boiler to drop relative negative, showing about -1 PSI or so.

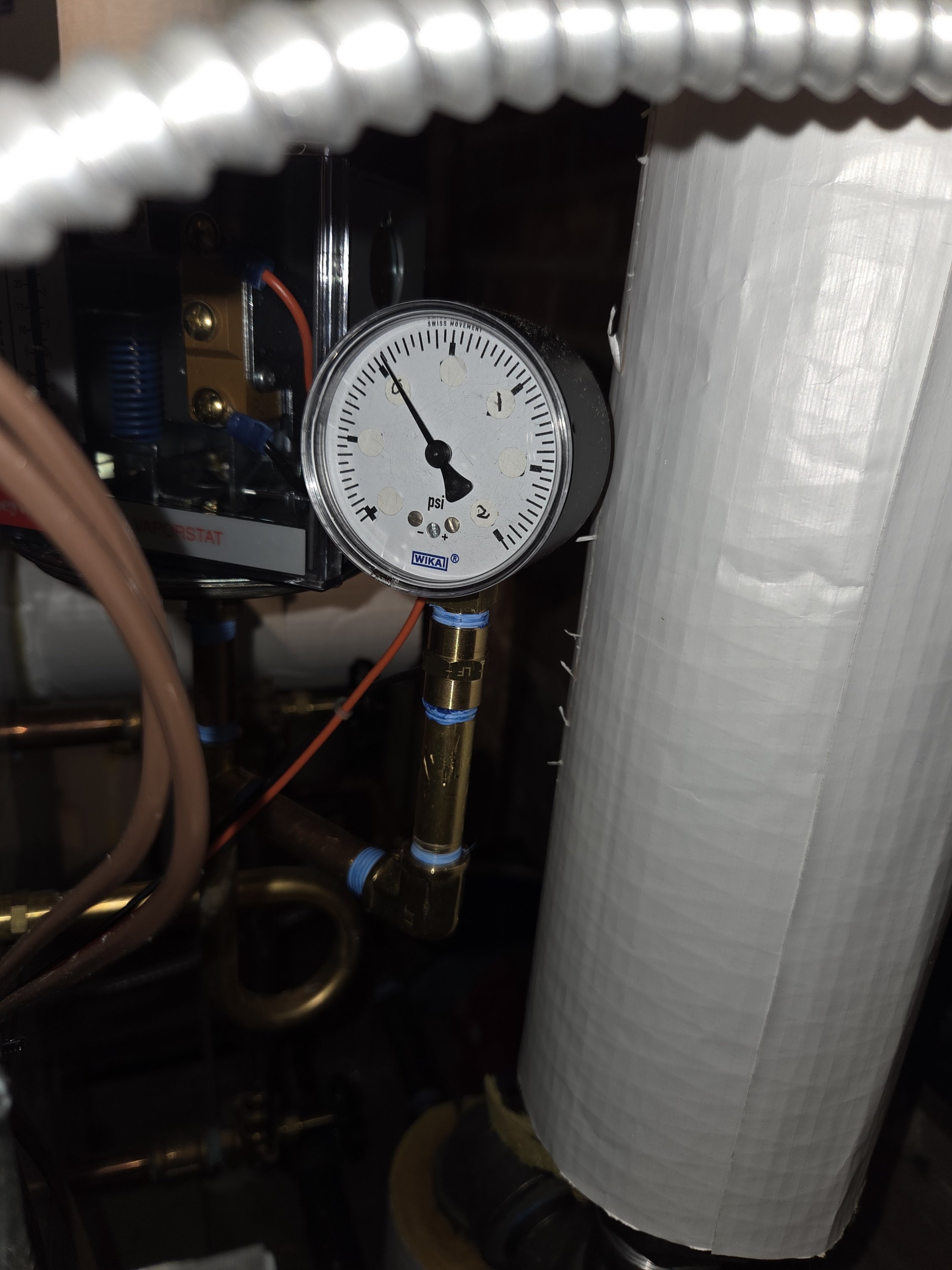

I have a 0-3PSI gauge, but it needle pops when going negative.

I tried adjusting the need to sit at 1 for the zero point, and put some stickers over each value, so I could re-label. I hoped that would help... but the gauge still makes an audible "pop" and the needle wiggles some when going negative.

Everything gets fixed instantly when the mains open up and equalize the pressure in the boiler.

two questions:

- do I risk destroying the gauge, and creating a "open" pipe if it fails? That would be worrying....

- is there a pressure gauge of this range (0-3) that can deal with that neg pressure occasionally?

Comments

-

I don't think it's your water pump that is making the pressure go negative. Rather, it is just the collapse of steam after the boiler shuts off that makes your pressure go negative. This is normal operation.

I haven't noticed my gauge having any trouble with this brief negative pressure, but if you're concerned you can put a ball valve under the gauge and only open it when you want to see the pressure.

Dwyer gauges including their Magnahelic can definitely handle it but one of mine is very similar to yours and it's OK.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Thanks. That is reassuring. Just wanted to make sure I wasnt going to destroy the gauge and end up with an issue.

0 -

You might destroy the gauge, I can't vouch for that, but I don't think it will cause you any issue beyond that

Honestly, your gauge already looks a little jacked up 😅 Is the needle no longer pointing where it used to?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

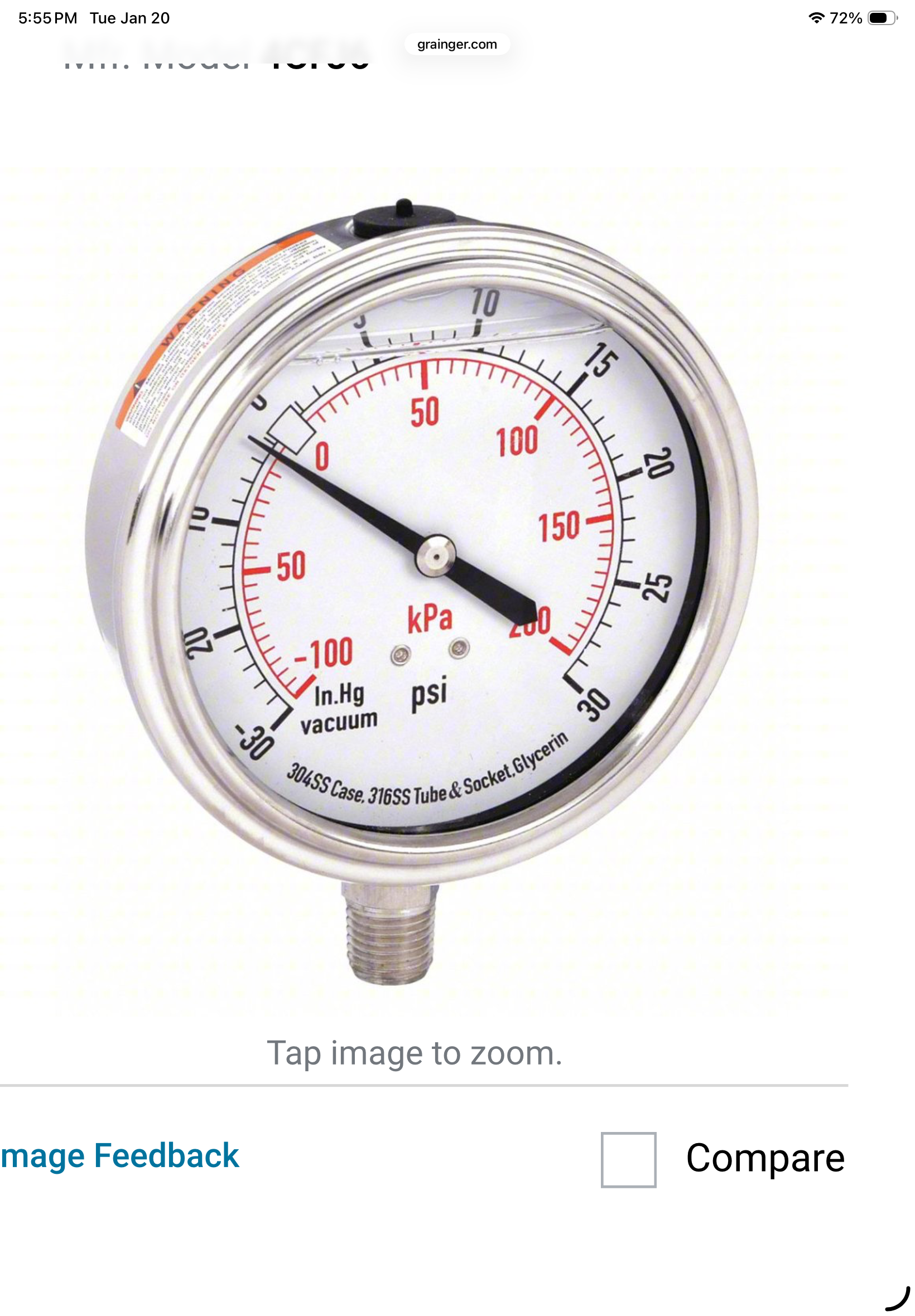

Look in to a Compound Gauge, or a center zero Dwyer Magnehelic (eBay) .

That 'pop' may already be the result of damage to the linkage.

The pressure or vacuum would have to be pretty great to damage the gauge to the point where it would be open to the atmosphere.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

There's a deeper problem here. If you are managing to get a vacuum, your vents are not opening properly.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I don't see a problem here. The vents don't open instantaneously after steam production ends, and even vents that never closed during the call for heat can't "inhale" fast enough to avoid a couple minutes in the negative pressure zone.

When that steam collapses it is a FAST loss of volume in the system and although nature abhors a vacuum, it can't always instantly be filled!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Buy a 30-0-30 compound gauge if you want. The vacuum will probably damage the gauge.

You could easily install a steam vacuum breaker on the system (Tunstall sells those) or use a swing check valve. Pipe it above the boiler water line so it will let air and close under pressure.

Is your HW loop pumping boiler water or are you pumping through a tankless coil or a heat exchanger.

0 -

I have the exact same gage. Mentioned this before on another thread but since I never see 3psi I leave my ball valve open all the time. Yes, the needle gets pulled down a bit end of cycle but after a short while comes right back up as vacuum leaves the system. Originally when I was leaving the ball valve closed for some reason the vacuum would get trapped in the gage permanently, until I reopened the ball valve. With the long exposure to trapped vacuum I noticed when I relieved the pressure by opening the valve the needle would stay below zero. I would then have to use those little adjusting screws to re-zero it. Conclusion, something must be funky with the ball valve I got but the temporary short vacuum drops now with the valve open do not seem to permanently impact the gage. A typical cycle which closes about 4 of my 13 radiator vents on a cold day like today peaks at about 0.1psi. Vacuum pulls gage to about -0.1psi for about 5 minutes then it come back to zero.

Boring video attached:

1 -

Hmm… OK. Maybe the reason I never see a vacuum for Cedric is that the main (and only) vents (Gorton #2 and Hoffman 75) are right at the boiler (on the dry returns) and never close. Pressure gauge is on the header, which connects though the Differential Loop to the dry returns…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

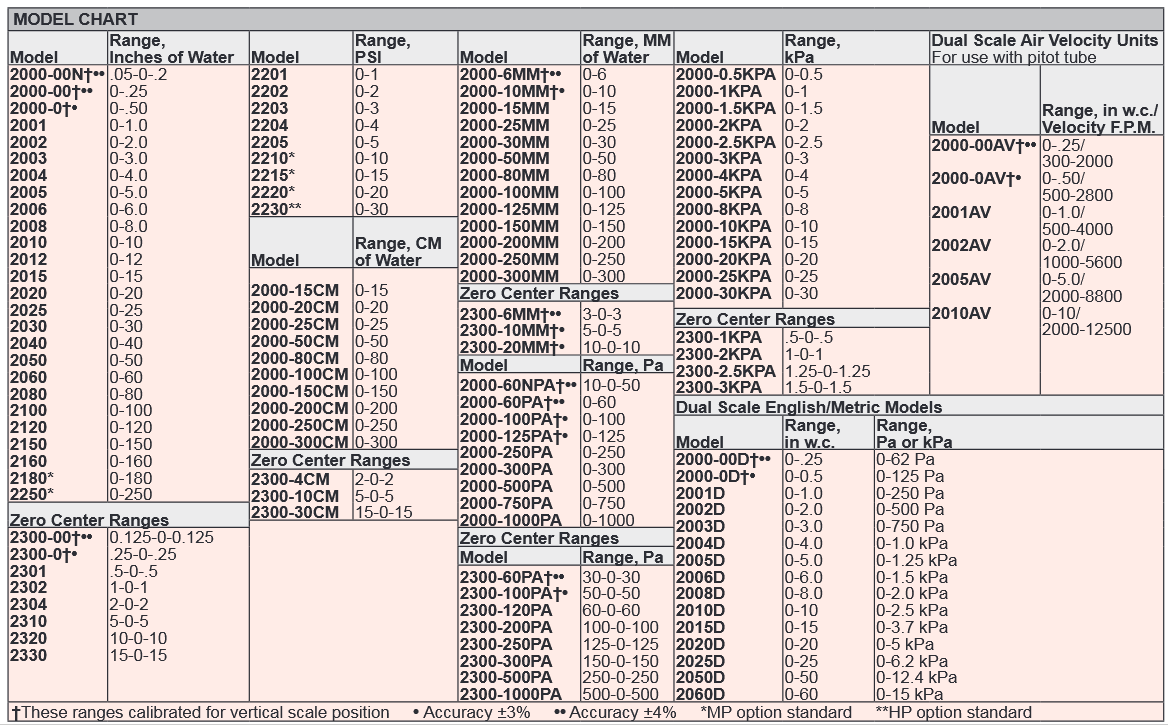

"center zero Dwyer Magnehelic"

Those look perfect, but I can't find one that fits the range of -2 to 0 to 2 psi (or -50 to 0 to 50 in water).

0 -

Excuse me if this was asked and answered and I missed it, but what brand and model of radiator vents do you have? I read an article by Dan Halohan about the old tyme vents from the coal days that tended to stay shut but it didn't matter because with coal boilers they kept them going at a low rate all day.

0 -

All the steam radiators have Varivalves. All are relatively new (5-10 years old) and are working fine. They all vent air nicely, snap shut at steam.

I just have 1 main loop, which feeds 2 floors. the 1st floor Varivalves are all mostly closed. Upstairs Varivalves are somewhere between 1/4 open and 1/2 open. It is pretty balanced this way, and the house gets pretty even temp in each room. (Not bad for a century house lacking wall insulation).

oh, and the Vaporstat is set at 1.5psi, so none of the vents should be closing on pressure, just steam.

0 -

All Heat Timer Varivalves here as well. Regular Honeywell Pressuretrol set at 1.5 psi cut out, 0.5 psi cut in. I have heard one inhale air noisily occasionally some time after a heating cycle so I think they can stick sometimes and not open a the same temperature they closed at. Haven't heard it happen this season.

I think what could be happening is that your hydronic loop with the circulator pump could rapidly remove heat from the boiling water and therefore the steamchest, causing rapid condensation of the steamchest, creating a vacuum (due to the fact that liquid water is more dense than the steam or approx. 1,600 x lower specific volume than the steam) before the radiators and the mains have had a chance to cool off, therefore the vents are still closed. A lot less moles of steam suddenly occupying almost the same volume (very slightly less due to the volume of the extra condensate) definitely results in a large pressure drop, easily going into a vacuum.

0 -

pretty much any gauge brand offers compound gauges. A liquid filled helps dampen needle vibration or sudden movements

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Yeah, 2-0-2 PSI seems odd.

Does your pressure really go that high ?

My boiler never goes over 2 inches of water column (0.072 PSIG). Maybe you can find a Compound Gauge with a narrower range than 30 PSI - 0 - 30 inHg.

Or even with the 2202 0-2 PSI I'd be very surprised if the vacuum would damage the Magnahelic.

https://www.mmcontrol.com/Dwyer/pdf/02-Pressure-2020.pdf

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

My system will pull down into a slight vacuum after heating and a pretty decent vacuum after a long cycle. Just the way it is and it doesn't matter.

I use a 0-2" Magnehelic and the vacuum doesn't bother it. That said I did have issues with lower pressure gauges on a Pigtail because the weight of the water pulls against the gauge when it's off. I almost broke a Wika 3 psi gauge because I kept rezeroing it. My 30 psi gauge is on the Pigtail but my Magnehelic isn't, it's protected by a straight length of pipe 18" long that acts as an air trap.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Well I guess it matters to the OP. I think that it can happen with a cold basement. I just heard one of my radiators inhale a bit a very short time after the burner cycle ended. It's 3.2 F here in NJ right now.

Where it matters is that having a hydronic loop that rapidly withdraws heat from the boiler, and isn't prevented from doing so right after a boiler cycle has completed (maybe there is a temperature switch lockout you can install?) will make the phenomena of getting a vacuum before vents can cool enough to open back up, much more likely to happen and deeper in vacuum.

It is making me wonder now. I have a 0 to 3 psi gauge which I don't remember the brand name right now, but it has a zero peg. I wouldn't know if it is trying to go below zero, or if that peg prevents damage to the gauge from a vacuum. I need to find out. It is true that my cut out that was pretty solid at 1.5 psi has drifted to close to 2 psi. I'm thinking about buying a new gauge to see if it is the gauge. Can't set the Pressuretrol any lower than it is.

0 -

-

If you read what I said, I didn't say that you can't get a small vacuum under certain circumstances, but it is WORSE with a hydronic loop that turns on at that time, and some types of radiator vents may be more susceptible to hysteresis (Dan Halohan's old tyme radiator vents from the coal era). Also, a cold basement absolutely can cool the boiler and near boiler piping off that much faster (basic heat transfer), which doesn't have any effect on the radiator vents.

0 -

I don’t think so, Captain, but opinions are free to have!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

" or if that peg prevents damage to the gauge from a vacuum. "

I think you will find in some situations the peg causes the damage. Since it jams the needle causing stress on the linkage and the Bourdon tube, that the gauge was not designed to withstand.

I would not worry about the vacuum, just get a suitable gauge.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

-

"Well I guess it matters to the OP"

yeah, not really. I was just initially worried about what happens if the gauge fails. At least I dont have to worry about that. I still might pick up a robust Magnehelic gauge, the 0-1 psi version with the stop pegs on each side.

I also am dropping the pressure on my Vaporstat to 1psi. I guess I should have gone with the 0-1 Vaporstat, or better yet just a 0.5-1psi switch and a delay-on-break timer (I like that idea fome another post I read).

one thing I have noted during this 10F weather....a bit of flash steam knocking in my hydronic line. If that pressure in the boiler does dip relative below zero (while the venta are locked shut), does it increases the pressure difference between the water in the boiler and the water running through the hydronic loop radiator one floor up? (It is 30+ years since I had Physics/Thermodynamics in college, and I dont recall how that works). At least, the pressure is lower in the radiator, no matter what, so the boiling point of water is lowered...

If so, that lowers the flash point for water→ steam.

0 -

no problem my friend. I know what it’s like to have people disagree with one’s opinions, even when they are backed with factual observation

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I guess it could be possible. Does your hot water loop have a bypass loop on it, or does it pull directly from the boiler water?

And is there a vertical drop from the boiler to the water circulator pump?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Turns out the one I got several years ago has no brand name on it and is made in Taiwan (edit to add - Kodiak Controls KC25, was $30 in 2014, now $39). I made my pressuretrol/gauge tree with a cross in the middle for cleaning out with an air compressor and a large cable tie when I don't feel like going the full monty and disassembling for better cleaning. I can install a second gauge or a manometer there temporarily for finding out what's what with this gauge.

1 -

OK sorry for assuming it mattered to you 😃. Anyway, I have been waiting for you to answer @EBEBRATT-Ed 's question above:

"Is your HW loop pumping boiler water or are you pumping through a tankless coil or a heat exchanger."

Edit to add - although I guess you just did, indirectly. Ask the pros how to prevent this cycling when boiler water is basically at Tsat.

Edit to also add - It's been a lot more than 30 years for me lol, but you are on the right track. Tsat is lower at lower pressure, therefore easier to get vapor in your hydronic line.

0 -

Sure why not ? Although you would need a fairly tall manometer (clear tube type) to maintain the functionality of the pressuretrol. You could put a T there and still retain the service port and connect the new measuring device out of the side port of the T. Compressed air may be a bit scary with a 3 PSI gauge

Personally I have no pigtail between my Magnehelic Gage and the boiler, just air for isolation. I don't like the small bias the water in the pigtail causes, but my system pressure never goes over 2 inches of water column.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

I've been thinking about getting a digital manometer for testing things like automotive PCV system and the like, and they do vacuum and pressure. I definitely make sure I don't have the pressure regulator on the compressor set too high and poke the long cable tie through the pigtail into the boiler first to remove any major restriction. Then I barely see the needle move on the gauge when I blast it with a shot of compressed air.

0 -

Rather than using a 30-0-30 compound gauge, use a 30-0-15 compound gauge. The needle movement is exactly the same on either side of the zero.

This is the gauge I usually see on the old 2 pipe steam systems I deal with.

Dennis Pataki. Former Service Manager and Heating Pump Product Manager for Nash Engineering Company. Phone: 1-888 853 9963

Website: www.nashjenningspumps.com

The first step in solving any problem is TO IDENTIFY THE PROBLEM.1 -

"Is your HW loop pumping boiler water or are you pumping through a tankless coil or a heat exchanger."

The HW loop is pumping boiler water. And yes, there is bypass loop. I had to install that bypass myself, as the original installers didnt think it was necessary....(and that why I love this site, so I know how to do this stuff myself).

0 -

oh, and dropping the preasure below 1psi seems to help ALOT with the negative pressure issue.

I guess even at 1.5psi, it was just pushing too hard, and compacting the steam, so that when the steam collapsed, more vacuum created.

Fun lesson. And now I am really on a quest to keep pressure low.

0 -

At least 3 of us have suggested compound gauges. Of course, a hard vacuum will eventually damage a low-pressure gauge they are pretty sensitive.

The vacuum will allow the steam to boil at a low temp when the boiler shuts down.

If you don't like the vacuum noise or the rads inhaling put a check valve or a vacuum breaker on the boiler.

0 -

I think I'd recommend a Magnehelic to anyone that wants a better gauge. They really seem to handle abuse well.

They seem to tolerate vacuum fine, even if they're not a combination pressure / vacuum version.

Here's mine showing a decent vacuum shutting down. The smaller gauge above it is a Dwyer 8-0-16"WC gauge. I think it's a LPG4-D9122N

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

1 -

So looks like about 3 in. H2O of vacuum? That'd be 0.108 psi of vacuum. Hard to believe that would damage a 0 to 3 psi low pressure gauge. However, how low could it go if one had a hydronic loop circulating through a heat exchanger in an upstairs room, pulling heat out of the steamchest rapidly, condensing that steam rapidly?

0 -

No lower. For the same reason as below:

I guess even at 1.5psi, it was just pushing too hard, and compacting the steam, so that when the steam collapsed, more vacuum created.

No, it doesn’t work like this. The pressure, whatever it is, goes to zero, then goes however negative it is going to go according to the volume of the system and the rate of air flow back in. It’s not a ball that bounces higher the harder you whip it at the ground.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Ha. I don't know what crazy science you two are using but if there is a rapid condensation (due to rapid heat extraction) in a closed system (vents still closed), that means fewer moles of vapor occupying roughly the same volume as before. Instead of imagining science look it up. That results in lower vapor pressure. That vapor pressure could easily go into a vacuum and a lower vacuum than would normally be observed.

0 -

if all the air is out then it doesn’t matter what the pressure is before the boiler stops. And rapid heat extraction or not, no air is coming in until the pressure just slides to negative. That’s as clear as I can put it.

And I certainly don’t care if you laugh at me, but for the decorum of the group, it’s not a good look

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

-

"At least 3 of us have suggested compound gauges".

only ones I can find are like 30-0-30 gauges, and thats not low enough. I already have a 0-30 gauge on the boiler, as required by code (and insurance!).

I am quite intrigued by those massive Magnahelic gauges, tho. I might have to find one that fits my operating range.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements