Air scoops for a AWHP install

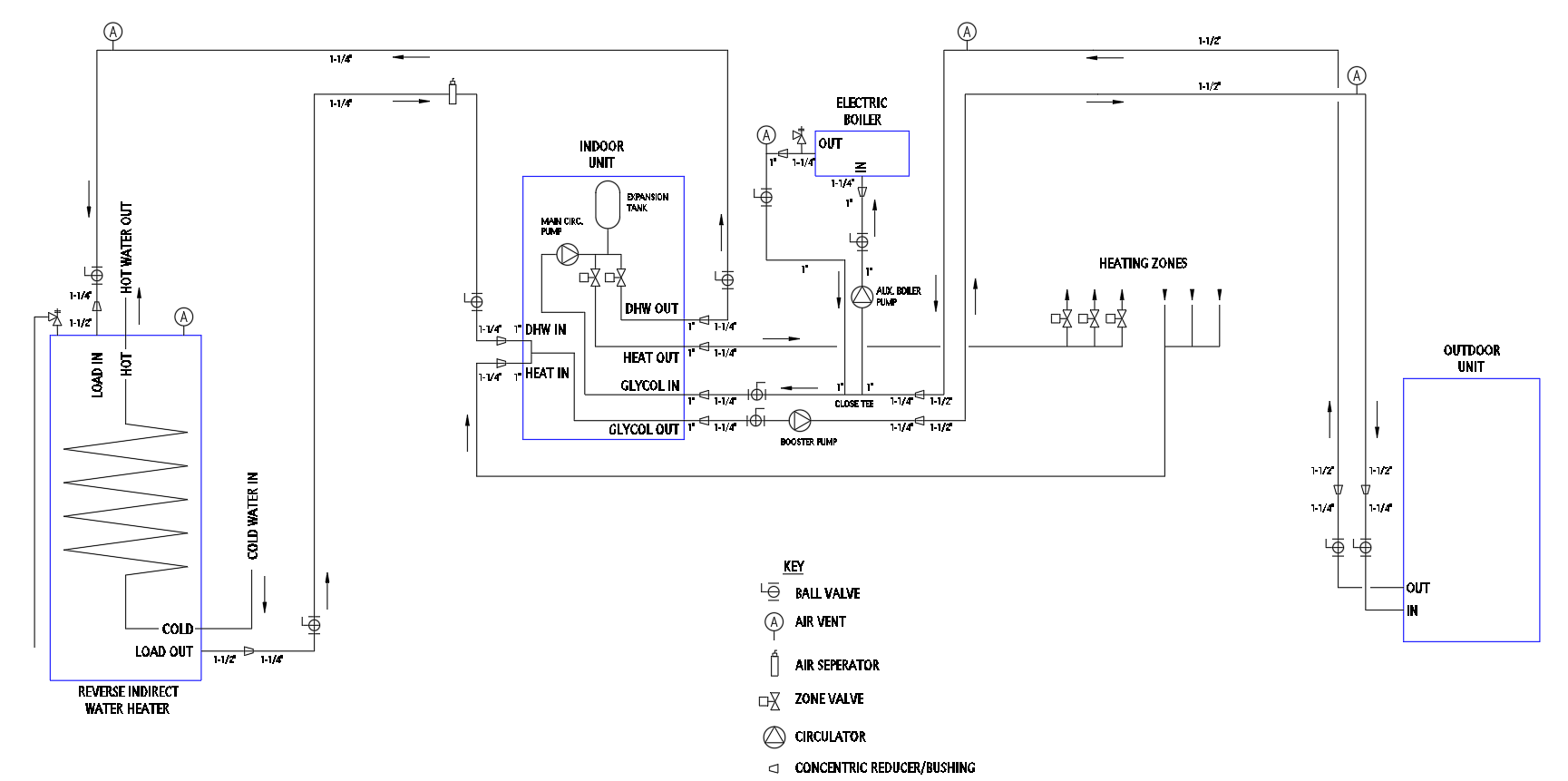

I'm installing an Entertech AWHP system. My layout is as follows:

(edit: updated drawing)

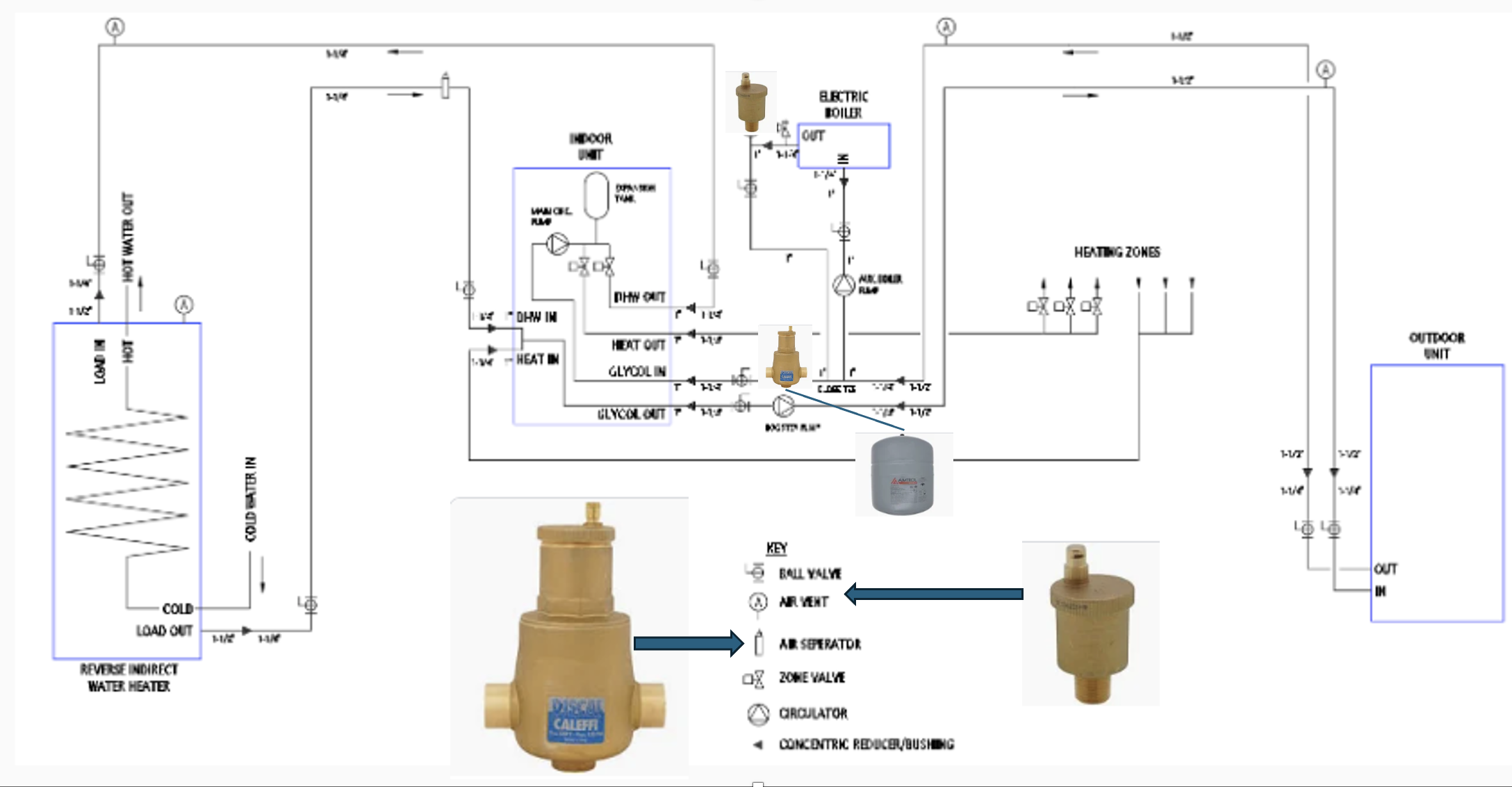

The install manual shows installing the provided 1-1/4" Taco 49-125C-2 air separator on the glycol return from the heat zones. I moved it to the return from the indirect water heater as I figure that will be circulating year round vs. just during heating season.

Because of space constraints, the runs from the indoor to outdoor unit, and from the indoor unit to the indirect tank all need to run at ceiling height. Am I correct in my understaning that only one air seperator is required per system, but I need to add an air vent (Taco Hy-Vent or similar) at every other high point i'm creating? If so, is a tee with a vent enough, or is a air scoop required for each vent?

Bonus question; Other then the heating zones, all the piping is Propress copper. The tank has threaded black iron stubs. Are dielectric unions required? I've read conflicting guidance on the subject.

Thanks.

Comments

-

There are a few ways you could do this. I put my air purger right at the outdoor module.

In your case adding one here covers the HP, electric boiler, and indirect best. You wantb the air sep at the hottest point in the system. I'd like to see the expansion tank connected here also.Then both the boiler an HP pump would be pumping away., but.

The expansion tank in the indoor module may not be large enough to handle all the piping? Plus use a glycol derate if you size a new one.

If you do upsize the exp tank, connect it to the air separator at this location, then the boiler pump and hP pump is pumping away. I'd add a relief valve there also so if the boiler is valved off the HP still has a pressure relief function. My Viessmann HP wants a relief at the outdoor units also, incase it gets valved off.

Put a float/ auto vent at high points like the boiler, use a good ball valve below it for easy service.

Looks like you are running the entire system with glycol. I used a plate HX at the indoor module, so only the HP loop has glycol. Glycol is an expensive, somewhat messy fluid. It has been know to leak (green fuzz) around press fittings from time to time.

Yes you can screw the propress adapters onto the black nipples, although some installers like to have unions on and tank or boiler connection.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The 80gal indirect tank is included with the system from Entertech. The 50' of 1-1/2" loop pipe is from the chart in the manual. I'm hoping, they did the math correct on the integral expansion tank.

I like the idea of the plate exchanger as 100 gallons of glycol mix isn't cheep. Unfortunately, the indoor unit is completely integrated into the heating and DHW loops, so not sure how I would separate out the loops.

I'd be all for replumbing so the outdoor unit just keeps the indoor tank hot through a heat exchanger, then take heating load (minimal in my case) off the spare taps in the tank (buffer tank style).

Enertech says that's not efficient and wants to drive the heating loops directly from the outside unit upon heating call, shifting flow away from the DHW loop.

0 -

"Enertech says that's not efficient and wants to drive the heating loops directly from the outside unit upon heating call, shifting flow away from the DHW loop."

This is one of the reasons why DHW isn't a good fit for AHWP's.

Generally you're better off just putting a heat pump water heater in the conditioned space. It costs less, uses no more electricity, takes up less space and is simpler. In the summer it provides free cooling.

1 -

Does the Entertech come with a reverse indirect 80 gallon? Like the install manual shows, The models with 3 coils can generate reasonable DHW with low tank temperatures. It is always about the surface are with heat exchange.

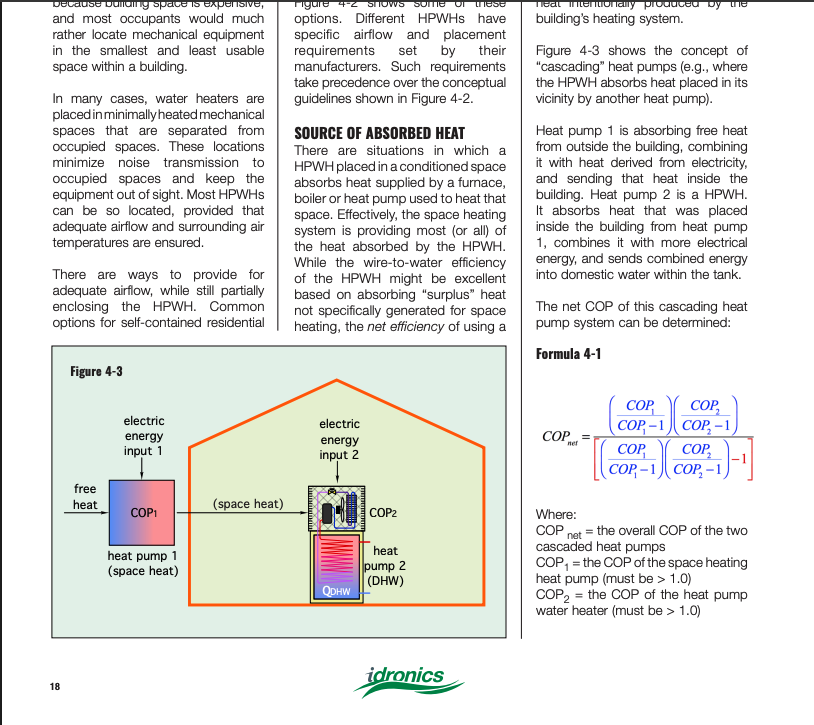

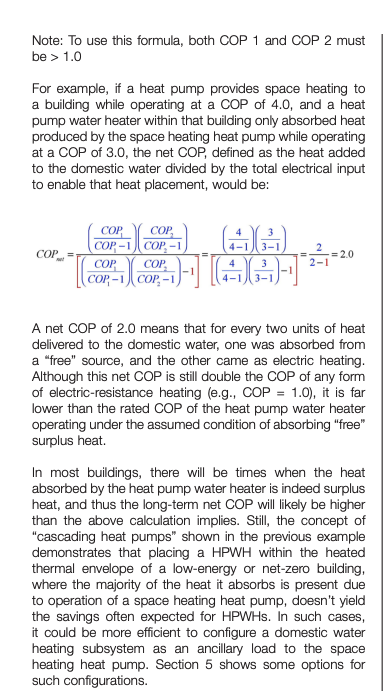

Cascading heat pumps may not be more efficient then using the indirect, depending if there is "free heat" available. Here is the math for a 3 COP HPWH in a space heated by a 4 COP heat pump

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The Enertech comes with an 80 gallon turbomax (reverse) indirect water heater.

In my case, my priority is making hot water. It's a timberframe house with a 40MBTU Jotul cast iron gas stove which supplied all the heating for 20 years. We meet our annual electricity with power to spare with solar production, so have been shifting away from gas to electric. Already have two mini-splits, but need to add some BTUs to a couple problem areas whre we cant put mini splits. Due to the construction, 2-3 toe kick heaters are the best option (two with floor housings). I want to pull some BTUs from the Enertech to run the toekicks.

I'm not interested in an indoor Heat pump water heater.

0 -

Every application or situation is different, in you case with excess PV you are wise to look a heat pumps, regardless if they are minis, or AWHP.

Although it does seem like $$ way to make mostly DHW?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The Monoblock is definitely not cheap, but we were forced to go cheap 25 years ago. Now, function, durability and made in America are the priority.

0 -

I don't believe there are any monoblock systems made in the USA.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements