Lochenvar WHB110N (LP) doesn’t want to fire reliably (FLAME FAIL IGN)

I’m stumped. The TL;DR is the thing ran for ten months just fine, now its under fired and doesn’t want to start reliably.

Here’s the long version: The boiler in question was hung on the wall in 2019 for a remodel and the project went dormant during Covid, never finished or fired.

Fast forward to Feb 2025, the gas company failed to bring NG to the street so it was It was converted to LP with the mfg’s kit, a new venturi and blocking plate. A 1000 gallon LP tank was buried and the boiler supplied with 1” Tracpipe, about 20 ft downstream of the second regulator. Intake and exhaust are approximately 10 feet of 2” pvc with several 90’s in each, all okay according to Lochenvar.

Unit was commissioned, gas pressure was 12” wc at high fire and combustion was within limits (don’t remember exact numbers but were as expected). Unit has been running successfully for ten months. Tank got down to about 200-250 gallons and the unit started throwing FLAME FAIL IGN faults about every other attempt to fire. It would recover and run okay for a day and then start failing again.

Tank was filled to 800 gallons but problem persists.

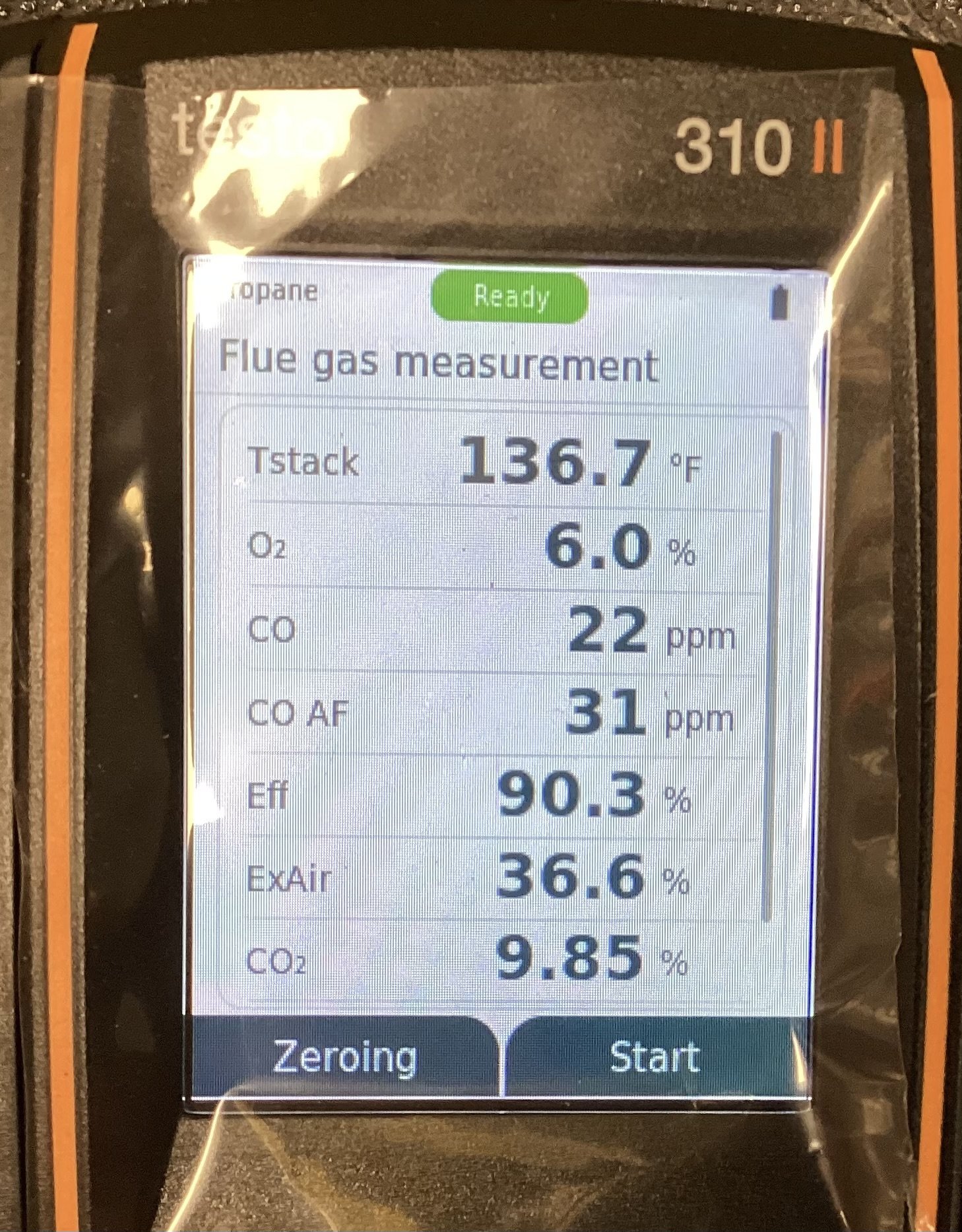

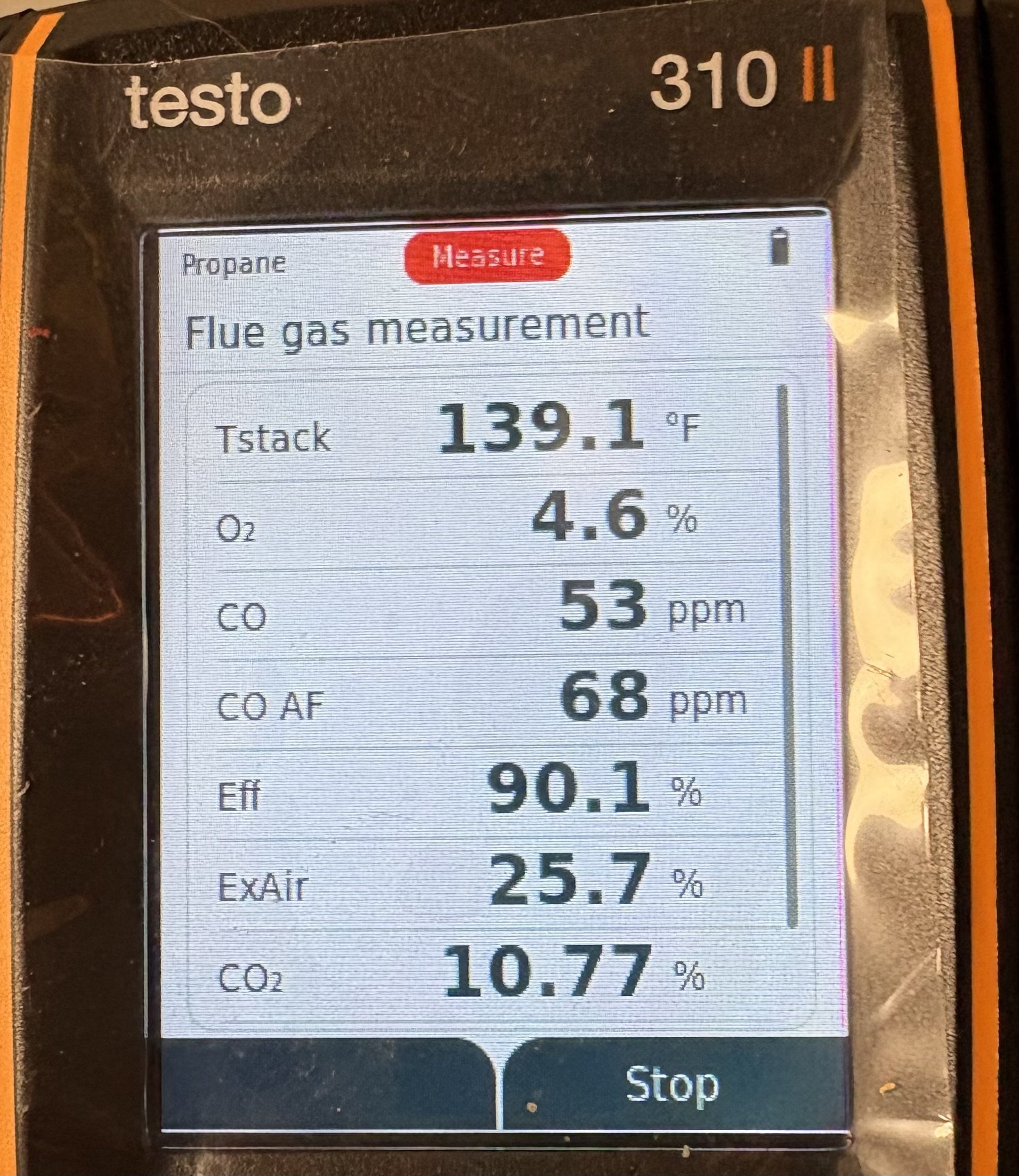

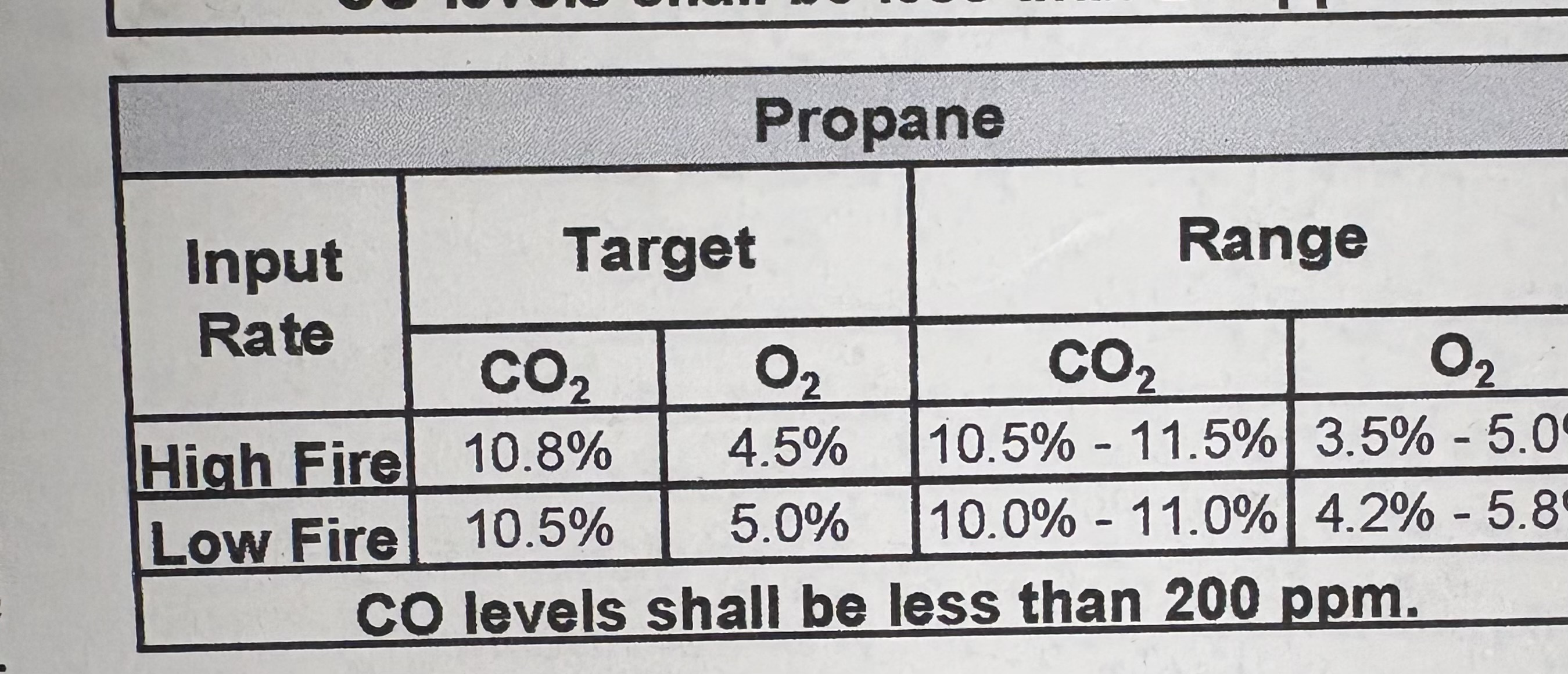

At high fire, Co2 is low at about 9.8% , O2 is 6.0%. Targets are 10.8 and 4.5. Gas pressure is good at 12”, in both idle and high fire. Gas value mixture screw has no effect on firing with a short, all blue flame.

Gas valve was replaced to little/no effect, actually the problem is a bit worse as start is even less reliable. Heat exchanger interior is soot/combustion particulate free, burner screen also clean. Igniter and sensor were cleaned, the very light buildup on them was whitish-grey.

I have checked for intake/exhaust blockages with an endoscope, I don’t see anything in the lines. I would check the delta-p across the heat exchanger but I have no idea of what it should be so I’m stumped and open to suggestions to troubleshoot further- and of course will answer any questions.

Comments

-

water in the propane tank? regulator vent icing? did you check the pressure at the appliance when it happens?

0 -

-

Yes, gas pressure checks okay with both analog and digital gauges, both idle and running at the gas valve test port.

Outdoor high pressure regulator is under cover, no icing. Indoor regulator feeding a manifold looks okay as well, pressure at 12” w/c with no discernible changes with other appliances running (range, fireplace).

0 -

does the pressure test ok when it is having a problem?

water in the propane will be harder to test for.

0 -

You dont need more gas incoming to the gas valve. You need to increase the fuel/air ratio in the burner. This requires a combustion analyzer. You need to increase your CO2 which in turn will lower your O2 to the proper value

0 -

i thought they said somewhere in there that adjusting the valve settings wasn't changing the combustion but re-reading i'm not seeing that.

0 -

I guess that you used the proper conversion kit for LP conversion for your boiler. A common mistake in converting is the placement of the brass orifice in the tube coming from the gas valve to the fan. It is directional and I have seen it installed backward. The orifice has a number stamped on it an must match your boiler. It should have been checked with the instructions that came with the conversion kit.

Also, the baffle plate under the fan must be installed correctly.

0 -

Homer, my conversion kit did not have the brass insert nor did the instruction kit show it.

The boiler and LP kit were purchased in 2019, perhaps they changed things since this was purchased. I do know the LP Venturi flapper diameter is different from the NG part, that was the only difference I saw. With respect to the baffle plate, it was installed

aligned along the long opening edge. I honestly don’t remember but I don’t think you can rotate it 90 degrees, making a very small opening. It cut the area about in half from what I remember.

Please note the unit ran successfully for ten months with the proper combustion readings. Now it’s quite lean and adjusting the gas valve mixture screw has no effect on the combustion analyzer, photo attached of the current condition. Installing a new gas valve did nothing.

The only thing I can think of at this point is that there is a blockage in the heat exchanger that is reducing airflow thereby reducing gas flow. Am I barking up the wrong tree on that one? If not, how would I check that? Couldn’t I measure the delta-p across the hx? I know there is differential pressure switch that monitors for excessive pressure drop but that’s never thrown a fault.One thing stuck in my brain was my distributor sales guy mentioned that “you never want to run these things low on LP as they’ll soot up the heat exchanger and you’ll be replacing the most expensive part in the unit”. I expect that has biased my troubleshooting but I’m up a tree looking for wood at this point.

0 -

They've got a point running low on LP but I don't think you ran it too low. there are some things I would check, I know you gave a gas pressure number but I'm curious how you measure it? measure at the boiler the inlet port of the gas valve, The number must always be within allowable range, but if you see a drop of 1" or more from static that can be problematic (this is the case with most mod/con boilers, all of them I have seen anyway) One thing I have encountered several years ago that was very frustrating was LP tanks with a ton of air in them, it was isolated to a single year and company and caused a lot of issues. You also would do well to service the burner and fireside of the heat exchanger, if the boiler had sat unused and partially installed since 2019 it is very likely that critters would have tried to make the boiler their home. There could be remains of some mouse etc causing issues. doubt anything could get in the burner but I would start with dynamic gas pressure and move to the burner/venting from there. confirm vent pitch etc. I would check the ignition transformer, cable, and flame sensor current, hopefully the book has the values you are looking for in there!

0 -

Gas pressure is being measured at the valve, it’s currently 12” w/c and stable regardless of boiler state (static, low, high fire). Checked with analog gauge just to be sure it wasn’t fluctuating and not seen on a digital. This is well within range of 8” min, 14” max per the i&o manual.

Other LP devices on the same regulator/manifold (cooktop, fireplace) don’t exhibit any issues so I doubt the air/water in the tank scenarios are in play.Pitch back to the boiler is good, critter screens are installed and piping was scoped at startup to confirm no debris was present.

Short of disassembling everything and pulling the exhaust stack off the h/x outlet, is there any way to check the pressure drop across the h/x?

There has to be some way to confirm this thing has proper (or improper in this case) air flow through it.

0 -

I vaguely remember a contractor now working for our wholesale distributor telling me about a Lochinvar boiler running on LP that had a problem similar to yours. What he said is that the fire tubes were all clogged up and the fix was to clean the fire tubes. He attributed it to bad LP gas. This was several years ago.

Our wholesale distributor hydronics department sends out a crew to look at boilers that they sell that have a problem that the installing contractor is having difficulties with. Really a good practice.

Let me add, is your condensate drain operating properly?

Still no model and serial # or did I miss it?

0 -

the hx being blocked should affect the firing rate but not the mixture. it will just move less air through the gas valve which is more like a carburetor and you will get less air and fuel through the unit, it still should be in the correct portions. another possibility if there is water in the tank is that it is freezing and thawing somewhere.

0 -

There is zero pressure drop from static pressure to ignition, to high fire? I don't think I have ever seen that before… as for the other appliances not being affected they probably don't have flame sensors, less sensitive so too much pressure drop won't lock them out. if you are sure it's not the gas then time to move on to the next things

Not sure if you can check airflow through the unit in any easy way, but I would definitely be doing a burner service to see what is actually going on inside the heat exchanger on the fire side, something tells me if the other items are checked and OK that you will know pretty quickly once you get inside the burner chamber. given the nature of the issue I would think the burner is due for a service anyway, check for sooting, flame sensor/igniter, verify burner doesn't have any defect, and make sure the heat exchanger is clear of debris and condensate freely drains without backing up in the unit (flush with water when done it should drain very quickly)

1 -

It was HomerjSmith for the win…

His photo of the conversion kit got me to searching. Found my boiler was made shortly after some major change in 2018. It was either shipped the wrong conversion kit or parts were missing from it, it was so long ago that the actual evidence is long gone, as is the distributor that sold it to me, they were sold to Ferguson and my sales guy long ago retired.

Ordered a new kit and installed yesterday. Of course that was the problem, the lack of the venturi. The only conclusion I can make is that the weather was warm when originally commissioned, once it got cold, it wouldn’t fire reliably. I do remember the tech adjusting the mixture screw on the gas valve when it was originally fired up (February ’25) but it was only providing DHW and did not provide space hearing until this heating season in the fall of ‘25. So, it may have been having ignition problems from the get-go and I never really knew it due to the indirect storage tank.

Gas pressure at the valve is about 10.5 inches, it fluctuates a bit, maybe a 1/2 inch in high fire. I did have to open the mixture screw (turning counter clockwise) about three turns to increase the co2 to get it into range, not sure it that a sign of anything else in play as Lochenvar says it shouldn't need adjustment and to turn it only a 1/8 turn at a time. It doesn’t seem at all sensitive.

Any reason to be concerned over the gas valve adjustment?

PS: I did have the HX open about two weeks ago and the unit was clean as could be. No residue, burner had no crud/deposits of any kind. So, I doubt there is any blockage. Condensate trap is clean and working correctly, ball moves freely and the pump empties every hour or so of operation.

A big thank you to all the contributors, especially Homer for that photo. You’ve saved what little bit of hair I have left.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements