One Pipe Radiator Sloshing Issue

I have an attic radiator that has always had an issue with condensate sloshing and spitting from the air vent depending on what style of vent is on the radiator.

I’ve never bothered to address this because the attic is being used as storage at the moment but I want to fix it this spring once we are out of the heating season.

Basically what happens is the radiator heats and when it heats up about mid way, it starts sloshing badly, audibly, sounds like waves. At this point, if I let it continue heating and I have a Gorton on there, it’ll start spraying water out the vent. If I have an adjustable Hoffman on there, it’ll close when the condensate hits it (by design) but then the riser sounds like someone flushed a toilet as the condensate drains down.

I’ve been noodling on this for 3 years now and not attempting anything because I’m not quite sure where to start but I think it might be one of these two issues and was wondering if anyone thinks I’m way off base.

- Previous owners put in new hardwood flooring which is about 3/4” tall. Presumedly the radiator was sitting atop subfloor so whoever did the flooring added a coupling and a close nipple before the valve. My thought is this is potentially pushing the runout downward causing a back pitch towards the valve side vs the riser. Reasons I don’t think it’s this is that runout would probably fill with condensate much sooner than when the radiator gets halfway hot.

- This is a big radiator, 16 sections, on a 1” valve and runout/riser. Additionally, there’s a reducing bushing on the radiator spud which would in my mind effectively raise the drain point of the radiator causing it to always retain some condensate. Additionally, I’m wondering if because this is such a big radiator on a 1” pipe, it simply generates way too much condensate to properly evacuate through a 1” pipe as steam is simultaneously trying to enter. I’m curious if anyone thinks there’s any validity to this line of thinking or sizing calculations that could confirm it.

I have a spare radiator in my basement that I may try hooking up, I think it’s 8 sections, maybe smaller, I’m going off of memory, but I don’t want to go through the trouble of lugging this thing up three flights of stairs if the radiator size isn’t the issue.

Comments

-

I would suspect you need more pitch on the radiator ….

There was an error rendering this rich post.

0 -

I would disagree about the pitch. You can't really change the pitch anyway, pipe doesn't bend that easily. Additionally, I have proven that radiator pitch doesn't matter.

The issue I see here is that is a lot of radiator for a 1" valve. Also make sure the valve is fully open. Also make sure the valve doesn't have rusted parts that have fallen down inside it partially blocking the backward flow of condensate.

If your other radiator is smaller give it a try. Or even easier, cover the radiator with a blanket and see if it is better.

My upstairs radiators that are on a 1" valve are about 20 EDR. That one is substantially larger and the steam is fighting to get past the returning condensate.

That's my best suggestion from here.

There is one more thing, how is the water level in the gauge glass while this is happening?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I figured the pitch was a long shot, and I was specifically referring to the runout below the floor, not the radiator itself. It just seemed like there was more plumbing dimension than floor buildup so that could be something but if it’s not, it’s not.

Yes, when I’ve tinkered with this radiator, the valve is always full open, until it starts spitting and I shut it down fully.

I’ve never checked the sight glass while this is happening, what should I be looking for or expecting to happen?

0 -

The horizontal piping under the floor could be pushed down just below the valve. I have seen that section of pipe plug up with minerals as well . The floor was added along with a coupling . You can open up the valve and pour water down to test . To correct the pitch jack up both ends. If that pipe was pushed down it can be pulled up ..

There was an error rendering this rich post.

0 -

Yes changes to pitch of the runout are a possibility too. Those would typically be accompanied by banging when the steam hits the cooled pool of trapped water. Then as the call for heat continues, the banging would lessen and/or disappear until the next call for heat. Do you have any of that?

The gauge glass would be used to see if the boiler is carrying over water out of the boiler during firing. You don't want to see a dramatic dive of water level during the call for heat. If that occurs, water is exiting the boiler and could possibly make it all the way up to your radiator. It's just an easy thing to rule out.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Disconnect the radiator at the spud/valve union. See if the valve/piping wants to move vertically by using some leverage and see if it moves vertically easily. If so you probably have a sagging horizontal section under the floor.

If you need to readjust things, good time to use a valve that is the same size as the radiator.

1 -

No, the radiator and surrounding piping is quiet until the sloshing starts.

The water does drop in the sight glass but not by a whole lot. I’ve never seen it with the problem radiator supply valve open though but I’m assuming if I’m not having any issues with water exiting the boiler normally, I wouldn’t have any issues with that supply valve open.

0 -

If all the piping is 1” I’m limited to a 1” valve right?

0 -

I'm not sure what you're saying there, but if you aren't having any banging I think for me that would rule out water being trapped by bad pitch in the runout. And if the water level is reasonably steady that rules out the boiler having serious carryover problems that would throw water all the way up into the system.

So for me that leaves

- Problem with radiator valve not being fully open, or being partially blocked due to rusted out internal parts (can be verified by opening the union and sliding the radiator away to look inside valve).

- Radiator valve is just too small for that radiator (can be rectified by reducing "size" of radiator by covering partially with a blanket or installing smaller radiator).

I think you'll have trouble putting a larger valve on there because the riser is 1" and you probably don't want to repipe that. How does the existing radiator perform to heat that space?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

The problem could be either of the things you identified. If you put a slow vent on the radiator, does that stop the sloshing, and allow enough heating? If so, that's your easiest fix.

It could also be bad pitch in a runout. Find the riser to that radiator in your basement, and see how it aligns with the valve. You should be able to get a sense of how long the runout is. If it is any length, you may be able to change the pitch depending on how the pipe is secured.

And you can definitely have gurgling without any banging. See the video of my (now quiet) radiator from seven years ago:

0 -

My comment about the 1” valve was meant to quote the comment about switching the valve to match the radiator, but I assumed it’s not possible unless I’m changing the riser and runout pipe dimensions.

The existing radiator heats the space fine, if I swap the Gorton vent for the Hoffman which will close when water hits it, it’ll get all the way hot and slosh but not spit, and almost be too hot for the space (it’s an open finished attic)

I have put a slow vent on the radiator and it does stop the sloshing provided the heating cycle doesn’t run long enough to heat the entire radiator. I haven’t messed with it in some time, but if I remember correctly, once it passes the 8th section, it starts sloshing, otherwise it’s quiet. This is what got me thinking that it might be a radiator/valve/piping size mismatch.

I don’t want to entirely rely on a slow vent because on the coldest night in February the heating cycle will run long enough to get the whole thing hot and cause the sloshing and as the condensate eventually makes it to the riser, it sounds like running water which is annoying when I’m sleeping if not anything else.

I also don’t want to slow it up so much either that the steam doesn’t reach the radiator during a call for heat.

like I mentioned earlier, I have a medium size spare radiator in the basement so I’m wondering if it was originally in the attic because I’m not sure where else it would’ve come from. I might try swapping it towards the end of the heating season0 -

You are right that in a long call for heat a slower vent does nothing. But a blanket on the radiator will slow it down every time. Swapping out for the smaller radiator is also a great experiment (but don't hurt your back)

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

the blanket prevents the covered sections from radiating to the room and giving off heat thus causing the steam to condense?

0 -

Thus reducing the amount of steam that will condense

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

ah yeah, I was in a meeting and not thinking as I was typing.

0 -

how does the runnout get there, is there just one long pipe up from the basement or does it branch off of something else? I'm thinking the runout could be trapping condensate that the air pushes in to the radiator as it vents out so it is air rather than steam pushing it around so you're not getting hammer. I'd try raising the riser by shimming under the radiator and see what that does.

0 -

you could do something creative with a reducer under the valve where that coupling is now to use a larger valve.

If i were to change something with the piping instead of making the runout bigger I would bring a second return pipe down and set that radiator up as 2 pipe air vent. That long riser to the radiator is potentially problematic no matter what and making it 2 pipe fixes some of those problems.

0 -

if the velocity of the steam is pulling some water along with it from someplace it is trapped the slow vent will fix that, it will keep it from spitting. The fact that is still sloshes makes me think that there is water trapped somewhere in the runout though(or the velocity of the steam is such that it is keeping the condensate from draining once the whole radiator is consuming steam).

0 -

-

Small pipe diameter (as Paul has pointed out) AND uninsulated pipe somewhere under the floor leads to a big fight between steam and condensate (thus sound of the waterfall/toilet flushing).

I've made a video about this:»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog1 -

That is a 16 section, three column radiator, right? If it is 22 inches high, at 3 ft.² per section that is 48 ft.².

According to TLAOSH, a 1 inch one pipe steam riser has a capacity of 45 ft.². However, a 1 inch horizontal runout to that riser, without a separate drip, has a capacity of only 28 ft.², and a 1 inch one pipe steam radiator valve has a capacity of only 20 ft.² because the steam and condensate must pass through a small opening in opposite directions.

If a smaller radiator will heat the room adequately, that is your best bet. The suggestion above of testing this by covering much of the existing radiator with a blanket, which will reduce the effective size, is a good one.

Changing the valve to 1 1/4" will certainly help and would not require changing the 1 inch riser, just a 1" to 1 1/4" adapter in place of the existing riser coupler and removal of the bushing at the radiator.

—

Bburd1 -

-

Yes, 16 section 3 column. I don’t think it’s original to the house because all my radiators are made by US Radiator, this one is not. It was probably swapped when the attic was converted to a living space some time ago.

I’ll test the blanket over the radiator to see if it solves the problem. I do have a spare 10 section 3 column radiator in the basement which I’m assuming was the original one for the attic because I don’t have any missing radiators or evidence that one was removed anywhere else in my house.

1 -

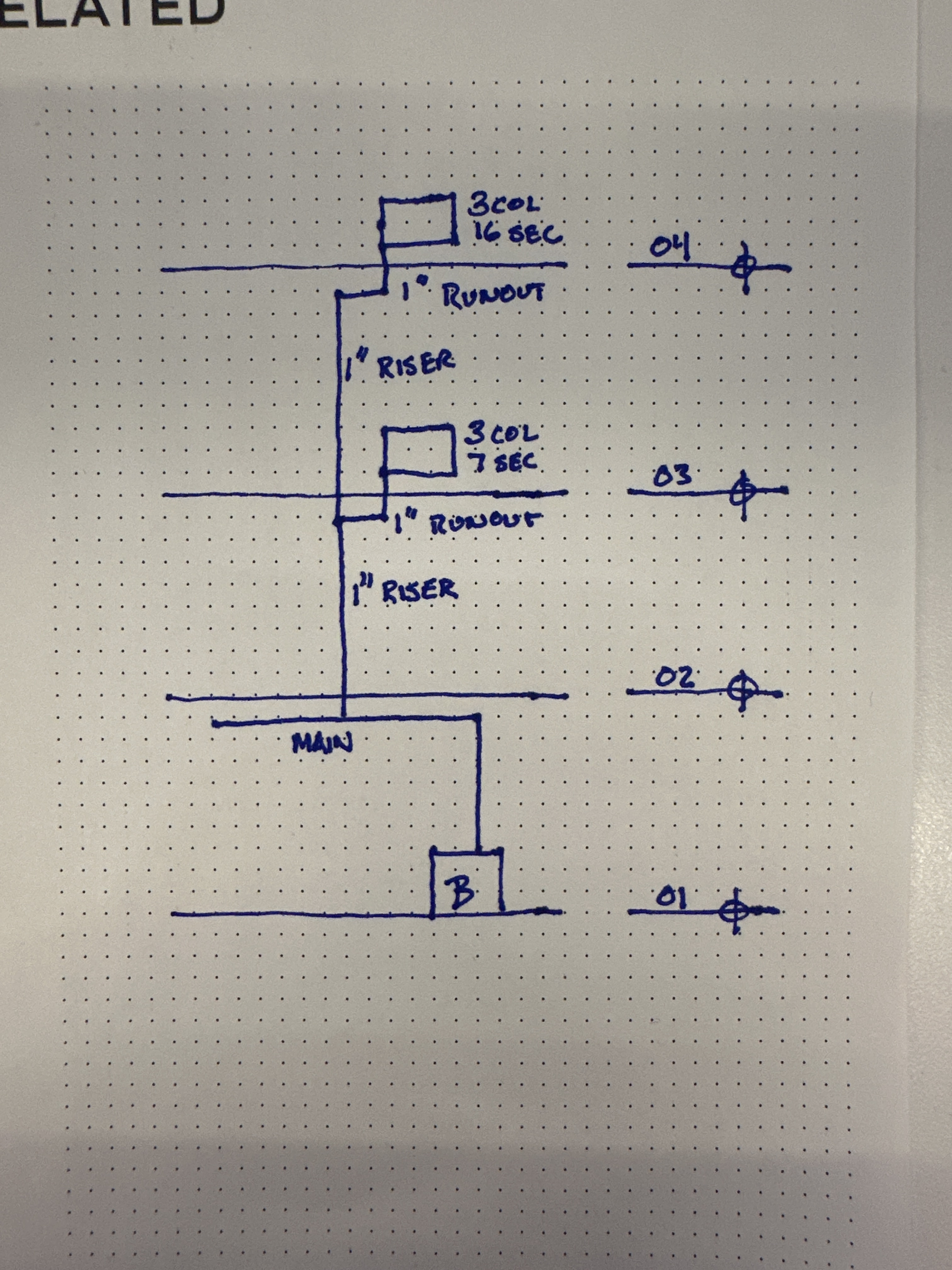

My best guess based on what I can see is a riser from the basement that picks up a bedroom radiator on the 3rd floor and then the attic radiator on the 4th floor. (I’m counting the basement as the 1st floor)

it’s a 1 inch riser and the bedroom radiator is a 7 section 3 column.

0 -

both are on a single 1" runout?

0 -

This is what it does. I’m pretty sure the riser is 1” but maybe it’s 1-1/4”. All the piping through the floor to the radiators are 1” on this particular run. Piping is within the walls and ceiling so it’s hard to tell. The riser off the main is smaller than the adjacent riser so I’m assuming it’s 1”

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements