Radiant under-floor system

Hello all.. I am just looking for any advice or suggestions on preference and procedures to install an "under-floor" radiant heating system. A customer is asking me about this for planning purposes, and I need to come up with some rough costs for his planning. I've done many systems in a concrete slab, but I have only done one very small area with under-floor panels. Never a whole home. The small one I've done in the past, I used the heavy extruded aluminum plates with 1/2" tubing. Then I stapled thermopan to the joists about 1" under the tubing for a reflective barrier. I then installed R13 fiberglass insulation under that. The heated area works well. This was a small area only about 120 sq.ft… So for a whole home, doing all of this will be costly.

This would be in a new construction home, (ranch style home) with about 1,800 sq ft of floor space. It would have heat in basement slab and then also on 1st floor level.

My main questions are, what type of aluminum panels are preferred for under the floor? And would 3/8" panels/tubing be an option? (I figure it would be easier to bend/route the 3/8")

I do not know exactly what kind of floor coverings there will be yet. And I did not even do a load calculation yet. This is just the very first initial thought process on installation procedures.

Any suggestions or opinions are appreciated.

Thank you!

Comments

-

my suggestion would be to use the aluminum extruded plates. The thin flashing gauge tends to to not grip the tube as well and can make ticking or squeaking noises.

3/8 barrier pex is fine, limit loops to 250’ or less. The A type pex is most flexible to work with. Rehau, Mr pex, Uponor are good brands.

Keep the coils warm if you can and an unwinder is helpful

A load calc and tube layout is helpful to assure it works properly

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

@hot_rod: "A load calc and tube layout is helpful to assure it works properly."

You're understating the case to say they're "helpful."

We get posters here all the time with floor heat systems that don't work, have never worked, and could never work. These systems need to be designed, the biggest mistake you can make is to assume they'll "just work."

Before you lay a single foot of tubing you need to know the heating load of every room. You also need to know what behavior you want out of the floor, and what your control strategy is going to be. You need to know how much flow is required to meet that strategy. And the reason you need to figure out all of those things before you lay tubing is that the layout of the tubing is going to depend on the design, there's no layout that "just works."

Let me give an example of behavior choice. Let's say you live in Boston, where the average January/February temperature is 29F, the 99% design temperature is 13F and the mean annual minimum temperature is -6F.

Do you want a heated floor that is the sole source of heat for the room? If that's the case, it has to meet the heating load when it's -6F out. Let's say you run a surface temperature at 85F to meet that load. On an average day, when it's only 29F out, the heating load is going to be 41/76= 54% of that, so the floor only has to be 78F. Which is nice but doesn't give the toasty toes feeling. In fact, it's not really noticeable.

Let's say instead what you want is toasty toes all winter. In that case you want to run the floor at 85F on an average day. But you can't run much hotter than that, you'll need some sort of supplemental heat on the coldest days.

What are you doing for cooling? Ventilation? Those should all be integrated in the design.

0 -

Hi @hot_rod —

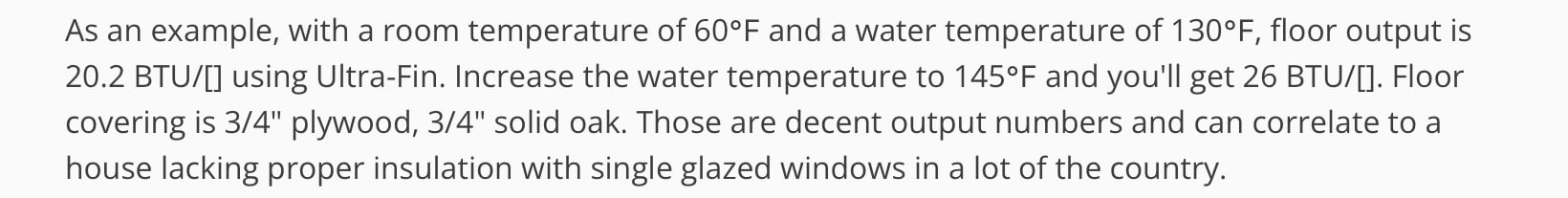

But if this is a new construction home, wouldn't it be better to put the pex in the subfloor rather than "staple-up" from below? Something like Uponor Quik Trak or similar?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I took the poster for his word (yet) that he would be doing a load and design calc, since he has had past experience.

I personally suggest 82° as the average floor temperature for a comfortable residential floor, ASHRAE 6.5 suggests staying below 80°. So base floor output on that 80- 82° number, and obviously that is a design day condition. If the boiler operates on ODR as it should floor temperatures will be constantly modulating.

While 78 may not provide the warm toe feeling it is still much better than a 68 or 70° ambient room temperature floor, especially with concrete floors.

Yes, floor coverings matter, both for the panel heat output and also for the comfort factor. 78° concrete vs 78° carpet or wood as an example.

If you want to look bigger picture then IAQ and MRT come into the formula.

Air movement, air replacement, air filtration, humidity control, odor control, cooling, addressing solar and internal gains, it is a longer story than just ambient air temperature. If you want it to be :)

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

ASHRAE 6.5 suggests staying below 80°

Do they give their reason for this? I'm certainly running a lot more than 80° on my floor…I mean…my house didn't have air conditioning for decades with summers reaching 90-100°F and the floor didn't fail.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I believe Robert Bean headed that TC 6.5 committee for years. I think the numbers may have been based on European studies. That info use to be at Healthyheating website, but it is down for a overhaul currently.

You will find a wide variety of opinions on acceptable floor surface average temperature, take your pick.

You can purchase the 6.5 at ASHRAE's site, I believe it is free if you are a member?

Certainly floors exposed to solar gain go much higher than 80- 82°, but not 24/7 like a heated floor might.

But that is different from heading design best practices.

Flooring manufacturers are another source of acceptable operating temperatures.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

It's not about protecting the flooring material. A floor that is hot becomes uncomfortable to stand on for long. There's even some research that suggests it can injure your feet.

It depends on the use of the space. I'd go warmer in a bathroom than say a kitchen, where you might be standing for a long time while cooking.

1 -

The first thing I think is what kind of floor covering do you want as @hot_rod mentioned. Most staple up is going to be in 16" o/c bays, which is going to be 2 loops and it's going to be serpentine. The advantage of Warmboard and like products is that you can put the hottest heat energy at the exterior walls and the cooler return water toward the interior of the building.

3/8" Pex type A is easier to work with than 1/2" Pex type A. Be aware that the heat energy delivered into the building is dependent upon flow and SWT and the temperature differential of the unheated environment.

3/8" Pex has a greater pressure drop (resistance to flow) than 1/2" Pex. I like to keep the insulation (fibre glass) two inches below the subfloor, especially when there is one loop per bay. I like heating the whole bay and that air space allows that. Two loops per bay with transfer plates, it isn't that necessary, and the insulation can be press against the subfloor.

Keep the length of Pex in a circuit under the recommended length for the size of Pex you are going to use as too long a length and you run out of heat energy before you return to the boiler. Consider Delta T, especially if the boiler isn't a Mod-Con.

0 -

You are right about the expense of aluminum plates. Most of my new construction jobs only get plates in the high demand areas like a Master Bath or sunroom. I run a design temp of 135-160 depending on house. The majority of rooms do NOT need plates. Folks say, " you need plates to operate at a lower temperature". Yes, thats why I plate a room or two to bring that outlier room down to the design temp of the rest of the house that has staple up.

A typical new house you will NOT recoup the cost of plates, like for ages, just because you can drop the water temp 20*. Put plates everywhere, then you will need something beyond plates in the cold room, if there is one. I have done many whole house radiant systems, from 5000+ sqft down to small houses and it is only a rare situation that needs supplemental beyond the floor heat.

0 -

My experience with transfer plates is to push the insulation right up against the plate, fill the joist bay with as much R-value as you can. There is no value to a reflective film or even an air space.

In some applications spray foam goes against the plates.

.35 gpm in a 250' loop of 3/8" pex is just over 5' head, reasonable. In a small home with multiple zoned rooms your loops may work out to 200', or less in bathrooms for example.

Even if you do not plan on numerous zones, doing a room by room tube layout gives you options down the road, should floor coverings change or you choose to zone bedrooms at different temperatures.

Pictures and documentation are nice to leave on site for future reference.

Drone shots are nice for slab on grade jobs. This is my shop with 6" OC 1/2" loops.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@hot_rod said, "Pictures and documentation are nice to leave on site for future reference." Yes! I can't tell you how many times I've been on a job and the documentation disappeared in to the Twilight Zone. When I was young and dumb, I didn't think it was that important. Thank goodness we get wiser as we get older thru experience, I suspect. Now I leave the tube layout drawings and other documentation that can be 1/2" thick. I'm tired of using an IR camera tracing these tubes. But, alas, even today finding documentation at a job is comparable as coming across a sighting of Bigfoot.

Who knows, I maybe the next guy that comes back to that job and my memory ain't so good.

0 -

I saw a post on IG where a guy walked through a large commercial job talking into his phone and taking pics and some AI based program put it into a glossy manual with pics, text, and chapters. a manual that was spot on built in just a few minutes!!

So both a paper copy and electronic version.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Using 3/8" is great for flexibility and ease of installation. Downside is that you have more loops, a larger manifold, more tails.

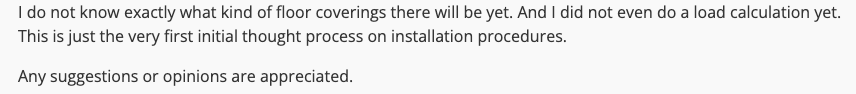

I used to use plates and then switched to Ultra-fin. You only need one run per bay instead of two (so, less tubing and labor) and water temperatures can exceed 120℉ if need be; something you can't do with plates under oak hardwood.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab1 -

It does seem to be about the flooring material and resident comfort also. But the material is definitely mentioned.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Alan, I understand the theory, but real world results are what counts. There is such a thing as back loss. Yes, hot air rises, but heat energy travels in a straight line to what ever is coldest. I want to see performance data and comparisons to other heat transfer plates. That is, efficiency and unit cost, not installation costs which, of course, are important.

2 -

Conduction vs convection heat transfer. Tube to plate is conduction transfer. Attaching the aluminum tightly to the floor is another conduction transfer.

Compare bare tube performance to UF performance, the UF drives more convection currents.

There is a place for both methods, conduction probably trumps convection for transferring energy from tube to floor.

Put your hands near a warm coffee cup.

Now wrap them tightly to the same warm cup

Results?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Yeah, this looks like it would be handy for renovation or retrofit situations where you don't want to tear up the existing floor or re-route the mechanicals below. Or if the subfloor is full of nails poking out. I also like that you can run it with 180F water and 3/4" pex so it's basically a drop-in replacement for baseboard radiators. It's convenient that it only takes a single run of pex per bay for when the bays are crowded, like under a bathroom.

But what gives me pause is the complete lack of any engineering data on the website. And I get why, they don't know what your floor is made of or how tight the subfloor is. But it would be good to have some idea of the behavior beyond plug it in and see if it works.

I note that they recommend 50% coverage with the plates, ie one 10" plate for every 20" of pex. It seems the way to tune output would be to use fewer or more plates as needed. But that would mean removing the insulation below, so it's not a quick job.

0 -

@hot_rod Here's something to think about. You can't have conduction without mass. Also, you can't have convection without mass. Air is mass. 14 pounds per sq inch at sea level. You can't measure heat energy because you can't measure energy, only the effect of energy on mass. My thought is that mass is constructed of atoms and atoms act like a battery. When energy (radiation) fuses into an atom, it moves electrons into a higher orbital state and when the energy moves out of an atom the electrons move back to a stable environmental orbital state. Why do we use Ex tanks on our heating sys? Is it because the boiler miraculously creates more water molecules or is it because the boiler puts heat energy into the water molecule causing it to get larger? I mean there is a volume increase.

Convection is really conduction. Tube to plate is conduction, Plate to air is conduction, and air to subfloor is conduction. Mass to mass is conduction.

Ultra Fin has louvers which help to move air and the plate is suspended not tight against the subfloor which helps air circulation. But, as I stated, it's really conduction not convection. My question is it the most efficient method of conduction? My thought is that the greatest mass to mass provides the greatest transfer of heat energy.

Ultra Fin

0 -

@HomerJSmith With either plates or fins, manufacturers' guidelines, installation methods and engineering have to be trusted and followed.

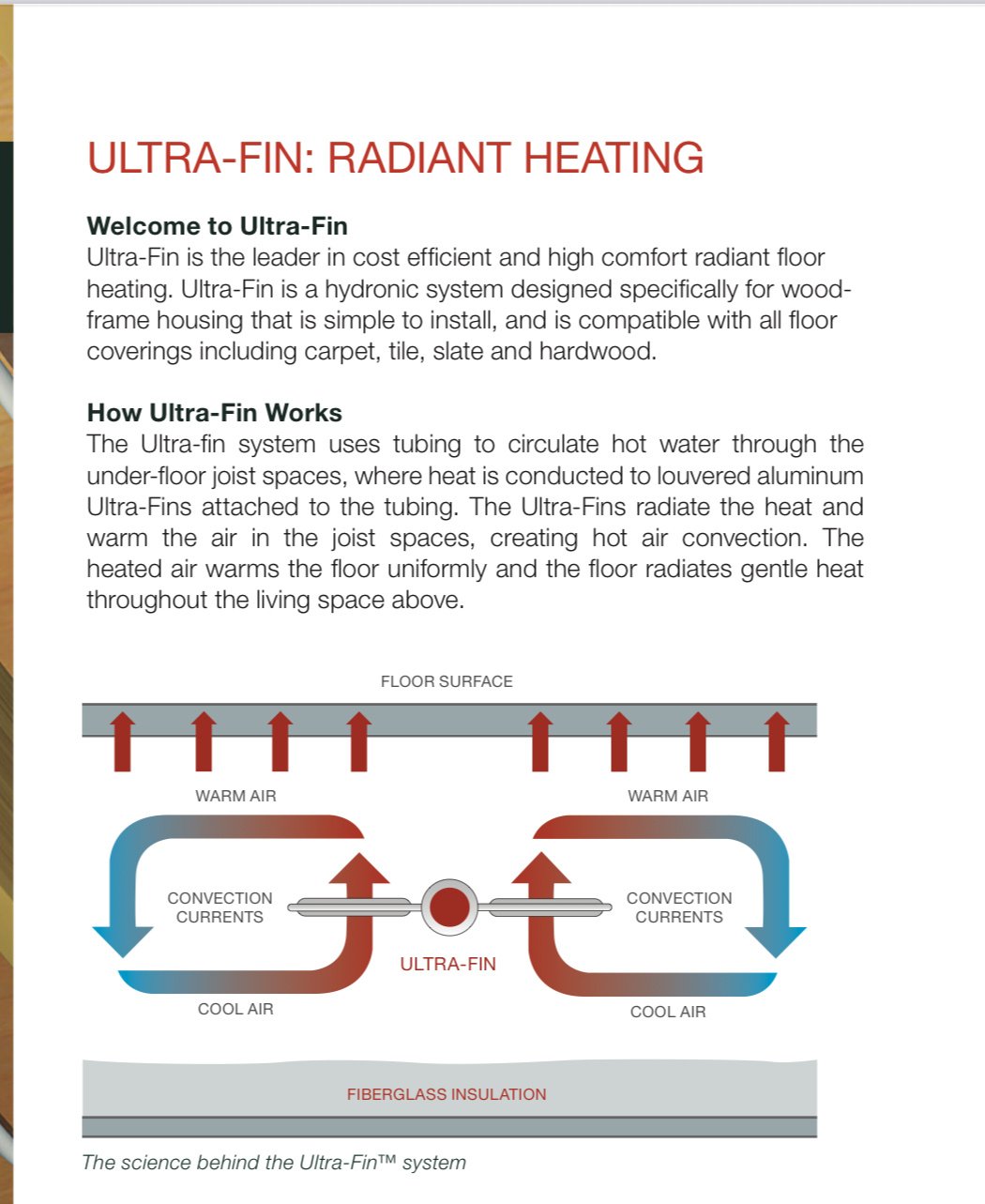

As an example, with a room temperature of 60℉ and a water temperature of 130℉, floor output is 20.2 BTU/[] using Ultra-Fin. Increase the water temperature to 145℉ and you'll get 26 BTU/[]. Floor covering is 3/4" plywood, 3/4" solid oak. Those are decent output numbers and can correlate to a house lacking proper insulation with single glazed windows in a lot of the country.

If the house exceeds these numbers, you have to use a different product or supplemental heat.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab1 -

Alan, I'll think about it. Ultra Fin's air conduction is the reason that I don't put insulation tight against staple up. I leave about 1 1/2" to 2" of air space, spreading as much heat energy over the joist bay. I want to eliminate as much as possible banding. Ultra Fin , I think, does just that. It give a more even floor temperature.

0 -

A sanity check:

A heated floor heats the air in the room through a combination of conduction, convection and radiation. Since all three are driven by temperature difference the exact combination isn't important, we just accept the rule of thumb that it's 2 BTU/hr per square foot per degree of difference between the air and the floor.

If you have heated air below a floor, you're going to get the same mechanism, in reverse. So it's fair to assume that you get the same 2 BTU/hr/SF/F from heated air. The heat flowing through an assembly has to be equal for all components, so if the room is at 70F and you want the top of the floor at 82F, you need the air below the floor to be the same 12F above the surface of the underside of the floor.

If you say the floor plus subfloor is 1.5" thick and wood with an R-value of R1 per inch, there's R1.5 between the two sides of the floor. With the top of the floor at 82F and the air at 70F, to get 24 BTU/hr/sf through the floor at R1.5, the two sides have to be 36F apart. If the top is at 82F, the underside has to be at 118F.

If the joists are 16" apart, 9" of length in a joist bay is one square foot. You'd have 9" of PEX in that square foot, and with 50% coverage, you'd have 4.5" of plate in that square foot. That 4.5" plate has to produce the same 24 BTU/hr, which works out to 64 BTU/hr per linear foot of plate.

So as a sanity check, two things have to be true:

- The plate on PEX has to be capable of heating a sealed, insulated area in a joist bay to 118F using 180F water.

- The plate on PEX has to be capable of producing 64 BTU/hr per linear foot into air that is 118F using 180F water.

Neither of those things on their face appear to be unreasonable.

Note that this assumes there is no air leakage through the floor into the room. If there were, the heat transfer would be greater and the underfloor temperature could be lower. But the 64 BTU/hr per linear foot to get 24 BTU/hr per square foot into the room doesn't change.

0 -

@HomerJSmith, said,"I mean there is a volume increase." in heated boiler water. If I take a glass of water and weigh it and put it in a radar range and heat it for 2 minutes and weigh it again does that glass of water weigh more. hmmm. If it weighs the same, it proves that energy is not mass which has weight.

0 -

this is how UF explains the heat transfer mechanism of their product. Air being an insulator doesn’t transfer as well as conduction. Hold the pan of water 2” above the cook top, time it to boil, then place the pan in the glass cook top as a demo of conduction transfer.

Regardless of how you transfer it is the floor surface, considered the radiant panel that the calculations as based on 2 btu/ sq ft.

The UF will require higher SWT to match the output of the transfer plate.

The UF example using 60 degree ambient 130 SWT is a bit odd. 60 ambient may be a bit low for comfort?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@hot_rod, you proved my point. You said, "Put your hands near a warm coffee cup. Now wrap them tightly to the same warm cup" What is the difference between the two? The second statement feels hotter. Why? The first statement has an air boundary layer that doesn't transfer heat energy very well. Narrow that air boundary and the heat energy transfers better and the cup feels warmer.

All the math that Alan and DCContrarian alluded to , I have no qualms with. The thing that they left out is time. I am sure that the heat energy will equalizing between the different spaces. But, how long or is that even important? Efficiency always has a time component. That's one of the things that I wanted to look at when I said efficiency between transfer plates.

We have a motto in Judo, "Maximum efficiency, minimum effort".

Great discussion.

0 -

my thought is wrapping your hand tightly you have no air boundary layer, that is the definition of conduction, direct contact between the plate and subfloor, your hand and the cup.

I have a IR pic of what it looks like when you pull heat transfer plates away from the subfloor, I’ll find it tomorrow.

The UF example Allan added

the comparison demo I would like to see is supply the Thermofin aluminum transfer plates with 145f, what is the btu output.? Actually similar example is in Modern Hydronics as a radiant wall example

If the 145 SWT to the transfer plate resulted in a floor temperature of 120F

120-60=60 60 x 2 (btu/ sq ft in a floor model) you get 120 btu/ sq ft.

that clearly shows the power of conduction heat transfer.

Obviously 120 degree floor would not be reasonable, the example is to make a comparison, with the same SWT, same flow, same room ambient transfer plates vs UF

My recollection is UF was designed to enhance the bare Pex suspended (dangled tube) method that tended to under perform.

It was also marketed as a simple way to add some radiant to a fin tube job without needing to establish a lower SWT.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Geez,, lot of information here. LOL. And I didn't mean to start any arguments.

I simply wanted to know what is the preferred plates to use, and whether or not 3/8" tubing could be acceptable,, considering cost factors and ease of installation thru the joist bays…

And yes, I will be doing a load calc of my own. And I've always used Rehau brand tubing and manifolds in the past. And I will even be consulting with Rehau directly to do a design/layout.

Again, I was just thinking about the plates as a cost factor and ease of installation… because the customer is just starting to plan out budgeting.

Also, let me clarify my "new construction" comment…

This will be a brand new home, but this is gonna be a modular "pre-fab" home where the flooring is already complete. The home is built in a factory or something and gets delivered to the site in two sections (halves) and then put together on-site. So all of the flooring is already pre-installed. Therefore, this is why it would be a "staple up" option from underneath.

0 -

"As an example, with a room temperature of 60℉ and a water temperature of 130℉, floor output is 20.2 BTU/[] using Ultra-Fin. Increase the water temperature to 145℉ and you'll get 26 BTU/[]. Floor covering is 3/4" plywood, 3/4" solid oak."

So let's plug those numbers into the model I proposed. 20.2 BTU/hr/sf means the floor surface is at 70.1F. Assuming the floor is R1.5, that means the underside is 30.3F warmer, or 100.4F. The air below the floor is the same 10.1F warmer, so the air is 110.5F, which seems reasonable for 130F water.

At 26 BTU/hr/sf the floor surface needs to be 73F, the underside is 39F warmer or 112F, the air below is 13F warmer or 125F, which again seems reasonable for 145F water.

I don't know if it's coincidence, but in both examples the air in the joist bay below is 20F below the water temperature.

So let's say that holds true for 170F water. And let's look at a 70F room temperature, I don't know why they would bother with 60F. What I get is air below is at 150F, underside at 134F, floor surface at 86F, heat flow of 32 BTU/hr/sf. That's about as hot as you're going to want to run the floor anyway.

The key to all of this is that the joist bay has to be well sealed and insulated. If not, it's not going to be able to achieve temperature and the whole thing falls apart.

0 -

the earlier uponor design manuals had output charts for the joist bay or suspended tube method. I don’t see them in the current edition? At least in the online version I found.

But they do seem to indicate joists bay method is more for floor warming than radiant heating type loads

Plateless in Radiantville july 2022 PM magazine and a later article article Shakeout Time suggests 15 btu/ ft for bare tube staple up. There is some conduction in those rubber and pex tube staple up. I would think tube suspended below, joist bay heating, output would be lower?

UF may boost that a bit by encouraging more convection currents

Limitations may be how warm the plywood or OSB can handle, 140f sticks in my mind.

Uf in Allans climate may be a good fit, mid 20 and higher BTU loads, maybe not. Uponor seems to have changed position on the realistic outputs?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I think you are on the right page. 3/8 or 1/2 is more a personal choice, Ford or Chevy. You are taking the right steps, asking good questions.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

"This installation is also used for floor conditioning, the warming of floors without providing heat into the space."

I think we can all agree how ridiculous that statement is.

0 -

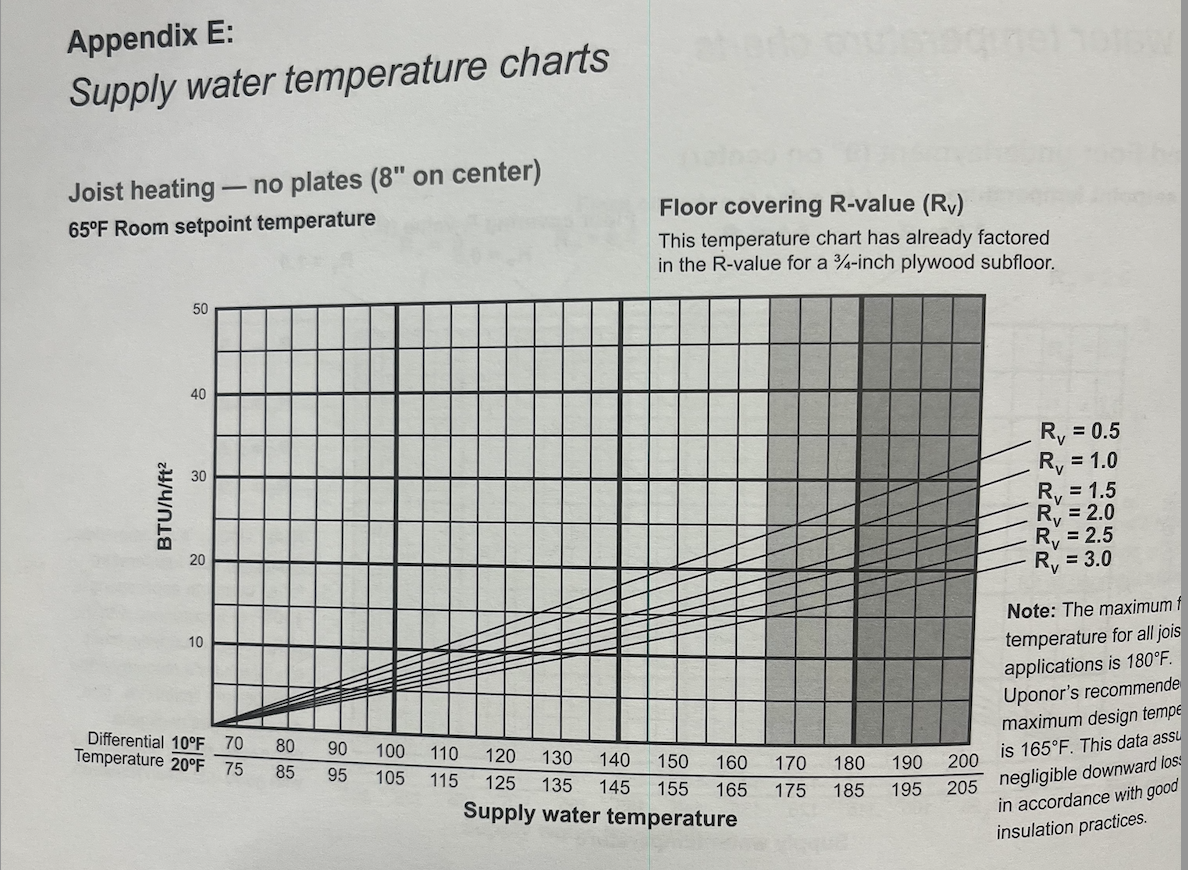

Here is the Uponor output chart from the current 8 th addition. With 145° SWT outputs are below 20 btu/ sq. ft.

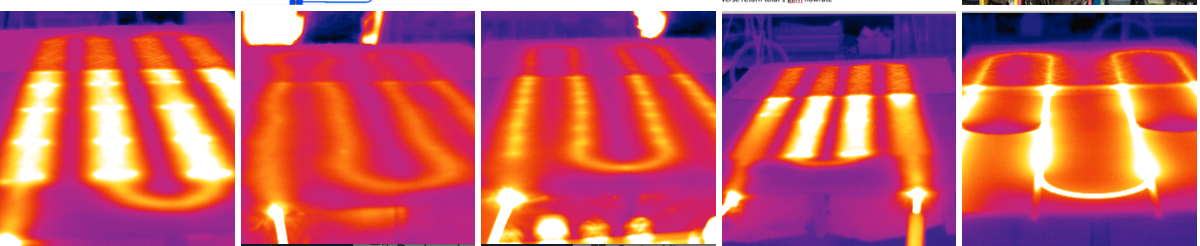

So IR testing I did at my shop at bottom, for more of a visual look at radiant floor mtube installation method.

So Uponors numbers, Siggys FEA, Dales FEA, testing at KSU by Dr. Kirby Chapman all seem to line up with regards to realistic outputs

My opinion,

Mid 20's btu/ for residential radiant, staying below 82° surface in 70° ambient

High 20's if you drop ambient to 68 or lower.

30 btu/ft for shops with 65 or so ambient.

I feel these numbers keep you from getting calls like "my radiant heat system is not keeping up" Those were common back in the 1990 radiant renaissance days. A fix was not always so easy other than cranking SWT and causing uncomfortably hot floor surfaces.

Installers throwing in rubber or pex with in those low budget dangled pex jobs, created a lot of bad press for radiant floor heating.

From left

Thermofin transfer plates with copper tube,

Suspended tube (joist bay Uponor method)

Direct staple up, bare tube

Thermofin with 1/2" pex

Warmboard

In pic 3 notice where I pulled the pex out of the Thermofin to connect to the manifold, lowering the conduction transfer from tube to Thermofin

The Warmboard #4 shows a similar effect where I routered across the aluminum layer mid panel stopping the conduction across the aluminum.

The back 1/2 of these examples has a piece of berber carpet, no pad below.

The key may be the average temperature across the panel also. Warmboard even at 12" OC spreads the temperature well.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Hey guys! New here and just figured I would say Hi. My recent remodel turned into a radiant floor rabbit hole as well, glad i'm not the only one. All DIY versions but I've got a few different styles running since it was an existing remodel so it would be neat to do the thermal imaging like above. If anyone wants details, specs or pics I can share.

0 -

What stands out in these IR pics is not the entire 4X8= 32 square feet of the panel is the same temperature.

So assume the yellow in these pics is 82°. A % of the panel is below that. Maybe assume the magenta color is 70°. So if you calculated the average surface temperature the entire panel output would be below hte math showing 32 sq ft at 82°.

Lets assume 50% of the left panel has a surface temperature of 82°, 50% at 70°. The average being 76°.

76-70= 6 X 2 = 12 btu/ sq ft output

looking at the suspended tube 2nd pic, first off none of the panel is at 82, with it receiving the same SWT, then the % at the orange color call it 78° is a much smaller number.

Hard to argue against the conduction power of the aluminum plates. And if efficiency is a gola the SWT difference to get both producing the same output starts to hurt. Probably taking suspended tube out of boiler condensing temperatures.

I feel that is where some of the underperforming systems fall down. As well as rooms with furnishings that block the radiation (line of site) output.

Back in the radiant heydays the number of under radiated jobs was becoming a big issue. In some cases I feel the manufacturers were too optimistic with their output charts.

The quick often unsuccessful fix was to keep cranking the supply temperature. This in turn added to the oxygen infusion and corroded many systems to death within a few years.

I think heatmeister out in Colorado has been wrestling with sludged rubber tube systems his entire career.

This tube did not come from the manufacturer looking like this. You are looking at your expansion tank, pump volutes, steel pipe and fittings in a reduced form :(

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

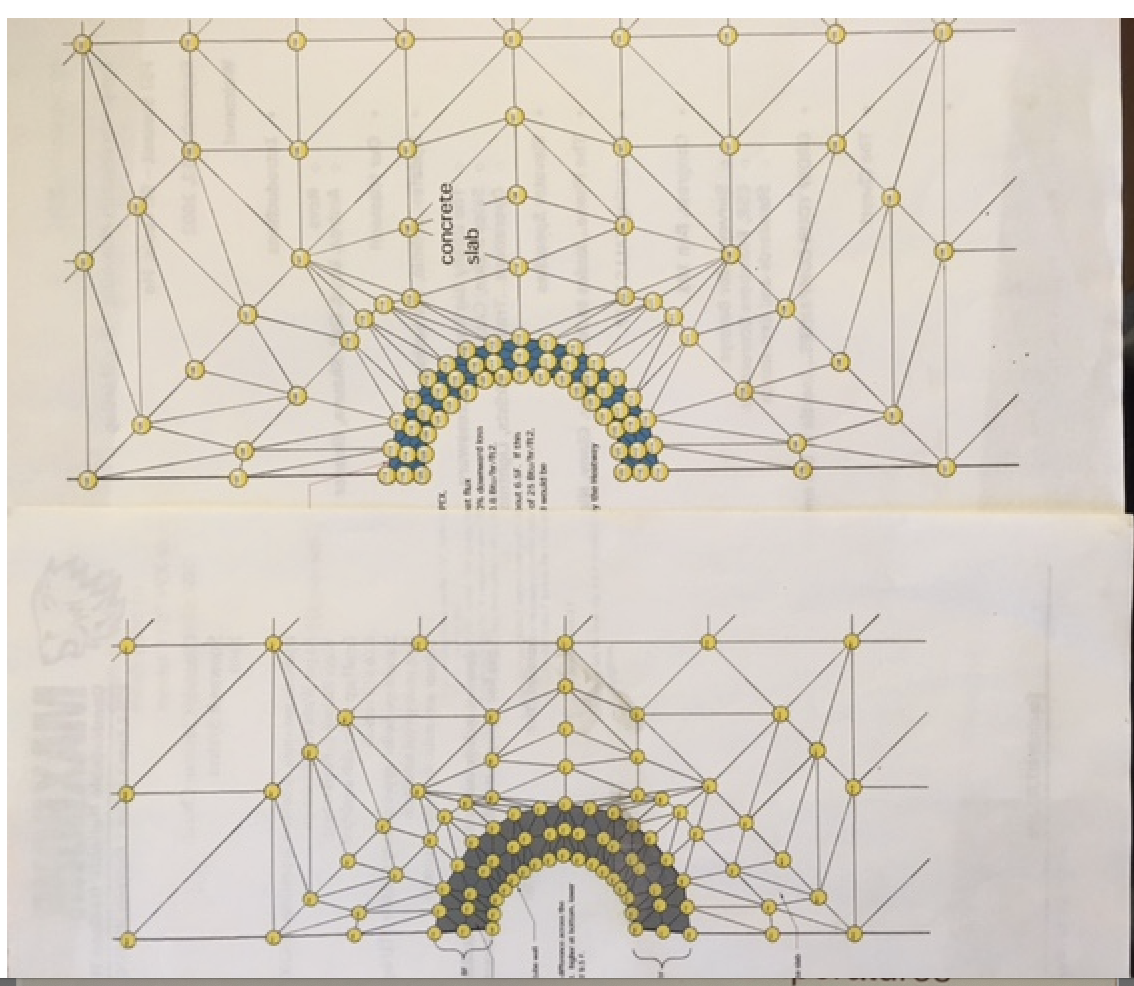

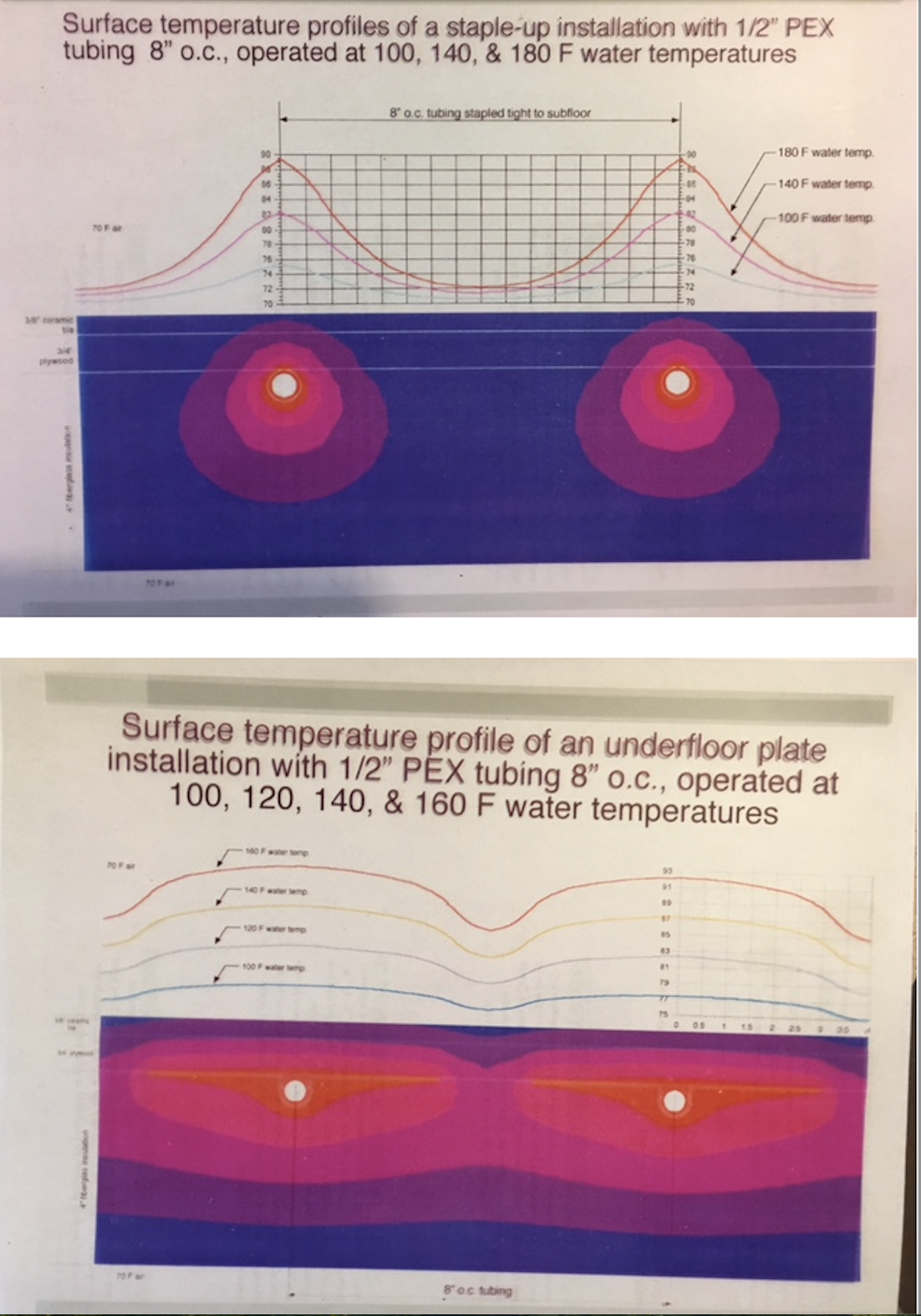

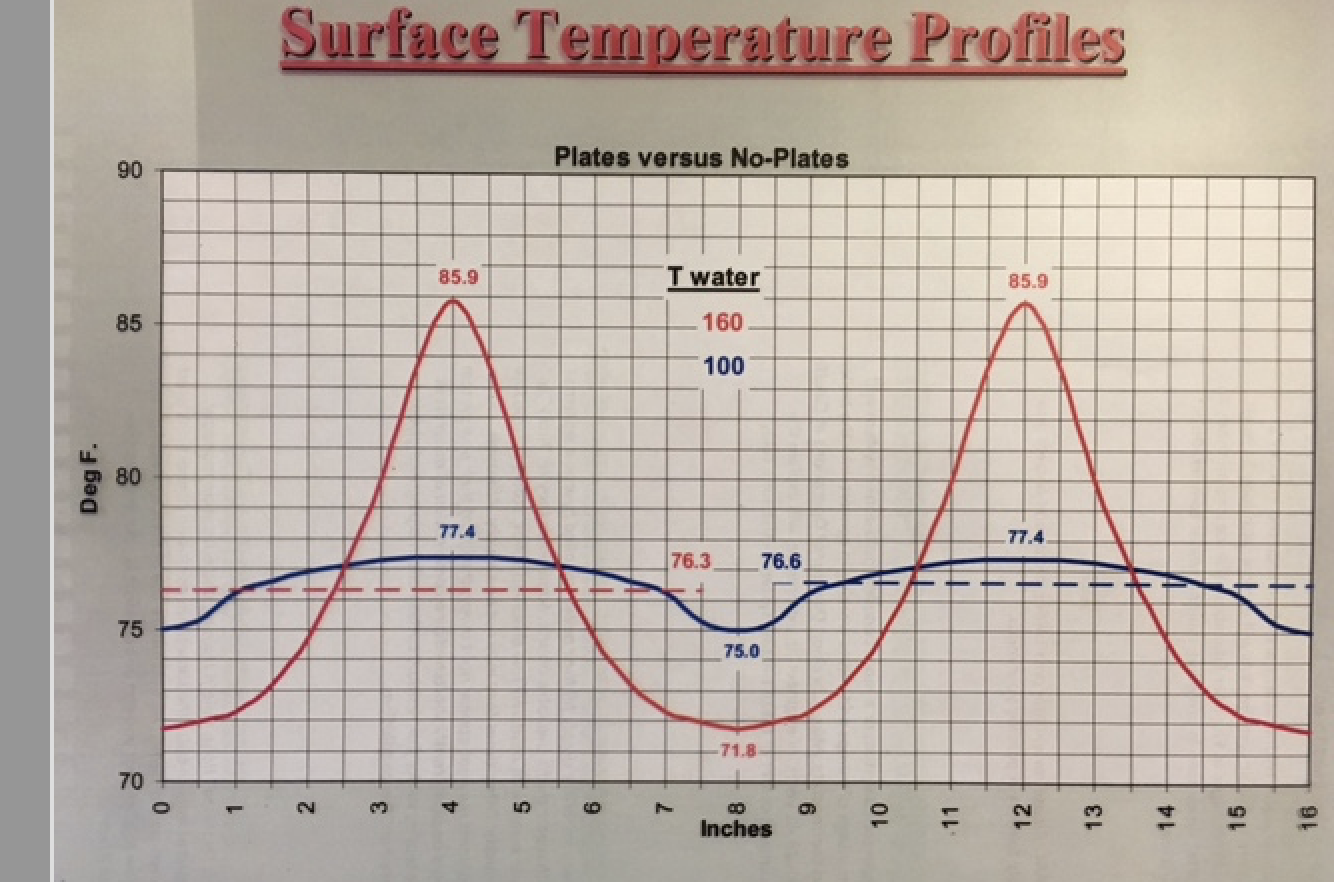

Here is how a FEA finite element analysis turns temperature nodes into graphs which used as the basis for my IR panel testing.

The first pic was modeling pex in slab vs much thicker walled rubber in slab. The rubber being an insulator and much thicker than the SDR 9 pex tube limits the outward temperature profile.

But if the rubber ends up in the condition of the post above it really doesn't matter much, does it?

The lower slide shows not only the better temperature spread of plates vs bare tube, the inches noted on the bottom axis, but also the wide SWT temperature difference required to get the 85.9° floor temperature.

Plates with 100° swt vs bare tube at 160° swt.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@gpjazz, it isn't an argument. It's a discussion, a learning event. I can see that your aware that there is a lot that goes into under floor and hydronics in general. We plan based upon the knowledge that we have, but, there are times that that planning goes awry. I forgot who said it. "It's not what we know that gets us into trouble, but what we think we know that just ain't so." Reality based knowledge is what counts.

A decision on tube size, tube quality, and performance is a personal choice. However, everything has advantages and disadvantages. 3/8" tubing is fine, just stay within the limitations. Remember, reaching set point under all environmental conditions is the goal.

Personally, my choice, considering your query, is heat transfer plates tightly stapled to the subfloor with insulation to prevent back loss. Whether you put an air space between the top of the insulation and the subfloor is your choice. There was some discussion about whether that provides an advantage. It's certainly not a detriment. Which transfer plate to use? Manufacturers give performance data for their products and that is helpful.

Things to consider in your choice. Cost, ease of installation, and performance. @hot_rod's thermographs gives you some idea of the performance characteristics of different under floor applications.

Fixing an under floor installation that's under performing is a big deal. Not as bad as pex cast in gyp-crete.

The tubing layout is going to be determined in the planning stage. I wouldn't worry too much about the heat transfer plates. They're probably going to be what your wholesaler is selling.

I use a heat gun to warm the pex when I make a 180 deg change in a joist bay.

Good luck.

1 -

@hot_rod Entran a Goodyear product had a law suit over their product. These rubber products were permeable to O2 ingression which did a nasty job to iron components is the sys.

There has been a number of product in the plumbing and heating industry that's touted as the "best thing that's come down the Pike" only to be unmitigated disasters. Forgive me for being leery about the next best thing. I'm thinking Pro Press fittings (installation cost savings) and plastic fittings for pex. I guess we will see in 20 years.

0 -

"I feel these numbers keep you from getting calls like 'my radiant heat system is not keeping up' Those were common back in the 1990 radiant renaissance days. A fix was not always so easy other than cranking SWT and causing uncomfortably hot floor surfaces."

This is exactly what I was referring to earlier about "floor heat systems that don't work, have never worked, and could never work."

0 -

I wonder if all that aluminum screws with the wireless.

0 -

"I simply wanted to know what is the preferred plates to use, and whether or not 3/8" tubing could be acceptable,, considering cost factors and ease of installation thru the joist bays…"

I'm a DIYer (full disclosure) that designed and installed my own radiant heating system. It works great - just as planned.

3/8" vs. 1/2" - 3/8" is easier to make smaller radius turns (so easier to install), but has less volume so flow rates have to be higher for the same heat conduction, especially if water temperatures are low. This might require a bigger pump or more electricity. I chose to use 1/2" to keep pump size and pump electric usage down, plus so I could get more flow rate if I needed it.

Plate vs. Plate or Plate vs. No Plate - The most important thing is to insulate well underneath your pipes. If you are running low-temperature radiant (e.g., geothermal heat pump supply) then better (thicker) aluminum plates will perform better than thinner plates (better contact with tube for better heat transfer, and a little more mass to even out the heat in the floor better). If you are running high water temps (140 degrees F or more?) and your building heat loss is low then maybe you can get away without plates - I'll leave that to the professionals.

I have a geothermal heat pump supplied system with thick aluminum plates and 1/2" tube with a Grundfos Alpha pump.

1 -

We did two retrofit jobs; one with @Dale Pickard's Thinfin and the other with Ultra-Fin. The two houses had very close heatloss profiles (moderate insulation, single-glazed windows, 100 year old construction). The Thinfin job (my house) struggles when it gets cold and I caused the hardwood floors to react when I exceeded 120F water temperature. I've had no problems with the Ultra-Fin job even though it's in a 5 degree colder climate. The Thinfin house has a heating curve of 1.4 and I can't go any higher because of the floors. The Ultra-Fin house is at 1.5 and I could go as high as 2.0.

Something tells me that heat transfer is only half the story.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements