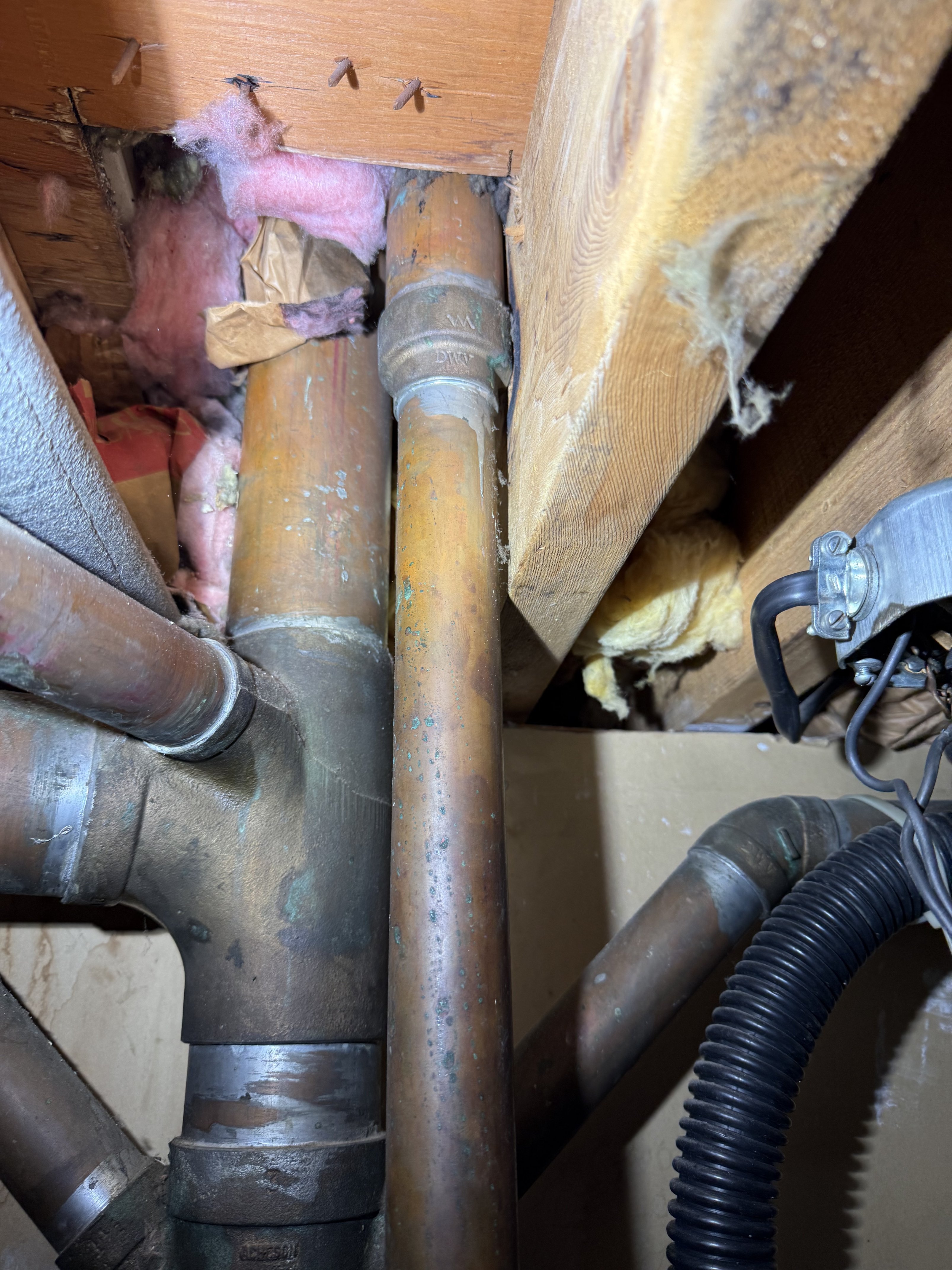

Cut in a copper dwv fitting with little room

happy new year plumber people

my daughters house- I want to do a bathroom in the basement

yes the second hose is from a butchered basement sink- gotta go

The bird brain 70s plumber stubbed the 2” future vent a few inches below the deck, butted against the joist- joy. 2 x 1 1/2 coupling is just out of sight. I’ll have to skim the joist to get a mission clamp on it and drop it down to vent the ejector and new bathroom

what do you think- cut out the wye for the laundry and put in a 4x2 double? I hate couplings (I make things look original whenever possible), but in this case there’s no choice. I’ll probably need two slips on this one or I have to cheat the buggers out of one slip

Comments

-

Gotta love it. At least he kept the pipe tight against the wall…

I've never minded using slip couplers — Ferncos — on adding to things. Yes, it looks a little odd, but… it works. But then most of my playing is on stuff over a hundred years old!

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Also the washer should go into the drain with an air gap. Taped like that sewage could back to the washer! Stand pipe should be 18-30" tall

Is the black hose a sump pump?

What about dumping the washer and other drain into the ejector tank and use the W that is for the washer for the ejector pump? Is it 2"?

The washer drain would help keep the ejector tank clean and odor free :)

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Hot Rod it's 1 1/2,and goes to 2" just out of sight as it enters the main level of the home. Gonna be fun to get the 2" below the joists.

I suppose the normal fly by nigher would pump the ejector into that 1 1/2.

Yes, 18 to 30, I see that rule broken in 1/2 the homes I am in. I can fiddle in a taller standpipe.

The black hose is coming from a cobbed - pumped sink with an open 'tank' under it. That will go when the real plumbing goes in.

0 -

Jamie yes I just have an issue with couplings, but I still use them when i have to!

0 -

-

my son in law is a licensed electrician, he's re-wiring the whole home. It's the shoe makers kid syndrome I guess.

Not sure if J box has been meddled with or if that's the way he found it.

0 -

thanks 1970 Plumber dude, you’re a peach😀

0 -

I'd unscrew the cleanout, replace it with a PVC fitting and run PVC to the ejector pump. I'd use a PVC coupling so that you can take it apart if you need to use the cleanout as a cleanout.

For the vent I'd cut into the 1-1/2" copper above the tee for the washing machine. I'd put in a copper tee with a threaded female leg and thread a PVC adapter into it and go PVC from there.

The original sin here was having the sewer pipe exit the house through the wall instead of the floor.

0 -

Good comments, I want to put the Ejector can in the same (roughly) 36 x 36" closet, so putting another wye into the CI Wye would push everything out. Still a fine idea.

Technically, the ejector and the new bathroom would need to tie into 2". Not a huge deal for me to shave into the joist a smidge to wiggle on a mission coupling. probably dog leg my way out of there with a couple 2" St 45's or just go straight (out of the joists) down if the shaving is minimal.

I get it, a smidge of 1 1'2 would stop the earth from spinning. If my daughter ever sells the house, that person sure enough will have a relative or a friend that's a plumber—-I don't want a check mark for "illegal" plumbing.

Out the wall, not sure why, it was one of two reasons I suspect: One- it was a septic and then got re-routed to the street (a 180 once it routes around the back of the house). Two- the street main is not that deep. It's most likely the septic tank reason.

0 -

I would check that the ejector you're using requires a 2" vent, some use a 1-1/2".

If you have to go to 2" for the vent, a 2" coupling is going to be thinner than the cast brass reducer that's there now. I think you can go straight down without too much trouble. Cut about an inch out of the 1-1/2" pipe about a foot below the joist so you have room to wiggle it, and then pull on it with channel-locks while you heat the reducer, it should come right off. The stub of pipe will have solder all over it so it should be not too hard to get a good joint. Prepare about an 8" piece of 2" copper with a stopped coupling, heat and push up. Use tinning flux.

0 -

one of those flare tools you hit with a small sledge?

0 -

-

I had a part with 3 1/2 goats to buy this bad Larry

0 -

goats must be worth a lot more than i would have guessed. maybe some drywall and paint would have been more cost effective.

0 -

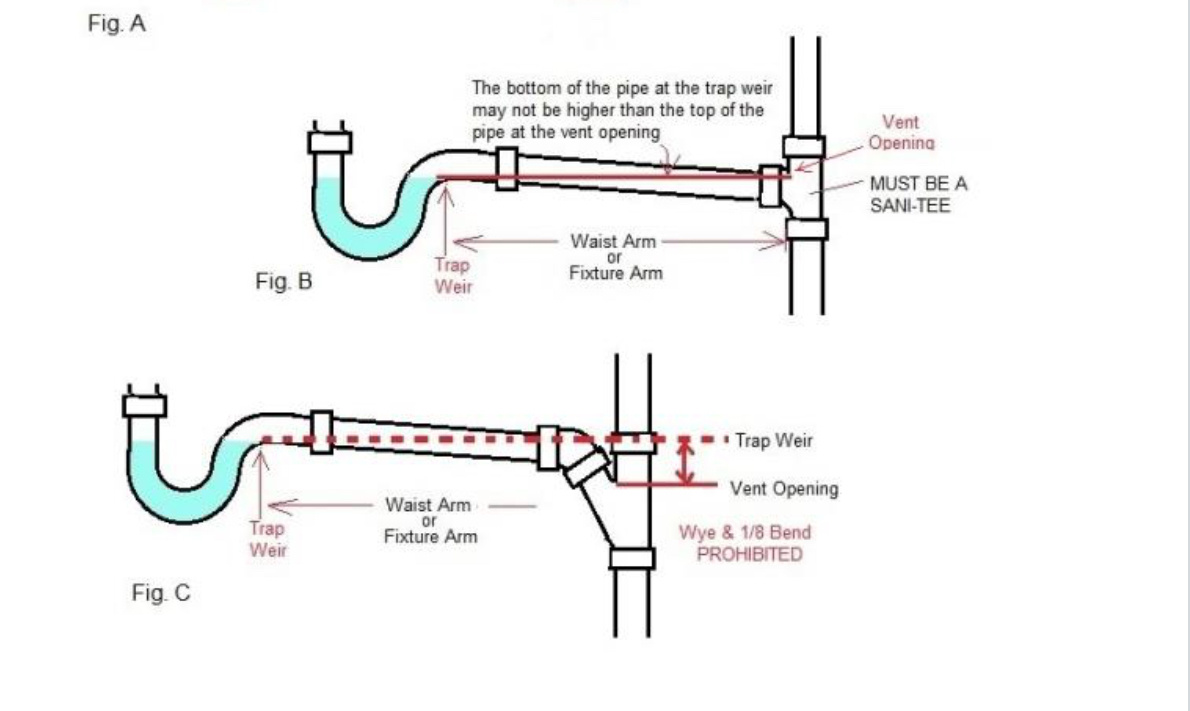

Typically you tie a horizontal drain into a vertical stack with a TY. You see one above that Y and also where the P trap connects to a vertical. A Y (WYE) is required on horizontal to horizontal connections.

But that Y may fit the existing piping best.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

how old was this? were they wiped in to it?

0 -

also, no picture?

0 -

No, it is brass, copper sweat. I could take a picture but for some reason I can't post them here.

0 -

Cutting into that 3" copper would be a bear of a job. You'd have to support all the weight above, and you'd have to cut out a section to get working room, there's not much length there. There's no room to run a pipe cutter. You need a big torch to solder 3" pipe and there's not much room to run it.

If you don't like my idea of going in through the cleanout plug, I'd be looking for an ejector pump that has a 1-1/2" outlet. Then take out the trap that has the two plastic hoses going into it, run the ejector pump into that tee and run the plastic hoses into the ejector pump pit. You'll need another tee above that for the vent for the pit.

0 -

The idea of using the clean out to adapt a drain is fine as long as the piping does not protrude to far into the room.

If you can't use the clean out, there is plenty of room above the cast iron .

Cutting the DWV copper above the cast iron and using mission couplings that will adapt the copper to PVC is a good alternative.

This is an example of a two band 3" PVC to 3" Copper shielded mission coupling. There is also a four band version that I prefer.

0 -

That 4 x 4 x 1½ x 4 offset tee thingy is something else! How would you even call that out???

0 -

It looks like 3" maybe?

So a 3X3X3 X 2" side outlet San tee would be my guess.

Here is an example of what is often called a side outlet ell and a heel outlet ell

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

1 - 3" copper DWV sanitary tee or (TY) with a 2" offset upper inlet.

0 -

And from looking at some of the other posts, from here I'm not so sure that's four inch copper, but that's from where I sit. looks to be 3" reduced in the cast iron with a manoff. Hard to tell.

0 -

that’s a 4” stack. That’s 4” cast iron. No reduction to the copper.

Hot Rod maybe Massachusetts is a little different. In general, Ty’s are used for “trap arms” or if it’s a full size branch (like a 3” TY in the wall heading to a 2nd floor bathroom). But if the branch will be “re vented” then wyes are a little more common.

That laundry drain is a classic example.

My plan is to remove the existing 4x2 and install the new 4x2 Double. One side will keep the laundry set up (I’ll have to reconfigure). The other side will take on the ejector. I’d just assume have the washer not require the ejector set up. If there’s ever an ejector pump problem, the laundry will keep going

I’ll need to cut a 4” pressure coupling in half and make two Slips out of it.

Yes I could probably fit two missions in there but I am a purest of the highest regard: old school or nothing.

I’m not worried about the stack moving on me- it’s not cast iron. It’s anchored in pretty well.

That existing 4” TY with the “heel”- I’ve never seen one. Well it’s like an “Esterbrook” but the “heel” is elevated pretty nicely. About 35 years ago I installed a 4 x 2 PVC Dbl TY Dbl Esterbrook fitting, it was a highlight of that job.

1 -

this is how the eye or combo was explained to me, and it was on the plumbing test, many years ago😏 the vent opening is at or below the weir then it could become fouled, plugged

Maybe if the trap arm is vented on the horizontal before the wye or combo?Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

yes, I agree with that sketch. I think we’re saying the same thing. That’s why I phrased it, “re-– vented”

TYs are mostly used on so-called trap arms, which is what the sketch shows. But of course, they are used all the time on stacks inside of exterior walls, obviously not enough room to put a Wye & eighth inside the wall of a house.

Wye on a stack- the automatic assumption: whatever is dumping into that Y is getting vented independently. The so-called stack vent effect is irrelevant at this moment.

such as the case with that laundry connection in the picture.

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements