Radiant floor heat controls causing oil boiler to short cycle

Hi all, was not sure whether to post here or in the oil burner section, but since the system is solely for radiant floor heat, I figured I'd post here.

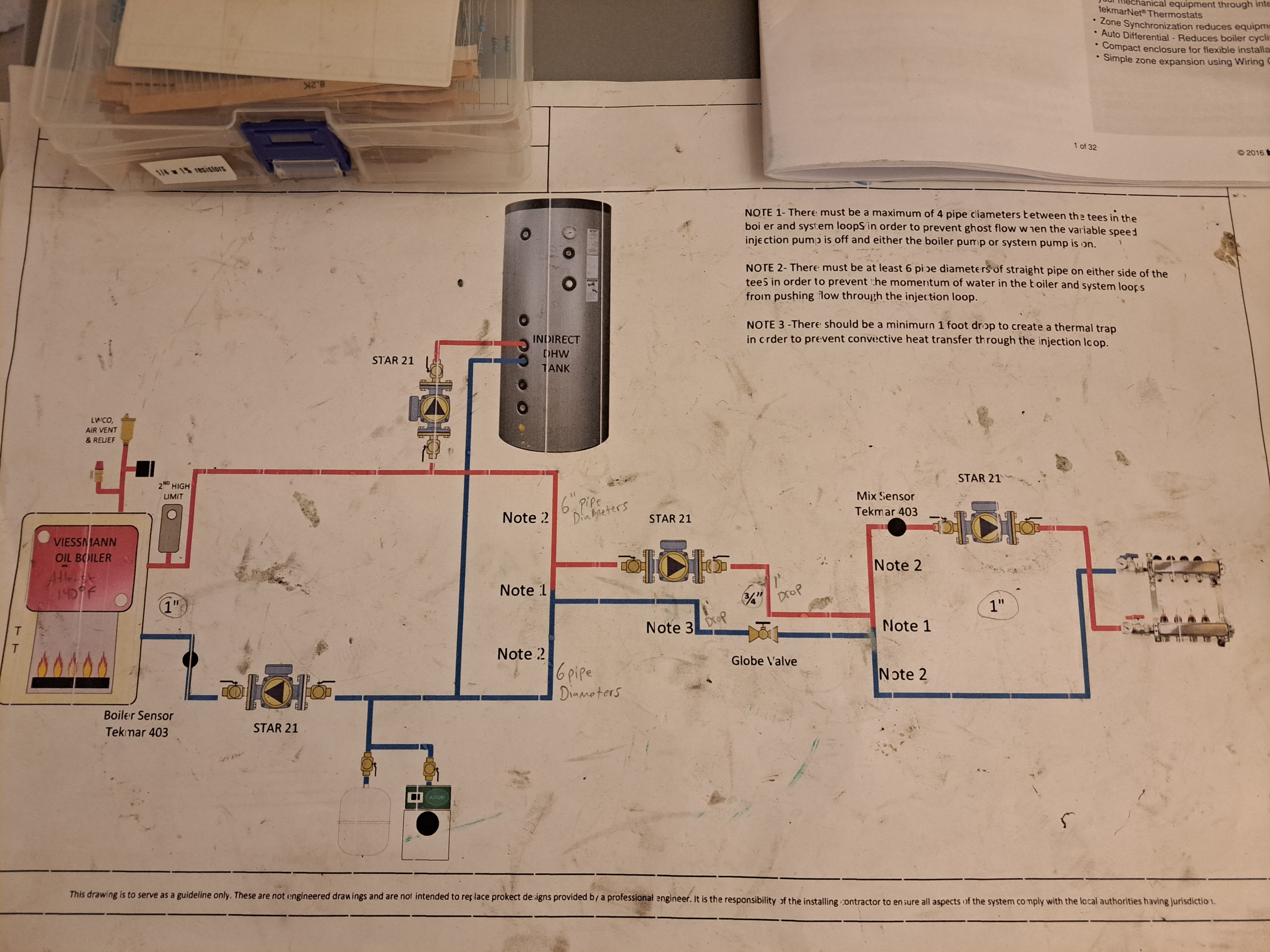

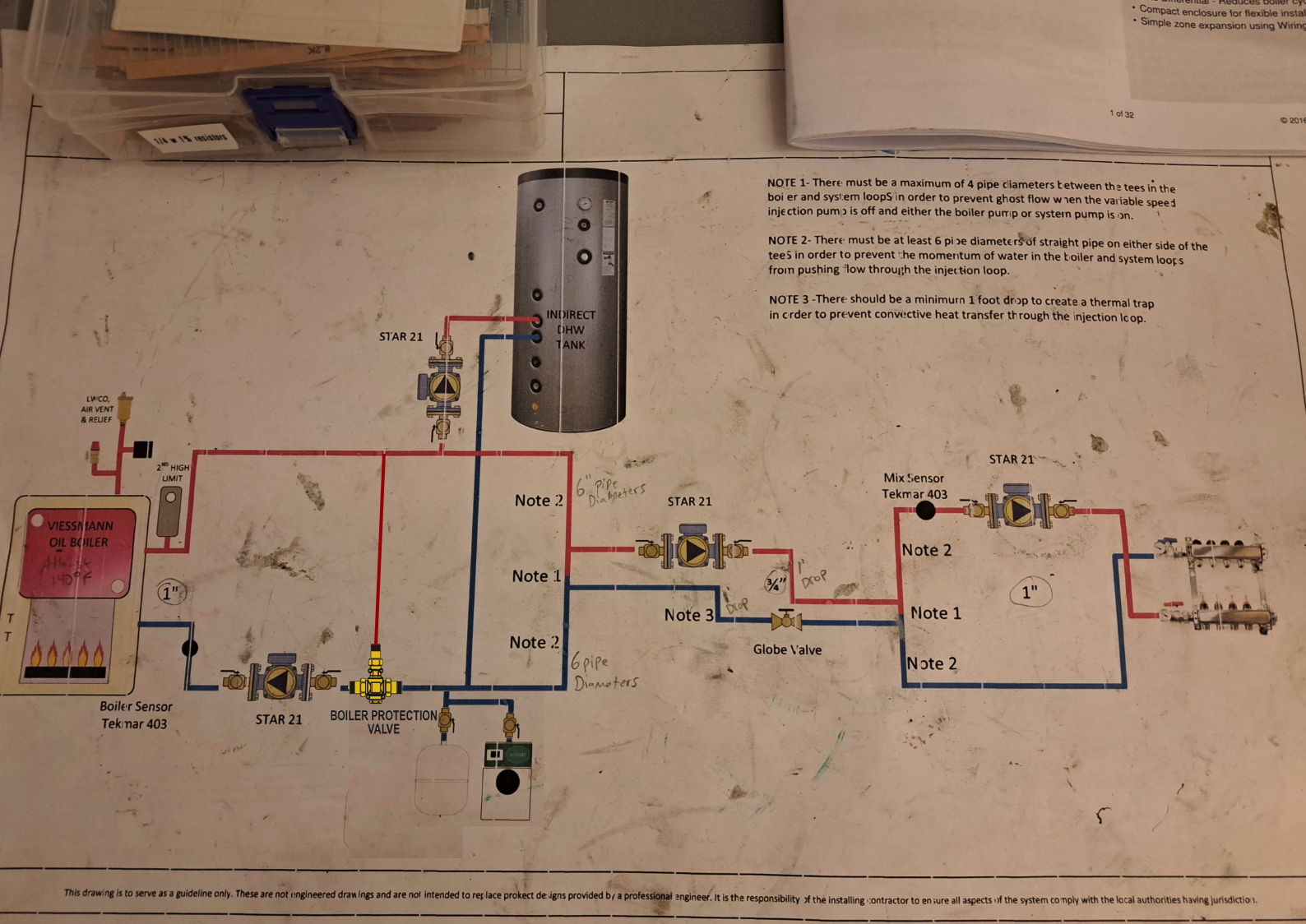

I recently moved a 1100 sqft 1960s house onto a brand new ICF basement and added in-floor heat to the slab. I had the plumbers install a viessmann oil fired boiler and pumps/piping for the in-floor heat as well as DWH. The main floor is heated by an oil fired forced air furnace. The system is an injection mixing system controlled by a Tekmar 403 with only one zone plus DHW. The system drawings are shown in the pictures. All circulators are controlled by the Tekmar.

In the future (2-3 years time) I will be adding an enclosed solarium and a garage. Both heated with radiant heat from this system. I believe this extra heating load will help the system operate better, but I need to to function properly until those additions are built.

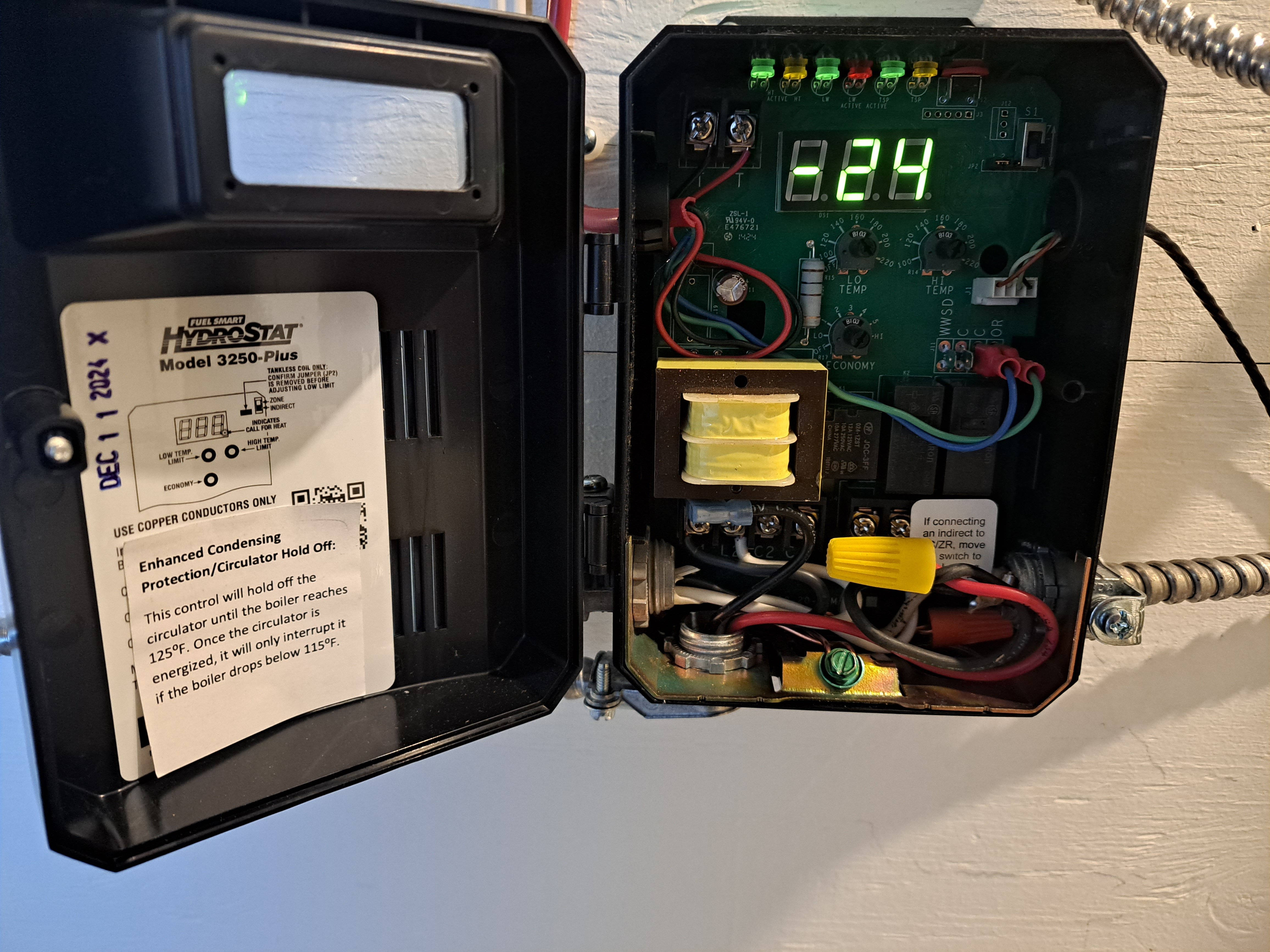

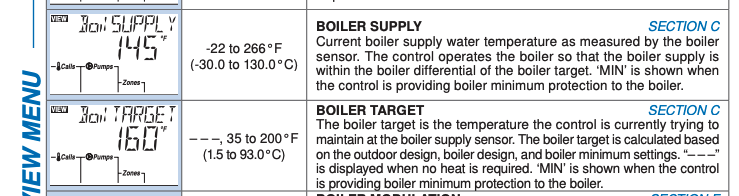

The oil burner is controlled by a hydrostat 3250+ which is controlled by the Tekmar. The problem I am having is that the boiler is short cycling. The burner will kick on, run for 2 minutes, then turn off. The 3250 has high limit set to 180, low limit set to 140, and economy set to 2. It was -24F outside when I took the pictures and the 3250's target temperature was 175. However, the Tekmar lets the boiler drop down to 135 before firing the burner, and then only brings the temp up to 160 before shutting the burner down. I do not believe the 2 minute run time of the burner is enough to get the chimney up to temp and prevent condensation. At least the furnace does run for 10 mins at a time, but I do not think relying on it to keep the chimney dry is a good idea.

Since the Tekmar is mixing the boiler water down for the floor heat, it does not care about having very hot water from the boiler, so the target boiler temp in the Tekmar always shows 140 as that is the low safety limit programmed in. The other issue is that on warmer days, when the furnace kicks in to heat the main floor, enough heat leaks into the basement to satisfy the boiler thermostat, and the boiler does not run for very long periods of time. This allows the boiler water temp to drop well below 135. According to my understanding of cast iron non-condensing boilers, I do not want this.

The problem is the 3250 will not fire the burner unless the Tekmar is connecting its TT terminals. But the Tekmar only does this when there is an active call for heat and even then it does not let the boiler get up to what I would think is a reasonable temperature for a -25 degree day.

I have read through the manuals for the Tekmar and 3250, but do not see what I can do to make this system operate better. The nozzle in the burner is already a 0.5 gph, so downfiring to increase the run time does not seem to be an option.

Any thought/opinions welcome. Does anyone know how I could set the controls better, or is it fine the way it is? The short 2 min run times does not seem right to me.

Comments

-

The first thing I see in your description is that you may have the LO limit set to a number (140°). This LO is for a tankless coil DHW boiler. You have an indirect for DHW. Your LO should be set to OFF. That change may let the burner run for a little longer, but not that much longer.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

-

In the piping diagram the boiler is pipes with a primary loop (the loop with the expansion tank) so the water can make a short run back the the return in order to get the return temperature up to the recommended minimum 135° is pretty short order. Once that return water is at that temperature the amount of heat removed by the injection pump should not cause the return water temperature to drop below that minimum of 135°. If it does the Tekmar is not able to make the necessary adjustments to get that return temperature back up to the minimum since there is no boiler return sensor. You may need to add a boiler protection valve on a bypass in order to accomplish that function. Caleffi boiler Protection valve. This would guarantee the boiler will reach the minimum return temperature every call for heat because the boiler will operate until the return reaches 135° before sending any heat to the zone or DHW Tank. This may end up using a little more fuel as a result of the extra heat building up before you actual start to heat the zone(s)

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Following up on @hot_rod 's questions about the size of the boiler and size of the load, the OP might find this older thread helpful. The OP's one radiant zone may be larger than a bathroom floor, but the same principles hold:

https://forum.heatinghelp.com/discussion/157311/do-i-really-need-a-buffer-tank-for-a-small-radiant-zone?utm_source=community-search&utm_medium=organic-search&utm_term=radiant+buffer+tank

0 -

Yes, I should have mentioned it was originally off and I had raised it to 140 to try. There is no difference in operation between the two settings.

The boiler is 91k BTU. I am not sure what the heat load of the zone is. Before the system was running, a 4.8kW construction heater was able to keep the basement above freezing which would be around 16k BTU/hr. Yes, I do believe the boiler is oversized. However, this is the smallest oil boiler viessmann makes, and I need the capacity for future zones plus DHW demand.

In the diagram, you can see the system actually has a boiler return sensor and a mix injection sensor. There is no boiler supply sensor for the Tekmar. I believe they may have set it up this way to make the Tekmar provide the boiler protection without the extra valve? Most applications I see online have the Tekmar connected to a boiler supply sensor.

Some interesting ideas in that thread relating to calling for cirulators without firing the boiler. I wonder if an independent control that calls the 3250 to fire the boiler to limit and lets it cool to low limit would help extend run time. The tekmar could still be tied in to the 3250 to fire the boiler on a DHW call. This would allow me to keep the ODR on the 3250 as it would dictate the high limit.

It seems to me I need some sort of additional control. Because if the system is short cycling on a -25 day, it will only get worse as outside temps increase and heat load is less. Plus the system still needs to provide DHW all summer when there are no zone heat calls

0 -

As I see it…

The first initial problem is the two controls (Tekmar & Hydrostat) concussing with settings.

The second problem may be you need a small buffer, but I would wait until you have all your connected loads.

I (we) need you to go thru the Tekmar, line by line, and list all your settings.

For starters on the Hydrostat, turn your economy setting off, set you high limit to 190 (it's your second high limit) the diff to 10°, the low limit off, and enable Circulator hold off.

Then we can tweak the Tekmar settings.1 -

If the load is small compared to the capacity of the boiler, the only way to keep the boiler from short cycling is to make the load appear larger to the boiler. This is not a matter of boiler controls, it's a matter of physical capacity. The way to do that would be with a buffer tank, when the boiler fires it runs until it brings the buffer tank up to temperature. The heating load then gets served from the buffer tank, and the boiler doesn't run again until the buffer tank has cooled off enough to give a decent boiler run time.

Let's say you want a 10 minute minimum run time and a 20F swing on the buffer tank. Ten minutes of 90,000 BTU/hr is 15,000 BTU. To get a 20F swing with 15,000 BTU you need 750 pounds of water, which is about 90 gallons.

2 -

I'm not familiar with that model 403, but it looks like it has a boiler return protection option?

There is a lot to learn about that control and it's settings. Read the manual and maybe contact tekmar for any clarification.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@hot rod. And that's part of the problem like I mentioned above. The control and the aquastat aren't working together. The aquastat needs to be relegated to basically a high limit device, higher than the setting on the Tekmar, and use the circulator hold off feature to protect the boiler, not the Tekmar.

1 -

-

Thanks to everyone for all the responses. However, it seems I need to be quite clear about a few things: The Tekmar only has 4 sensors connected to it - boiler return, injection mix, DHW, and outdoor temp. The Tekmar has no knowledge of the boiler supply temp. All circulators are connected to and controlled by the Tekmar, there are no circulators connected to the 3250.

This system was neither designed by nor installed by me. It seems unusual how the Tekmar is monitoring the boiler return instead of boiler supply. However, the system was designed by a professional heating company so there must be some reason for it.

Tekmar settings are as follows:

OutDesign = -22F

MixDesign = 120F

MixType = VAR

BoilType = 1 STG

BoilDesign = 180F

BoilMin = 140F

Flushing = OFF

WWSD = 70F

DHW Mode = 2

DHW OCC = 70F

Setpoint = 180F

I have turned the low limit and economy off on the 3250. There is no real change in the behavior as the Tekmar still ends the heat call before the boiler temp rises very much. I left the high limit at 180 as it is my primary limit (see above). There is a Honeywell L4006E secondary high limit set to 190. The diff was already 10 degrees, and the circulator hold off makes no difference as there are no circulators connected to the 3250.

I agree that there are really only 3 ways to increase the boiler run time with my current heat load:

- Reduce the firing rate (only possible by lowering the pump pressure as I am already at a 0.5gph nozzle)

- Increase the thermal mass of the system (buffer tank)

- Increase the temperature delta during a burn (135 to 180 instead of the current 135 to 155ish)

It is the last option that I am trying to achieve as it seems the simplest/cheapest to do. However, I have read through the manuals and don't see any way to configure the controls to do this.

Thanks

0 -

-

The heat call is not being satisfied, the Tekmar just ends the call for the burner to fire once it sees the return temp to the boiler reach 140. The boiler target in the Tekmar is always 140, I have never seen it go higher. I imagine due to the fact it is mixing the water down for the floor, it is just keeping the return at 140 since that is what I have set as the minimum.

0 -

How you wire it now I would have to think about that but its going to change when the other zones are added so it will have to be done over anyhow. Right now it is not an efficiency thing. Its to limit short cycling. At least that is my opinion.

I would start the boiler on a call for heat and keep it on until 190 even if the call ends. Shut it down and don't let it restart until the boiler temp drops to 120.

If this doesn't limit the short cycling then you need a buffer tank.

0 -

I agree, this seems to be the only reasonable option to keep flue temps up until I have more load on the system. However, I don't see any way to achieve this with my current controls.

0 -

Agree but we are not talking a lot of $$. Maybe a couple of aquastats and a relay or two. Probably can use some of what you have and leave the other stuff in place and disconnected until the other zones are in.

0 -

you could just jumper the boilers TT and let it maintain a temperature. Widen the delta as much as the control allows. Similar to a tankless coil boiler operation

That would not take any new components.

It would assure it gets out if condensing conditions.But it is not an efficient mode of operation and short cycling is not addressed

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@skippy_ replied: "In the diagram, you can see the system actually has a boiler return sensor and a mix injection sensor. There is no boiler supply sensor for the Tekmar. I believe they may have set it up this way to make the Tekmar provide the boiler protection without the extra valve? Most applications I see online have the Tekmar connected to a boiler supply sensor."

I took a closer look and see the return sensor. but I do not see tghe option in the Tekmar to select that boiler supply sensor as a return mounted sensor as other Tekmar controls have. But I didn't look at the entire manual either. So if that is the case then toy have no other option for prolonging the burner on cycle since you don't have a large enough load to cause the burner to operate more than a minute and a half. The only other option is to use a buffer tank and draw that small load from that tank for as long as it can offer enough heat. When the tank reaches a low temperature then charge the tank again with a 8 to 10 minute burner on cycle to heat up that larger mass of water to start the process all over again.

As you add more load, the cycles will get longer. You can try to add a hot water duct coil to the furnace and stop using the furnace burner in leu of the boiler providing enough heat with its additional capacity.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

I did some more thinking and believe I have found a reasonable way to improve the short cycling. As a test, I let the boiler drop down to 130F and then manually fired the burner with no zones calling. It took the boiler 5mins 45secs to heat the water to 180F.

I jumpered the B1 and ZR terminals on the 3250. This has the effect of latching any call for heat and having the boiler run to high limit. I also set the low limit to 145 on the 3250. So once the boiler temp drops to 135 (LL -10 degree diff), the burner fires and latches on. It then heats until high limit (180). I left the Tekmar connected to the TT terminals on the 3250 so that the Tekmar can still initiate a burn for a DHW call without having to wait for the boiler to drop down to LL to fire. I also had to set the minimum boiler temp in the Tekmar down to 80 (ODR causes the boiler target to change) so that it wouldn't prematurely fire the boiler and reduce my burn time. The low limit in the 3250 should be protecting the boiler.

With the new configuration, I turned up the zone thermostat and the burner ran for 13 minutes to go from 135 to 180. I imagine regular run times will be less since I had just raised the setpoint and all the heat was getting dumped into the slab. But worst case scenario, the shortest burn time should be 5mins 45secs.

Is this enough run time to keep condensation from forming in my chimney? Or I guess the better question is how can I tell if this is enough run time to achieve an adequate stack temp?

Any thoughts/comments appreciated.

0 -

Minimum stack is around 300 but others have boilers like @jesmed1 if I recall correctly runs around 250. So check the stack temp.

0 -

The general suggestion is the boiler return temperature reaches 130 within 10 minutes of run time. Anything below 10 minutes burner on is considered a short cycle.

Run cycle efficiency can be calculated if you know run time and off cycle time duration

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Is the required stack temp not influenced by the size of the stack and outdoor temperature? I will have to do more reading on the subject. In my old house the oil furnace spent more time running than off, so minimum stack temps were never a concern for me.

That is interesting, so I should be able to set my low limit even lower than 140 so long as the return gets up to 130 in less than 10 minutes. Is this an absolute minimum requirement that will cause ill effects long term, or does it not present any issues having the boiler temp be less than 130 at startup? Most of what I have read says to maintain boiler temps above 135. I am quite new to non-condensing boilers as my old house had a forced air oil furnace only.

0 -

ALL boilers condense at first start up. But non condensing type need to get above dewpoint at some point before they go off

130 is the number used by most boiler manufacturers

If not water vapor will cause damage to the boiler and flue pipe or chimney

Measuring the flue gas temperature above the boiler is another way to determine operating condition

Or looking at the roof top vent when the boiler runs can indicate if it has warmed up enough

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

So the Tekmar is now basically just a zone panel with DHW priority.

The boiler holds 9.2 gallons, but still needs a buffer tank with an aquastat that offers a 50° differential. Leave the economy off on the Hydrostat. Hi- 180°, Lo- OFF. Return sensor on the buffer tank return to the boiler.

0 -

Just for the record, our WGO-5 gross stack temp is around 400 despite having return water temps below 130 degrees for most of the typical 40-minute boiler cycle.

The boilers are cold start and will reach stable stack temps of around 400 within a few minutes of startup. But because of our old high mass, high water volume gravity conversion system, the water temp in the boiler does not reach 130 F until 30 minutes into the run.

Both boilers have run this way for 30+ years with no evidence of internal damage from condensation. I've seen the heat exchangers myself when the boiler tech cleans them. There is some pin erosion, which is expected from normal wear. But the heat exchangers could easily run another 10+ years IMO.

Let me repeat: our boilers reach stack temps of 400 degrees within minutes of startup even while running the first 30 minutes below 130 degrees water temp, with no evidence of internal condensation damage.

This convinces me that the fears/warnings of condensation due to low return water temps in cast iron oil boilers are overstated, and if the OP gets a buffer tank and can get his boiler cycles up to 15-20 minutes, I don't think he will have a condensation problem in the boiler. They key factor is not the return water temp, it's the stack temp. If the stack temp is reaching 350-400 degrees, there is no way the vapor is condensing inside the boiler, regardless of water temp. It's physically impossible.

0 -

It's possible with very low flow conditions the condensation could evaporate ad not cause issues. The potential is job specific.

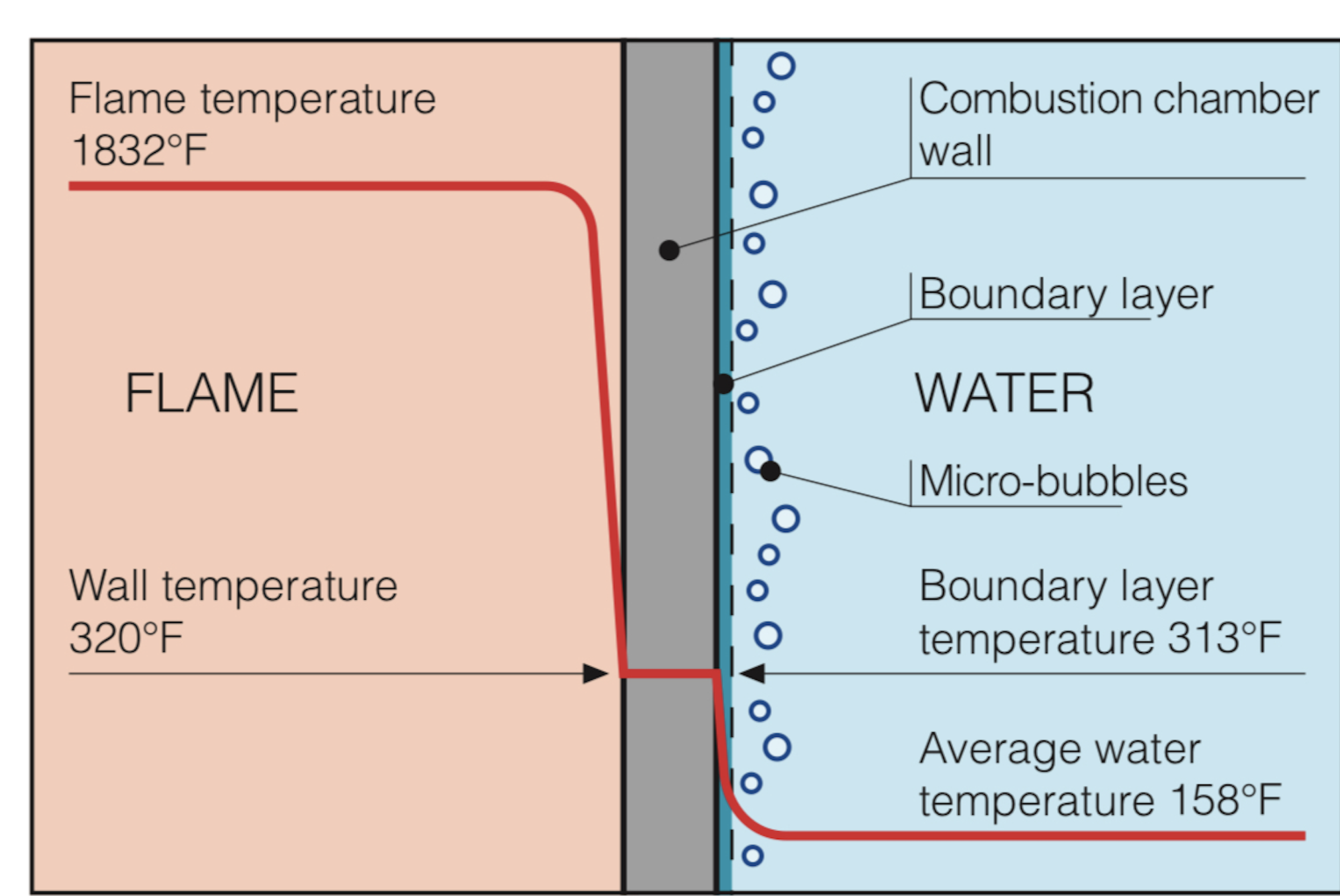

I could put my temperature probe in the blue flame tip and record well over 1500° F and still be condensing on the boiler castings.

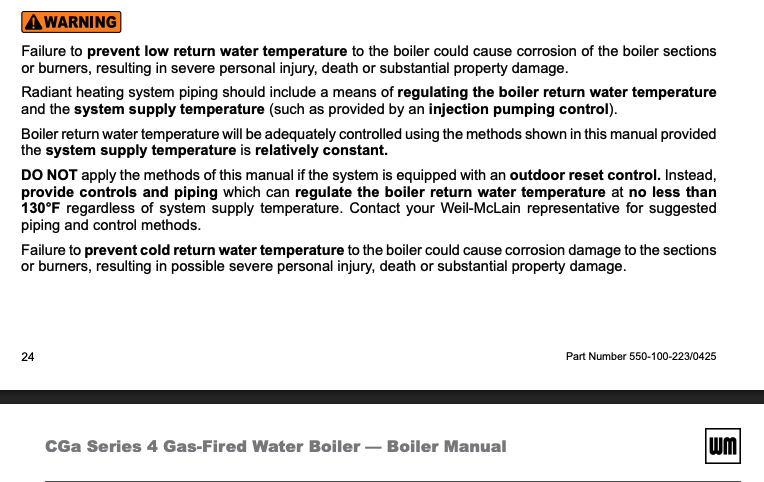

My advice, as well as that of the people that design, manufacturer, rep, sell boilers, and educate the industry is to follow the boiler manufacturers guidelines. That is who you will be contacting if you have a warranty claim.

I see the current manual for the Weil Cga series has this warning on three different pages now. Must be a reason? Similar verbiage in the US boiler manuals.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

@hot_rod Thank you for that info. I did read that Siegenthaler article. Just to be clear, I am not advocating that anyone should ignore mfr recommendations on return water temp protection when installing a new boiler. When I replace our boilers, I will follow those recommendations for installing a bypass on high water volume systems like ours.

But I would just observe that the graphic you posted actually makes my point. It's important to remember that the only temperature that matters for flue gas condensation inside the boiler is the wall temperature on the hot gas side, where the lowest temps will exist from cooling by the water. The graphic shows temperatures that would be representative for a hot boiler running in quasi-steady-state conditions, by which I mean the boiler has run long enough that the boiler stack temperature is probably 350+ F and most of the heat generated is now being transferred to the water, not being absorbed by the exchanger itself in startup.

The graphic shows that the wall temp on the hot gas side is 320F, far above the 105F dew point for oil burner combustion products with 10% CO2. It also shows that the water boundary layer can be 150+ F hotter than the average water temp. So, for example, if we imagine all temperatures reduced by, say, 50 degrees or so to represent an earlier point in the burn cycle, the graphic would show an average water temp of 100F, a water boundary layer temp of around 250F, and an HX surface temp of around 270F. Of course, the exact temps will depend on a given boiler and a given operating point, but from a heat transfer point of view, a temperature profile like that is entirely possible. The water side can be only 100F average, and yet the surface of the HX can still be well above condensing temps. And I contend that is exactly what is happening in my boilers.

I apologize for digressing and will leave it there. Some day I'll figure out how to instrument one of our WGO-5's to show temperature profiles on the HX surface which, I contend, will show that all HX surfaces are well above condensing temperature within 10 or so minutes of startup, after which I could run 100F water through the boiler all day without causing it to condense after the startup transient.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements