Am I Going To Need a Power Flush?

I have a Burnham boiler and single-pipe steam. When I bought the place, there was a main section in the basement with no pitch - basically flat for about 20'. I finally got around to correcting this (if you profile-dive me, you'll see the last time I corrected it - there was still one last flat section that I only recently fixed), and it helped - a bunch of sludgy water came out, and those stacks started heating up faster. But, they still heat up pretty slowly compared to the rest of the building. My mains are vented, and the radiators in that stack all have oversized vents as well.

I suspect sludge built up in that main section, from years of water just sitting there in the off-seasons. Is a power flush the way to fix this? If so, I'm a retired construction pro (electrician), could I have a shot at doing this myself? Or should I leave to the big boys?

Thanks for any advice!

Comments

-

How about some pics of the pipe in question and the boiler and it’s near piping?

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

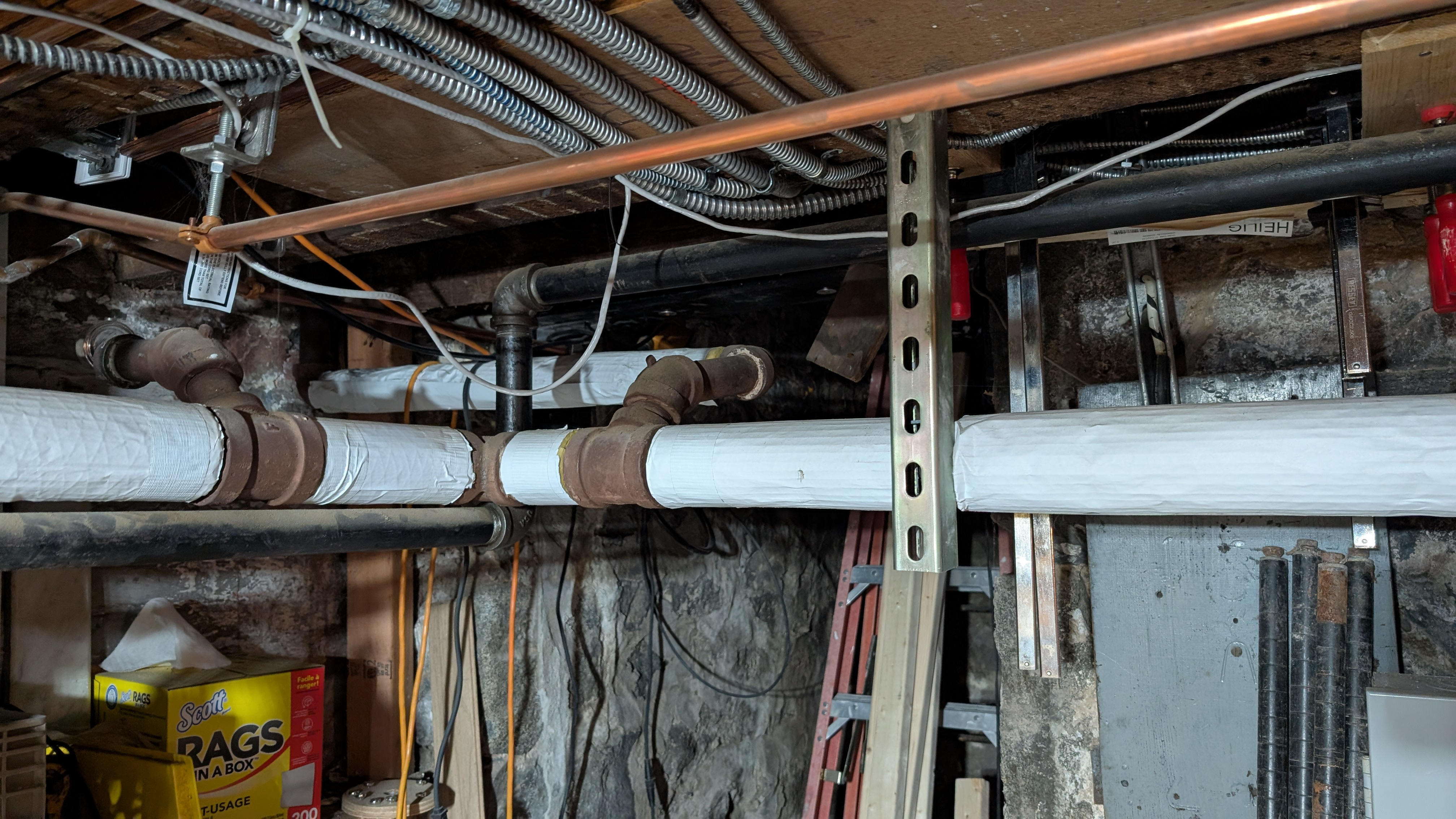

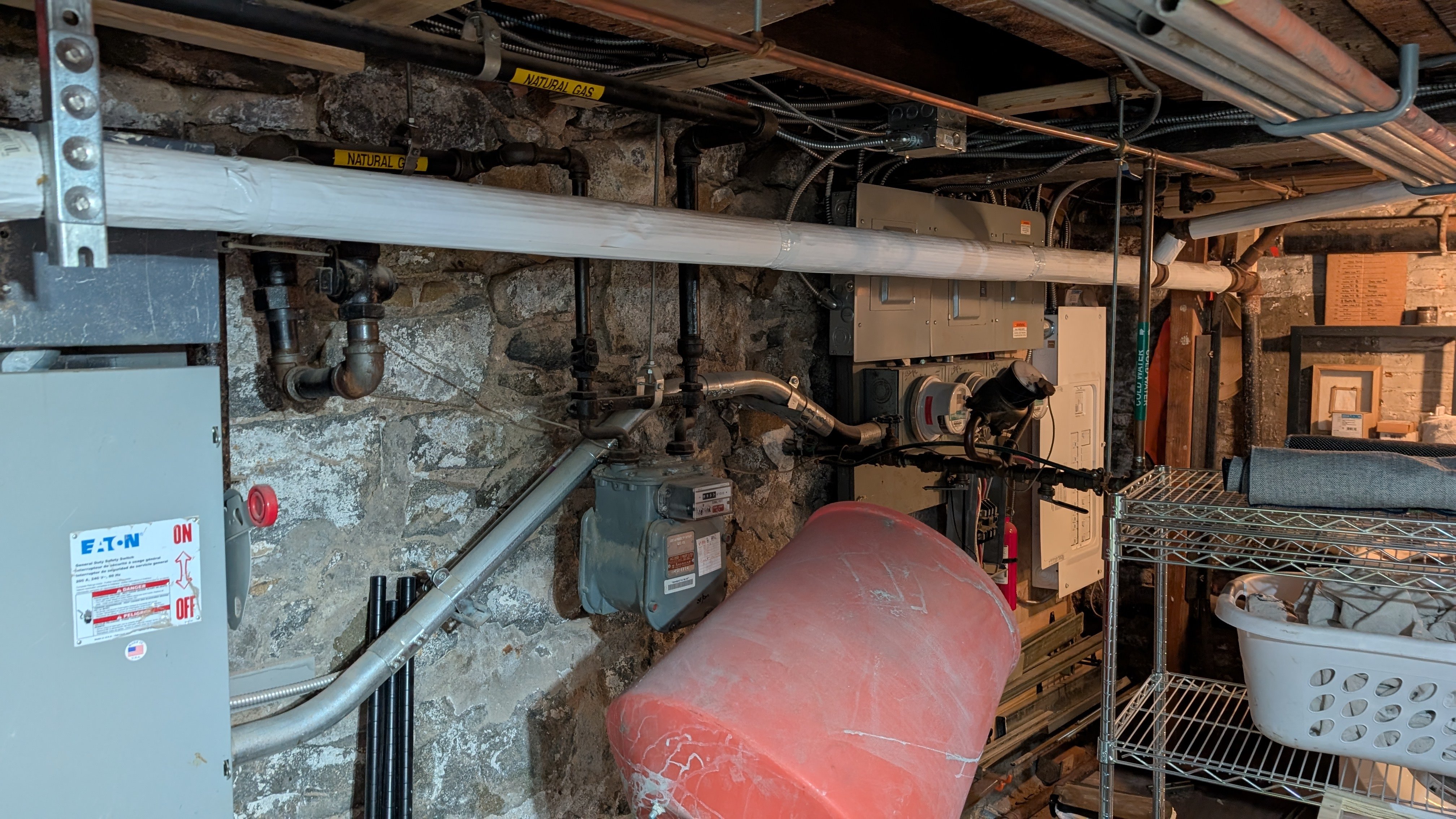

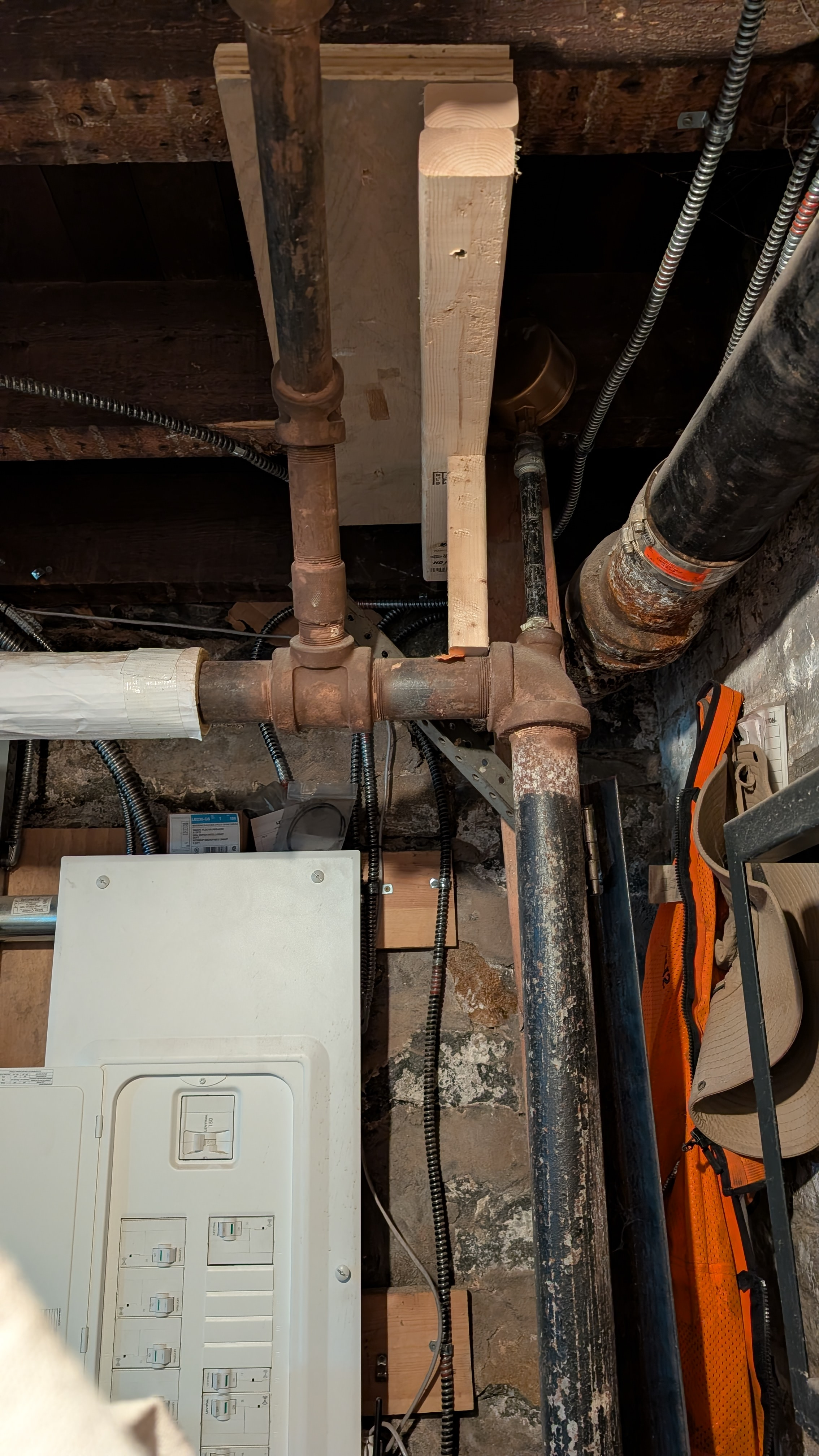

Sure thing! The main pipe sections you see here are the ones that used to be sitting flat. The strut and the wooden blocks are now holding it in a pitched position.

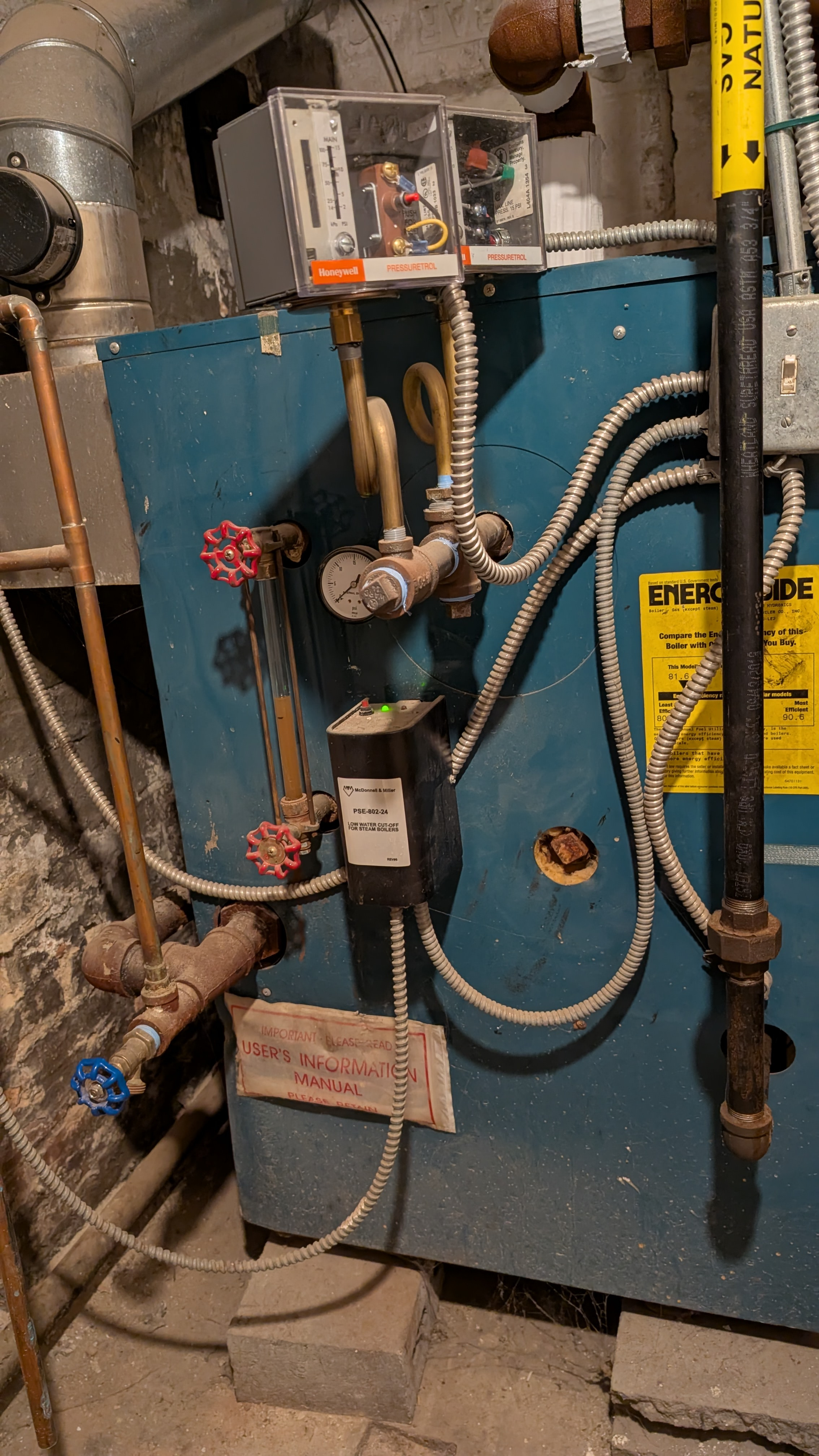

Tried to get a decent shot of my main vent. Just noticed my dirty gauge glass.. it's not normally like that, but I just put in an anti-corrosive. Maybe that's related.

Just realized it's hard to see my operating pressure - it's 2PSI with a 2PSI subtractive differential (seems a little odd but that's what the plumber did).

0 -

wat is the length of the slow main vs the fast main? how are they connected at the boiler?

0 -

The slow main is a 40' long north-south section, followed by a 1/4 bend, then a 17' east-west section. That east-west section is the really slow part. On the other side of the building is a separate main, about 10' long before it hits the only vertical stack that it serves.

Not quite sure what you mean by 'how' - there is a header, shown in the photo above, the long/slow main section I'm describing here is the vertical pipe on the right. The short (10') section is the vertical pipe on the left. Let me know if you need other information, and thank you for taking a look at this!

0 -

The pressuretrol setting is a little od — and a little chancy. I'd change the subtractive differential to 1.5 psig if it were mine…

Also… that long straight section of main (does it really go by in front of what looks like the electrical switchgear? It's a wonder the inspector passed that, if it does!). Could it still have a slight sag in the middle? You wouldn't think an iron pipe could sag — but they can. It's amazing how little pitch one can get away with — but only if the pipe is really straingt.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

-

Thanks @Ironman, that's exactly what I needed to know.

@Jamie Hall I've been using a four-foot level, but yeah, I should probably get a ten-foot straightedge to go with that before I do anything nuts. Good advice about the differential setting, I'll do that.

I gave up trying to understand NYC inspectors a long time ago, except to say that they're usually very generous about grandfathering :)0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements