Single Riser BUT no equilizer?! one Pipe Steam: gravity return

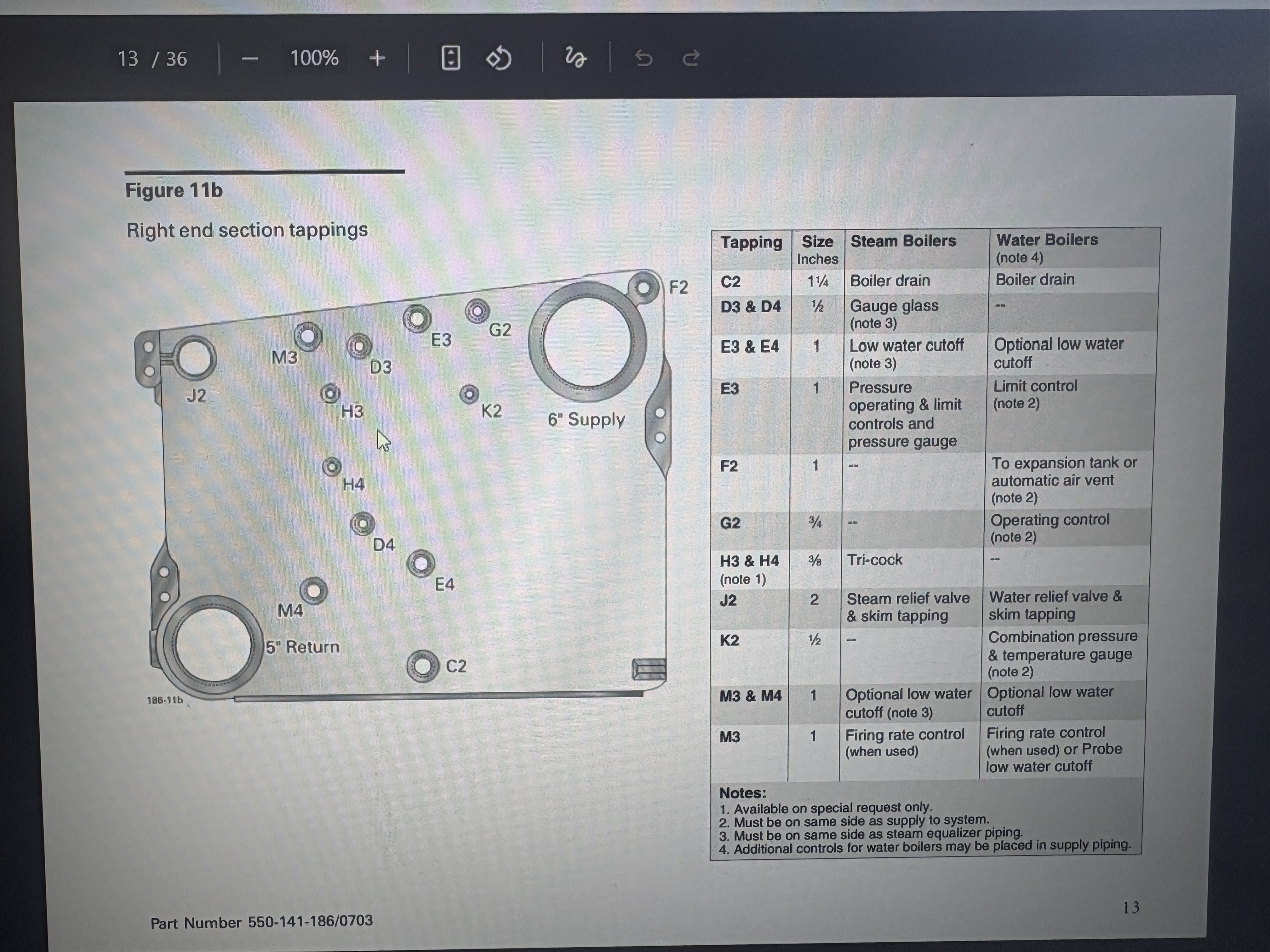

LGB-10 Series 2 Boiler

(Long post trying to get out all the info I know)

1 riser out “left” 6” screw pipe as header into main that splits out to perimeter of basement (most likely original set up from coal fire system: coal chute and old coal present in basement)

NO Equilizer back to Hartford loop.

2 blow outs for 2 LWCO

Per boiler manual I have blown these out quickly every week. (sometimes it was suggested by tech. to do it a little less to avoid new water into system and calcification)

1 drain valve BUT no apparent boiler “blow out” 1” valve

No king valve to isolate system

No gate valve or strainer on condensate return: would have to dissemble the 2013 pipes to flush or check?

Install 2013-2014 winter.

leaks steam at start up last 8 years causing control board condensation and short circuits. Replacements. Lockouts. Visits from boiler techs.

I now understand what I did not know in 2014 and it seems we are headed for a new boiler or a regasket. And a hefty price tag.

Original installer graciously met me, but basically blamed sediment and me not blowing it out (LWCO)enough or us not treating the water into system or not “blowing down the boiler”

He admitted to not counting the radiators.

boiler is 1,170,000 BTUs input. Old boiler was 1,300,000 American standard before my time.

we ONLY have 25 radiators with 3 more “off” for an EDR of 186,000btus =constant short cycling.

23 “small” radiators: 2880-8,000 BTUs

2 “big” main floor radiators: 19,000 bTu

1905 brick apartment building one pipe steam gravity return.

NO main vents visible.

No Riser vents visible.

14,000 total square feet

Minus

-3,000 square ft on electric heat.

-non heated hallways (don’t have sq ft on those. Hallways basically heat indirectly from apartments and 2 bathroom radiators.

Building will still get up to temperature set at 66-68 degrees (unbalance in system, some rooms too hot so I installed Vent Rite)

BTU performance test was roughly around

247,000 bTU

[60 seconds fire 90 seconds off from a cold leaky water start up]

65 seconds fire 100 seconds off recovery heating 66 degrees to 68” “warm” boiler start sections of (basement main 6” pipe had been replaced. No insulation basically acting as a big radiator tube for 60feet?)

Original question:

- Is no equilizer “allowed” if riser is “big enough” in anyone’s experience?

2. Why No blow off ball valve

3. Only blowing out the LWCO can’t act as a “boiler blow out” correct?

4. Small garden hose faucet at bottom of boiler is only to drain boiler? It can’t act as a blowout?

5. With no king valve or

Isolation, how would I even blow down the boiler? Make 5 psi running boiler (instead of the 10 recommended by Dans deadman seminar?) and pipe a valve outlet far away from boiler to blow out 212 degree water from bottom of boiler?)

original installer has 44 years of experience. 30 when our boiler was installed and says he’s not touching it.

Comments

-

pictures LGB 10 Series 2

0 -

0

-

Sounds like the boiler needs to be replaced or the BIG gamble of regasketing it which might be a waiste of time once you get it apart. Your noted questions I suspect you already know the answers to since you have the manual on the book. You just want a bunch of people to confirm your findings to make the other installer look bad? I would open up the LWCO and look for mud for my own liability reasons and if I found some in there I wouldnt run it until rectified. You can blow it down all you want but if 100 steam guys are brought into court because a LWCO failed due to sludge then they and the jury are going to blame you, suggesting that your not telling the truth about blowing it down. Ive seen regularly blown down LWCO's get sludge in them.

1 -

I’ve blown down the LWCO regularly. At start of season it’s brown water. Takes roughly 2.5-5 gallons to come clean based on my bucket method. No drain in boiler room.

during season first quart or so is dirty. Second quart is cleanYear one the installer back flushed and cleaned the LWCOs because they were dirty.

Further questions:

Is the boiler too big? Will it just short cycle.

Main question: does it have to have an equalizer to tie together the system?

or what other problems in system can happen when you don’t have the equalizer back to Hartford loop?0 -

On a 1 pipe system, the equalizer does not affect the operation of the system relating to pressure. There is no actual "equalization" function it performs.

It makes an excellent drain from the header for any condensate or carryover that makes it to the header. But if carryover occurs, it's going to go all the way to the mains, and that's not great. Water can get pushed all the way to your radiator vents and your main vent.

A boiler can run just fine without it, but there's no reason not to have one. It helps.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

I don't know but someone should be shot for jamming the boiler in there with the controls up against the wall. Makes it difficult to maintain.

Just replace 2-3 sections if they are bad and re- gasket where it is leaking and move on. Make sure the controls work and fix any leaks and fix the venting.

Then in 2-3 years you may have more leaks

1 -

Thank you, I wasn’t there, but I think it was a bit of give and take with city inspector. Old boiler was out in open with no fire wall. So the installer arranged for someone to build out cinder block wall and got that passed.

now it’s possible the direct air vent from outside isn’t big enough: 1,170,000 \ 4,000 BTUs seems to call for roughly 22 sq ft of direct vent?

so we ve left the boiler room door open where there is access to leaky doors, rock foundation, floor vent opening on far side of basement.

the boiler room has a 12x18” for 216” grated vent from above grade in the brick. To boiler room ceiling. 1 foot horizontal. 6ft vertical to boiler room ceilingwe do have water hammer in the main line. Could be due to our unidentified low spots,

Some radiators will spit a tiny amount of water every now and then even if I have them sloped, Hudson valves get a few spits. Some have failed before. Now replaced.

main plan of attack is to size boiler down to 400,000 BTUs and add back radiators and get to a closer EDR and insulate all main pipes.

By the time this gets broken down this summer and sized smaller and put back together, is probably pay for the equilizer, and some sort of condensate screen and reservoir depending on how much time we figure out it takes for condensate to returnThank you for the help and opinions

blowout valve water 1x a week. 5 quart bucket

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements