Old Weil-Mclain Boiler No response.

Comments

-

Thanks for this info!

0 -

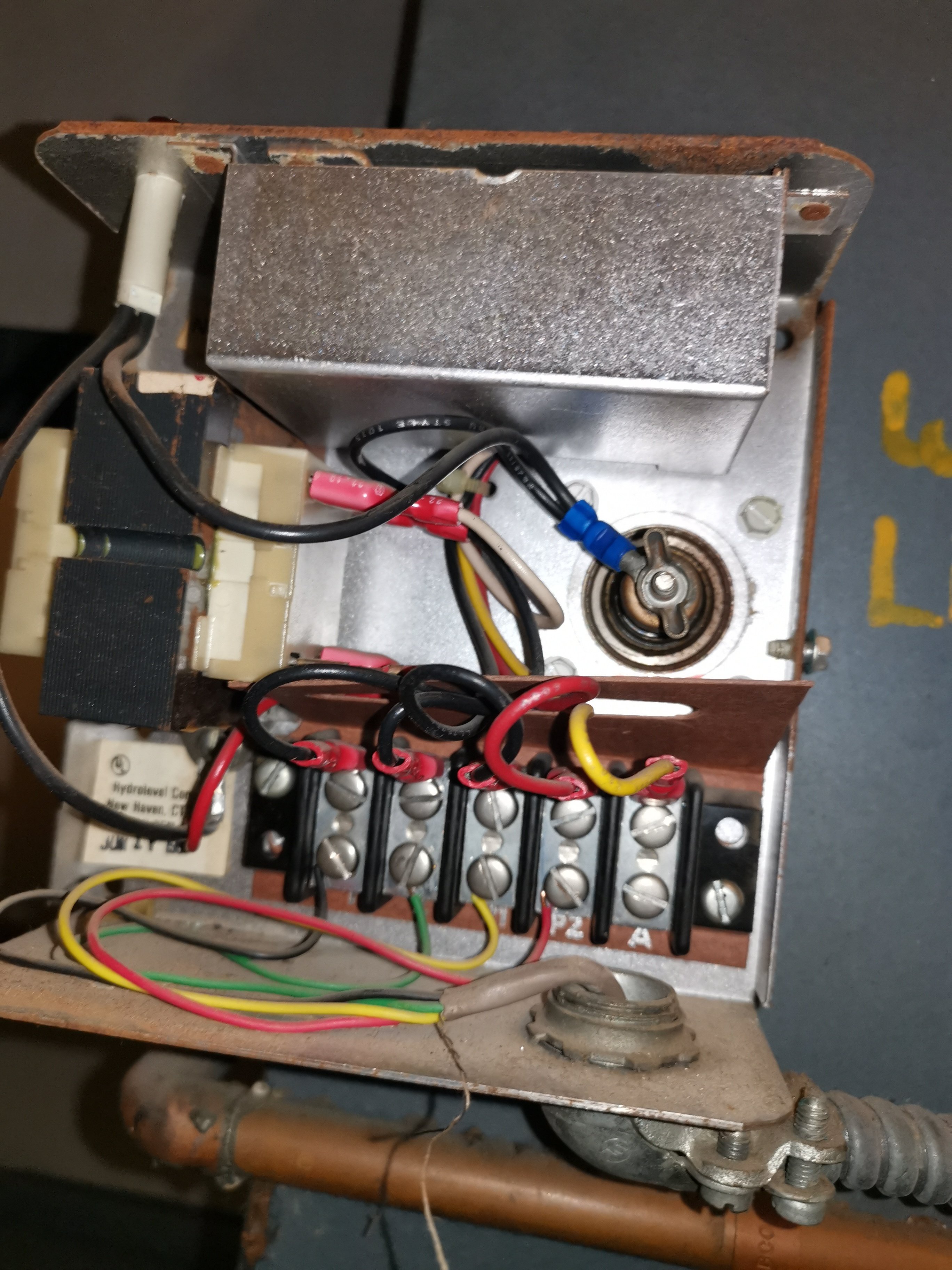

It's powered by 24 V, I traced every wire in that mess, lol.

0 -

I will, when I get a chance, thanks for the concern!

0 -

That is an older LWCO. Nice and simple.

I believe the 24 VAC input voltage is stepped up to a higher voltage for the probe circuit. When water is present the current through the probe and the boiler water energizes the relay. If the water level is low the relay will drop out (or never energize) disabling the burner. If power to the LWCO is missing the relay will never energize so the burner will be disabled.

If the power is present to the LWCO and the boiler water becomes low the probe voltage will be higher (in reference to ground). This will cause the relay to drop out and I presently believe it will light the lamp (probably neon) on top of the LWCO unit.

What does the note say on top of the LWCO ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

If the input voltage is stepped up it must happen inside the LWCO because I traced the wires back to 24V source. There's only 1 wire connected to the probe so I think you are right that current must flow through water to activate the safety chain somehow? I can't take the probe out yet, seized in place.

The note on the LWCO says something like "the red light will lit when water is low".

0 -

Yes that is what the transformer is for. The 24 VAC power to the LWCO should be verified, the Black and Green wires. IMO the basic operation of the LWCO electrical part could be verified. Wire to the probe under the wing nut disconnected the burner should not work and the light is on. If the probe wire is grounded the burner should work. Make any changes for tests with the power off since there may be high voltage at the probe wiring connection.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

The LWCO relay is under the metal cover just above the probe wing nut connection.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Just put a big wrench on the probe well it will come out

0 -

When you put it back in use pipe dope or Never Seize available at an auto parts store it will make it easy next time. No teflon tape.

0 -

Ah that makes sense. Didn't realize there's a built-in transformer! I'll test more if it still doesn't work after i dealt with the probe.

Thanks!

0 -

Big wrench and pipe dope yeap. I took it off today, much easier after 1 day of penetrating oil. It looks like coated very evenly with this copper color stuff. I'm not sure if i should sand it off. But the color does look like this silicone boiler additive that i was told to add every 2 years by the previous owner. Also when i do continuity test with the multimeter, most parts on the probe doesn't make it beep when i had the other meter contact at the other end of the probe. Only beeps when touching the corners of the probe where the metal is a bit shinier.

I'm thinking the silicone additive finally covered up the probe over years and i need to sand it off.

What do you think? Thanks!

0 -

clean it with scotchbrite or steel wool. if it is plated with something nonconductive it likely won't work right.

since it is a safety device and it is like 30 years old it wouldn't be a terrible idea to just replace the whole lwco with a new safgard.

0 -

-

I'd clean the probe, kind of wonder if a newer style probe has enough surface area for the relay to energize properly, may depend on the water. The electrical part is dirt simple, no weird high tech issues when you need heat.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I cleaned the probe and it's conductive again, confirmed by continuity test. Still has problem though.

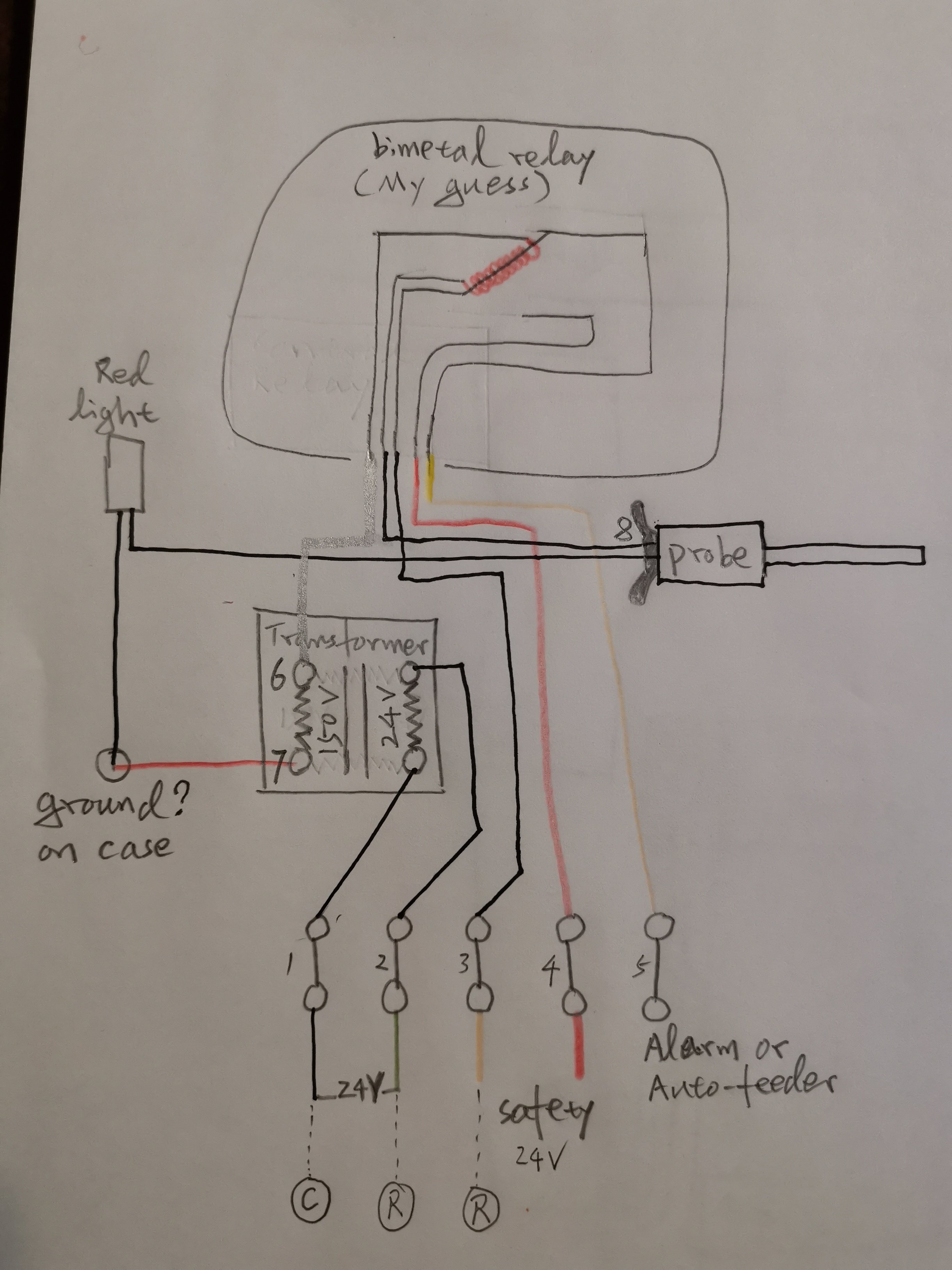

When the power is on and water is low, the warning light lit up. When water reach the probe, the light turn off. I guess it means the probe is working? However, when heat is called, boiler still won't respond. If i jump terminal 3 and 4 (the label on my hand drew diagram) when heat is called, boiler fire up. So the problem must still be the lwco.

I tested continuity between terminal 3-4, 3-5, 4-5. No call to heat, power off or power on, there's only continuity between 3-5. That means the bimetal switch is not shifting position to connect the safety circuit if i understand correctly.

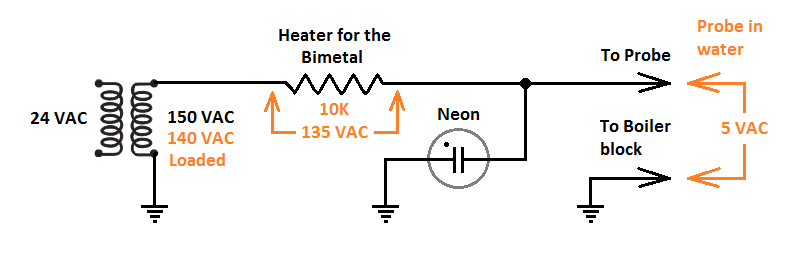

When the power is on, the voltage between 6-7 is 148v, between 6-8 is 138v, between 7-8 is 10v.

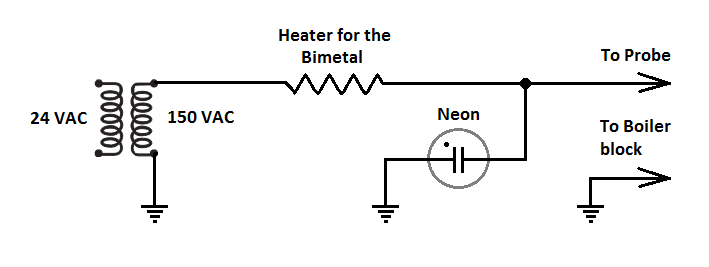

Do you know what's the circuit inside the bimetal relay box? I took a guess and drew a diagram. It's riveted in place so i can't easily take is off.

What other test can i do to diagnose?

I know it's probably time to get a new lwco but I'm curious also still confused about a few things. For example, I don't understand the circuit connecting the warning light and the probe, and the possible heating element on the bi-metal switch. Maybe I drew it wrong.

Thanks!

0 -

when the probe is conducting the voltage across the probe falls so it isn't enough to light the light, when the probe is out of water it isn't conducting and the voltage rises so there is enough voltage to strike the neon light. it is probably a transistor that closes the relay if there is enough current through the probe. the relay most likely is bad, most likely the contacts are corroded and not making good contact but the could could be open or the transistor could be bad too.

0 -

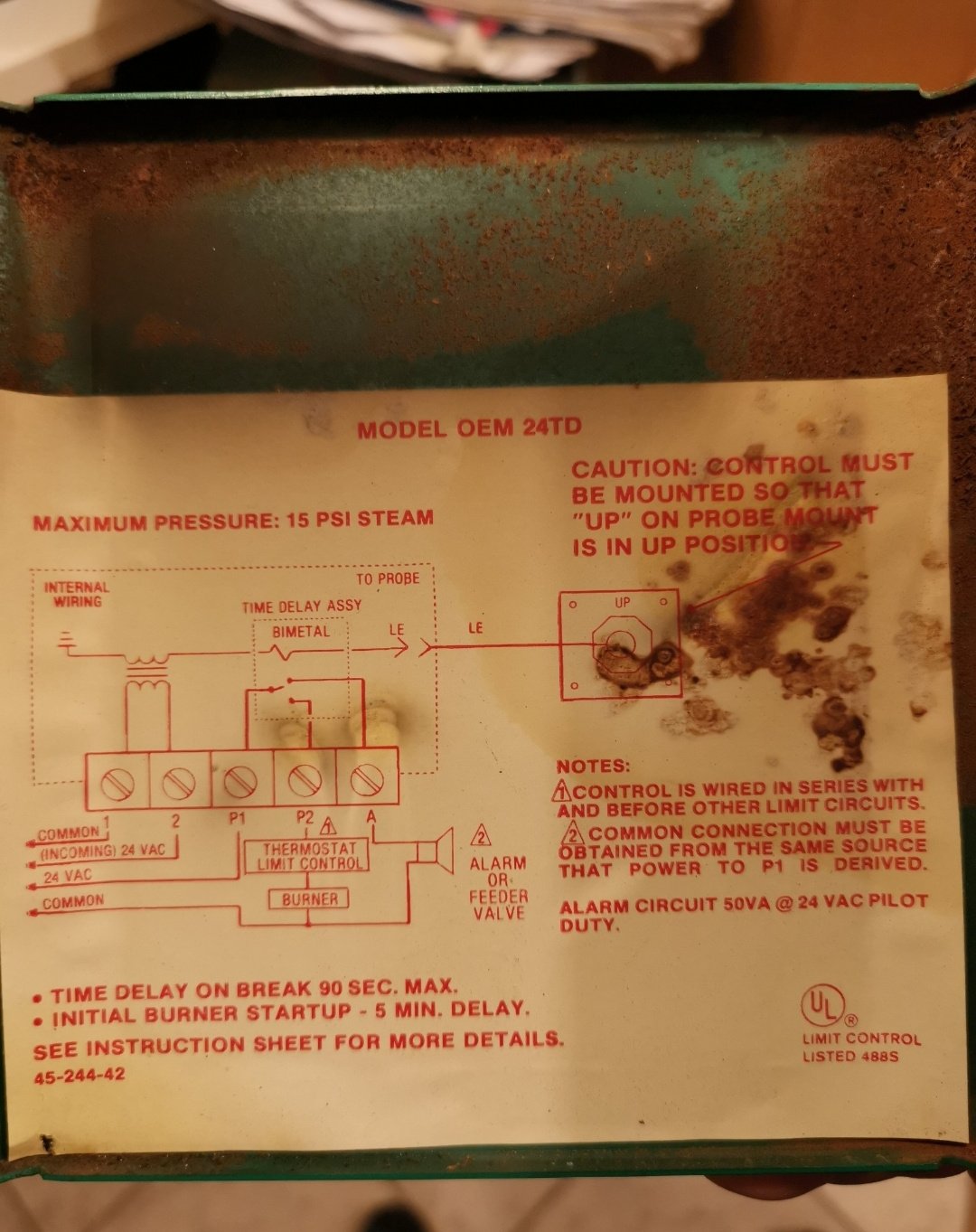

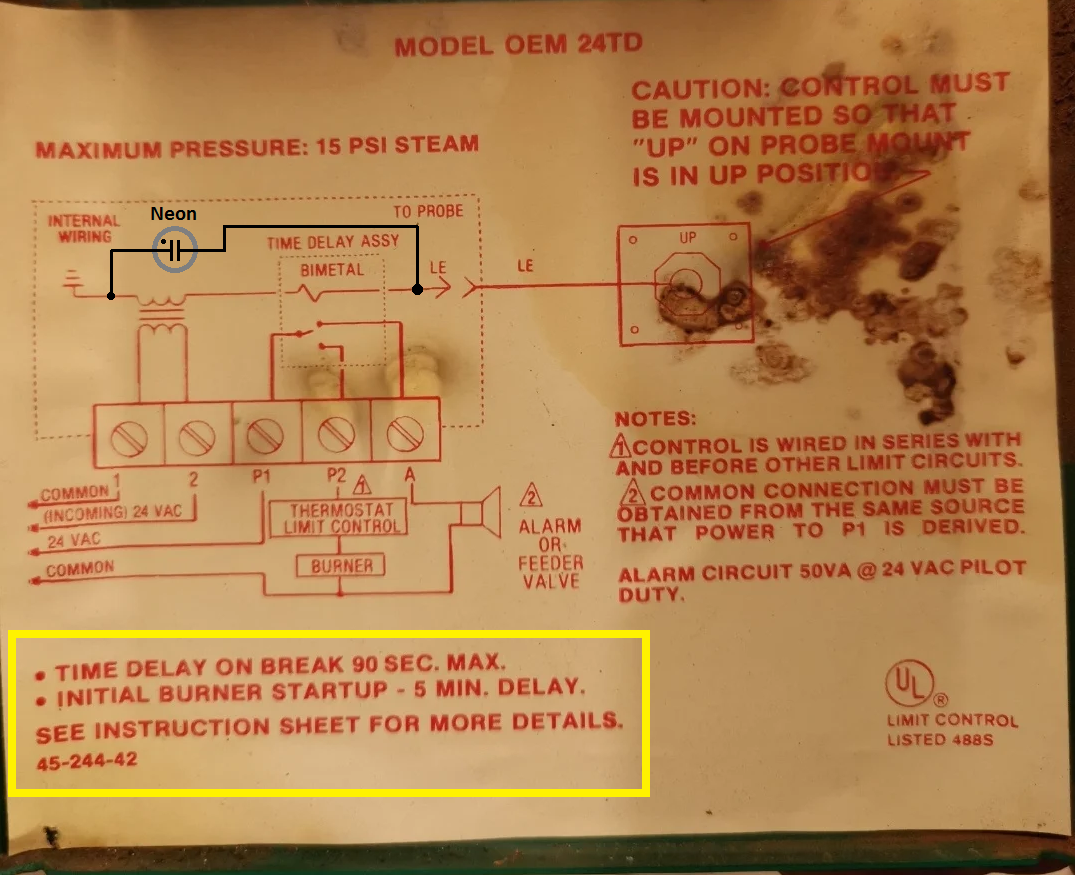

The probe basically shorts out the neon lamp and more current goes through the relay coil (heater).

The Bimetal Relay - most commonly relays have a coil that makes a electromagnetic field and that moves an armature and opens or closes the contacts, in this case the coil most likely acts as a heater and the Bimetal flexes to open or close contacts. Since they used a Bimetal and a heater it is probably gives the unit some needed delay to avoid nuance interruptions and maybe a short water fill delay to get a bit more water into the boiler.

If it was me I drill out the rivets and see what is going on, maybe the contacts just need cleaning. If needed the rivets can be replaced by screws. Replacement of the LWCO is always an option, but I like fixing things and / or just knowing exactly why I need to replace it.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

If the probes continuity to the boiler's water is intact it effectively shorts out the neon lamp or the voltage is below the neon lamps firing voltage. When the water goes away the probe is basically an open circuit the Bimetal heater only has the neon lamps current through it so it cools down and the relay changes state.

See delay times at the bottom of the label.

Dirt simple, I bet the relay contacts need cleaning.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Note the "UP" position if you reuse that probe.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

if it is using a bimetal timer rather than a relay it is fairly common for the heater on those timers to burn out too, especially in this case where it spends a lot of time energized although if it is connected directly to the probe rather than through an amplifier the lamp won't light if the heater is open.

0 -

I think you are right about the bi-metal switch and neon light.

The interesting thing is, without power there is continuity only between terminal 3 and 5, which is expected because the heater is cold so the bimetal switch connect the alarm/auto feeder circuit. However even when the power is on, without heat call (so the outside circuit through the thermostat is still open), there is still continuity only between terminal 3 and 5. I mean, if the heater is working, the bimetal switch would move away from terminal 5 then there shouldn't be continuity between terminal 3 and 5. However if the heater a bust, then the neon light won't lit no matter what.

I'll open it tomorrow and see what's going on.

0 -

Ok, I see what you are saying. The contacts are probably 'Break Before Make' and the 3 to 5 never even opens up. I suppose the Bimetal being a spring something mechanical has failed so even with heat the Bimetal does not move the contacts properly.

On your wiring diagram you could measure the resistance between points 6 and 8, with 8 disconnected from the probe, I'm thinking maybe higher than 20,000 Ohms but probably not higher than 100,000 Ohms.

I'm starting to wonder if there is just a Carbon Composition Resistor for the heater and its value has drifted enough that it does not heat the Bimetal sufficiently any more. Even with the higher resistance due to age the neon lamp could still easily work.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

it is usually a little piece of nichrome wrapped around an asbestos sleeve over the bimetal strip

0 -

Yes in general agree, but in this situation, the higher voltage 150 VAC (would be lot of nichrome wire), not much wattage needed, the low current through the water, and the Initial Burner Startup Time being a 5 Minute Delay and I bet nichrome wire is more resistance stable with time.

I'll wait for the pictures.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

120v bimetal timers were very common before things were microcontroller controlled. it is an off the shelf part although the current will be dependent on the water which will have a high resistance so the voltage across the timer will be far less than 120v.

0 -

Yeah, don't look like an off the shelf tube type to me.

https://youtu.be/4i04D_6A3Ho

Looks like it may be Vitreous enamel coated ceramic wire-wound resistor for the heater, maybe the connections to the heater have dilapidated.

Tube type

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

they usually are just open leaf contacts on a terminal strip

0 -

that is just uninsulated nichrome wound in layers separated by mica or kynar.

in the case of the hydrolevel it is probably more like 5v so the nichrome is much shorter since most of the voltage drop is in the water.

0 -

5 VAC across the heater resistor makes little sense. The Neon lamp would be on all the time. The voltage drop across the water has to be less than the firing voltage of the Neon lamp. So there is way more than 5 VAC across the heater resistor.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

150 vac is open circuit

0 -

It is what the OP measured, I don't know how the OP measured it, besides how much do you really think it drops in a situation like this ??? A resistor that makes the needed heat with the current going through water.

You think if you loaded the transformer down to just above the Neon lamp's firing voltage it would last very long ??? NE-2 lamp (for example) is about 65 VAC + your 5 VAC so if the transformer has to be loaded down by the water to below 70 VAC otherwise the Neon lamp will be lit all the time. So if the transformer is loaded to less than half its open circuit voltage how long is it going to last ?????

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

My prediction if @Daboosa gets it to work is something like this. For about almost 2 watts heater dissipation. And BTW I suspect the Neon Lamp assembly has it own current limiting resistor inside.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

yo should be thinking current rather than voltage. the resistance of the water is a huge unknown because the mineral content and the condition of the probe will change that resistance a lot. it would make a lot of sense to use the probe to drive a transistor in to saturation then you'd be working with known current through the timer. you can design the impedance of the transformer such that it keeps a relatively constant current so the voltage drop across the heater in the timer is relatively constant. obviously it has to provide a very low current at 150v for safety reasons so it would have to be designed for the voltage to drop as it was loaded by the water.

0 -

indefinitely if you design it that way. it is the same sort of physics as pump curves that are designed for constant flow vs constant head.

0 -

That looks like a plain old transformer, noting special like a current limited Neon sign transformer. I'm just working with what is there, not re-engineering it. BTW I had no problem getting enough current through plain tap water, I tried it.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

the problem isn't getting enough current, the problem is that it is going to vary widely depending on the tds of the water. if you have very low tds water the resistance will be much higher than if you have water with high tds. i don't know enough about xfmr design to know how you design to favor the current or the voltage being what changes when there isn't enough field from the primary to sustain what you are asking of the secondary but i'd imagine it has to do with the actual number of turns you use to get your needed turns ratio and the inductance of the core.

0 -

Good grief. You need one transistor and a resistor. Feed plus 5 volts to the emitter. Ground the collector. Connect the base to plus 5 volts through something handy like maybe 10K resistor. Connect the base also to the probe.

Probe in water? Base gets pulled down, transistor conducts. Do something with the current… maybe a bimetal time delay, maybe a relay… Probe out of water? Transistor shuts off, no current, relay flips.

Or use another transistor to reverse the logic on the sensing transistor.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Not sure why you want to re-engineer this thing, apparently that model worked for decades.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

some manufacturers are slow to move in to the 1950's. although the all passive component approach means you really have to abuse it to cook something.

then there was that primary control with the tube.

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements