IN6 : Cracked Heat Exchange.

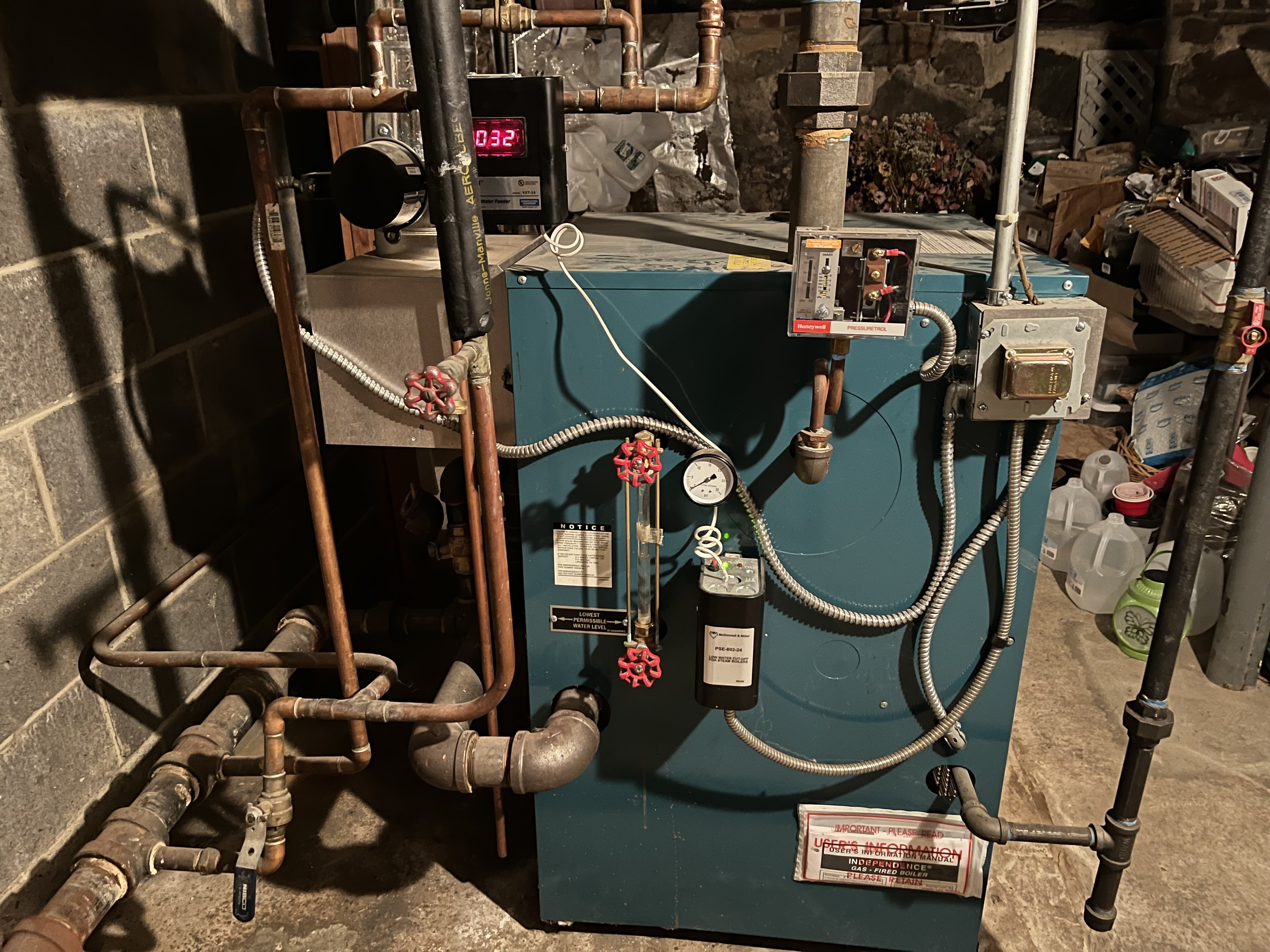

Four days ago, I’d called in a local company Heating & Cooling company to diagnose high water consumption on an IN6 gas fired steam boiler. They came out twice, checking the LWCO, feeder and exchanger (to some extent ). They diagnosed it as a cracked heat exchanger after hearing steam leak and moisture at the rear of the boiler from the hood area. I’m sure they did some other tests, but I’m not an expert, but did try to stay around the entirety of both visits to glean as much info. They have said I need a new steam boiler. I asked for a quote for which they did a radiator calculation, asked about our window and insulation as the home is older (circa 1865), but has newer double pane windows throughout and blown in insulation from the prior owner. Their quote for replacement was $ and suggested downsizing to an IN5 as they thought the IN6 was oversized. The boiler is only 7-8 years old, with a mfg date of 06/2108.

My wife asked that I contact the original installer, who has since been absorbed by another company, as the heat exchanger has a “10-Yr warranty.”

The company came out and after some Q&A disassembled the burners to look for up for any cracks. After noting nothing and no signs of water around the base, filled the boiler after cooldown and discovered the hole/crack at the top of the leftmost heat exchanger section. They proceed to take a bunch of pictures, and notes toward a warranty claim. I was close by when they called the mfg, and heard the Independence rep say that the heat exchanger was covered, but a $ core charge plus labor, or I could choose a rebate of $1,000-$1,500 on a new replacement Independence IN6 or SteamMax.

With the boiler being just under 7.5 years in use, I’m leaning towards replacement of the heat exchanger and awaiting an estimate from the original installer. I know it’ll be a lot of labor hours, so I’m wondering what the forum members who are professional heating and cooling contractors thought.

Notes about the system:

Independence IN6 gas fired boiler (spindle pipe steam) feeding radiators into (4) bedrooms, (1) bathroom, a family room, living room and front entrance hallway (approx 1,560 sqft). The boiler also has a separate hydronic loop pulling off it that feeds the kitchen, mud room and 2nd bathroom on the first floor adding approx another 295 sq ft).

Any help / input would be greatly appreciated and thank you for taking the time during the holidays to read through this lengthy post if you’ve made it this far.

Thanks.

Comments

-

Here are some images:

0 -

I'm sorry your Burnham Independence boiler only lasted 7 years. This story is all too common. To clarify, it is not a "crack" but it is a hole rusted in the top of a section casting.

The one thing I would not do is to put another IN series boiler into service. You'll likely be in the same boat in 7 more years.

Maybe a SteamMax lasts longer, but personally I wouldn't want to be the one to find out.

These boiler warranties are just as bad as tire warranties, IMO. You could try a lawyer if you have the means, but regardless there's no easy answer here.

On the topic of sizing, it wouldn't surprise me at all that the existing boiler is oversized, they almost always are.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

We can't post prices here on this forum but the price you quoted doe does not appear out of line.

Many on this forum love Burnham boilers. I for one am not one of those so take everything I say with a grain of salt.

Sounds like both companies have decent knowledge:

- make sure the boiler size is based on the installed radiation

- make sure they install the piping in accordance with Burnhams instructions (don't take this for granted that they know or think they know how to do this.) we get horror stories on this forum every week about installs that are not done right.

- the installer is more important than the boiler you pick

- make sure they allow for cleaning and skimming the boiler waterside

- It would be smart to correct any problems with venting (steam vents) and steam/water leaks at the same time.

- ask if you need a chimney liner.

That being said and with my disgust for Burnham I would stay away from the independence unless you are going to sell the house. The steam max is supposed to be ok I am told.

It would be smart of you when the boiler is selected to download the boiler manual ahead of time and read it and understand the piping.

Many times when a boiler fail it is a good idea to figure out why so the problem does not repeat.

Excessive make up water is one cause of a failure like you had.

Others will comment

0 -

Thank you both for the quick and thorough replies.

I just received the estimate for the heat exchanger replacement at $6.8K. The $700 core charge is in that cost along with removal, disposal, etc., but no mention of permits. They’re calling it a block replacement, so I’m assuming that’s all six sections of the heat exchanger and not just the one section with the hole?

I believe I should at least ask the company about the price of the SteamMax if I went with a new boiler. I see there’s an STMX150 which seems about right. I’ll take a look at the manual(s) of both. I don’t recall anything in the IN6 manual about a running a hydronic loop off it, but there was info in the manual about piping an indirect water heater off it. I wonder if the near piping of the SteamMax might be close to that of the IN6 as I have to believe that also adds to the cost.

Thanks for the reminder on skimming. Is this something done day ofor the installer would need to return a day or week later to do it?

Regarding the steam vents, all but one are original when we purchased the house in 2017 (mix of Groton, Hoffman, and one Vari-Vent). Never had any crazy hissing or water sputter. The initial quote of $12K did come with all new vents at the radiators, including the two mains in the basement. I’ll check for that if the other company can quote those out also on the SteamMax.

Thanks.0 -

One other item, though I’m not sure if relevant, is that the hydronic loop is on a separate thermostat than the steam heat. I do find that the boiler short cycles a fair amount when called upon. I think the aquastat is set at 180 degrees, but not sure of the differential setting, so I guess it’s mainly when the other thermostat is not calling for steam when the boiler cycles to satisfy the call for heat in the areas served by the loop.

I wish it was all steam in the house and not have to have a hybrid system, but I suppose I have bigger fish to fry with the exchanger or boiler replacement decision.1 -

i'd go for the warranty repair but wouldn't put another IN series in when that one fails.

how much make up water is it using?

0 -

compare the hydronic load to the pickup factor of the steam. if the hydronic load is less than the 30% pickup factor in the boiler output rating then it will have no problem covering that.

the hydronic gives it separate zoning which is usually desirable in additions or renovations because they usually don't match the heat loss of the rest of the house.

0 -

@1865 a block replacement is the entire heat exchanger. Everything else stays the same, jacket, burners and controls are used over.

Rediculuous that it failed so quickly. Plenty of boilers installed in the 20s and 30s still running and Burnham can't go 8 years.

Maybe a few more pictures of the piping above and around the boiler? The Steam Max is a whole different design which is supposed to have "solved" Burnhams problems. They blamed the issues on chlorides in the water and flue gas on one sided of the HX and steam on the other side instead of water. But who knows.

Their are other boilers besides Burnham. Weil McLain, Peerless and Utica.

0 -

With respect to warranty or rebate, it seems that I would be limited to Burnham. I’d say that the boiler is losing 2-4 gallons per day based on the auto feed number. It’s currently set to 2 gallons with a 2 minute delay, which takes it from the LWCO limit up to the normal water line that had been marked on the site glass with tape from the factory. I believe it had be set do the default of 1 gallon and 2 minute delay prior, but since the issue it was set higher to 2 gallons.

Regarding the pick up factor of the loop, the not sure how that is calculated. Along the loop there are (2) slantfin baseboards and (2) Hideavectors (?) in series. The Hideavector has a sort of multiple “S”ing of copper tubing with slant fin and blower motor. I have noticed that due to the hole in the heat exchanger, I now has gurgling in the loop from time to time.

I watched a video of a Burnham Independence heat exchanger being separated via a hand sledge and wedge. I have to imagine that exchanger is pretty darn heavy. Wondering how they “gently” replace a heat exchanger with messing up anything else. Worries me a bit. Like replacing it and screwing something else up in the process.

0 -

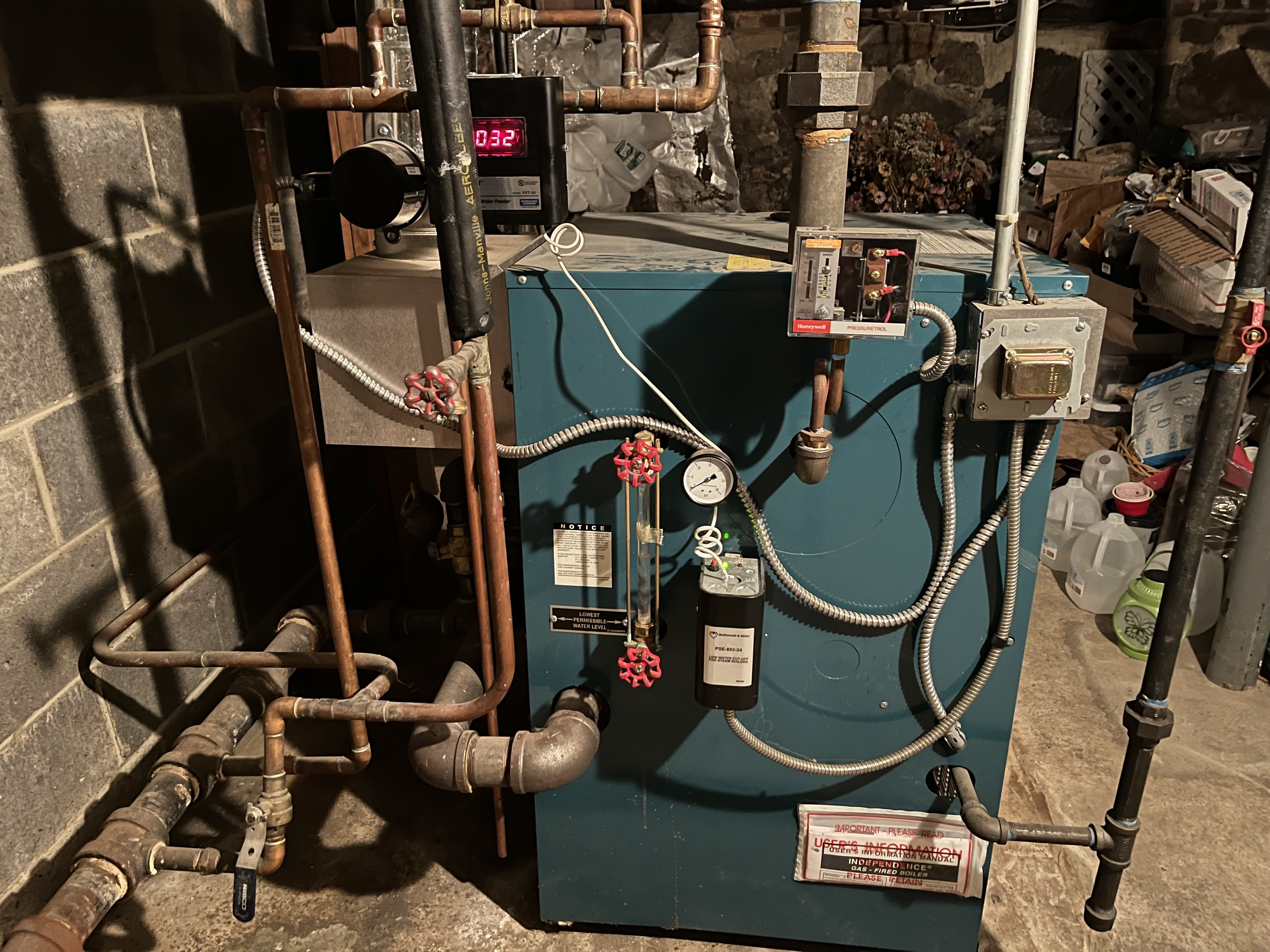

Here are some additional images:

0 -

@1865 , what would the warranty be on the replacement block/heat exchanger?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

if they are replacing the block they are replacing the whole hx, not just one section so they wouldn't need to disassemble it. they may assemble the new sections on site depending on if they get an assembled or unassembled block.

the pickup factor is part of the square ft of steam output rating of the boiler. if the boiler is rated 100 ft^2 of steam the actual output is 133 square feet of steam. 33 square ft of steam is the pickup factor. you would compare the edr of the connected radiation and the square foot of steam rating of the boiler and determine any excess boiler capacity. if the boiler is rated 100 ft^2 of steam and the connected radiation is 90 ft^2 of steam the excess there is 10 ft^2. you have that plus the pickup factor of 33 ft^2 giving you 43 ft^2.

1 ft^2 of steam is about 240 btu/hr so 43 ft^2 of steam gives you 240 * 43 = 10320 btu/hr of capacity for a hot water loop. i think you would look at the heat loss of the area heated by the hot water loop, not the output of the emitters. you would have to use your own numbers but in this example if the area heated by the hot water loop is around 10,000 btu/hr you would have enough capacity for the hot water loop.

0 -

Under the Burnham warranty, a replacement heat exchanger is a $700 core fee plus whatever the installer’s labor fee is. If I wanted to purchase a new Burnham boiler, I could receive a $1,200 rebate on another Independence series gas fired steam boiler or $1,500 on a SteamMax series.

I was going through the original installer to begin the warranty process. Originally, I thought to just take them up on the warranty replacement of the heat exchanger, but the labor is coming in at just over $6K plus the $700 core charge.

Now I’m rethinking it a bit. Likely less expensive depending on how one might look at it. Plus how many heat exchanger replacements doe installers do. I suppose entire boiler replacements are more common.0 -

replacing a heat exchanger is the same as installing a knocked down boiler where the boiler block and jacket are shipped unassembled to make it easier to handle and possibly to make it small enough to move in to the basement. it is something that companies that do a lot of boiler installations do frequently.

0 -

Replacing the block is no different than installing a new boiler for all practical purposes. They just disconnect the piping, wiring and the flue pipe. Strip the controls and burners off the old boiler and remove the sections and install the new sections.

Depending on the size of the boiler and access to the basement the block of sections may be factory assembled or field assembled.

0 -

Thank you all.

Am I assuming correctly that I or the installer of the heat exchanger will need to secure a permit prior to install and/or secure a post inspection approval from the town?0 -

If they just replace the block I doubt a permit is required. It's more of a repair than a new install.

If you go with a new boiler it would be the contractor's job to get any permits IMHO

0 -

Thank you again.

I was reading the tiny type of the estimate for the warrantied exchanger replacement and it mentioned that they (the installation company) cannot guarantee a functional hydronic loop (see below job description):

REMOVE EXISTING BOILER SHEETMETAL COVER, TRIM, BURNERS AND GAS VALVE. REMOVE AND DISPOSE OF EXISTING STEAM BOILER CAST IRON BLOCK. SUPPLY AND INSTALL BURNHAM INDEPENCE SERIES BOILER BLOCK ONLY UNDER WARRANTY. REINSTALL EXISTING BOILER SHEETMETAL COVER , TRIM, BURNERS AND GAS VALVE. RECONNECT HOT WATER LOOP. WE CANNOT GUARANTEE HOT WATER LOOP FUNCTION. ALL EXISTING BOILER PIPING TO BE REUSED. ___________________ NINTY (90) DAY LABOR WARRANTY ON _________________ CRAFTSMANSHIP ONLY NO PARTS. BURNHAM BOILER CHARGES 700.00 PLUS TAX FOR NEW BLOCK. PRICE IS INCLUDED.IMO, the installation company, knowing that it is a direct warranty replacement, should reassemble everything back to working order, both steam and hydronic loop. Is this too much to ask for?

With that said, the hydronic loop does not have an expansion tank and some time ago, the mixing valve on the bypass was turned off. Any additional work will add to the price, but would it be better to address these things on the hydronic loop now (if they are an issue), knowing what the they mention in the job description?0 -

you could ask them about it, weren't they the ones that installed the hydronic loop in the first place? why is the bypass closed completely?

0 -

The original installer of the IN6 was absorbed by the current company that will do the warranty work. I thought it best to go through the original installer (albeit they’ve been absorbed) to claim the warranty repair.

The hydronic loop was preexisting on the older system when we converted from oil to natural gas.

The previous system was a Smith 8 Series boiler (S/W-5) with DHW heating coil. There was also a separate electric HW heater, which I suspect was used during the spring & summer months as opposed to running the boiler for HW during the warmer weather. The electric HW heater was replaced with a natural gas HW heater during the conversion.

The only item that had been replaced prior to conversion from oil to natural gas was the circulator pump on the hydronic loop. It was replaced with the same Taco cartridge circulator model (007-F5-7FIC).

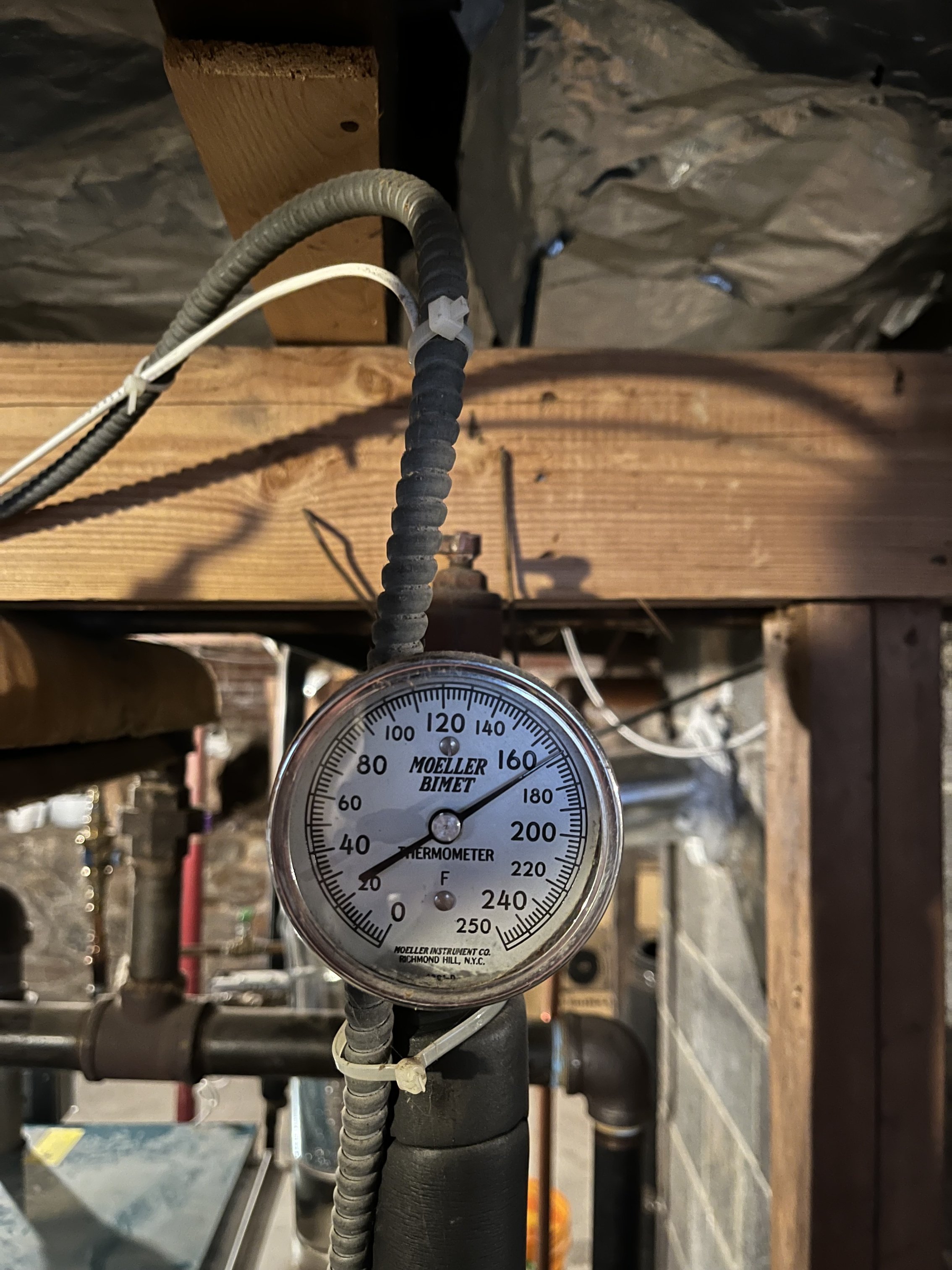

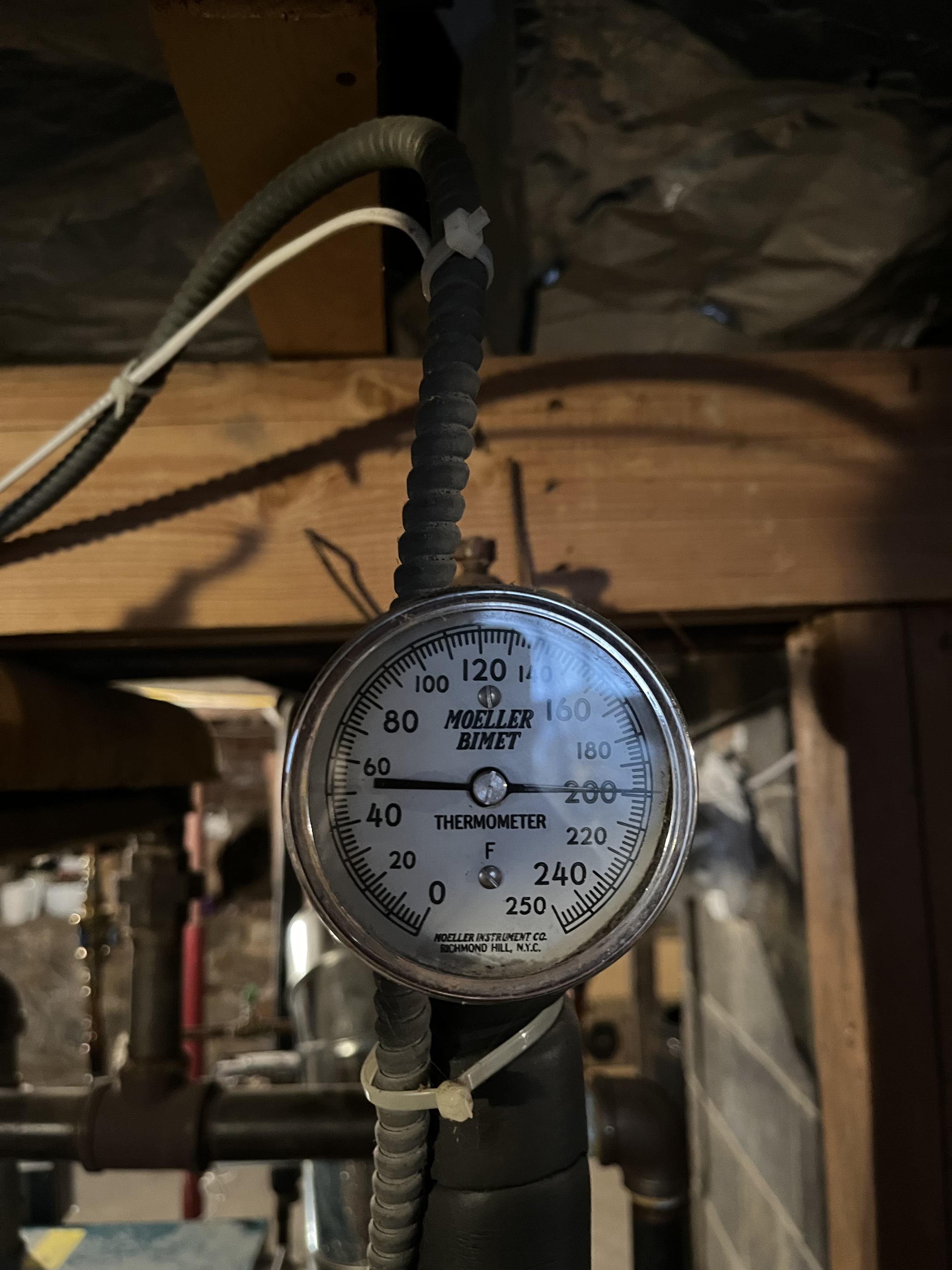

I’m not sure why the valve was closed on the bypass loop (see pic). The bypass loop connects just below the circulator pump.The boiler does seem to cycle a lot when the hydronic section of the home is calling for heat. The boiler will come on for a minute, and I can see the thermometer that is attached to the loop after the circulator go from 162 degrees to 200 degrees, then the boiler shuts off. About 4-5 minutes later when the thermometer falls back to 162, the boiler kicks in again. The aquastat is set to 180 degrees. The return water from the hydronic loop goes in to the boiler wet return, and the hydronic loop is being pulled off the bottom of the boiler.

0 -

is the bypass that pipe along the back wall? i don't even se a valve on it. if the load on the hydronic loop is small compared to the output of the boiler then it will short cycle

0 -

Isn't the bypass in the first pic? looks like a balancing valve maybe, like a tee with a screwdriver slot?

I wish the Smith model 8 was still made those were good boilers. Was it removed because it failed or due to the oil-gas conversion?

The quote looks ok but the way it is written they will probably look to charge you for any incendiential parts they need. IMHO I can't think of anything they would need unless they have to cut out some old fitting and have to replace them…..something like that.

I would definitely ask them if they see anything needing replacement.

It's the kind of job if I was quoting it I would include a #$$ to cover any minor parts.

0 -

Yes. That is the bypass that runs along the wall. Maybe I’m mistaken regarding a mixing valve. If you look at the first of the six images, there is a valve(?) with what looks to be a flathead screwdriver slot, that is perpendicular to the water flow. I believe if that slot was parallel to the piping, it would allow (at least some) of the hydronic loop return water from the bypass to mix with the (supply) water exiting the boiler before heading into the circulator pump and on its way to the first baseboard unit and so on until it returns into the bypass and or steam wet return. I’m not certain how much would return into bypass vs the steam wet return (visible in the fifth image).

If all of the hydronic loop’s return water is now going into the steam wet return and then into the boiler, I’m guessing that (when the steam zone’s thermostat is not calling for steam), the boiler water is constantly being cooled by hydronic return volume of water. If the bypass was open and (some) of the hydronic loop’s return water was allowed to mix, maybe this would help to lessen boiler cycling w/o changing the aquastat’s setting?

0 -

i see it now. that should be partially open. i didn't piece the multiple pictures together right and i thought that was a check valve until i looked closely.

the purpose of the bypass is to reduce the temp of the water coming out of the boiler which may be at or near boiling temps so it doesn't flash boil with the reduced pressure from the suction of the circulator or the lower pressure at the top of the loop. if there is a steam call or just was a steam call the boiler will be at steam temps.

the aquastat for the hot water loop should be somewhere in the boiler away from the loop flow. i can't tell from your pictures if that is the case or not. it should be holding the water in the boiler at 160-180 or so

0 -

mattmia2,

Thank you.These might be a better angle to see the how the aquastat is placed .

0 -

the aquastat might do better in a different tapping up higher or with a longer well. also what is the differential, it could probably be 30 or 40 degrees.

0 -

The aquastat (Honeywell L4006A) differential is currently set at 5 degrees.

The mixing valve flathead slot is a bit too mangled for me to rotate it. I suppose best to replace when they come up to install the warranty heat exchanger. Is there brand/type of valve I should be looking for or similar that could be adjusted with a flathead screwdriver?0 -

i'd just use a ball valve or a globe valve

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements