Hoffman 75 valves letting out steam

Hello,

I am the caretaker in a building that uses an old steam boiler (100ish years old, I think). It has a single pipe system, and goes to radiators in 19 units spread across four stories.

I have been in the role for just under a year, but this problem existed before I took over. It has been a problem for something like three or four years.

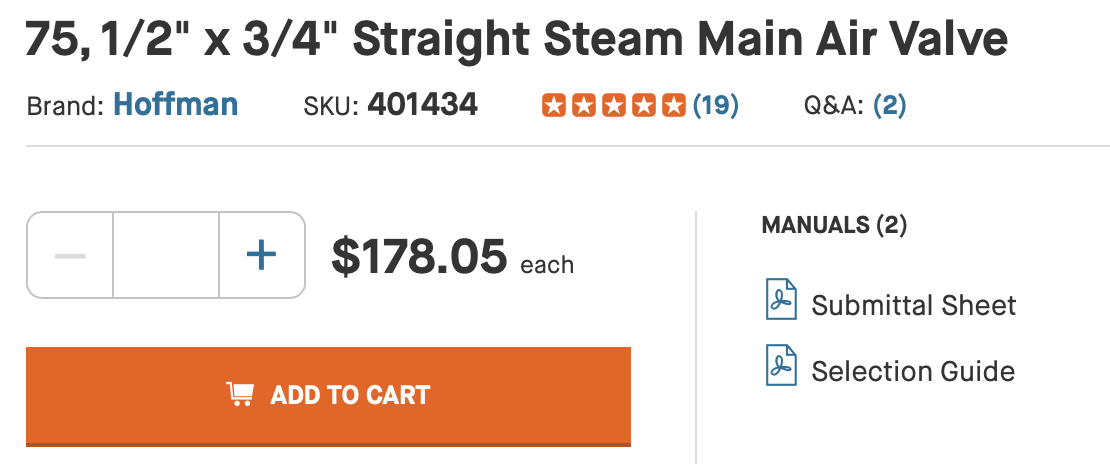

In the basement of the building we have two valves, both Hoffman 75s that consistently lose steam. It doesn't happen every time the boiler cycles on, but it happens multiple times a day on days when it is below freezing. If you tap the vent with a broom handle it works again, and the steam stops escaping.

We have tried replacing the valves multiple times, and that has not solved the problem. We have tried increasing the pitch of the steam line around the valves, and that maybe helped a little bit, but only minimally.

Does anyone have any other ideas?

Thank you!

Comments

-

What steam pressure are you running at? In most cases you shouldn't exceed 2PSI. The lower you run the better.

To much pressure can cause the vents to leak.

0 -

You've replaced them with what model? The same Hoffman 75 model? It's not a very good main vent in my opinion because it costs a fortune and doesn't have much capacity if I recall correctly.

Have you considered a different brand for your main vent such as Gorton?

Post a picture of the scenario near the vents and we can see if anything looks weird.

Look how much $$$!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

It is right around 2 PSI, I think lower. They installed a new pressuretrol and gauge not long before I took over the job. I don't know off the top of my head if they changed the PSI it was set too when they did that. The problem existed before and after those replacements were made. It is possible it has been set too high that whole time.

Is the distance between the vents and the boiler correlated with how much pressure affects its potential for leaking?

0 -

Is the distance between the vents and the boiler correlated with how much pressure affects its potential for leaking?

No

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

if the vent is undersized the higher velocity will make it more prone to propelling particles of rust from the main in to the vent or of there is water in the main. putting as long a riser as there is space for between the main and the vent will help protect it from water and dirt in the main.

you might be able to clean out whatever is contaminating the seat by soaking it in vinegar and flushing it out with water.

0 -

Here are pictures of the two vents. They are on different lines (one on each side of the building), both in the basement. The one in the last two pictures was replaced last week and is still releasing steam.

0 -

Vent tapping's on the side of the pipe are not the best but thats what you have.

I don't know if this will work but it may be worth a try.

Take the vent nipple and elbow off and just leave the short nipple coming out of the main. Put a tee like a 1 1/4 x 1 1/4 x 1/2 " with the branch on the short nipple coming out of the main. Put a 1 1/4 nipple and a reducer and the vent on as long as possible to get the vent up to the ceiling. On the bottom of the tee put a reducer and a valve to be able to blow the rust out occasionally.

It may not help but it will reduce the velocity going to the vent so any water will drop to the bottom. Cheap $$$ to try it. The vents belong on top of the pipe

1 -

you could also put a strainer somewhere in there to trap the particles before they get to the vent, if i were to do that I would do it in addition to the large diameter chamber with the 1.25" pipe.

0 -

Are the side tappings a problem because particles get caught in the elbow?

0 -

I would be more concerned about water getting into the vent. If the vent keeps getting slammed with water "water hammer" they will leak and fail.

0 -

Got to disagree with the quality concern. They are quite expensive. They have about half the capacity of a Gorton #2. But I find them to be very well built. Would not suggest dropping them. I think maybe I had a few bad ones a bunch of years back. But I have since installed many without issues. They are a lot smaller than the Gorton #2 and space is often the deciding factor

0 -

Did I raise a quality concern? If so it wasn’t intentional. I have no information about their quality

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

you could also put 2 or 3 on a tree to reduce the velocity through each vent which would reduce the likelihood of particles or water getting propelled in to them

0 -

-

no problem at all! I sure have had my share of misreads!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

So is the general consensus that too much condensate is getting into to the vent stems, because of where they are located on the pipes, making it so the water is being directed out of the vent rather than through the main line?

If I am understanding that correctly, are there ways to limit the amount of condensate in the system? Could I be keeping the water level in the boiler lower? Is the temperature in the basement too cold that it is causing condensation in the line or the vent stem?

I am just trying to narrow it down to the most actionable solution.

Thanks

0 -

-

Those side tappings will work, as long as everything else is OK. My guess is the mains did not have vents originally, and someone drilled and tapped the pipe to add them. It's also possible they tapped a smaller hole (maybe 1/4") and increased the pipe size going to the vent. Cut the insulation away to check this, as long as it's not asbestos.

@ClearBoiler , how long is each main, and what pipe size?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Would it be possible to see an example of the reducer you would use? (Or possibly an example of the whole set up?)

Thanks

0 -

use a reducing tee in place of the ell out of the main and a simple reducer at the top of the riser

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements