Indirect water heater as steam(water) to hydro zone HX (poor heat transfer)

My heat exchange from 200k res steam boiler set at 190degF to a 30 gal superstor set at 180degF is pathetic… looking at interior water quality after replacing a circulator I’m suspecting the SSU30 corrugated coil is totally fouled. Tank is 11 yrs old now. I inherited (as the service babysitter) the setup about 2 yrs ago. I’m considering a TFI Everhot external water heater, but also considering perhaps just a different brand of indirect tank… I’m done with HTP.

There is about 45k btu hydronic load connected.

I don’t want to turn up boiler water limit because I’m already getting passive steam heating when not requested, and the system is already wasting so much gas/energy.

Can anyone weigh in some thoughts.

Thanks.

Comments

-

clean the coil out with acid then raise the ph on the boiler so it produces little mud. pumping the coil full of mud isn't HTP's fault.

if you are just using it as a shell and tube hx you could run it the other way, put the boiler water in the tank and run the hot water loop water through the coil, then there'd be a lot more space for the mud.

1 -

Changing to a different brand of heat exchanger or even an indirect is not going to fix the problem: 11 years of lack of maintenance. As @mattmia2 suggests, spend a little time and effort to clean and descale the poor thing, and flush it out a couple of times.

If you do decide to splurge instead and spend a lot of money on a new system, also decide to maintain it properly so you're not there again in a few years.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I am the technician/operator that recently inherited care of this neglected system.

I wasn’t clear…I’m seeing significant fouling on the hydronic side of the system not the steam side… I expect steam side sludge… it has had wet side clearing service and water treatment, but I can absolutely appreciate the possibility of sludge on the inside of the coil.

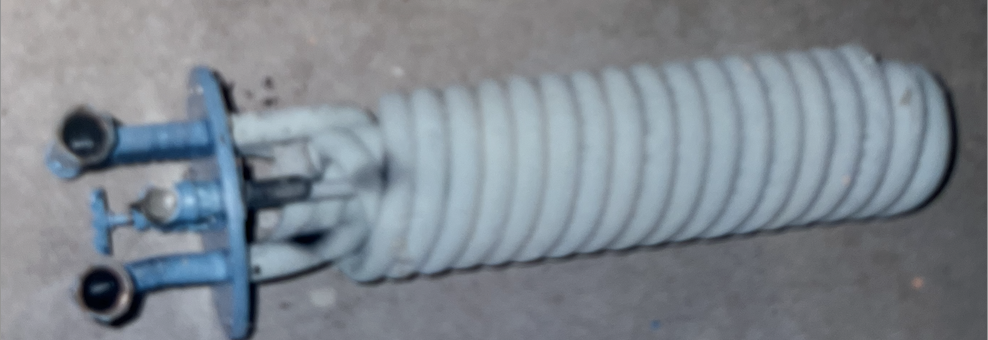

If anyone has cut open a superstor specifically, they will see the outside surface of the coil is fin-corrugated. I’m suspecting this is caked up. I’m pretty sure this system ran for years without adequate water content and/or functional air elimination. I’m trying to rehabilitate it now.

I’ll be sure not to speak lowly of brands in the future. Thanks for the check. Not a good look.

0 -

What I meant was, I’m considering changing to a different brand/style of indirect that has smooth faced coil.

0 -

To cleanse the outer face of the coil would be impossible now, wouldn’t you agree??

0 -

-

That was my question as well. Small pex radiant zone via mixing valve, and small fin tube baseboard zone. There is hardly any iron in the system. Maybe isolated to the circulator by low water content and poor air elimination.

0 -

Flush attempt on coil inside is a worthy endeavor because the hydronic setup barely achieves 130degF in 20degF outdoor.

0 -

-

-

or that

0 -

the sludge would be on the part of the indirect connected to the boiler. If that is the coil, then that is the sludged portion

If the tank is just the hydronic water, mineral scaling is possible. That is generally from ongoing fill water being added

Descaling the outside if the coil is not so easy

At that age??

Go with a smooth coil rank

Laars, bradford white, Lochinvar, Bock are some brands

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

whatever rusted the circulator is going to rust a steel tank too.

0 -

Thanks everyone. Very good points.

The pex appears to be the first stadler viega orange/white which I believe is barrier. Good call on that anyway. I have another job where I recently discovered bon-barrier on some radiant, after progressively changing noisy circulators that grew rust into the impeller.

I have make up water off at the moment and it appears to be holding steady.

I was looking at Bradford white or Ideal. Both are all stainless with smooth outer coil.

I’ll def be cutting this one open to see what the coil looks like.0 -

-

-

-

it is a superstore

0 -

Hydronic circ for sure turning. 3 speed Grundfos on steam loop showing water hammer at quick close of ball valve.

190 at coil supply, 5-10 below on coil return. With hydronic flowing barely getting to 130. If I close off supplies tank slowly recovers… I mean slowly. Worth looking in on the primary/coil circ I suppose.

$40 coil in there, $200 labor ;)0 -

This was my experience with a finned coil tank, less than 1 year into the tank the owner started to notice DHW production falling off. I did the boiler work, a different plumber supplied the indirect. Guess who sorted it out.

Yes it was hard water, but…

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

if the coil is removable you can dip it in acid and clean it. or maybe get 2 and rotate them. only $40 for the coil? put anti seize on the bolts so it comes out again later.

0 -

-

I’m saying cut it out for $40 scrap retrieval. Haha

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements