Boiler Sizing

I am in the process of getting estimates to replace a cast iron boiler for a hydronic baseboard system. I would like some recommendations for doing or getting a heat loss calculation. My only reason is my current boiler is a burnham propane 205 w/DOE rating of 135k and IBR rating of 117,4k.All my est have quoted 199k condensing boilers.Some have measured baseboard (180 ft 2 zones 2300sq/ft 2 floor over basement) some just look at the piping but their answer for the size is it's a turndown boiler we can set it lower. Seems kind of like buying a corvette to drive in a parking lot.Where would a good place for a heat loss est be? I am looking for a condensing boiler just for some efficiency gains

Thanks for any advice you can give

Comments

-

I like your analogy. Or an F350 SuperDuty as a grocery getter?

There are three ways, really, to size a boiler for hot water heat. The best is to determine the actual heat loss of your house — what is called a "Manual J" estimate. But that may be overkill. The next best is to look at how much fuel you have used in the past versus historical climate information. That works well, but tends to underestimate a bit for extreme conditions. The third is to measure — as you have done — the radiation which the boiler can power and not get a boiler bigger than that. In your case, for example, figuring around 500 BTUh per foot of baseboard that would be around 100,000 BTUh output power.

Yes, a modulating boiler can and will turn down to match the load (if it's set up right), but there's no need to go way oversize just because it's handy.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

180' of 3/4 fin tube total in the home? Is that the actual fin, or the enclosures lengths?

180 X 500 btu/ ft output = 90,000 btu/hr. That is what the fin tube can deliver to the home. So really no need to size the boiler above that unless expansions are planned? Your current boiler may be spot on?

I too would like to see a load calc for the home.

Suppose it came in at 25 btu/ ft 2300 X 25= 57,000 btu/hr required.

The good new is you have that much "fin" and a smaller load is you could run the boiler at lower temperature.

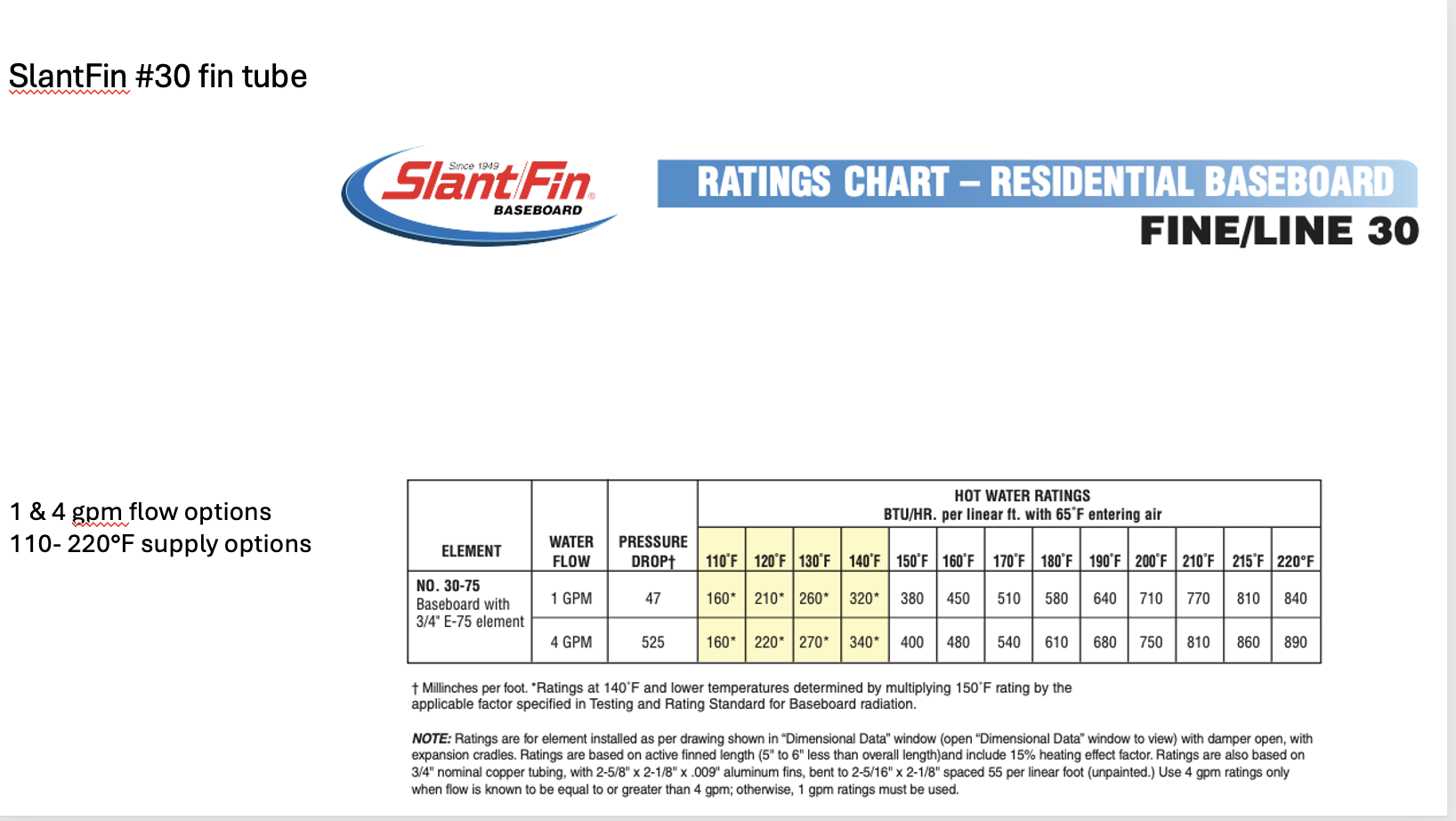

Here is an example of a typical fin output.

So if theses numbers are accurate you could heat the home with 140- 150 SWT= 320 btu/ft X 180'= 57,600 btu/hr!

Furthermore 80% of the heating season you are below design conditions, this data is available from local weather databases. An example here.

Now a mod con really makes sense, as you will run high, 90% plus efficiencies. They come with ODR for an added benefit and it modulates as one or two zones call.

Unless they are bidding a combi boiler which needs the high btu for DHW production?? You could be looking at something like an 80,000 btu/hr modcon.

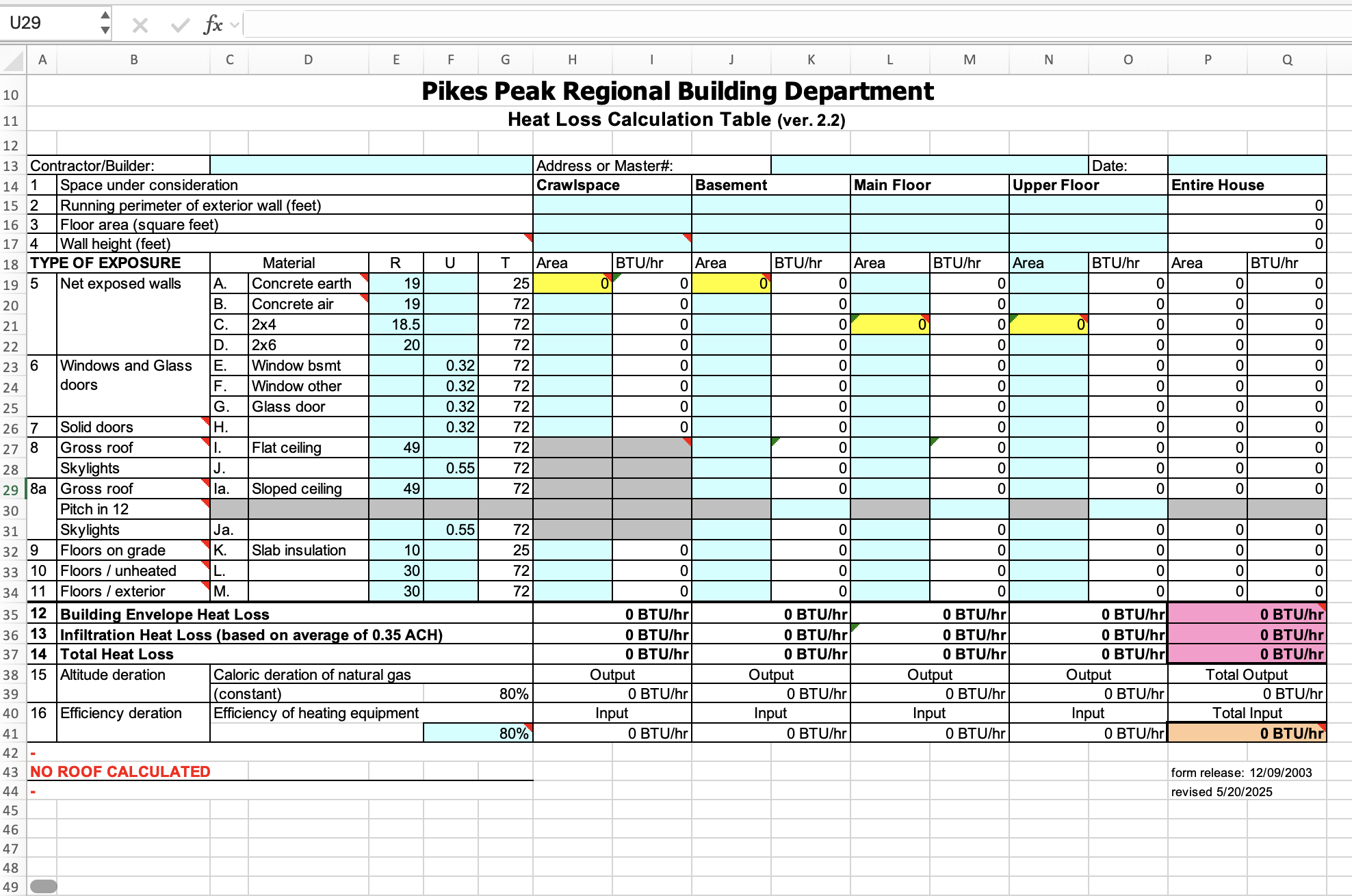

So do the load calc, confirm the amount of finned tube, and see where you end up. If you want simple and accurate, are good with Excel, here is a calculator at the Pikes Peak building dept website.

I use the load program at www.hydronicpros.com, they have a free demo.

US Boiler has a fairly quick, simplistic calc program.

Some prefer the fuel usage method the Green Builder promotes.

More info if you download this free journal

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks for taking the time to respond.DHW is not a factor as i switched to a heat pump WH last year. 180ft is close as all units have fins to within 2 in of housing ends,although my 2nd floor zone is only 50 linear ft(2 bedrooms and a bath)and could use an extra 15 ft as the wall with the prevailing wind is the only one without a rad. I was just going over my propane bills from last year and i used 667 gals.I used the 65 deg heating day calc closest to my location (08867) and came up with 4800-5200 depending on weather stations. It just bothers me that they dont take certain factors into account(Spray foamed accessible roof spaces and basement joist bays,kitchen floor over crawl space and air sealed knee wall on 2nd floor).I will put in some time this weekend using some of the resources and post my results.

0 -

Certainly the more you do, or has been done to lower the heat load, reduces the boiler size, lowers heating costs.

If the envelop has been upgraded over the years, a good chance the the fin tube and boiler is a bit oversized.

The load calc is just a best guess

With a mod con, say a 60- 80,000 they can be derated to the actual load. The 80K models can often turn down or be locked down to around 8,000 BTU/hr!

You get rid of the flue and any combustion air openings with a mod con, that takes some infiltration load away.

A bit oversized with a mod con is not a problem. But really no reason to put a 199,000 in a home with a load at or under 50K

If you take the time to dial in the ODR you can get near constant circulation, the boiler adjusting it's output to match the ever changing heat load.

That would be an ideal system, the boiler fires in October and never shuts down until April or May. The flame just modulates up and down throughout the heating season.

My money tells me, with those building upgrades you may be under 50,000. That would be 1/2 the size of the boiler you have now!

If you are a risk taker, put in a 55,000 mod con.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

As others have said, you wouldn't be able to push more than 100k through 180LF of element so a boiler larger than that would be rather silly. There is the fact that your HPWH is robbing its BTU from the space so you have a higher load than the baseboard alone (consider hot water another zone, I suppose, of roughly 15k BTU). With that said, only 667 gallons with an 80% boiler and 5000 HDD, your actual heat loss is probably closer to 60k plus the DHW load from the HPWH so 75k worst case scenario. "Contractors" who throw a 199 at everything because they modulate, are people you should stay far away from. My advice would be to keep getting estimates until you find somebody who actually knows what they're talking about. Needing to tell somebody what size boiler you need should be an immediate disqualification.

1 -

“I was just going over my propane bills from last year and i used 667 gals.I used the 65 deg heating day calc closest to my location (08867) and came up with 4800-5200 depending on weather stations.”

can you get dates on these? How many gallons used per heating degree day means we need start and end dates. But based on that - you have a low heat loss. 100kbtu with a turndown to 10kbtu is nearly perfect. You could do 80kbtu with a turndown to 8kbtu, but that’s marginal.0 -

Crunch the load numbers a few different way, fuel use and the Manual J programs.

If you can get by with the 80, the low turn down is a bit lower, around 8,000 btu/ hr

The 100 will be 10, 000 or so. Most boilers are 10- 1 turn down, some 5-1.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements