Mystery water leak - excess water take up problem

Comments

-

NH state law gives a home owner the right to do their own electrical work, in an owner occupied non-rental unit. However, the home owner's work has to comply with code. Local governments are allowed to require permits.

0 -

I've had 3 people over today.

One appears to be what would be affectionately called a "knucklehead". Don't think that one is much help. Was threatened by my knowledge of steam heat. Didn't understand the leak test that I had done, even after a couple explanations. Asked me if I was a plumber, and why did I need him. I said I believed that I needed a new boiler, and would he quote me one. He didn't seem to trust or even acknowledge what I had told him. He was incredulous that I had calculated out the EDR, from measurements, and Dan's EDR book.

Second fellow had a minor reschedule due to an emergency, but then called and showed up. The second contractor gets it. He was quoting from our favorite book. He's read it multiple times, cover to cover. We had a nice chat. He understood the water fill test that I had done. He will get me a quote today, with some options. He indicated he had an opening on Monday, which is very good. He grew up with steam in his house.

The third contractor was decent. Actually showed up on time, which seems to be rare these days. Not sure he really is a steam person, but was amenable to various options. He has been in the business a while, knew all the players locally. ( I knew them as well.) Felt comfortable discussing things with him. Pretty sure he understood the implication of the water fill/leak check.

Hopefully I get two or more choices to evaluate.

0 -

my guess is, it will be the price of the boiler plus 2x that price for labor.

»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog0 -

-

Shot in the dark here for a very temporary solution…. If you remove the jacket as others have said, maybe you can find the exact source of the leak to add some Hercules Boiler Liquid if the leak isn't all the way at the top.

Maybe it is an inch above the normal water line. You could add the Boiler Liquid and fill it just pass the leak and get a few more days/weeks out of it. Might seal it up enough to limp by.

0 -

Beats me what boilers cost these days. I know what an install cost in 2013 though.

I think #1 up sells on maintenance plans. To some extent they are good, especially if the home owner cannot attend to some maintenance. But the guy that #1 sent, seemed to be taken aback by what I was saying. Oh well, you'd think they have heard it all by now…

0 -

Thanks for the suggestion. There one panel that I could open, without piping interference, maybe something is visible there? I'll check the installation manual, just to check that nothing weird will happen if I loosen those screws.

Don't think the leak is near the normal water line. I had to fill it above the sight glass and nearly to the steam exit port (at the top) before I saw any water coming out from the block. I filled the boiler slowly, mostly because I didn't want a flood, but to get a rough idea where the leak might be. The water level was pretty high.

In any case, I will have to limp by. At best, maybe, with some good luck, I could get an install as early as Monday. It will be 4F tonight, so that boiler's going to be working hard. Hope the boiler retains enough steam (the hole doesn't open up) to keep the house warm. I have some electric heaters, I'm going to set them to 63F or so, just in case.

0 -

I'm in MA and it is scheduled to be 3F tonight. Murphy's law right? Boilers never fail in spring when it is 60F out! Perhaps you can set your thermostat low as you can to try and make it work as little as possible. 55F, 55F, 60F?

Leave the water faucets on a trickle (hot and cold) as moving water doesn't tend to freeze as fast. Save the space heaters for the areas where pipes have a history of freezing.

Last suggestion…If your boiler cycles on pressure, meaning when it runs it eventually hits the pressuretrol limit… try and lower that limit if you are comfortable doing so. I see yours is set at 2psi which is correct. Perhaps others who know that pressuretrol model can comment on if it can reliably be set lower.

Lower pressure might help it from losing steam as fast. Food for thought.

1 -

Good idea on the trickling water, will have to remember that tonight. Those space heaters are going where we had a freeze up. (-17F night, howling wind too! Other than that, never had a freeze.)

I don't know if it's cycling on pressure at this point. Don't have a low pressure gauge on this boiler. Previous one I had installed a 3 psi gauge. With a 30psi gauge, you can barely tell if it has moved off the peg.

Think I am set at about 1psi (or 1.5) with a 0.5psi differential, might be a parallax error or camera angle that makes it seem higher.

0 -

Installing and piping the boiler correctly according to the manufacturer’s instructions is extremely important on a steam boiler. They are the MINIMUM standard. Two risers with a drop header is an upgrade that’s well worth it as it will assure dry steam is sent to the system.

Make sure that whoever you select guarantees that they will at least pipe it per the manufacturer’s instructions as well as do the initial skimming.

Also make sure it’s done in black iron - no copper above the water line.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

leaks like that usually form slowly, it likely was leaking all of last season at least and was unnoticed until it started losing huge amounts of water. If you can get to where it is leaking some jb weld and a wire brush and maybe a metal plate could probably keep it going for a few weeks to months. Could probably pack some lead wool in the leak too.

1 -

I got a price from contractor #2, a steam guy. Seems reasonable, and not that much more expensive than what it cost in 2013. What's unreasonable is the fact it croaked to begin with. But this is not the fault of #2.

I'm going to sleep on it. And ask a couple of questions of him. Haven't heard from #3 yet, that gentleman said it would be tomorrow. Will decide what to do hopefully tomorrow morning.

Need to get this fixed. This heating plant stuff has already prevented me from visiting family, which makes me unhappy.

0 -

Since the boiler is shot take some tin snips to the jacket or whatever you have to do to remove the jacket and find the leak. It can't hurt to try, and you have nothing to lose.

1 -

you can just cut it and bend it where there are pipes in the way if it makes you feel better if you put it back when you're done.

0 -

it doesn't look like the top of the jacket is trapped by the piping and that is where i'd start looking.

0 -

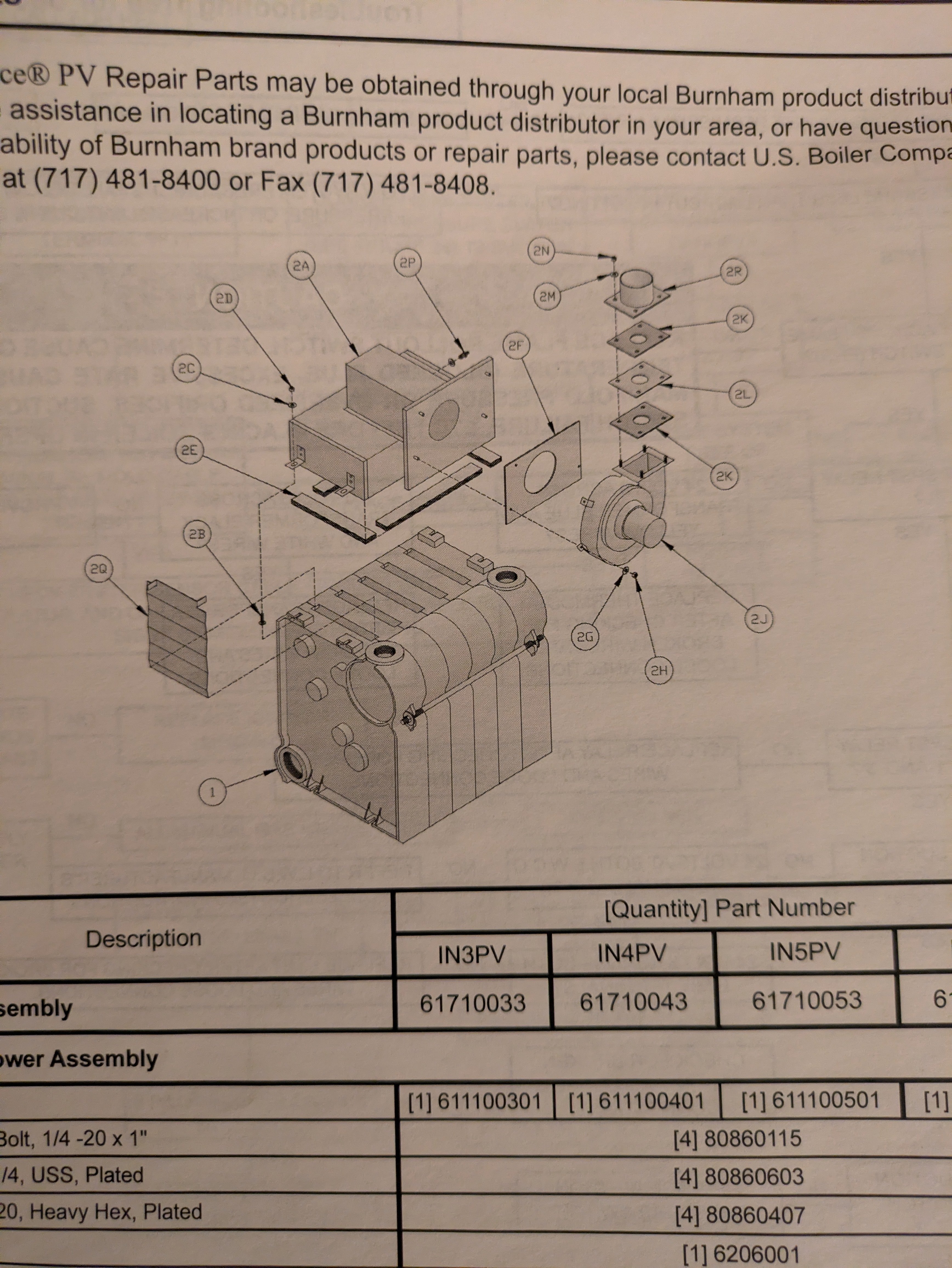

Looking at the parts diagram, the block is 100% covered by the canopy/blower assembly. It would seem that a total disassembly would be required. I'm not willing to do that in this winter season.

I take apart cars and work on them. I can machine things, I have a lathe and a mill and welder. I repair all sorts of things. But I also know when to hire someone for things that I can't or am unwilling to do. This appears to be one of them, especially since it's cold now. It's currently 17F with a 20mph wind and cooling down to 3F or 4F, depending on which weather server you use. I feel the risk is too high for me to pull it off. Could I do it? Probably, if I don't break something.

Will I risk a frozen home to try this? Not a chance. Now if I had done something similar in the past, maybe I'd give it a try. Having seen a frozen home before and what it looks like up close, and knowing that it only took 24 hours to cause over 30K in damage, (that was in 1980 dollars) I'm hiring someone. Someone who has done it before. I have never seen such devastation in a home. Boiler block frozen and split, washing machine cracked open, toilets burst, dishwashers ruined, pipes burst, ice on the walls and floor. Wallboard and plaster ruined. And this over powering feeling of being in a frozen tomb, where all the heat was being sucked out of your being. It was cold in there. It felt so much colder than outdoors. It was ghastly. Wasn't my house, it was my grandparents. Anyways, it made a deep impression on me.

0 -

I agree the top isn't trapped. As noted in the previous post, the block is covered by a canopy assembly. This is getting in deeper than I am comfortable with. In the spring, summer or fall, I'd give it a try. With the wind blowing and the temperature dropping rapidly (now at 16F), I'm not willing to try, especially tonight.

0 -

are you in michigan because that is what seemed to be happening on my ride home from work just now.

0 -

-

I want to make a point of thanking everyone for their suggestions. I think all of them were good ideas to try. Not all of them are within my skill set, or confidence level, but all are greatly appreciated. My apologies if it appeared I didn't like or valued your suggestions. This is not the case. I think this is a valuable community providing a great service to people.

3 -

Well the replacement is done. My contractor did a pretty fine job. He was pretty thorough about testing the boiler, including testing all the sensors, including the pressuretrol.

Had a minor event when a vent failed on me. Gorton #6 vent failed to close, and also got some pumping out of some darned hot water. Not the contractor's fault at all. That radiator was hot, but water had gotten pushed up the pipes. Only place where there was an issue. I know the piping is marginal there, but I just am not going to finance that modification. If I slow down the vent a little, the problem will disappear.

It's nice not to heat the outside world (via steam escaping the flue). My wallet will like that. Also nice to be in a warm house again.

0 -

Well, I think I have wet steam. Terrible racket at start up. Water being pushed out multiple vents. Is this just more skimming? Boiler water in sight glass isn't pretty, kind of dark. I mean a week ago, my vents were all fine and apparently working.

I kept the same drop header, and plumbing. Should just be the new boiler blues, with crud that needs to be removed?

0 -

A new boiler needs to be skimmed multiple times. The oils from the manufacturing process inside the boiler cause surging and wet steam. Draining and refilling the boiler will get some crud out of it but oils float to the top and will cling to the metal. Skimming is the process of removing the oils.

Side topic. I know you said you intend to move out in the not too distant future…how long are we talking? I know you don't want to invest any more money but now would be a good time to address and main venting or radiator venting inadequacies. Fine tuning (minimizing) the boiler operating pressure would help too.

It will yield a cost savings through efficiency and make for a more balanced comfortable house. And you'll be setting the future homeowner up for a trouble free heating system.

1 -

Thanks for your comments. Previous new boilers were full of crud, so I'm not surprised that this one needs more skimming. But this one is bad right now. So bad, and so much wet steam, that 3 Gorton vents failed today. None of them closed, and they were pumping out black water. One in my bedroom, one in my bathroom and one in the kitchen. The puddle in the kitchen was about 8 feet long.

I called the plumber back. I prevented the boiler from firing until he got there. He could hear the steam hammer, and immediately started looking for classic issues. We replaced radiator vents. He found a pipe that was level rather than having some pitch. Fixed that. He then noted that there wasn't a main vent at the end of the line.

I explained, that I had installed that tee, and initially installed a main vent there. I said that vent failed within a few days and was geysering water. So I plugged it. I also noted that the system behaved ok with the plug, for the last decade. He said there really should be a vent there, and I agreed saying that's what the book says, but it didn't seem to work in that location. He talked me into installing a vent there. Put in a Ventrite 35. It seemed to work.

However, after he had watched a full heating cycle, he left. He checked for the differential cutout was working, and loads of other things. But apparently, it wasn't enough. The next heat cycle was when everything went to pot again. On a cold start, less than 3 hours after he left, that Ventrite was spurting water, just like the old one I had installed a decade ago. The vent is within 6 inches of the floor above it. The floorboards were wet. And the 100A electrical service cable that ran on that joist was wet too. And my dehumidifier, and my milling machine table. Oh, and the steam hammer was back. I was kind of mad. I undid that vent, and plugged it again. At least my machine shop won't be damaged.

The issue is primarily cold start. Restarts on pressure cycling are generally ok. I'm at 1.5psi cutout with a 1psi differential. Probably needs 2 more skims.

As for leaving. I hope to sell in the next 1-2 years. Hopefully before 2 years are up. I had dialed in all the radiators without a main vent, using the venting guide on this forum. I had used Gorton vents for all my radiators. Good lord, they are pretty expensive these days. Now, some of my issues could be that 3 Gorton's failed. I don't know how to test them correctly, but all vented pretty darned hot water onto the floor, multiple times. I don't think they are supposed to do that. But all I know is the heat distribution tonight is terrible, and for over a decade it was great. I spent a lot of time in the past dialing in this system, buying two of Dan's books, and was successful at it. I'm surprised that an exact replacement of the boiler, reusing the original piping is behaving so different. Could it simply be just more skimming?

0 -

One thing I don't have (thankfully) is a hole in the block. Outside, you really can't tell the burner is on.

I get some terrible cold start banging. At the end of the main, I hear water being pushed into the furthest radiator, the steam or air is gurgling through water. Tons of banging. Eventually the system turns off on pressure. All the water drains back to the boiler. The next start is more normal and significantly quieter. Behaviorally it is like it's way over fired or still terribly full of crud and oil.

0 -

show the far end of the bad main, does it drop to the floor as a wet return, or stay high as a dry return?

wet return? is it clogged, not flowing?

known to beat dead horses0 -

Not a wet return, it's a dry return. Mostly One pipe steam. 8 radiators are one pipe. 2 are 2 pipe. The two pipe radiators sort of changed character. Maybe it's just another vent failing, another Gorton.

Might be a red herring, but this guy wanted me to close off some valves to radiators when it was first fired up. Many of those valves hadn't been touched in decades. Some of them turned and I closed them. Later, I opened them back up (fully).

In a way, it feels like all the stuff that I had done 15 years ago to balance the system got undone. But all that had physically changed was the boiler, and me turning all those valves shut then open. And perhaps the ravages of time.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements