LAARS MASCOT FT 140 k model

any help will be appreciated. Thanks

W

W

Comments

-

I was working on the exact same model boiler yesterday.

You need to confirm whether or not you have flow in the house loop before assuming that the 3 way valve is bad.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

And how can you do that. I checked the circulating pump electrical and it get power when I call for heat.0

-

With a heat call, feel the temp of the system supply and return lines a few feet past the boiler. There should be about 15-20* difference after it's been on for a while.

Then feel the supply and return coming out of the bottom of the boiler before the manifold. They should be about the same as the system lines. If they are extremely hot, and the system lines are substantially cooler, then you don't have circulation on the system side.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Thanks bob for getting back to me. So I had the unit running for 15 min. Pic 1The pipes inside the unit are hot, the pump is hot too. Pic 2

However the outside piping is cold 56deg ( basement temp) pic 3

0

0 -

If the DHW function is working, the internal circ is flowing water. This is a very common issue with these, the 3 way is stuck. They don't always throw an error code0

-

Thank you very much for the reply Groundup. It seams like it’s the 3way valve.I purged the lines, I descaled the exchanger. I also checked the zone circulating pump and it seams to work. I will give the 3 way valve a try0

-

If the pipes between the the bottom of the boiler and the manifold are both hot, then its not the 3 way valve, its a SYSTEM circulation problem.

There's also a strainer at the pump inlet on the bottom of the boiler. Caution: you have to valve off the boiler and depressurized it first.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Thank you guys for the insights. I ended up replacing the 3way valve, and it’s working good. Now the zone pipes and heaters are hot, a Temperature are about 112 to 95 ( in - out).If someone this issue in the future there is a good video on YouTube

https://youtu.be/9eJdG3bG84k

https://youtu.be/9eJdG3bG84k

Or you can just type laars mascot 3way and come right up.For those who took time to provide their expertise, thank you very much. his

his

0

0 -

-

The piping between the boiler and the purge tee was coldIronman said:If the pipes between the the bottom of the boiler and the manifold are both hot, then its not the 3 way valve, its a SYSTEM circulation problem.

There's also a strainer at the pump inlet on the bottom of the boiler. Caution: you have to valve off the boiler and depressurized it first.0 -

All that rust is not a good indication. It's probably the cause of the failure.

That system needs to be properly flushed and cleaned and a dirt mag installed on the return. Also, any leaks need to be located and repaired.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.2 -

Bon,

i did flush both the heating and the DHW loops using city water, is there some kind of liquid that can be Introduced into the system to clean the inside pipes?

i already descaled the exchanger0 -

-

-

-

I’m wondering why more manufactures don’t use the Caleffi made three way valve that is in the Lochinvar Noble combi.0

-

-

This is one of the reasons why we shy away from wall hung combi units. To much reliance on poorly manufactured components to operate once heating or cooling equipment.1

-

The cost of the 3 way valve is around $80, and it’s covered by the warranty. Actual replacement $, out of pocket. Go figure! These manufacturers come up with crappy products and hide behind their warranty.0

-

I know this is a few years old but I’m considering one of these and I’m curious these still experiencing similar failure points in the 3way valve like some of the other posters say? I love the idea that it seems like it’s easy to work on and parts are available and normal O rings everywhere0

-

Looking at the water in the bucket and the rust build up inside the valve body, that is not a manufactures defect. A squirt of conditioner in every boiler you install could prevent most of these type of failures.

Assuming the system is leak-freeBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

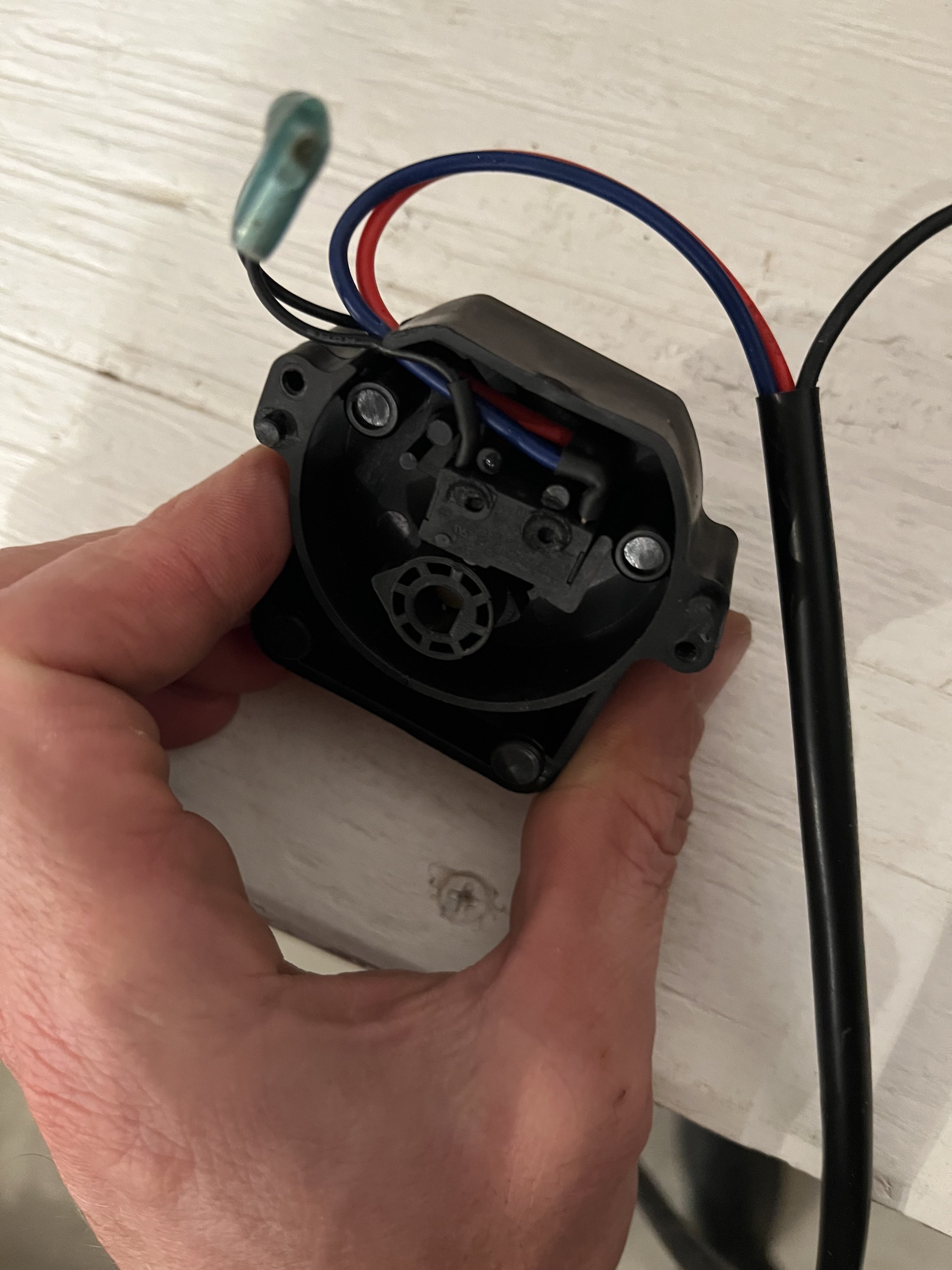

I was having the same issue and couldn’t believe the 3way was faulty so I dug deep on this and found micro switches under the cover, one had failed, carbon on the contacts, was able to clean up and get it going. Couple bucks on Amazon if you’re so inclined. PN KW4A(S). They’re plastic welded onto a couple pins and I got lucky they popped right out.

Found two part numbers for the 3way ft1220 and ft2071, maybe the new one is improved.

Anyway mines all rusty inside but that wouldn’t cause the micro switch to fail… I’ll try the conditioner as suggested.

hope that helps0 -

Wanted to add that I had no error codes. Symptom was hot dhw but no zone heating. This was caused by the blue wire switch failure and can be tested with a continuity test between the blue wire (follow wire up to a blue, red, black connector on the main board) and the double black wires on the actuator motor. They are normally closed switches so blue circuit should have continuity in dhw mode and red circuit should have continuity in ch mode.

0 -

Good work everyone! Nice sleuthing and solving.

0 -

Short, succinct discussion. Good pics. Very helpful to all.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements