How do I correctly add water to boiler system?

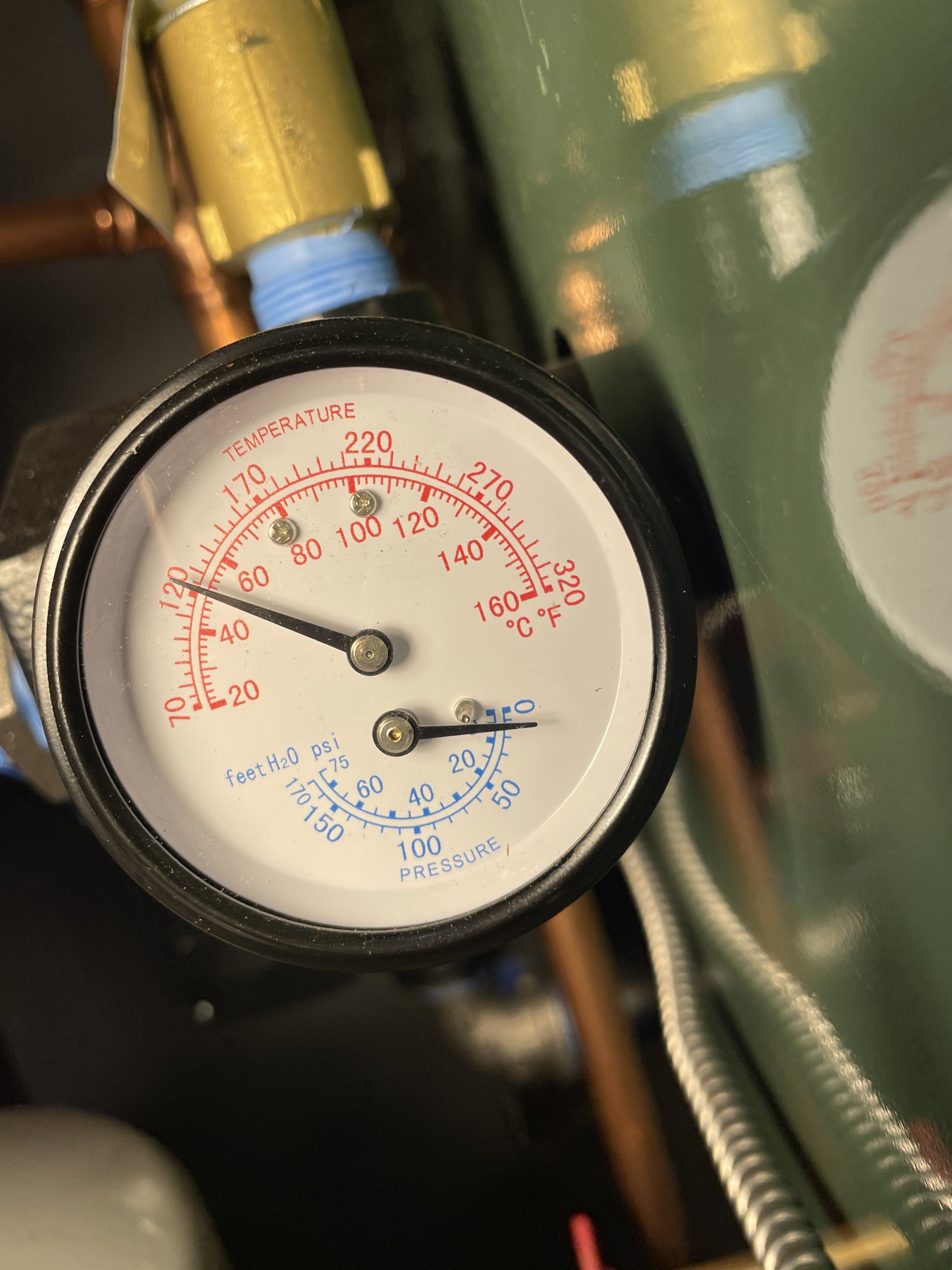

I recently had a new cast iron water boiler installed in my home. It replaced a 70 year old system that was failing. Even though this new boiler is a simple one zone system, it has way more components and valves than the old one. The old boiler had one water supply line valve. I would bleed radiators, the water pressure would drop, I'd open the valve and add some more water and then bleed again until all the air was out of the radiators and the pressure was at around 20psi.

This new boiler has what looks like 4 water supply valves: one large one before the back flow preventer, two little green valves on either side of the back flow preventer and one just above the boiler. An internet search suggests the two on either side of the back flow preventer are so it can easily be serviced without draining the system. Is that correct? What is the correct procedure for adding more water to the system? Should I let the boiler cool, open these 4 valves to add more water and bleed the radiators the same way as I did with the old boiler? I want to do it correctly. I'm planning to have a professional out once a year to do a tune-up, but I want to be able to do basic maintenance like this and also be able to drain/refill the system because I sometimes need to replace failing radiator valves. See pic of 4 valves

Comments

-

Right now the green valves are vertical, meaning they are closed. They should be horizontal, meaning open. Turn them horizontal to allow water to flow through it. I would keep them open always since you have a ball valve downstream of the backflow. Do you have a pressure reducer downstream the white handle ball valve that is also closed based on the orientation it is currently in. If there is a pressure reducer downstream of it, I would open that ball valve as well as long as the pressure reducer is set to 12 assuming this is a water boiler and not steam

0 -

That will work just fine.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Also 12 psi is usually default setting on the pressure reducer but you said pressure is usually at 20 so you will probably need to bump it up

0 -

This is the orientation the installers left it (all 4 valves closed) so I hesitate to change it. 20 psi was just a ballpark I would fill the old boiler to

. The installer told me a range (something like 12-20psi) was fine and of course as the system heats up the pressure rises.

I can look for a pressure reducer, how does that affect adding water to the system? Do I need to be concerned with it?

The installer told me to wait a few weeks and bleed radiators again. I did one radiator and the pressure is not high enough to bleed the second radiator.

0 -

The pressure reducer will automatically add water to the correct pressure that it was set to based on what your system needs. You may need more pressure if radiators on upper floors are not getting flow. Is the expansion tank old or new?

0 -

A new expansion tank was installed with the new water boiler. The original one was huge compared to the new one.

I'm going to add water, but since I have no experience with this new boiler or back flow preventers, I'd just like to know exactly how to do it. Probably a dumb question, but does it matter what order I open the 2 ball valves and the two green valves? I'm inclined to first open the green valves and then the up stream ball valve and then the down stream one, but maybe it makes zero difference.? I don't want to damage the back flow preventer with a rush of water pressure.

0 -

-

Are there any valves that I should shut off before adding water to the system? Such as valves to the expansion tank to keep water from entering it or is that not an issue?

Also, in the last photo I posted there is one valve that is just cracked open a little. The installer explained why it needed to be this way, but I didn't really understand what he was saying. Can someone simply explain why this valve is set like this? He insisted that it needed to stay like this.

0 -

The valve that is halfway looks like a bypass to control water temp.

Leave that one as is

I would open the backflow valves (green) then the one nearest the boiler. Then the one upstream of the backflow preventer slowly.

When you are done I would shut only the upstream valve.

I would also ask the installer why all the valves were left shut off.

For a 1 or 2 story house 15 psi is enough and is the normal setting. 12-20 is considered safe. The pressure will rise when the boiler is hot and up to temperature.

1 -

What does this circulator supply, heat or Hot water?

0 -

These pipes are huge. You're burning a lot of fuel to heat all that water.

0 -

Yeah, that's good advice. I wasn't planning to move the valve that is just cracked. I still don't get what it means to have "a bypass to control water temp" but I guess it doesn't matter, I'll just leave it.

I also don't understand what the back flow is even doing. Since the shutoff valves on either side of the back flow preventer are off , even if the the green valves are open, the back flow never sees any water flow. It can't be preventing back flow if it's not even open to water flow, right? Is it only preventing back flow while I'm putting water in the boiler?

I think I'll open everything as you say to add water to the boiler to get all the radiators bled and the pressure up to acceptable levels. Then I'll put everything back and just ask the technician when I have them out for a tuneup in the spring.

0 -

code requires backflow preventers normally. The valves being closed will also prevent backflow but I don’t know if they are required to be open. You normally have them open if you have a pressure reducer so that if you did lose water, it will automatically add more to the system keeping the pump from running low on the inlet side. The bypass is probably there to mix the cold and hot water so you don’t shock the system with cold water and crack the cast iron, this would be my assumption.

0 -

Yes, the installer said the back flow was for code. I was able to add some water and bleed all the radiators and it's sitting at around 15 PSI now. Thanks everyone for the help. It's basically the same thing I've been doing with the 70 year old Janitrol boiler for the last 30 years only there are 4 valves to turn on/off instead of one. I'll ask the technician these questions about the back flow valves in the spring, I think it will be fine until then. For now I'm just glad to have all the air out of the system.

0 -

can we see a wide shot of how the makeup water and backflow picture and those large system pipes, connect with the boiler and expansion tank bypass picture,

also, I dont think we've seen a pressure reducing valve there anywheres,

known to beat dead horses0 -

Given the water supply line was left off by the installer, doesn't that imply there is no pressure regulator that adds water automatically on this system?

0 -

Yes, unless it's unseen,

as long as you're ok manually filling if you're venting air, or refilling after maintenance work, and are comfortable doing so, then have at it,

known to beat dead horses0 -

I've been doing that work myself on the old boiler for 30 years. I'd be more nervous about the regulator failing and overfilling the boiler. Shutting off the water supply and checking the pressure periodically is fine with me.

0 -

It's really up to you about leaving the water fill valves open or closed. It seems every time we poll people on this question it is a 50% split open, or closed. Systems with glycol antifreeze are not connected to fill water at all, generally.

Some systems use a fill tank instead of a fill valve, so there are options.

It looks to be a bit of an oversize on that backflow device, typically we see a 1/2" valve used, but.

If the system is air-free, no leaks and you monitor it, then leave the fill valves closed.

Some folks choose to add a low water cutoff switch to add additional insurance should the boiler ever leak all the water out. A rare but possible chance. And another control is another fail point.

The white handled valve, a system bypass loop, this allows some of the water leaving the supply pipe out of the boiler to blend with the cooler return water. This helps keep the boiler temperature above 130° to prevent it from sweating or condensing.

Since all the piping is inside the home, any heat loss from all that piping is within the building envelop. With no insulation in the floor joists and an open stairway, much of the heat is going into the upper level anyways.

Un-insulated pipes may over-heat the area they occupy, but it is still better than heat going up the flue without adding anything to the home.

It looks like a nice clean professional installation, enjoy the hydronic heat.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements