Blower motor shaking but not starting

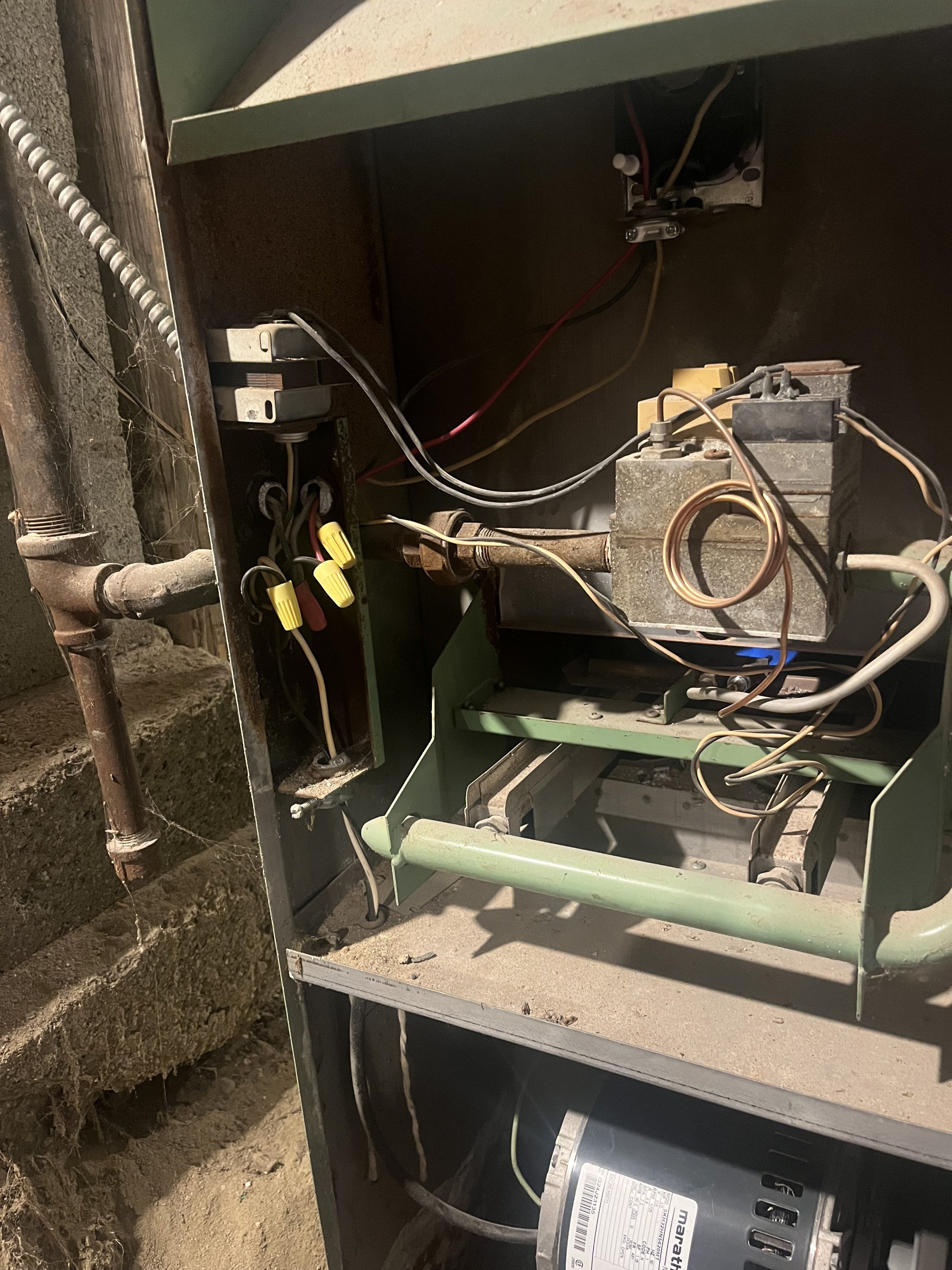

Hi all, I have a very old furnace in my 1950s house. I have replaced the fan and limit control coil (as seen in this picture) because the old one was not turning on the blower. I also had to buy a new motor because the other one would not turn on and was so hot that it burned some wires. Now, when the limit control coil tells the blower motor to turn on, it periodically shakes rather then spinning the pully. Please watch the 11 sec video below to see an example. What could the issue be?

Comments

-

Check the start capacitor. Check the electrical connections. Also, I can't tell from the video if the belt is too tight or too loose. Try running the motor without the belt connected.

0 -

Something is haywire with that motor. Re check all the wiring connections for voltage, rotation etc. Try it with the belt off. With no power on spin the motor and the fan to see which one has the issue. Check capacitor also as @Intplm. mentioned

1 -

did you install a capacitor with the new motor?

I can't see the label on the motor well enough to see if it requires a capacitor or if it has to be wired a certain way to set rotation direction but that is where I would look. Looks like the classic bad capacitor start of a motor but you don't appear to have installed a capacitor.

does the blower wheel spin freely if you take the belt off? if you give it a spin it should keep spinning for at least a few seconds after. should do that with the belt on too.

0 -

OK, I am going to turn off the power and test those things. I will send these pictures for now because I’m wondering if I do have a capacitor. I really don’t know what all of these components are.

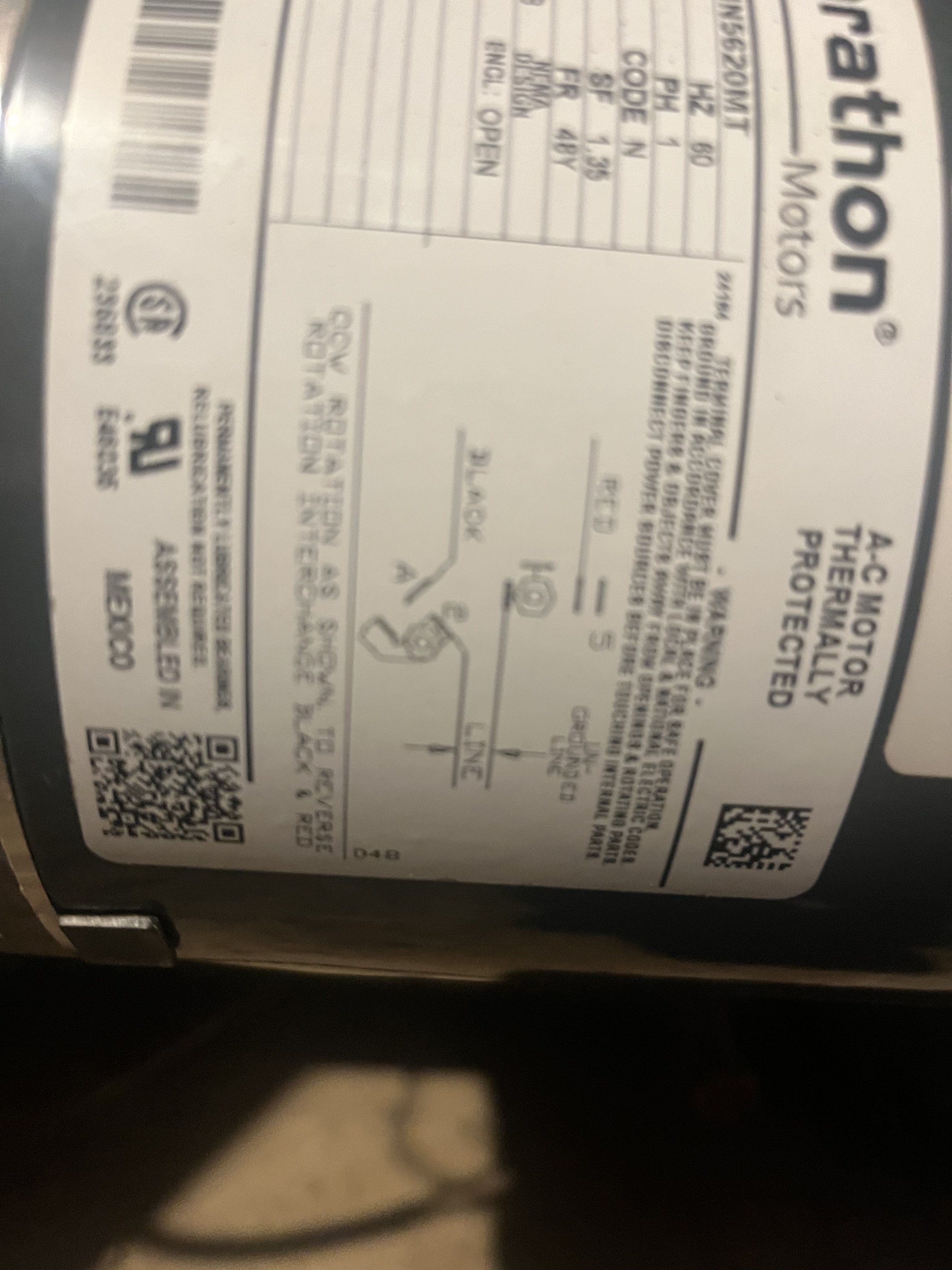

I’m also sending a couple clear pics of the label

also, I have determined that the belt is pretty loose. Check out the slack

0 -

The pulley on the blower turns freely. Same with the pulley on the motor. I’m going to run to the store and buy one size smaller of a belt.

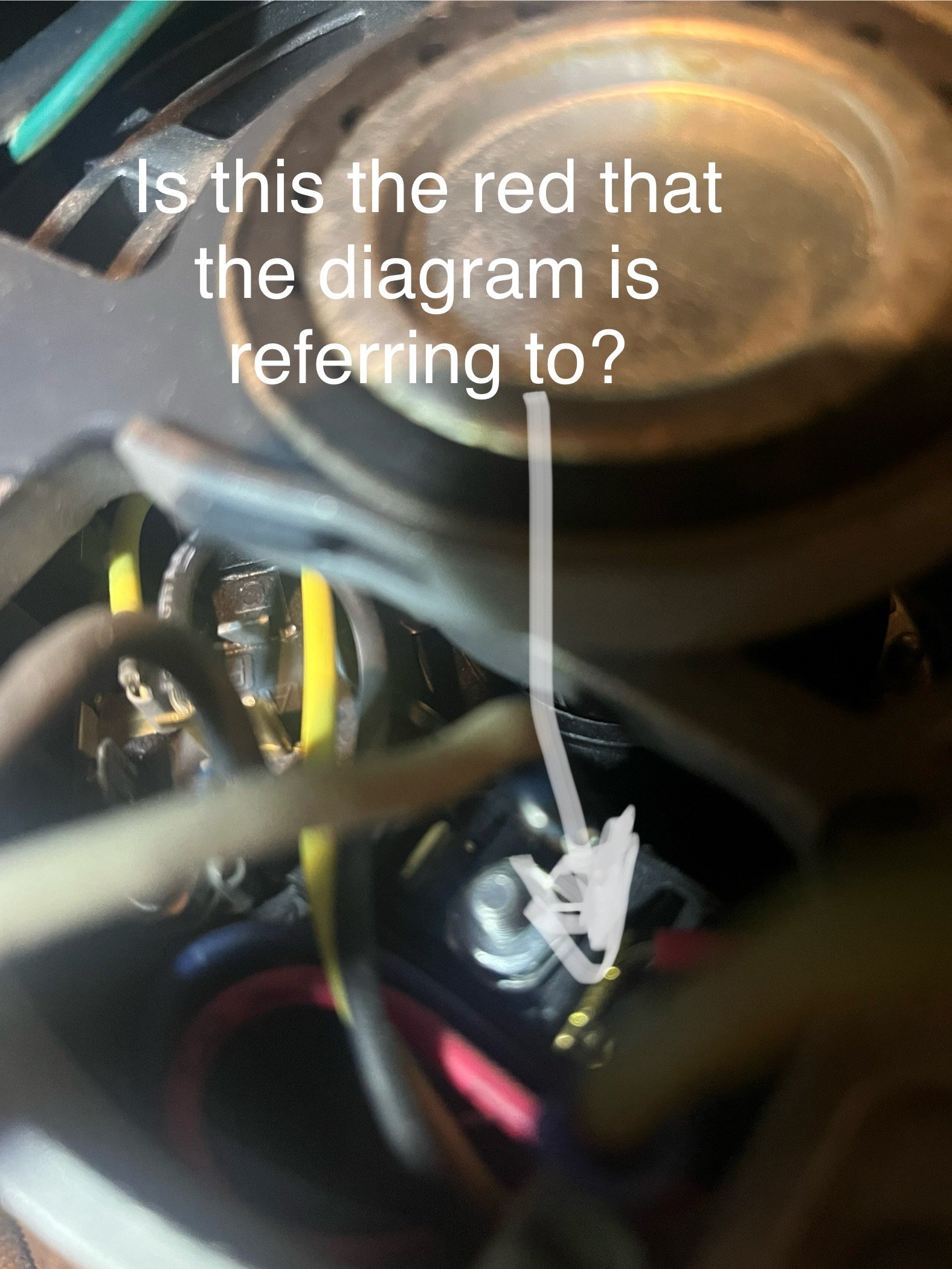

I’m also attaching this picture of where the neutral wire connects because there are two possible slots and I can’t tell from the motor the diagram if I put it on the right Slot. Hopefully you can see in the picture that there is a slot on the left it could attach to.

0 -

No capacitor. That's a shaded pole motor.

We're assuming this is 120 volt? Have you tested voltage at the motor? Hot and Neutral, and Hot to Ground. Can you post the wiring diagram? Some wires might be on the wrong posts, or might need to switch posts.

0 -

how does it turn if you try to turn it by hand? it is a split phase motor so it doesn't use a capacitor but I think it does have a centrifugal start switch. that could be bad if the motor/blower assembly spins freely. make sure the red and black wires are plugged in as noted on the label to the right terminal numbers. if the bearings on the blower are trashed it won't be able to start it.

0 -

-

Everything spins freely when I spin it by hand

I will try to make sense of where things should be plugged in. This stuff is all new to me. So I’ll have to figure out the diagram.

here’s another piece of the puzzle….half the time is works perfectly.0 -

That motor does not need a start capacitor but does use a Start Relay AKA Centrifugal Switch.

0 -

I put the new belt on and when I roll the pulley with the belt there are times when it easily and then times rotation it is very difficult. Is that normal? Here’s a video.

0 -

no. that is your problem. turn off the power and pull out the blower and figure out what is binding. could be a warped or broken blower wheel or housing or debris i the blower or something with belt alignment or bad bearings on the blower or some sort of manufacturing defect or debris in the motor.

when you rotate it by hand it should keep rotating at lest for a second or 2

take the belt off and try to turn the blower and the motor by hand. try to move the pulley on the blower up and down and front and back, there shouldn't be much play in that direction. there might be more play in and out which might be ok.

0 -

also that belt shouldn't be super tight, too much tension will damage the bearings

0 -

both the motor and the pulley each rotate on their own with no belt.

Video:So maybe alignment?

0 -

or bearings or mounting. the tension might be moving the blower wheel around and causing it to bind with something with the belt tension on it

there should be some bolts or pins or clips or something that you take out and the whole blower assembly should slide out so you can see where it is binding

0 -

I readjusted where the blower mower was sitting and I think I have smooth rolling.

when I turned the power back on, it seemed to spin on OK but like I said earlier, it sometimes sporadic when it stalls Let’s let this sit for a couple hours and I’ll come back and tell you either way if had success or not.

Either way I want to say thank you so much because it is amazing how a bunch of people who don’t even know me are willing to spend some time and give me a hand. Thank you so much!

2 -

Your new motor is 1/3 horsepower which is a pretty small motor.

Was the old motor the same HP. It is strictly a 120volt motor the only change is rotation.

Look at the wring connections carefully and make sure they are right and connected firmly.

0 -

Going back to the first video, the noise alone is a bad sign. Does it make that noise without the belt attached?

Purchase an electrical clamp meter so its also capable of checking amps.

In the first video it looks like you manually push the belt foward, which is clockwise when looking at the motor shaft. Is that right? Doesn't seem like thats correct. The blower wheel should be CCW.

Same pulley on the motor? When replacing a belt drive motor, alignment is a must. Amp draw is a must.

0 -

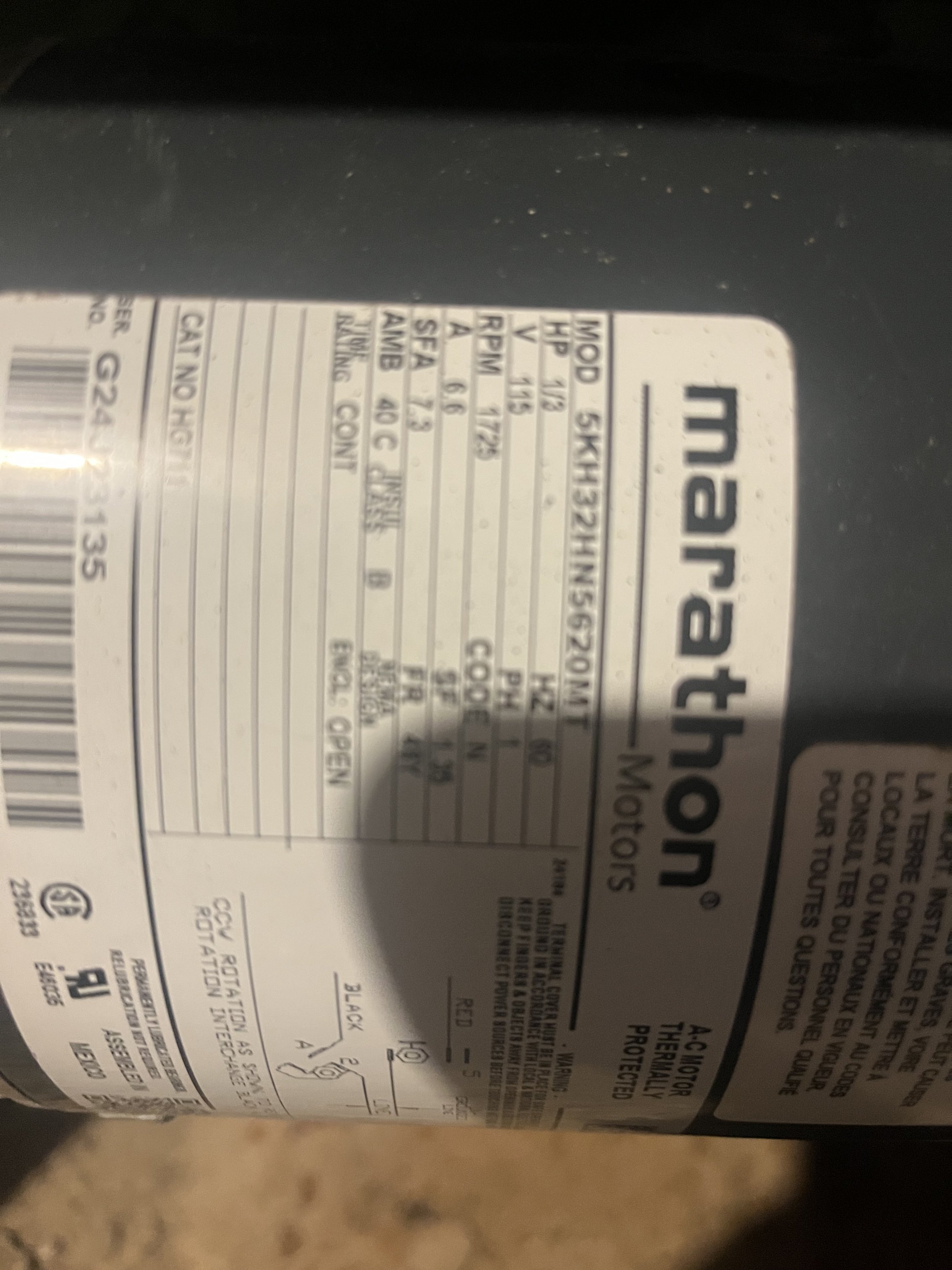

here is a picture of the label from the previous motor. It seems as though they are the same unless somebody different than I do.

0 -

I didn’t realize that they must go counterclockwise. I likely have the neutral wire on the wrong post.

I am going to pick up a meter and see if I can figure out the voltage0 -

you have to swap the wires on the internal terminal board in the wiring compartment to reverse rotation. they just plug in to that board usually.

reversing hot and neutral in the power supply won't reverse it.

it is also possible the start switch was defective or got damaged in shipping but that type of motor doesn't have much starting torque.

what is wrong with the old motor? the bearings wearing out or a bad start switch is more or less all that can go wring unless it was really abused.

0 -

I actually replaced it because I thought it was the issue, but it was actually the limit control switch that was the problem. By that time I had already taken off the pulley and switched it so I didn’t bother to put it back

I’m not really sure how to make this motor spin the other way.

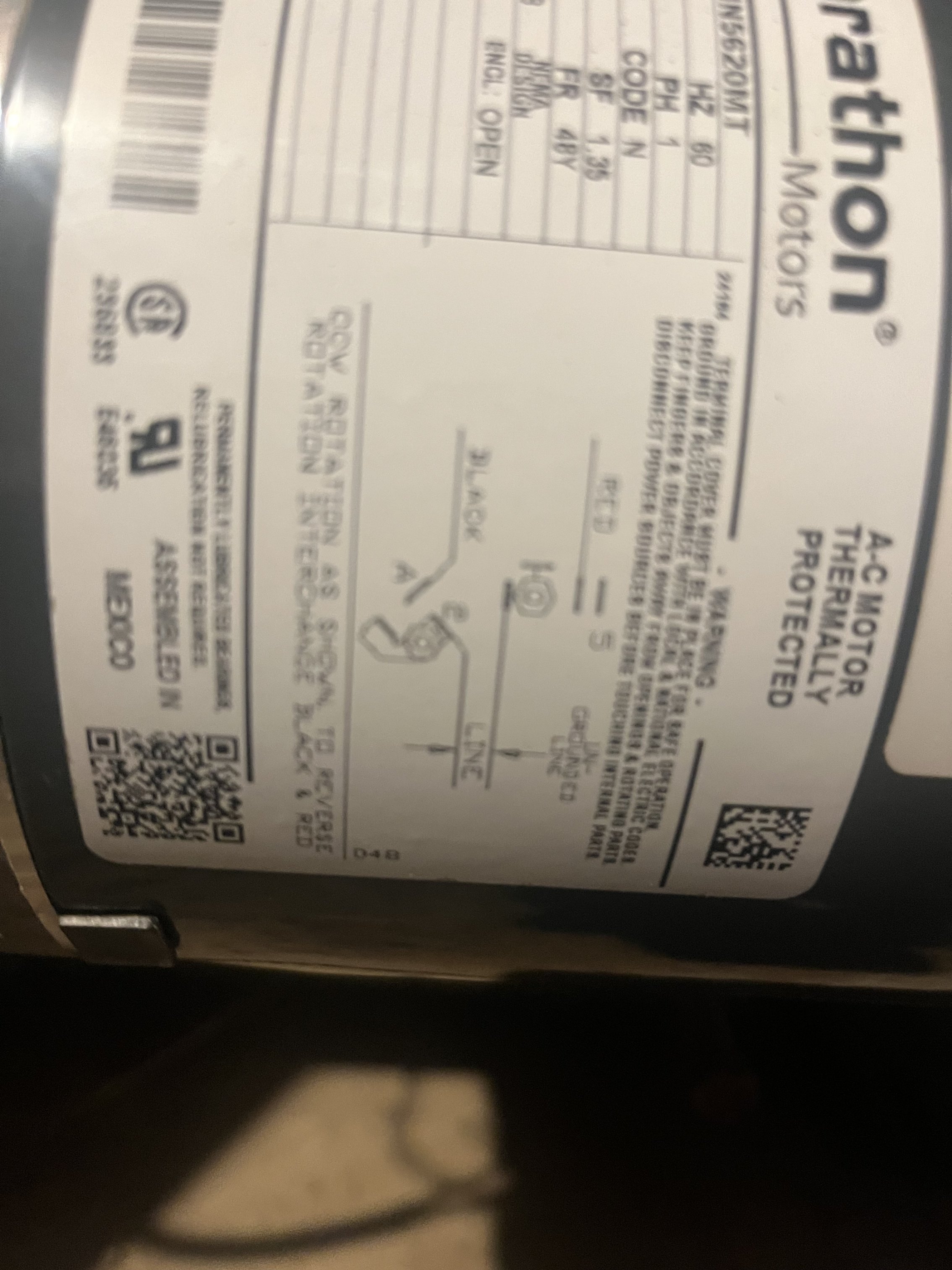

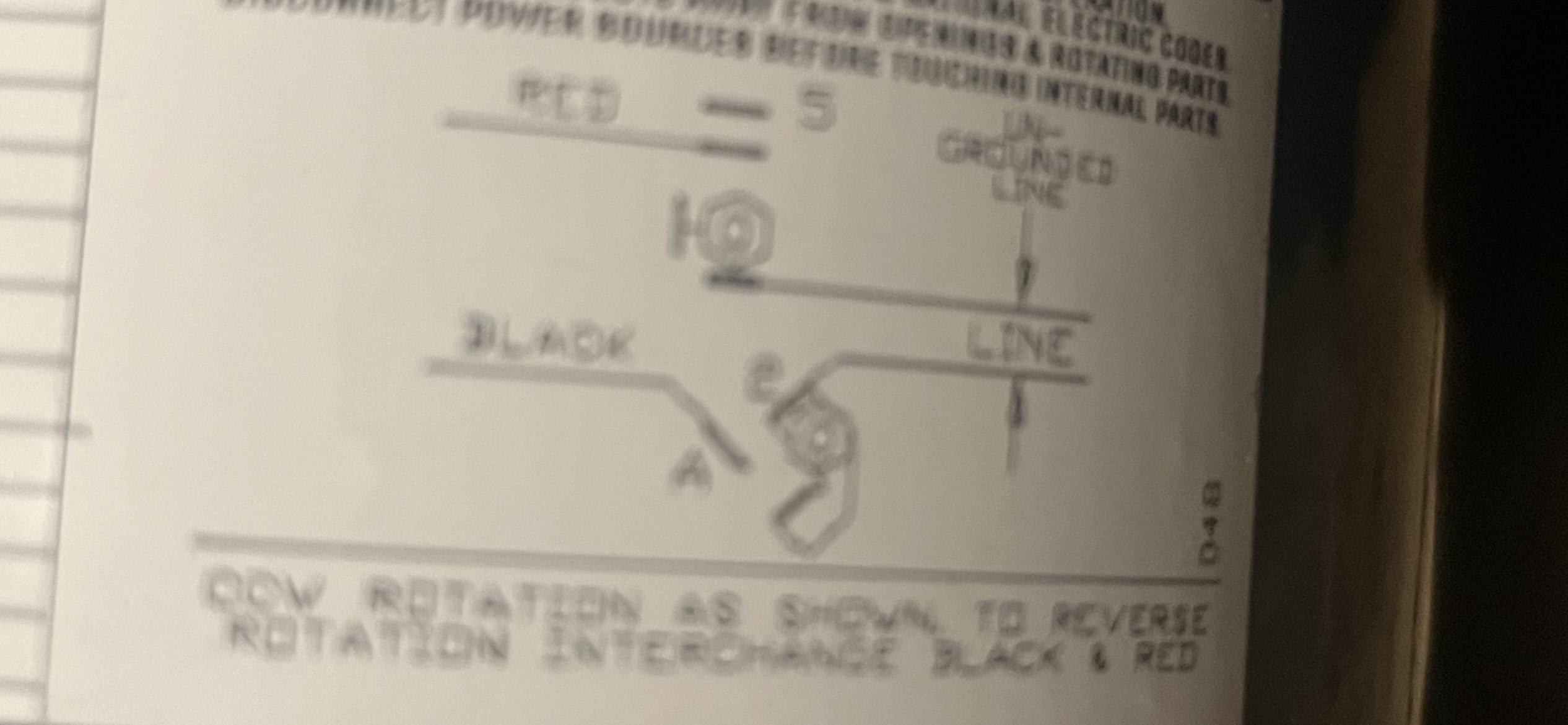

I know it’s blurry, but this is what it says on the front of my motor.

The words at the bottom of the diagram indicates I have to switch black and red. Where are the black and red?

0 -

yes

0 -

-

-

So now its the correct rotation but still shaking?

0 -

Is it working now or still having problems stalling and vibrating?

0 -

-

I still have the same issue but only periodically. (Approx 5 times per day). There’s no pattern to when it does it. It happens for about 30 seconds, stops, then after about a two or three minute timeframe, the motor successfully on.

I will recap everything that I have done.

1. Swapped the red and black wires of the motor so now the motor rotates the other direction.

2. Purchased a new belt one size smaller.

3. Moved the motor slightly to the right to improve alignment. Now when I spin the motor by hand, it spins freely for a couple seconds with the belt on.4. Disconnected the wires from the motor and gave each spade connecter a little squeeze with needle nose pliers so that they are tightly connected to the terminal block.

5. Ensured my ground wire is tightly connected.6. The limit control coil is brand new.

0 -

I’m not sure

it says ENCL: open

what would that indicate?

0 -

That's an open enclosure. Air can circulate to cool the windings.

0 -

now the furnace won’t kick on at all

guys I’m at a loss here0 -

so based on what everyone is saying, I’m assuming my motor keeps failing because it is not getting any air to cool it. This has now probably flipped the limit switch. I’ve called an electrician to help me because I live in Canada and my house is now at 56°

0 -

can you take an in focus picture of the schematic section of the label on the motor so we can read the notes and labels on the wires and a good picture of the terminal strip? for the terminal strip you may need to use a light pointed in the wiring compartment and press the screen on your phone where the bottom of it is to make it focus and expose to that area. there should be little numbers/etters molded in to the plastic by the terminals.

if you have the neutral connected to the wrong place(i didn't see that question, it might have been flagged for moderation for some random reason and wasn't there the first time i read this) it could be just energizing the start or main winding instead of both. I'm not sure if that motor has a start switch or not, do yo hear a click a second or so after the motor starts and another click as it stops spinning?

if it is the overload kicking out it should do noting at all until it resets.

0 -

I would have your electrician friend certainly do an amp draw.

I know the old motor was 1/3 hp and the new one is the same hp but that is really small for a furnace blower motor.

If the motor is hot you could be tripping on thermal overload, or the blower bearings could be the problem putting too much load on the old and the new motor.

An amperage test will show this.

1 -

Everything is up and running properly. I just wanted to report back that the issue was the wrong kind of motor.

So now I have a motor that is for a belt drive fan and everything seems to be working just fine now.The other motor was overheating and then it was causing the whole system to overheat because it wasn’t blowing when it was supposed to.

A special thanks to @mattmia2 for pointing that out .1 -

What specifically was wrong with the other motor?

0 -

it was an enclosed type so it required the fan from the blower to cool it. So it was over heating.

0 -

if it was air over either open frame or totally enclosed, being in the blower compartment should have been sufficient as long as the blower was turning the right way and the door was on the blower compartment.

i think you either wired to the wrong terminals or it had a bad start switch or possibly one of the internal wires was disconnected from the terminal block.

if it was overheating it would have just tripped the overload out and not done anything until it cooled down and the overload reset.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements