Main vent questions - newbie

Comments

-

So are those two main vents venting OK with that pipe pitch issue? No water, gurgling, spitting or anything? Can you witness air being expelled once steam has reached the header at the boiler and begins to travel down the main? Then, witness them closing when the steam reaches them? If they vent fine without issue then I guess you don't need to change anything there. (Sorry if you answered this before somewhere… TG morning, no time to go back and read).

0 -

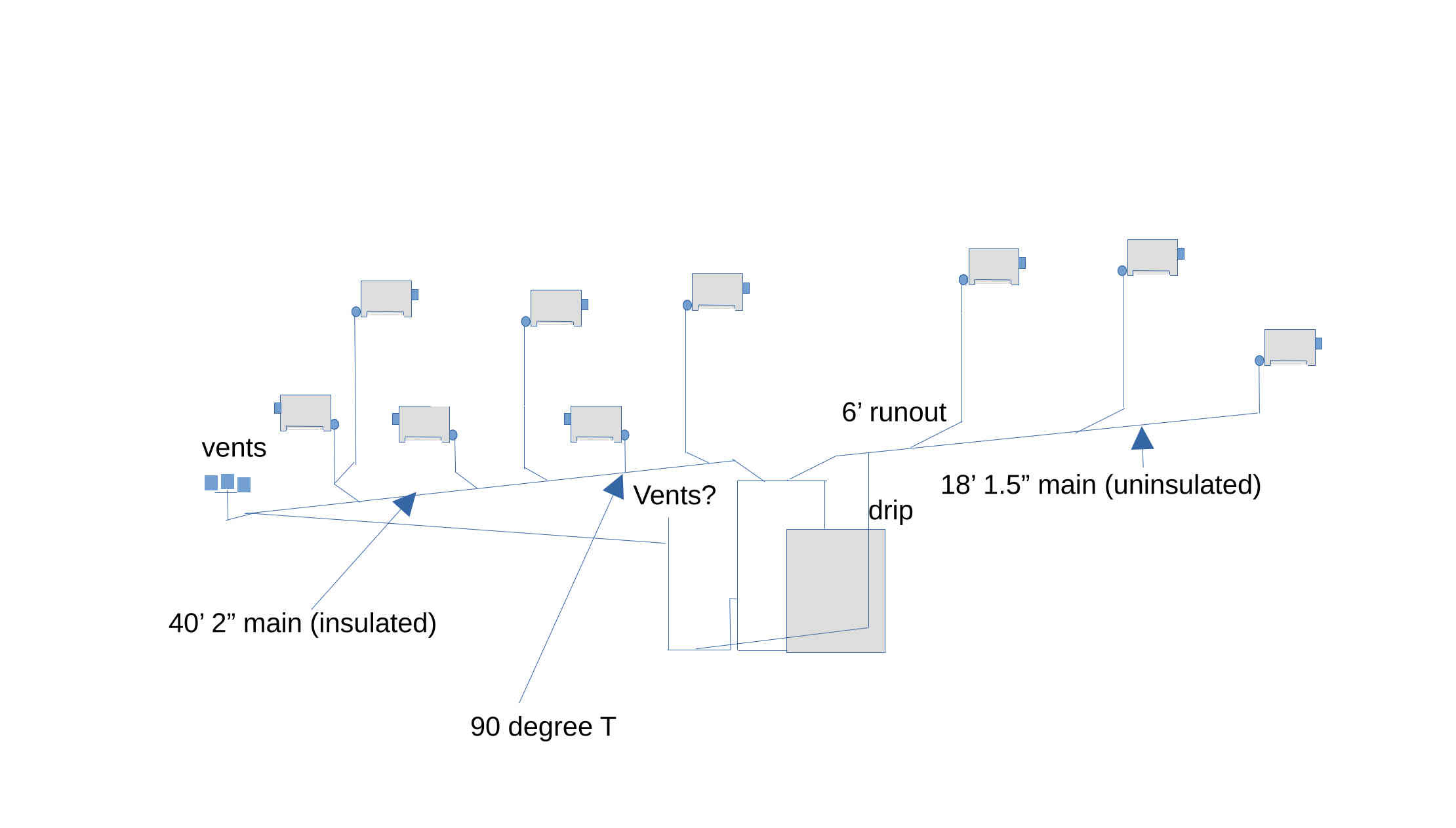

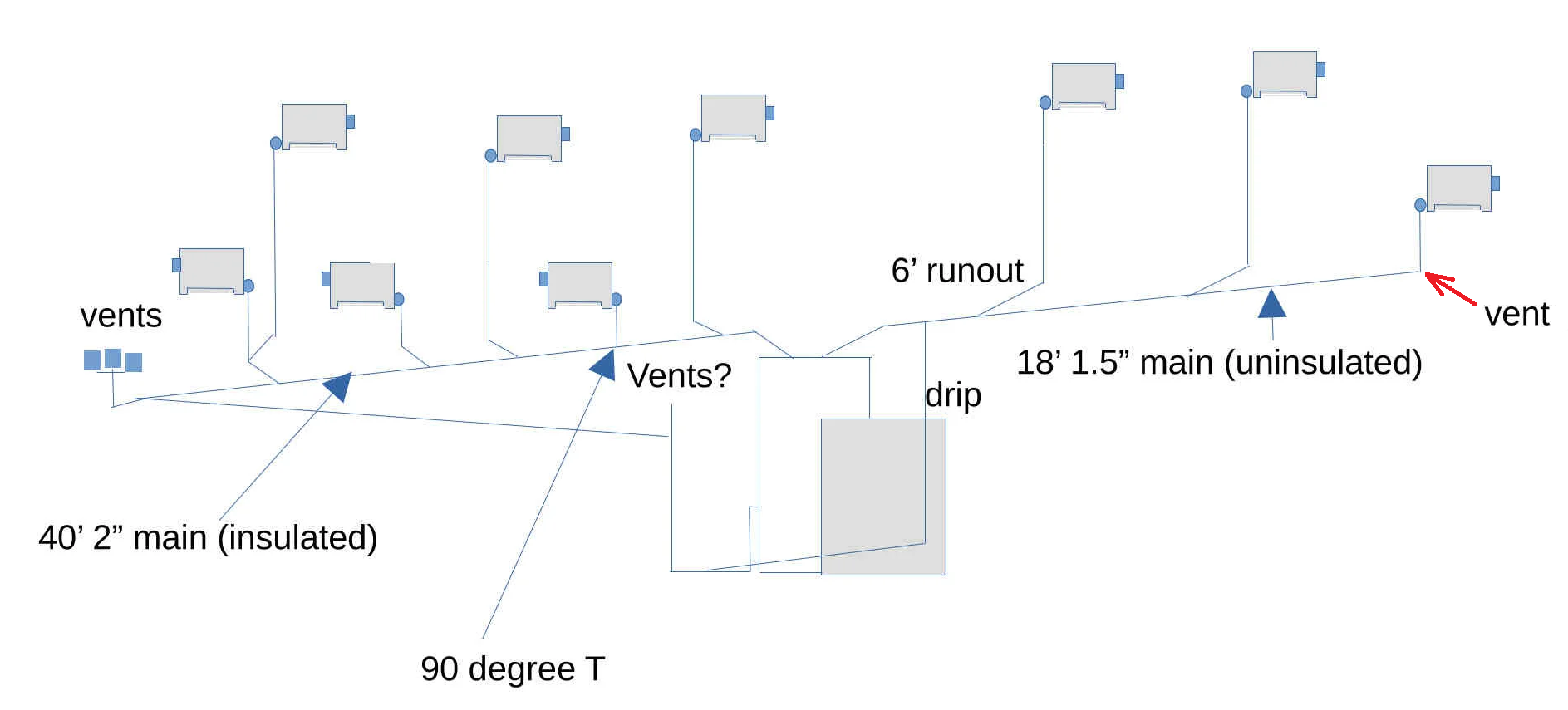

The pipe downward pitch at the pictured vent obviously is not the best situation.

However it may not affect the venting too much.

The pipe coming out of the T is dead ended to the vent so it sees very little flow and not much velocity. It is only carrying air.

Increasing the vent capacity at that location may be ok or the increased flow may cause the pooled water to make the vent spit.

0 -

To make a long story short. The vents pictured are doing little because of the back-pitched pipe. That pipe, as you know, fills with condensate, rendering the vents useless.

Your earlier-mentioned concerns are well placed as to how to correct this issue. Removing that end run of the tee to improve the vent piping can turn into a nightmare. That ? 2" x 11/4? x 11/4 ? Black cast iron tee can crack and open up a large can of worms.

If it were me, and I had access to a mega press fitting and tool, I would cut the pipe back and repipe with a mega press ell to the left of the beam. This should fix the venting issue. And while you are at it, build a nice new antler vent set. I hope you can find a Mega press. If you can, do that. There's less chance of cracking a fitting or damaging anything else.

0 -

That pipe should come out of the tee if you use a big enough wrench and heat the tee where it connects. Then screw a street 90 into the tee and go where you need to go from there. This will minimize the water that collects.

A MegaPress elbow would leave too much room for water to collect.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

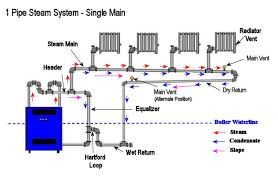

Based on what I am seeing they are at the end of one of the mains after the last run out but piped off of the main incorrectly on their own runout after the turn down to the dry return. Per Dan's book they should be on the main after the last runout but before the pipe in the lower left corner of the picture, dry return, which carries condensation away from the main and the vent so it can do it's job and vent the air out of the system.

The current location will fill with condensate and has no way to drain other then building pressure and blowing water out of the vent which defeats the purpose of having vents in that location.

Note in the picture above the vent is inline and not on an off shute so it does not have issues with puddling and drains properly.

This can easily be fixed by plugging the current extension at the main and placing the vents at the end of your dry returns before they turn down to wets were your danger sign is, they will work as designed since they are not blocked by water in the pipe and your system will breath much better and work more efficiently.

0 -

More info:

Here's a schematic showing both mains.

I measured the operating pressure using a DIY tubing manometer and measured the pressure to be 0.5" - 1" of water or about 1/2 oz per sq in.

Today, the boiler was running ~35min every two hours with an outdoor temp at ~40 degrees. I have no idea how insulated the house is. It was built in 1925.

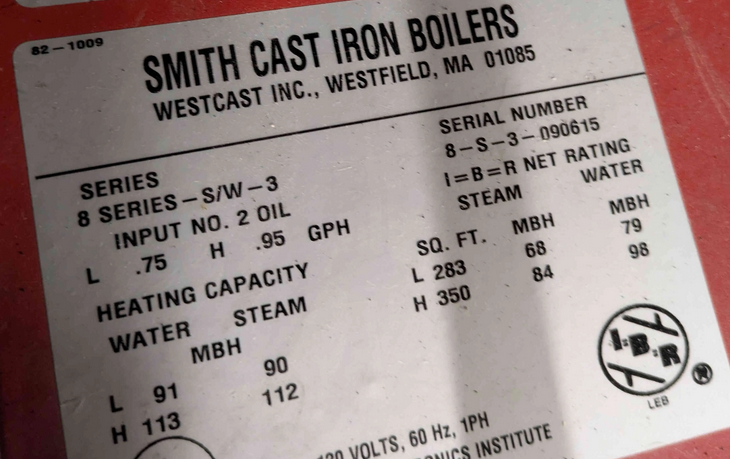

I measured the radiators and calculated the total EDR to be 302 sq ft. With a 1.33 pickup factor this comes to ~400 sq ft. If you scroll back, you can see the boiler rating plate. And the current nozzle is .65, which is lower than the "L" .75 GPH.

Is the boiler way underpowered or am I misinterpretting something?

0 -

29 % duty cycle does not seem too bad.

So the boiler will be less than 283. A system EDR of 302, that may work fine. You would have to see how well it keeps up on the coldest day of the year.

If it were my system, I'd fix the possible present main vent puddled water restriction as previously discussed. I'd also insulate the 18' main and put an appropriately sized vent on the end of the 18' main.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

don’t add your piping to the calculated EDR

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Based on the pic you posted I agree with @109A_5 you need to insulate the main on the right.

The main vents on the far left should be plugged to eliminate the the pooling of water and blocking the vents from venting. You should relocate the main vents to where the "90 degree T" arrow intersects with the return, the pipe below where you indicated "Vents?" and put them on a six inch nipple so they can drain and vent correctly. This will let your system breath correctly and have your vents in a place you can service them easily when needed.

You probably want two Barnes and Jones Big Mouths or two Gorton No 2's for the vents. The more main venting the better.

0 -

Running at 50% duty cycle overnight with outdoor temp at 10 degrees. Lowest winter temp in Boston in recent history was -18 degrees.

Should I talk with the boiler technician about putting in a .75 nozzle? Service records indicate it was .75 back in 2007, but was switched to .65 in 2012. Possible explanation is that I think the LR radiator was removed around then.

I'll work on moving the mains vents to end of the dry return. There is a ceiling clearance issue, so it'll take a larger wrench and a torch. Over the summer, I'll fix the pitch issue and move the vents back to the end of the main.

Insulating the 18' main will be difficult, if not impossible, as there is little clearance between the pipe and the ceiling. The end of the 18' main is tight up against the ceiling (previous owner installed a darkroom) and there is no room to add a vent. There is currently a Gorton #5 on the radiator which is on the riser at the end of the main. I can bump this up to a Gorton #6 or greater if recommended?

ethicalpaul - My calculated EDR is 302 sq ft. Are you saying I should leave out the pickup factor?

0 -

If you can't access the end of the main another option to consider is putting a main vent before the radiator valve:

An 18' main is not that long so you might be OK just doing the #6 on the radiator but more venting would be better. What pipe size is the 18' main?

0 -

ethicalpaul - My calculated EDR is 302 sq ft. Are you saying I should leave out the pickup factor?

I'm saying when you are calculating your EDR, don't include piping in the calculation. Just include the values from the radiators themselves. There is already a too-large 33% "pickup factor" added to each boiler's sq ft of steam rating to account for piping.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I'll bet the mains are connected in the dry return, just to the left of the fat red downward arrow in the picture above. There's be no reason for a Tee at the left of the image otherwise. If that's the case, it's a good location for the main vent, it just needs to be big enough for both mains… and the air needs to be able to get to it.

0 -

Your rads total 302 square feet. The boiler is rated at 283 square feet with a firing rate of .75 gph and it is rated at 350 square feet with a firing rate of .95 gph

Happy thing is you have the right size boiler.

All you do is compare the 302 calculated square feet to the nameplate square feet. the 1.33 PU factor is already calculated in by the mFG into their sq ft rating.

Notice above I mentioned "firing rate" not nozzle size. Nozzle ratings are calculated a t 100psi oil pressure. Many modern burners run over 100psi. The oil pressure is adjustable. So the exact firing rate you have is determined by the combination of nozzle size and oil pressure.

Also, these calculations give you a starting place. Its better to live with it and see how the system performs before making any adjustments.

Today is a good test day MA is just about at design conditions this morning. At this point I would not fiddle with the firing rate

1 -

At 29 % duty cycle at about 40 degrees and 50% duty cycle at 10 degrees I think I would keep that nozzle size.

Unless you need the heat in the basement from the uninsulated main I'd try to insulate it as best as possible. Maybe the next pipe size or two down to cover 75% of the pipe would help.

Filling the main(s) as fast as possible, minimizing reheating them with each new cycle will provide the best fuel economy and system performance and efficiency.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

@dabrakeman the second main is 1.5" pipe

@mattmich the second main does not connect to the dry return. The condensate flows counter to the steam until it hits the drip line shown in the schematic. The drip then connects to the wet return from the primary main.

0 -

Slow heating on your long main was your initial stated issue so I would say you just focus on the main venting on that and once done then see how it balances out with the short main.

0 -

Thanks again, everyone, for all of your help and advice!

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements