Grundfos UPS15- Mounting position, flow direction. Check valve action.

A DIY-er question. In process of hooking up a Grundfos UPS15-35SFC for recirc in a radiant system.

I know I can mount it horizontal or vertical as long as the shaft is in a horizontal plane.

Question is, can I mount it "vertical" with the flow arrow pointing down? Does this affect the internal check valve in any significant way?

I can more easily mount and plumb things if that is OK. Did not see that info in the user pamphlet.

Comments

-

If you mean pumping downward with the motor horizontal, then yes.

I’m not sure what you mean by “a radiant recirc” system. If this is a closed loop hydronic heating system, then that circulator may be too small. We never use anything smaller than a ups15-58 in a hydronic application.

If this is a domestic recirc line, then it’s probably fine.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Yeah, pumping downward. It will supply hot water from domestic supply to an in slab radiant loop in a 4 season sunroom that is mostly complete. The loop tubing is potable certified.

It's the pump recommended and sold by the radiant outfit that designs and sells systems for DIY.0 -

Generally you don't want to pump down if there is a loop of pipe above where air can get stuck. Once you get air there the pump will loose prime on a down facing unit. Best option in this case is to have an air separator at the high point before the pump.

Best is always to put the pump in a location and orientation where it is self priming.

There are many ways of doing an open setup like this wrong and very few ways of doing it not terrible. Open system is also a bad idea if you are on well water as there is no chlorination. Most codes limit open system length to 50'. If you are above that, you need some way to prevent the water in the pipes from stagnating.

You can tap a hot water heater for space heat but it is best done with a plate heat exchanger to isolate the two systems.

0 -

Anytime we see a circ with a S in the number that indicates stainless steel body

Which is usually an indication of an open/ combined system

Not an ideal system as it can harbor bacteria when it is off for a period of time

In the summer I would circulate it occasionally at 140 f for an hour

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The tap in location would be above the pump suction end.

The off season "sanitizing" - probably rig up a timer to over ride the thermostat.

0 -

The off season "sanitizing" - probably rig up a timer to over ride the thermostat.

That will work fine as long as you have the tank temperature set at or above 140°F. If that is the case, then you want the water to the faucets to pass through a mixing valve so it is not a scalding hazard.

It sound easy when the Radiant Outfit pitches the concept. but it gets more complicated as you consider all the other things that can be problematic and you do something to account for those problems. Now a timer and a mixing valve need to be added. What thermostat do they recommend to keep the room from overheating? Is there a relay involved?

I may work out just fine as long as you can follow directions.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I was not planning to have it set that high. It is at 130 now. I have a Azel units. D-508F thermostat, SP81 relay and DS-60p and sensors for temp display.

0 -

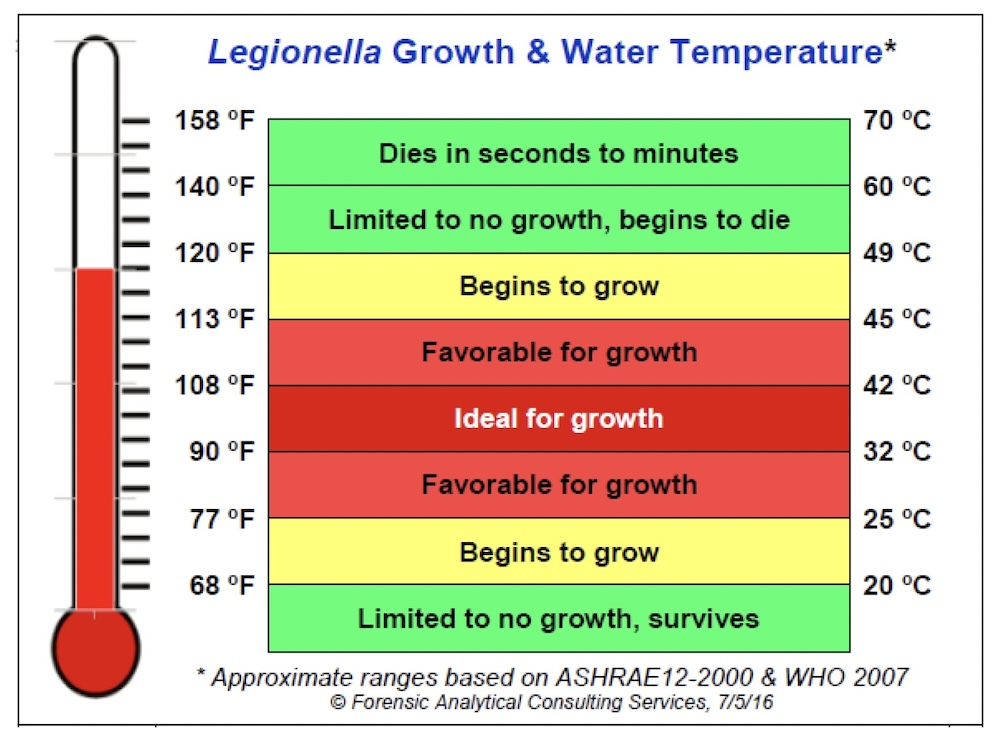

Heated slab typically uses 110F water. Look at the chart bellow.

Very few ways to stay out of trouble, to pasteurize the loop you probably will need more than 140F water and run it long enough that the returns water goes up to above 140F. It will take a fair bit of energy to get a slab hot enough for that to happen. The slab will also be a bit too hot to walk on.

0 -

Thanks for all the comments. Seems like at 130 would be sufficient if done every week or so for an hour.

It's well water that has been chlorinated for light sulfur smell and through a large carbon filter. So legionella seems a low risk in any case. But, regardless, seems weekly, or more often, recirc for a few minutes would not allow "stagnation" to be a concern. Hope that's not wrong.

I do have a "standby" Super Store style indirect tank as a loop off the oil burner. It's plumbed in such a way that I can simply operate two ball valves and connect the tank thermostat to supply domestic HW in case the propane unit fails. But, it has not been active for quite some time and now realize it may pose a problem.

Perhaps I should rethink this and use the indirect for radiant heat? That would require I get another expansion tank (and a few more bits and pieces) and run the systems independently, with no cross over ability.0 -

"recirc for a few minutes would not allow "stagnation" to be a concern"

In a few minutes you won't budge the return water on a slab at all, so it doesn't work. Timer recirc works if you have a low mass system like a fan coil or small staple up floor heat. It still also needs 140F+ to fully kill nasties.

If you have a boiler, why are you connecting to DHW, connect straight to the boiler. You'll need a thermostatic valve to reduce the supply temperature for the floor heat.

0 -

My bucket list included removing the oil boiler and moving to propane.

The "Super Store" used to supply domestic HW before getting the on demand propane unit and was all plumbed to allow use as an emergency backup. I got tired of the boiler firing in the middle of summer and dealing with ever increasing oil prices, at the time.At this point, I'm torn between just hooking up "as is" to get some heat in the slab so I can complete electric work and such, and dealing with a permanent solution toward spring time.

I can always look at the digital readout to see inlet and outlet temps and act accordingly.

0 -

Find out where the coil is inside your indirect. If the coil goes higher up, you can use it as a reverse indirect. In this case what I would do is mount the indirect downstream of your tankless. Use the UPS15-35 on the indirect as a recirc pump back to the tankless*. The indirect aquastat drives this pump directly.

You can now connect the floor heat to the coil inside the indirect which isolates the two loops.

The nice benefit of this setup is the indirect acts as a buffer so there will be no startup delay or cold water sandwich issues.

You would only have to buy one more pump (watch if your slab pex is not oxygen barrier, you can't use any steel parts) and expansion tank.

*ideally you connect the tankless hot water supply to a port near the top of the indirect, your house DHW to indirect Hot outlet and the pump the indirect cold inlet (or port near bottom). You might have to remove any thermosyphon valves as the water will be flowing backwards when the pump runs. When the pump runs, you want to bring in hot water to the top and have the pump send the cold water on the bottom back to the tankless to be heated up.

0 -

Don't understand "if the coil goes up higher". It looks like a typical Super Store, about the size of a 55 gallon drum, with a SS coil vertically oriented.

It does not have it's own aquastat, it's a priority zone of a 5 zone box for the oil burner recirc pumps.

I think at this point, I will just hook it to the indirect, "for now" so I can get on with closing out my building permit and dealing with a lasting solution in the spring or early summer.0 -

Looks like the coil is on the bottom, so it won't work as a reverse indirect anyways. A reverse indirect is where you use the space heat coil in the tank to pull heat out of the tank. Since water stratifies, you can only pull heat out of the water that is bellow the coil. Since the coil here is near the bottom, that is very little volume. On some indirects the coil is taller and reaches up near the middle of the tank which would work.

To pull heat out of an indirect you need the coil closer to the top. I guess you can flip the tank upside down but that will get some strange looks down the road.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements