Steam Boiler Help

Comments

-

a mix of the first 2 options. I would like to try it out myself first without breaking things but if it’s something that I clearly don’t know or will know how to do, then I’ll get a pro.

0 -

OK, some more details.

Why is the pressure so high, radiation to boiler mismatch, radiator EDR vs boiler Square Feet rating. Is the gauge accurate ? Does the pressuretrol work ? Pigtail and path back into the boiler clear of any obstructions.

Your 5 PSIG is concerning. With your situation you may have an oversized boiler and/or other issues, my house heats fine at no more than 0.07 PSIG (2 inches of Water Column).

For best performance the boiler size should match the radiators' ability to dissipate the heat the boiler makes (the total of all of the radiators). The steam moves the heat. With the radiators they call it Equivalent Direct Radiation (EDR), with the boiler they call it 'Square Feet' on the rating plate, these two numbers should be close to each other. The EDR of each radiator can be calculated from charts of different radiator types then all the radiator's EDRs are added together.

A common situation is the boiler is oversized so the radiators can't dissipate all the heat the boiler is producing so the pressure rises, to me this is wasteful. The pressuretrol is suppose to shut off the burner when a certain pressure is reached, commonly 1.5 PSIG. Assuming the pressuretrol is set correctly and operating correctly it needs to be able to monitor the boiler's pressure, this is done through the pipes connecting it to the boiler. Very commonly the pipes (including the pigtail) between the boiler and the pressuretrol plug up with debris causing the pressuretrol to not be able to monitor the boiler's pressure. If you have an oversized boiler the pressure will keep building (until the thermostat is satisfied) since in this example the pressuretrol can't sense the boiler's pressure and shut off the burner.

A redundant pressure gauge like 0-5 PSI can be added as a second opinion of the system pressure and to verify the pressuretrol functionality.

Pipe pitch correct, can the system drain condensate back to the boiler properly. Any low spots that traps water. Incorrect piping that traps water.

Since you have odd noises and hammering and water coming out of the vents, besides possible excessive pressure issues there may be water (condensate) puddled in places where it should not be. So the steam pushes it along to places it should not be. In a steam system the pipes should be pitched so they drain correctly, minimizing the amount of condensate in a steam pipe. With age, renovations and other issues the pipe pitch may not be correct in various places trapping water where it should not be causing problems. The system's pipes should be visually inspected (possibly using a level if needed) for proper pitch.

Clean boiler water, skim to remove any oil.

The boiler works best with clean water that is not contaminated with rust or oil and other stuff. Draining the contaminated water can help remove the rust in the water however fresh water has oxygen so draining and refilling should be done as little as possible. Skimming is a process to remove oil contamination from the top of the water. Oil contamination will cause the boiler water to do strange things. Most boilers have a skim port which allows the oil to be drained away from the top surface of the water.

If you don't have the boiler's manual, with the make and model you probably can find one on the net and it should show where the skim port is.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Regarding whether the boiler is oversized or not can you remove any of those radiator covers so as to see what you actually have underneath for a radiator? I.e. are they convectors or column style radiators? I would start here, totaling up your radiator sqft and comparing to the rated sqft for the boiler. Then we know whether we are dealing with a vastly oversized boiler situation or not. Secondly making sure the pressuretrol is seeing correct pressure would be an equally high priority. Take the pressuretrol and pigtail off and clean out the pigtail. Also poke a coat hanger through the opening into the boiler to make sure clear there.

Here are a couple radiator lookup tables to help with totaling up your connected EDR:

If column or tube types then measure the heights of the radiators from the floor and then the depths. Identify what type (i.e. 2 column) and total the sqft edr given for each section X then number of sections.

0 -

most of the radiators in their pictures are sunrad type radiators. that is the shape the cast iron is cast in.

0 -

-

ok, will get someone to take a look for pressurepetrol. Also, I uploaded a new video and I think this could be one of the major causes that I’m having in my system. There is a video titled “11-20-2025-Living Room Radiator Leaking.MOV”. It is leaking from the pipe itself. I’m assuming this is the job for the professionals. I don’t know if this is the cause for high pressure, cycling on and off but definitely the low water issue and maybe the gurgling from the other radiators.

0 -

-

Sunrad or CastRay. Should be able to get sqft ratings from one of these:

0 -

I will have a guy out on Friday. I’ll see what happens after that

0 -

sorry for the delay. Took a while to find a person. Apparently one of the pipes on the equalizer is wrongly sized. Said it can’t be 1 inch.

0 -

I will predict that changing the equalizer will not help you

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Either way…a boilers maximum allowable operating pressure it set by your pressuretrol. Oversized boilers, poor piping, bad vents, oil in the water, etc will make no difference in that.

Your gauge is either inaccurate or your pressuretrol is not operating correctly.

You mentioned you want to try and fix it yourself. Install a new gauge that reads 0-5psi first to see what the pressure is actually operating at. If it indeed is operating at 5psi than your pressuretrol isn't working correctly.

A plugged up pigtail is usually the culprit as the pressuretrol can't activate because the pigtail is plugged up. A long flexible pipe brush or a big zip-tie is an easy way to clean them out. You should be able to blow through them easily.

And lastly…you shouldn't have to add water to a boiler other than a little top off PER YEAR. You are either leaking water or leaking steam. Adding water frequently is going to cause it to rust out and fail at a much sooner pace.

0 -

do you have any suggestions on what videos I should look at when it comes to replacing this? Tried to search it and found no helpful information. I don’t want to miss something in the process of replacing which makes matters worse.

Brought in another guy earlier said something about replacing the transformer for about $800 for my boiler cycling on and off and even he’s like it might not even fix that. Like what do you mean? I’m just so tired of figuring out who’s bullshitting me and trying to take my money to do things that are completely unrelated.0 -

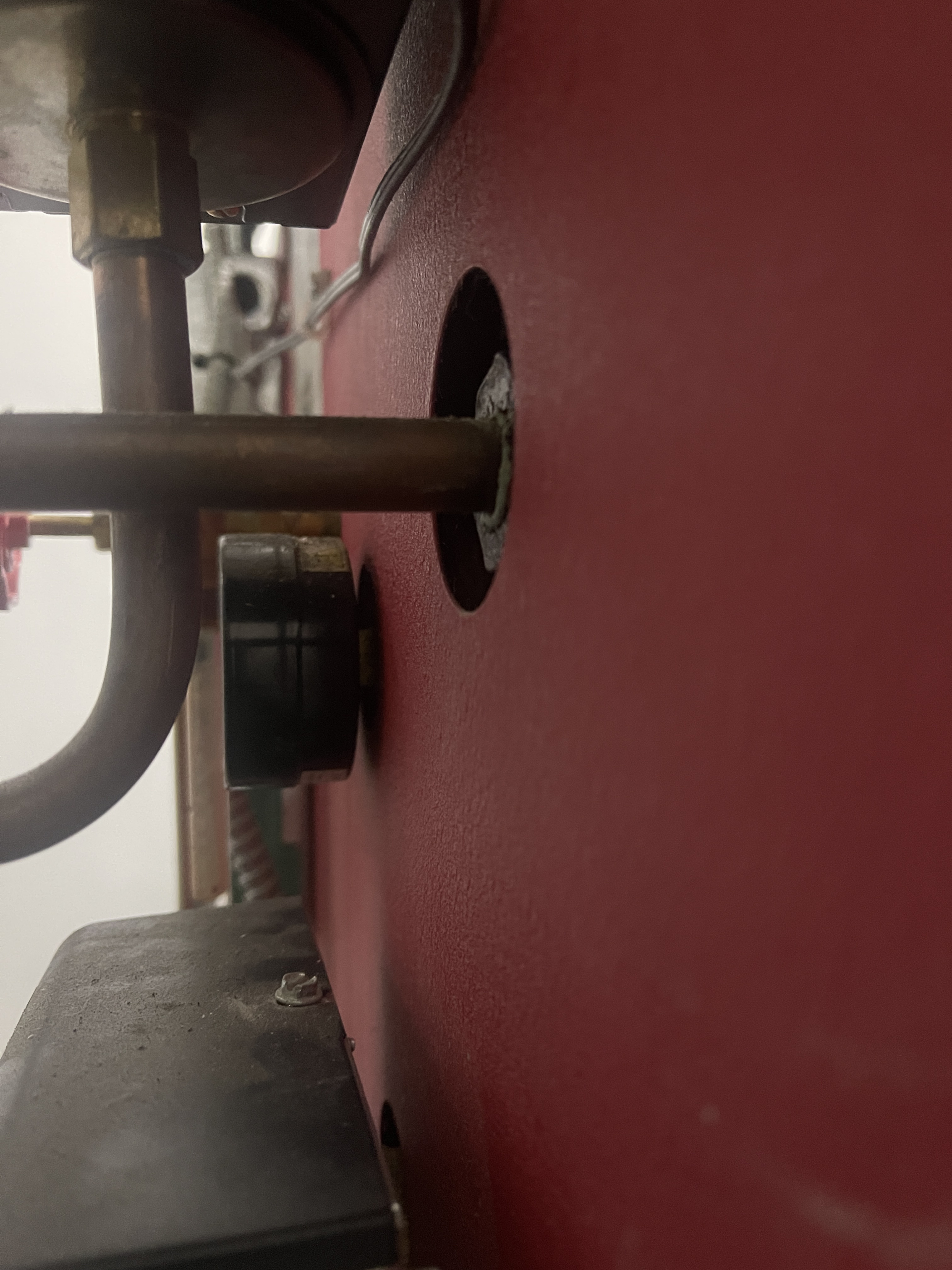

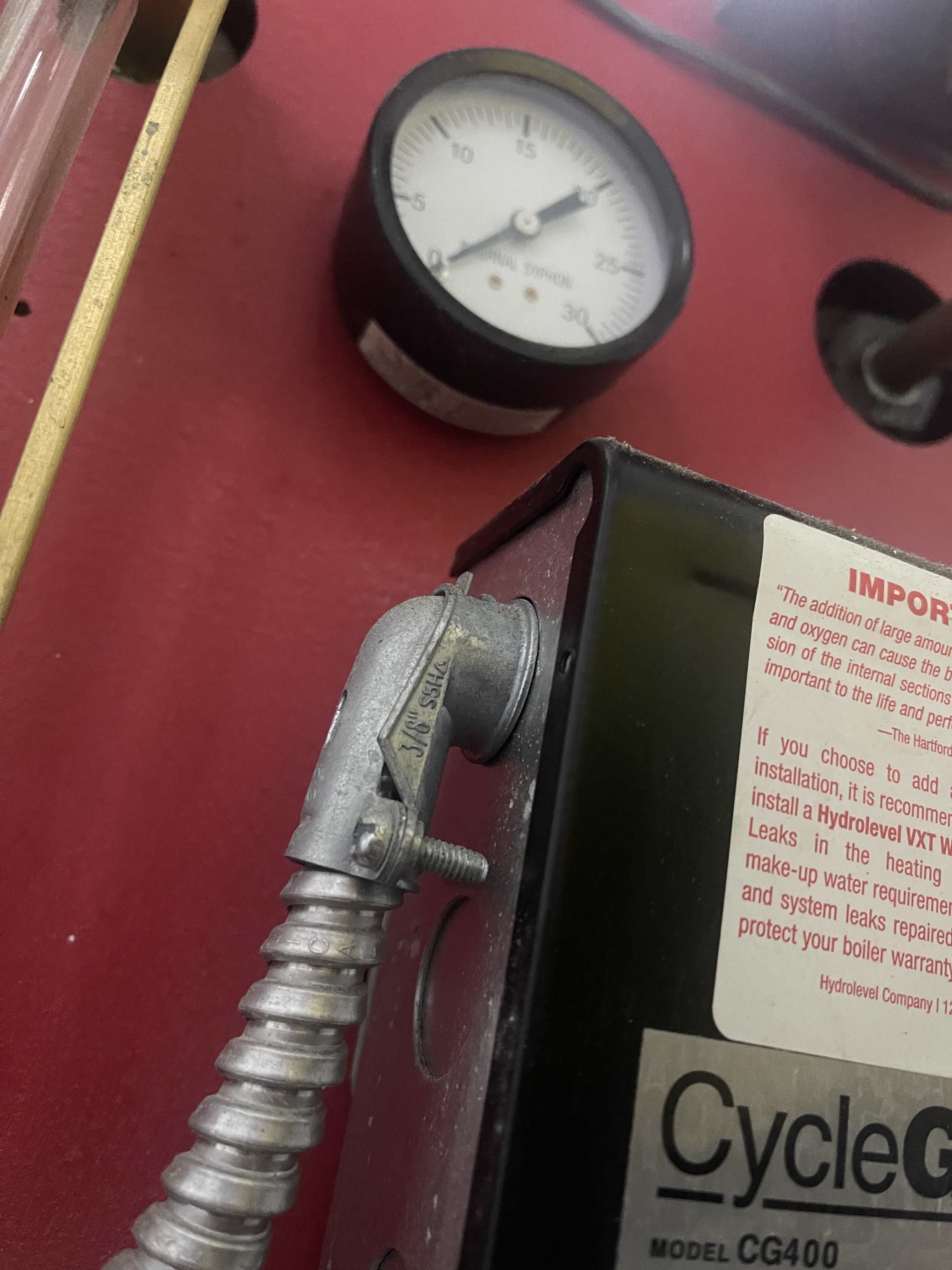

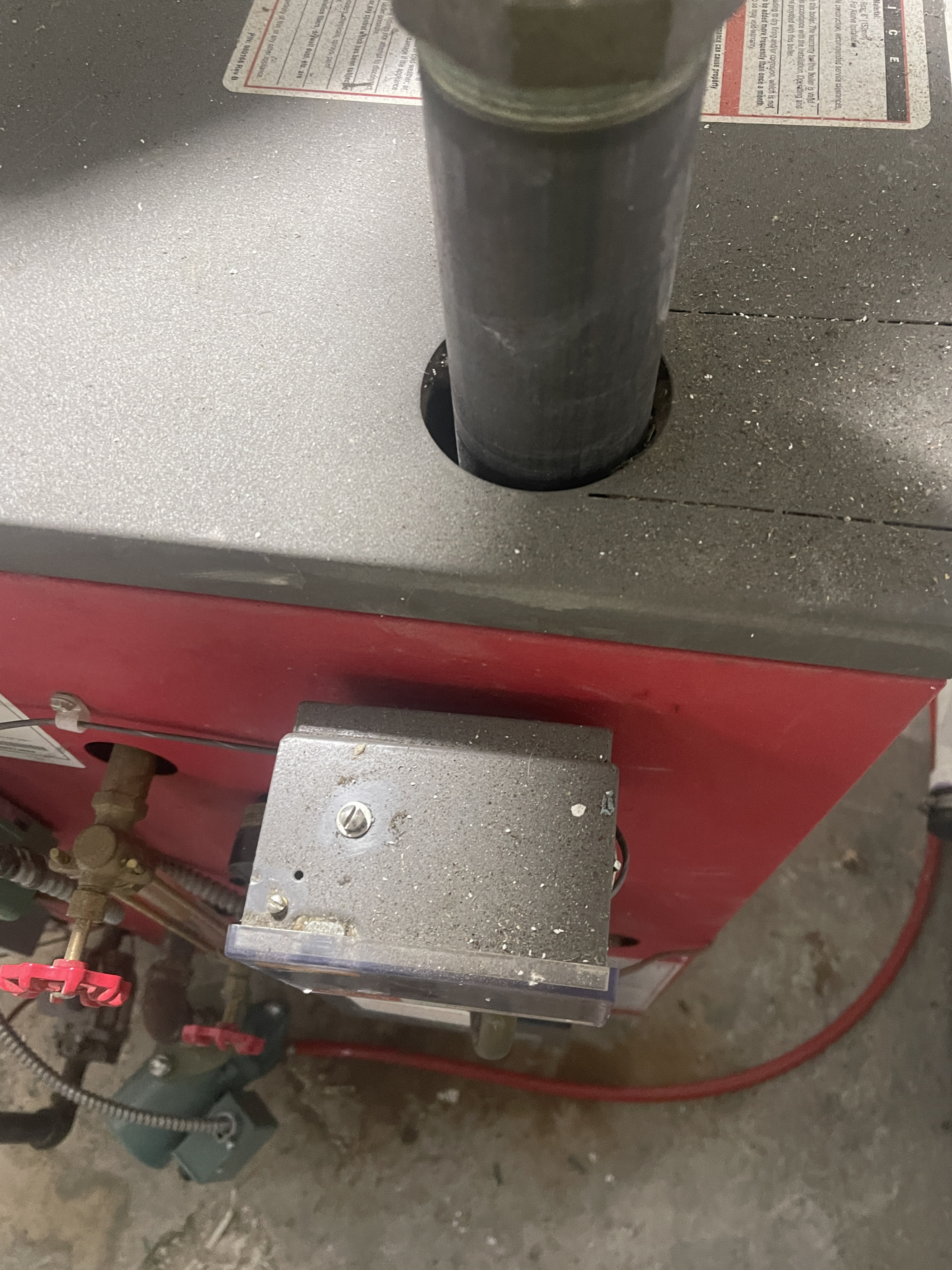

Can you take a picture of your existing gauge from a couple angles? And perhaps a picture of your pressuretrol from a few feet back? And if you can, post them directly on here?

I can't open your google drive link.

0 -

here they are, let me know if there are any problems when viewing

0 -

The gauge will be by far the easiest to tackle first. If you look at the back of it there will be a nut on it. Put a wrench on it and go lefty-loosey :) It will spin right out. Replace it with a 5psi version.

Disclaimer…This is technically a temporary solution as you are supposed to have a 30psi gauge installed.

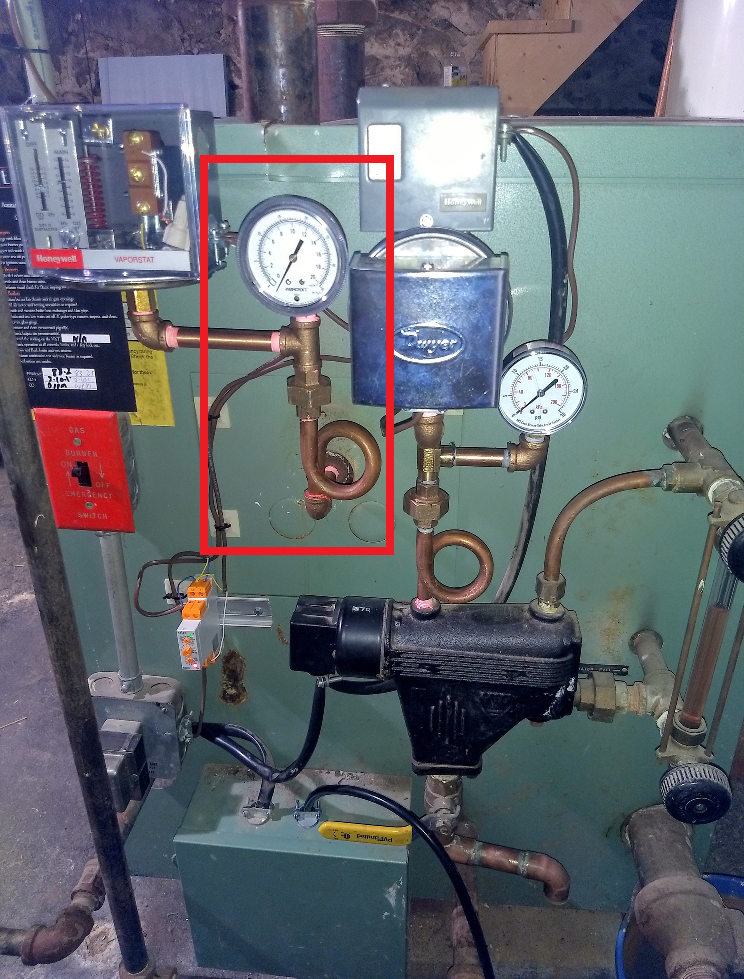

The best way to do this would be to install a 90 degree elbow, a pigtail and a union. Your pressuretrol is in the way…so use a small pipe nipple to raise the gauge above your pressuretrol and install it above it. Use a Tee and install both a low pressure gauge and get yourself a new 30psi gauge.

Something like the picture below (from my boiler). But instead of the vaporstat on the left add the 30psi gauge instead.

For your pressuretrol…. I can see the problem now. Has this boiler ever seen proper yearly maintenance from a pro? Part of the maintenance process is to clean out pigtails as they are part of the safety circuit.

I'll bet you a dozen donuts that your pigtail has never been cleaned! There is no way to remove the pressuretrol without removing a bunch of other stuff. Your cycle guard, pressure guage and site glass are in the way. No maintenance person is going to remove all that stuff just to get your pressuretrol off of there so they can clean the pigtail.

The correct way to fix this is to cut the pigtail in half and unscrew it from the block. Then install new pigtail and a union before the pressuretrol so it can be removed easily and the pigtail serviced.

0 -

no, it hasn’t been part of the maintenance process so I know the pigtail hasn’t been cleaned out.

From your steps, it looks like I’ll need to do a lot which means more room for failure on my part.

0 -

I should also note that this may seem a little daunting if you have no plumbing experience but if you can turn a wrench you can learn! No special tools required. A pipe wrench, some teflon tape and maybe a couple of regular wrenches or an adjustable wrench is all you need.

And then learn to skim your boiler! That is very DIY too.

Then you need to track down your leaks. You should hardly ever need makeup water added. Maybe a gallon or two per year?

You will be surprised how much water you will lose with a couple steam leaks. Before I learned a lot about steam heating I had a steam leak on an fitting going into one of my radiators. It was on the top so it didn't drip water but you could feel and see it. I was adding a couple gallons of make up water per week. I then learned that this is bad and fixed it. No more adding makeup water!

0 -

If you are truly interested in doing it yourself many on here would be willing to give you some great advice.

And where are you located, generally? Have you clicked on the "Find a Contractor" link on this website? A regular HVAC person isn't going to do you much good. You need someone who knows steam.

0 -

I’m located in NYC. I contacted some but majority that I’ve contacted don’t even service my area apparently

0 -

This is who I would call:

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements